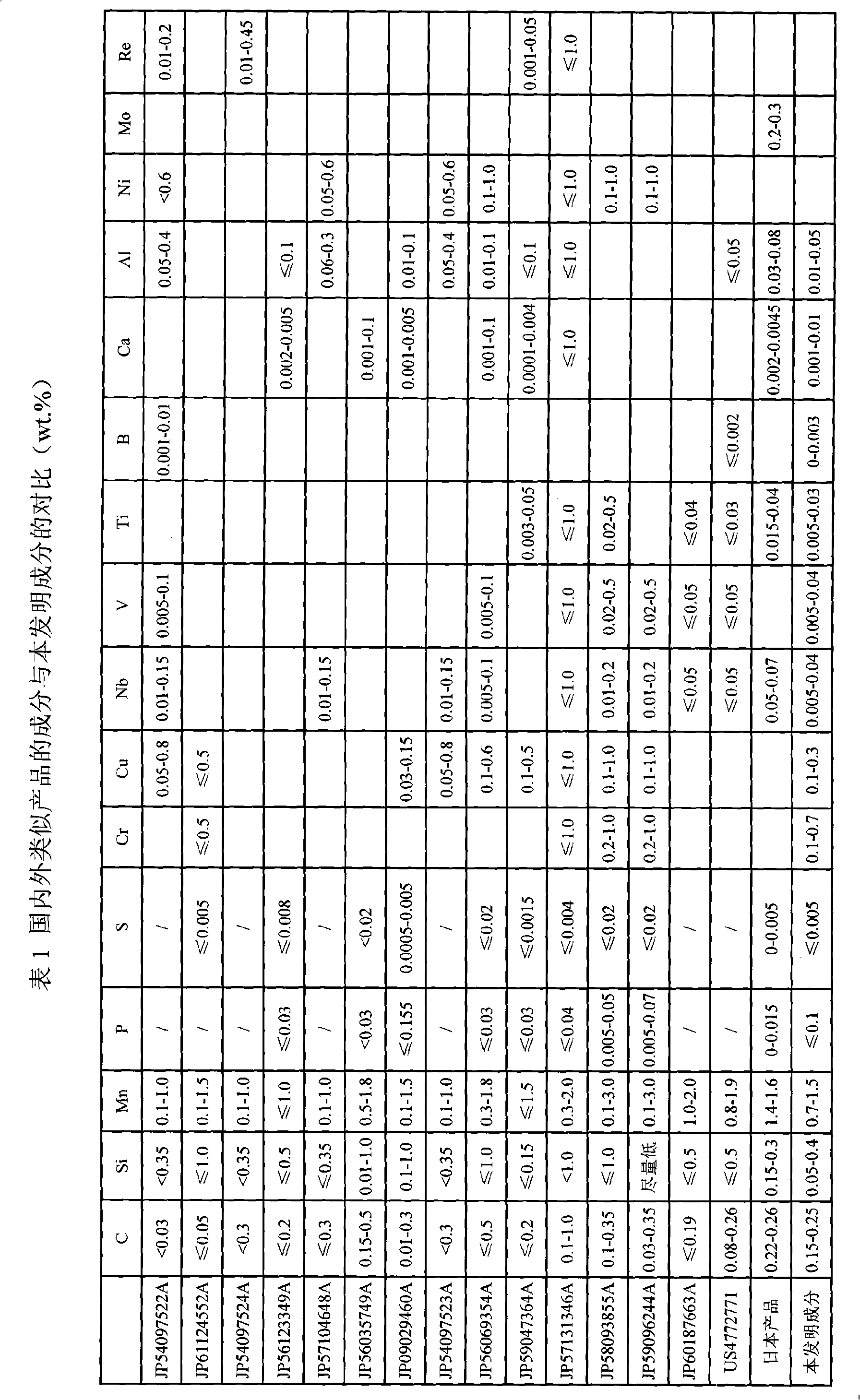

Grooving corrosion resistant high strength steel for ERW soldering sleeve, sleeve and production method

A technology of groove corrosion and welded casing, applied in the direction of temperature control, etc., can solve the problems of no groove corrosion resistance, impossibility of groove corrosion resistance, low strength of steel pipe, etc., and achieve excellent groove corrosion resistance , good anti-groove corrosion performance, and the effect of optimizing the structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The chemical composition mass percentage of the steel for casing in this embodiment is: C: 0.16; Si: 0.27; Mn: 1.33; P: 0.007; S: 0.004; Ti: 0.025; Nb: 0.035; V: 0.011; Cr: 0.33; Cu: 0.13; B: 0.0022; Al: 0.036; Ca: 0.007, and the rest are Fe and inevitable impurities.

[0040] The molten steel after converter smelting and out-of-furnace refining is treated with Ca and then continuously cast into billets. The continuous casting billet is heated at 1200~1250℃ and then hot rolled into strips. The final rolling temperature is higher than 850℃. After rolling, the strips are cooled to 570℃ by laminar flow and coiled into coils. After shearing butt welding, plate coil forming and ERW pipe making, the weld is subjected to induction heating and normalizing treatment. The heating temperature is 930°C and the heating time is 20-60s. Finally, the steel pipe is sheared and processed to produce The invention provides the N80 electric resistance welded oil casing with anti-groove cor...

Embodiment 2

[0045] The chemical composition mass percentage of the steel for casing in this embodiment is: C: 0.18; Si: 0.27; Mn: 1.24; P: 0.007; S: 0.004; Cr: 0.22; Cu: 0.24; Nb: 0.024; V: 0.022; Ti: 0.019; B: 0.0018; Al: 0.029; Ca: 0.007, and the rest are Fe and inevitable impurities.

[0046] Others are the same as in Example 1.

[0047] After testing, the results of the mechanical properties of the casing in this embodiment are as follows: R 0.5 666MPa, 681MPa; R m It is 776MPa and 764MPa.

[0048] After testing, the groove corrosion sensitivity coefficient α of the casing in this embodiment is 1.12.

Embodiment 3

[0050] The chemical composition mass percentage of the steel for casing in this embodiment is: C: 0.19; Si: 0.25; Mn: 1.18; P: 0.007; S: 0.004; Cr: 0.32; Cu: 0.20; Nb: 0.021; V: 0.021; Ti: 0.017; Al: 0.047; Ca: 0.007, and the rest are Fe and inevitable impurities.

[0051] Others are the same as in Example 1.

[0052] After testing, the results of the mechanical properties of the casing in this embodiment are as follows: R 0.5 621MPa, 614MPa; R m It is 709MPa and 701MPa.

[0053] After testing, the groove corrosion sensitivity coefficient α of the casing in this embodiment is 1.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com