Patents

Literature

166results about How to "Low alloy content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength-and-toughness low alloy wear resistant steel and manufacturing method thereof

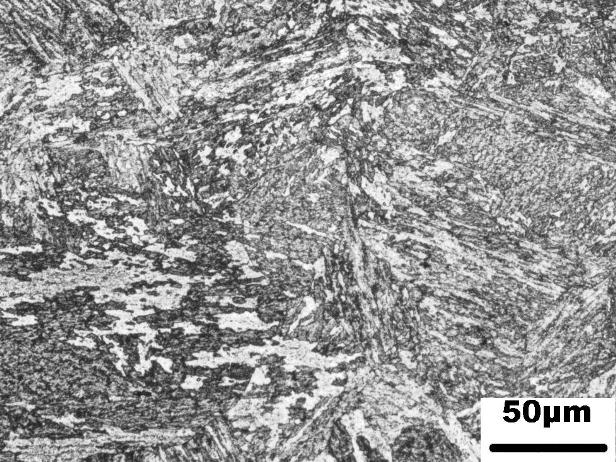

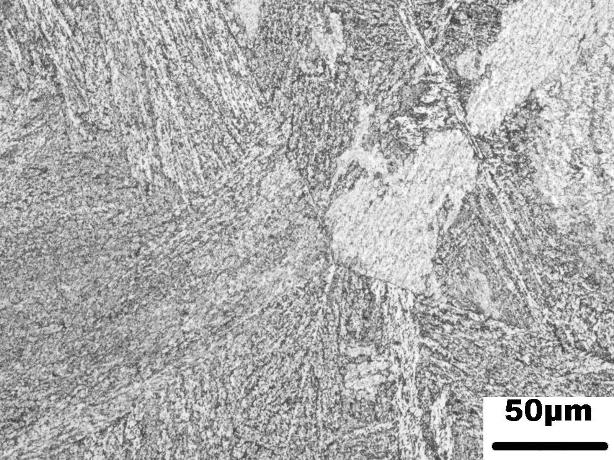

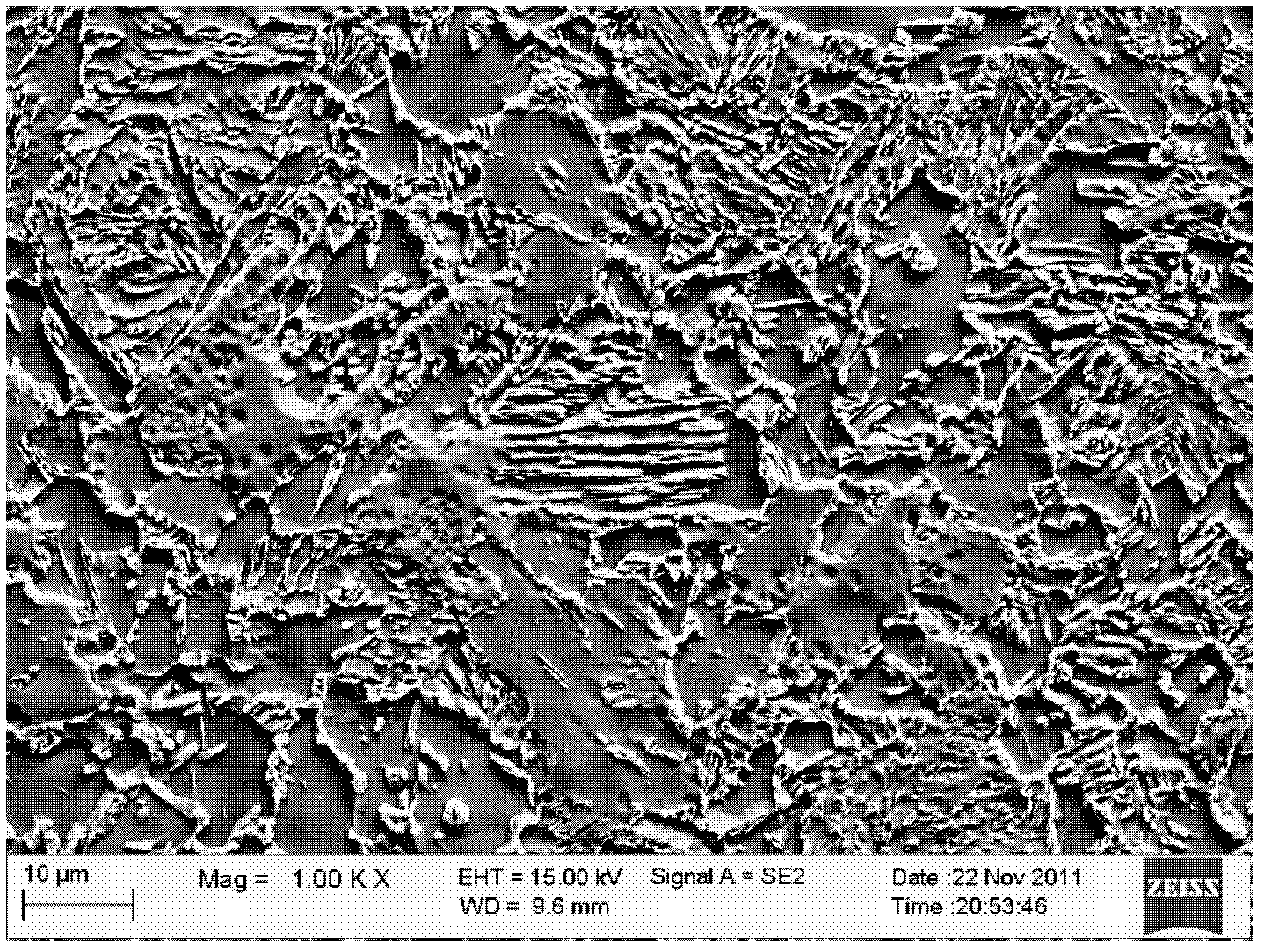

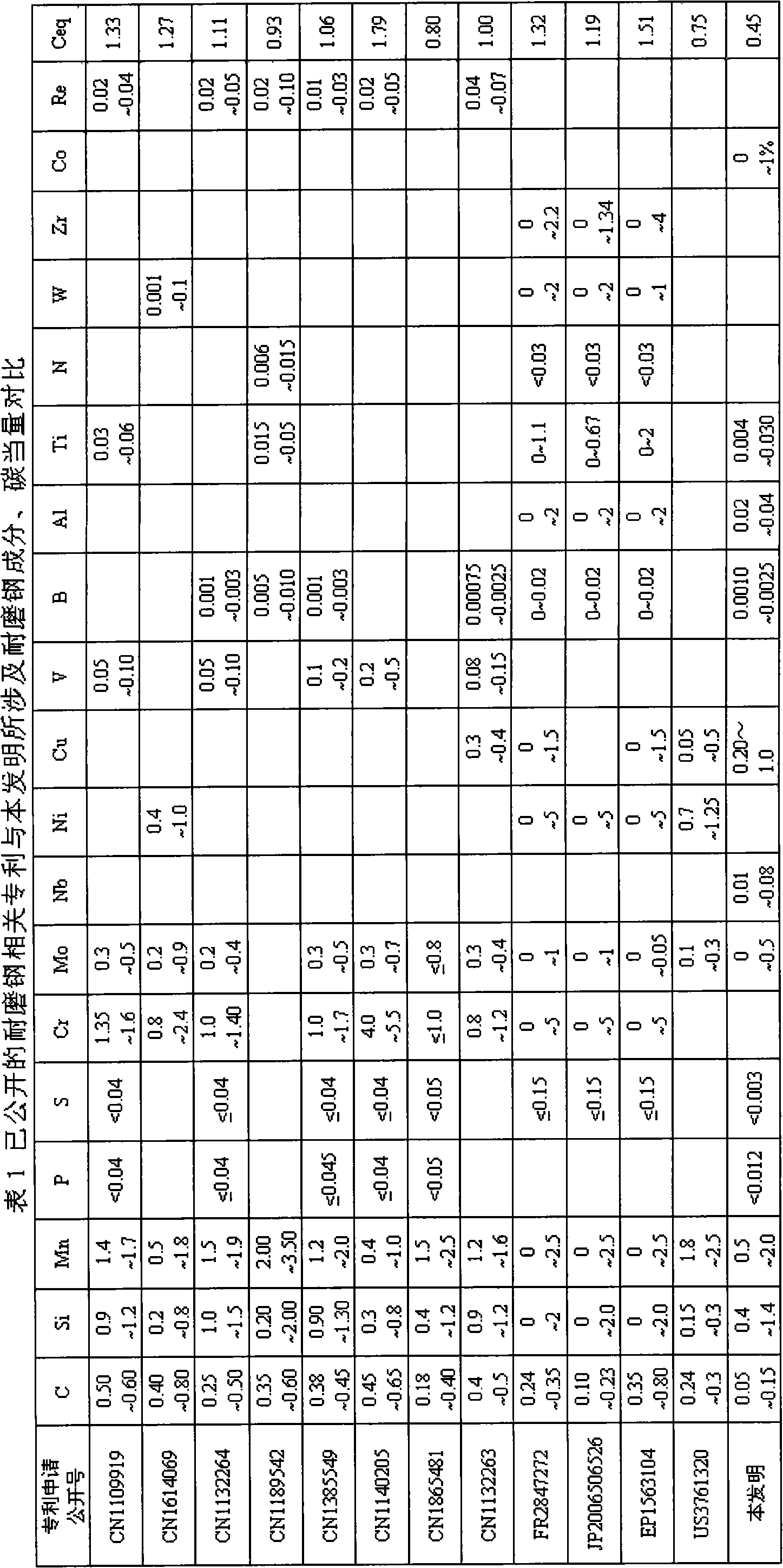

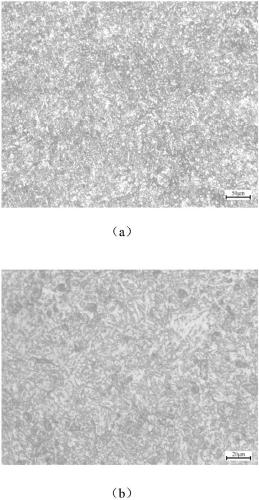

The invention relates to high-strength-and-toughness low alloy wear resistant steel and a manufacturing method thereof, belonging to the technical filed of metallurgy. The high-strength-and-toughness low alloy wear resistant steel comprises the following components by weight percent: 0.15-0.20% of C, 0.1-0.5% of Si, 1.2-1.6% of Mn, less than or equal to 0.015% of P, less than or equal of 0.005% S, 0.02-0.04% of Al, 0.016-0.022% of Ti, 0.16-0.20% of Cr, 0.16-0.22% of Mo, 0.001-0.0015% of B and the balance of Fe, and simultaneously the carbon equivalent Ceq (%) is less than or equal to 0.55. The manufacturing method comprises the following steps: smelting molten steel and pouring into a slab, and carrying out rough rolling after heating and heat insulation; and then carrying out complete quenching treatment, or sub-temperature quenching treatment, or carrying out the complete quenching treatment and then carrying out the sub-temperature quenching treatment, and adopting low temperature tempering to eliminate stress after the quenching. The method of the invention ensures higher hardness, simultaneously can obviously improve the impact toughness of steel plates, increase the impact resistance of the steel plates, and prolong the service life of mechanical equipment, and can obtain wear resistant steel plates with different strength and toughness grades by using the steel with same components and different quenching processing methods.

Owner:NORTHEASTERN UNIV +1

Bainite pre-hardening plastic mold steel and preparation method and heat treatment method thereof

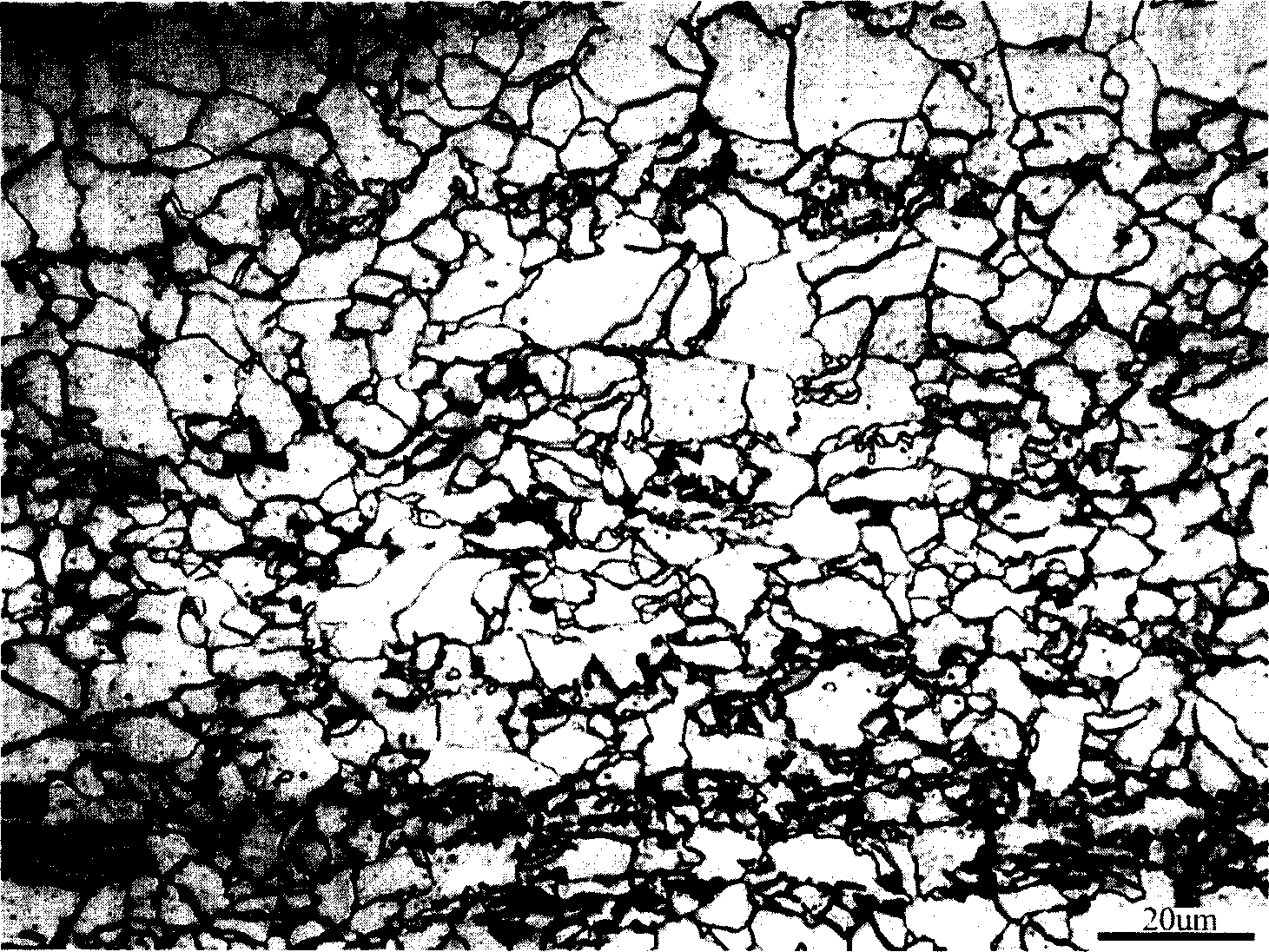

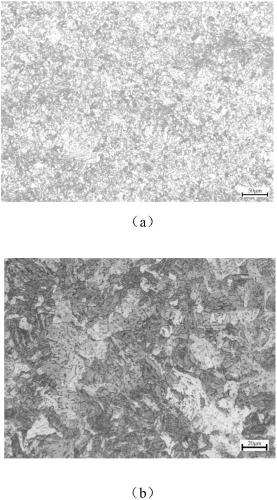

The invention relates to bainite pre-hardening plastic mold steel and a preparation method and a heat treatment method thereof. Chemical components of the steel are optimized on the basis of P20 steel, the content of manganese (Mn) is appropriately increased, the content of the chromium (Cr) and molybdenum (Mo) is reduced, little niobium (Nb) is added, and no nickel (Ni) and vanadium (V) in expensive price are not contained. The preparation method of the plastic mold steel comprises the following steps of: compounding, smelting and casting; carrying out the multi-directional forging heat machining; carrying out the wind cooling and the air cooling; and finally carrying out the tempering heat treatment. The plastic mold steel has characteristics of large cross section, low cost, high hardenability, good hardness uniformity and the like and also has low susceptibility of flake formation, a diffusion hydrogen annealing process is omitted, in addition the post-forging normalizing is adopted to substitute a thermal refining process, so that the production period is greatly shortened, the domestication of the plastic mold steel with large cross section, long service life, top quality and short period can stride forward for a large step, and the existing domestic manufacturing concept of energy conservation, emission reduction, sustainability and economical type can be met.

Owner:SHANGHAI UNIV

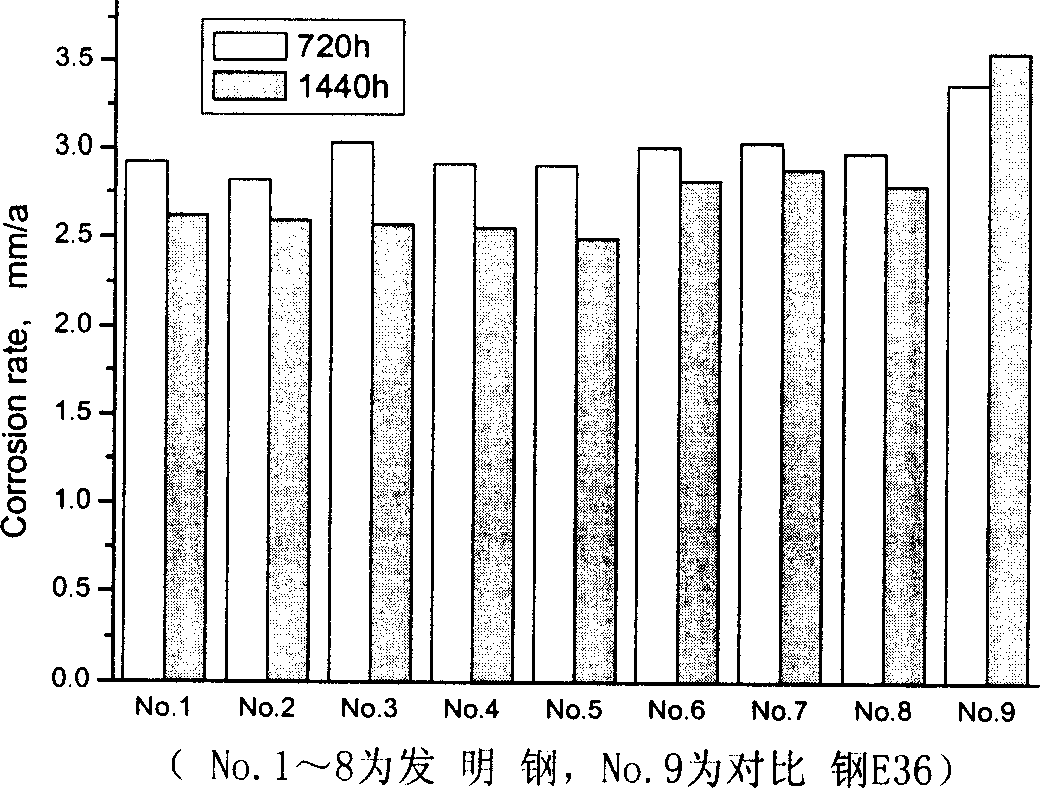

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

Petroleum casing pipe with high strength and high toughness and preparing method thereof

InactiveCN101586450ALow alloy contentLow costDrilling rodsProcess efficiency improvementAlloyMechanical property

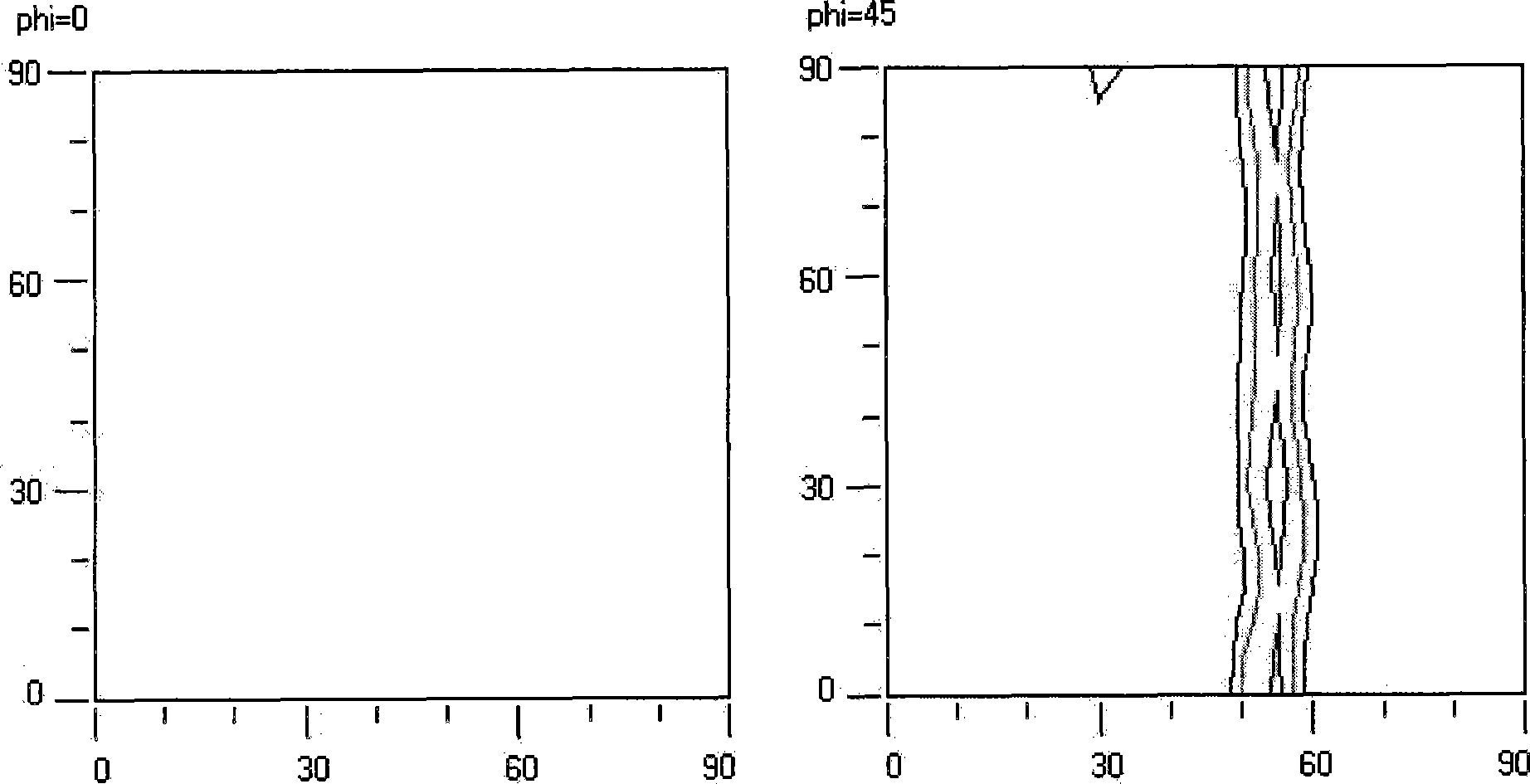

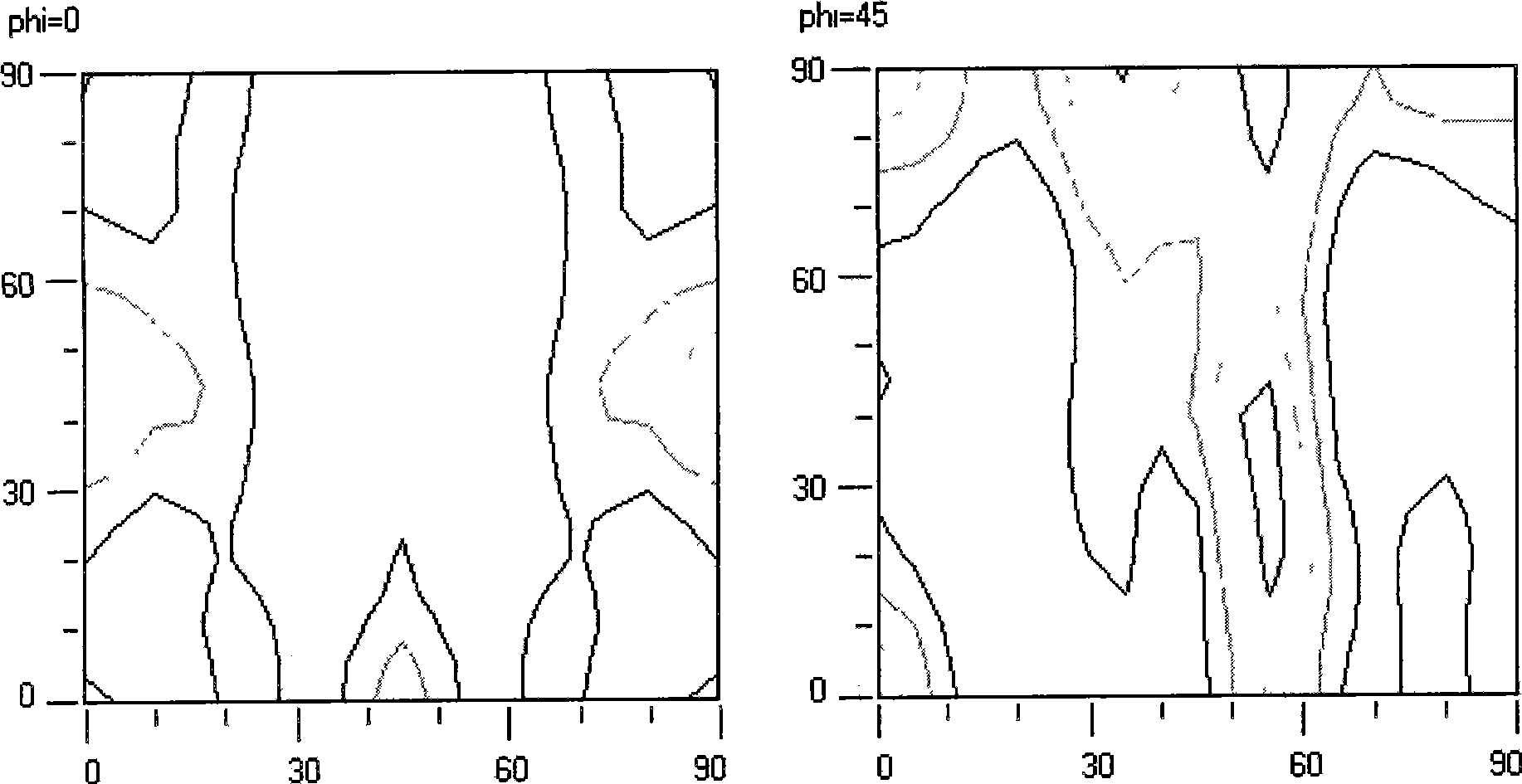

The present invention provides a petroleum casing pipe with high strength and high toughness, wherein the weight of the component element of the casing pipe steel is characterized proportionally. The invention also provides a preparing method for preparing the petroleum casing pipe with high strength and high toughness, wherein the method comprises the following steps: 1. smelting the ingredients and casting the tube blank; 2. punching and tandem rolling of the steel tube; and 3. heat treating. The invention has the following beneficial effects: the performance of the petroleum casing pipe obtained by the method is the performance of the steel with lower content of alloy and the cost is low; a low carbon content is adopted so that the lath martensite tissue is obtained after heat treatment, the high toughness is provided after tempering and a delayed fracture resistance is provided; the complex micro-alloying processing techniques of V, Nb, Ti, B, etc. are adopted for strengthening the matrix, strengthening the grain-boundary strength, increasing the tempering resistance, reducing the content of manganese element, reducing the content of the impurity elements and improving the shape of the inclusion. The rolling ratio is optimized so that the aeolotropism of the material is remarkably reduced and the horizontal and vertical impact toughness of the material is larger than 0.8. The casing pipe of the invention far exceeds the prior highest steel grade requirement of the API standard.

Owner:TIANJIN PIPE GROUP CORP

High collapse-resistance and hydrogen sulphide-corrosion-resistant low alloy petroleum case pipe and method of manufacturing the same

ActiveCN101245437AImprove toughnessImprove anti-collapse performanceTemperature control deviceFurnace typesAlloyPetroleum

The invention relates to a low-alloyed petroleum casing pipe with high anti-collapse and high hydrogen sulfide corrosion resistance and a production method. The weight percentages of the chemical components of the low-alloyed petroleum casing pipe are: 0.24-0.34 percent of C, 0.35-1.0 percent of Mn, 0.20-0.50 percent of Si, 0.4-1.1 percent of Cr, 0.2-0.7 percent of Mo, 0.007-0.07 percent of Al, 0.005-0.05 percent of Ti, 0.01-0.05 percent of Nb, 0.05-0.15 percent of V, 0-0.6 percent of Ni, 0-0.2 percent of Cu, less than 0.003 percent of B, less than 0.015 percent of P, less than 0.005 percent of S and less than 0.01 percent of Ca and the rest of Fe and inevitable impurities. The production method comprises: external refining and vacuum degassing, and then Ca treatment, smelting, continuous casting to form round blocker and pipe making, soaking, air cooling after rolling, sawing, and then quenching and tempering heat treatment, heating to 880-900 DEG C, water quenching after heat preservation for 30-60 min, tempering and heat preservation under 680-710 DEG C and hot sizing under 550-650 DEG C, the temperature of hot straightening is more than 450 DEG C. The low-alloyed petroleum casing pipe has better anti-collapse performance and hydrogen sulfide corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

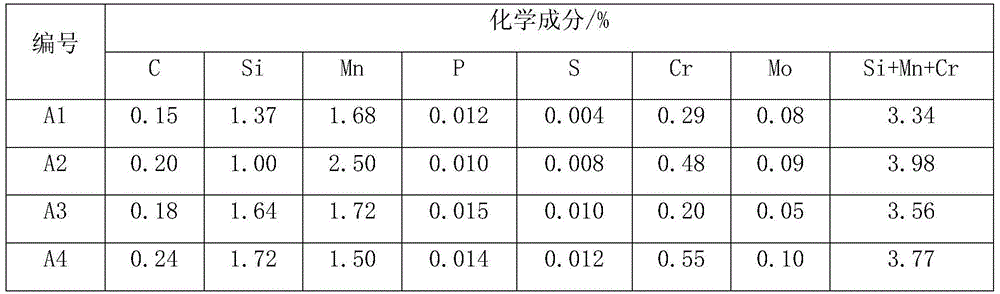

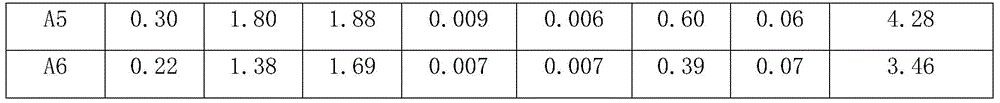

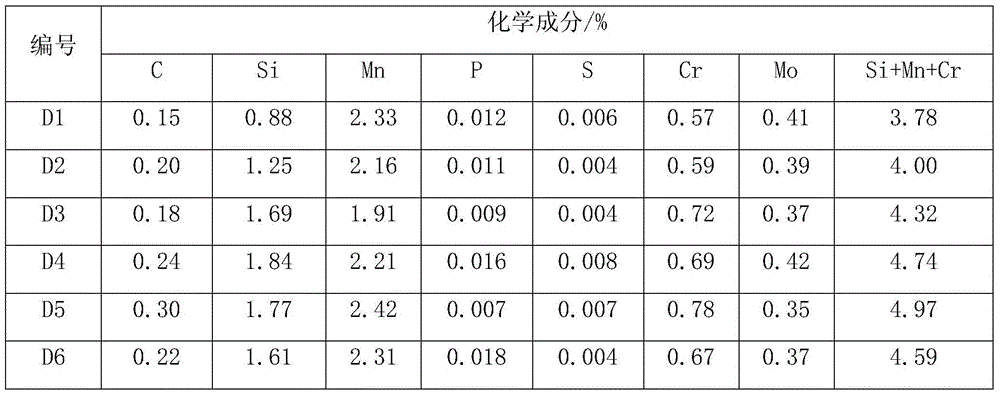

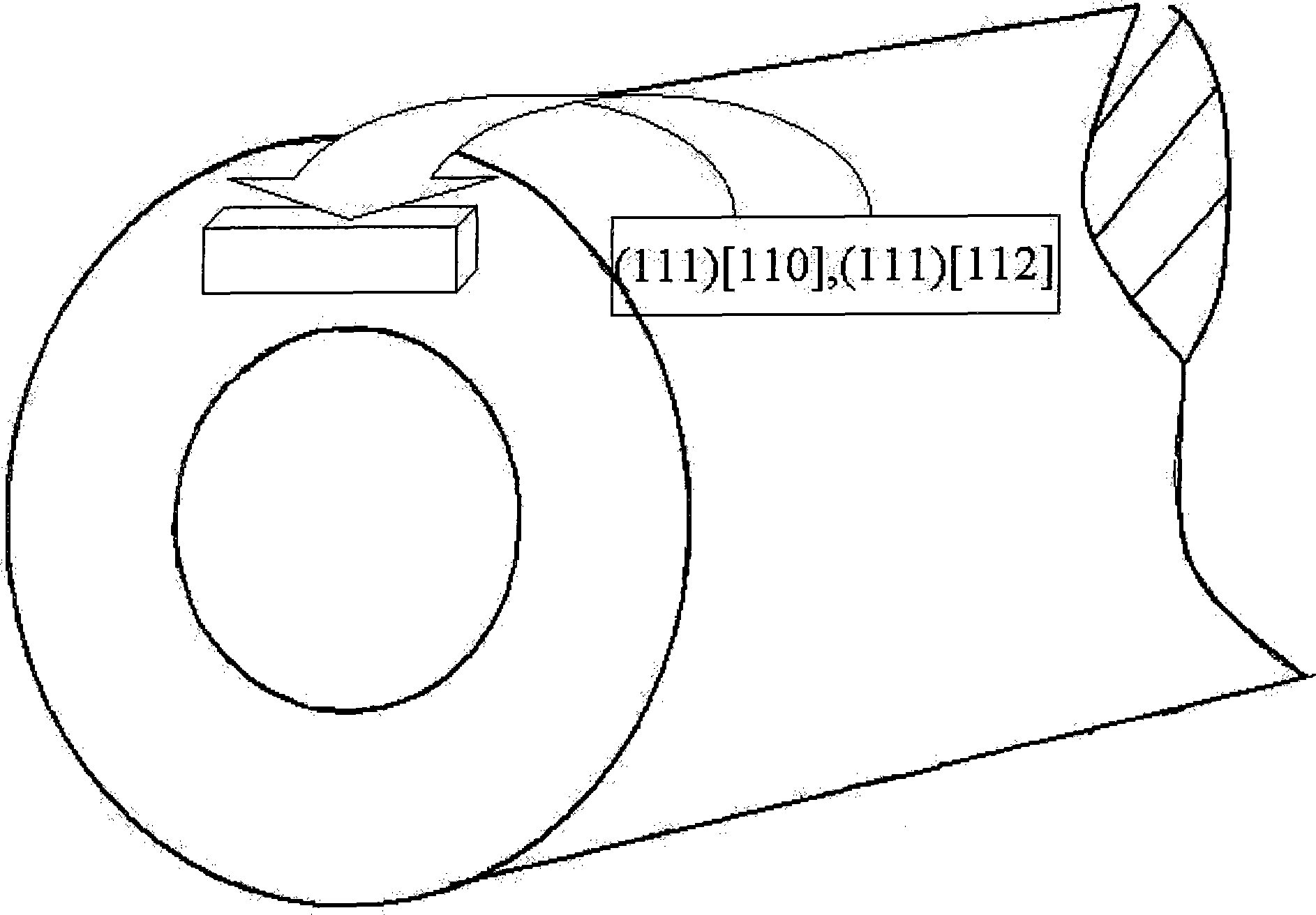

High-strength bainite steel rail and production method thereof

ActiveCN104087852ALow alloy contentReduce contentFurnace typesHeat treatment furnacesHigh intensityAir cooling

The invention relates to a steel rail material and in particular relates to a high-strength bainite steel rail and a production method thereof, which solve the technical problems. The production method comprises the following steps: heating steel containing 0.15wt%-0.30wt% of C, 1.00wt%-1.80wt% of Si, 1.50wt%-2.50wt% of Mn, 0.20wt%-0.60wt% of Cr, 0.05wt%-0.10wt% of Mo and the balance of Fe, rolling the heated steel into a steel rail with needed section, utilizing waste heat of the steel rail, performing accelerated cooling on the rail head of the steel rail at a cooling speed of 3.0-6.0 DEG C / s when naturally cooling the tread surface of the rail head to 450-500 DEG C, stopping accelerated cooling when cooling the center of the tread surface of the rail head to 220-300 DEG C, and performing air-cooling to room temperature to obtain complex phase steel with carbide-free bainite, a small quantity of martensite and a small quantity of residual austenite. The steel is excellent in wear resistance and applicable to heavy haul railway.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Anti-collapse oil casing and manufacturing method thereof

ActiveCN101532113AImprove performanceDelayed crush instabilityDrilling rodsTemperature control deviceChemical compositionQuenching

The invention discloses an anti-collapse oil casing and a manufacturing method thereof. The mixture ratio of chemical compositions thereof by weight percentage is as follows: 0.18-0.34 percent of C; 0.2-1.5 percent of Mn; 0.20-0.50 percent of Si; 0-2.5 percent of Cr; 0-0.8 percent of Mo; 0.02-0.25 percent of V; 0.001-0.06 percent of Al; 0-0.05 percent of Ti; 0.005-0.05 percent of Nb; 0-0.5 percent of Ni; 0-0.5 percent of Cu; 0-0.05 percent of Zr; 0-0.004 percent of B; less than 0.015 percent of P; less than 0.010 percent of S; less than 0.01 percent of Ca; and the balance of Fe and unavoidable impurities. The manufacturing method includes the following steps of: 1) forming round billet through continuous casting; 2) soaking and perforation of the round billet in an annular furnace; 3) helical tube rolling, pinch rolling and sizing; 4) air cooling and saw cutting after tube rolling; 5) quenching and tempering, and water quenching; 6) high temperature tempering, hot sizing and thermal straightening; and 7) flaw detection. With the mixture ratio and the method, the invention can obtain the anti-collapse casing with superhigh anti-collapse capability and excellent performance through texture and microstructure design and control.

Owner:BAOSHAN IRON & STEEL CO LTD

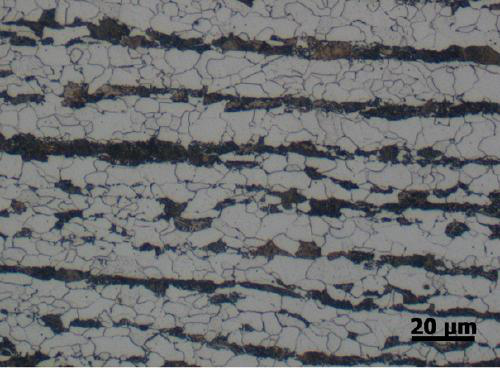

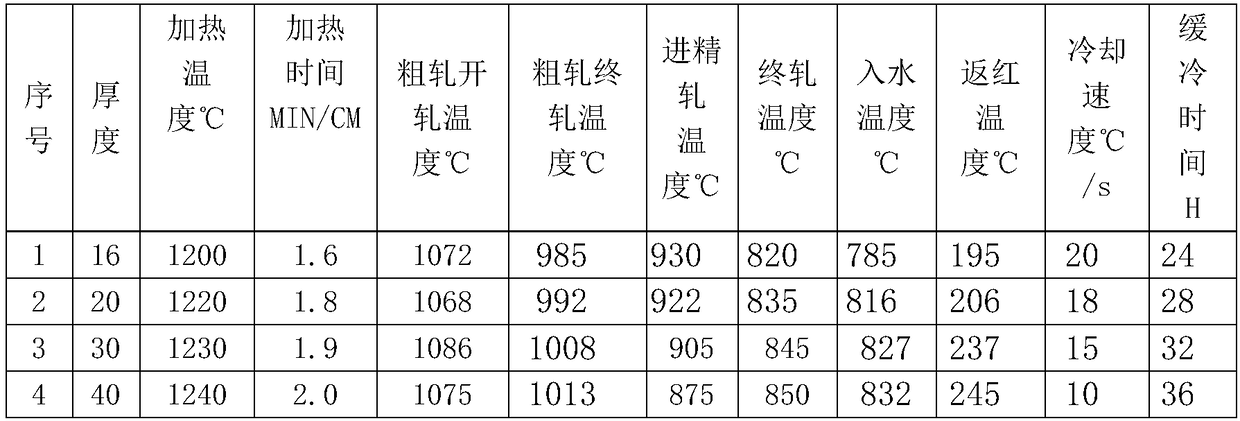

On-line quenching production method of low-cost high-strength abrasion-resistant steel plate

The invention relates to an on-line quenching production method of a low-cost high-strength abrasion-resistant steel plate, and belongs to the technical field of the production of abrasion-resistant steels. The on-line quenching production method comprises the following processing steps of: selecting a continuous casting blank which meets the requirements; carrying out general hot rolling, wherein the heating temperature is 1170-1200 DEG C, the start rolling temperature is 1050-1100 DEG C, the finish rolling temperature is 900-950 DEG C, and the water entry temperature is more than 880 DEG C; realizing the on-line quenching of the steel plate by utilizing a UFC+ACC cooling mode, wherein the average speed of a cooling zone is not lower than 25 DEG C / S, and the quenching is finished when the temperature is reduced to 150-250 DEG C; and heating the quenched steel plate to 250-400 DEG C, wherein the heat preserving time is 1-2 hours. The on-line quenching production method disclosed by the invention overcomes the defects of long period, high cost, and the like of the conventional hardening and tempering heat treatment production mode, realizes the short production flow, the low energy consumption and the low cost, can be used for stably producing high-strength high-toughness abrasion-resistant steel plate with the specification of 6-30 mm, the surface hardness more than or equal to HB360 and the -20 DEG C impact work mean more than or equal to 60 J and is widely applied to mine, engineering, agriculture and railway transportation machinery products which have high requirements for steel type properties.

Owner:SHOUGANG CORPORATION

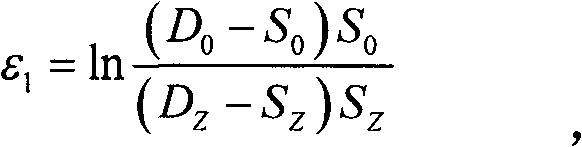

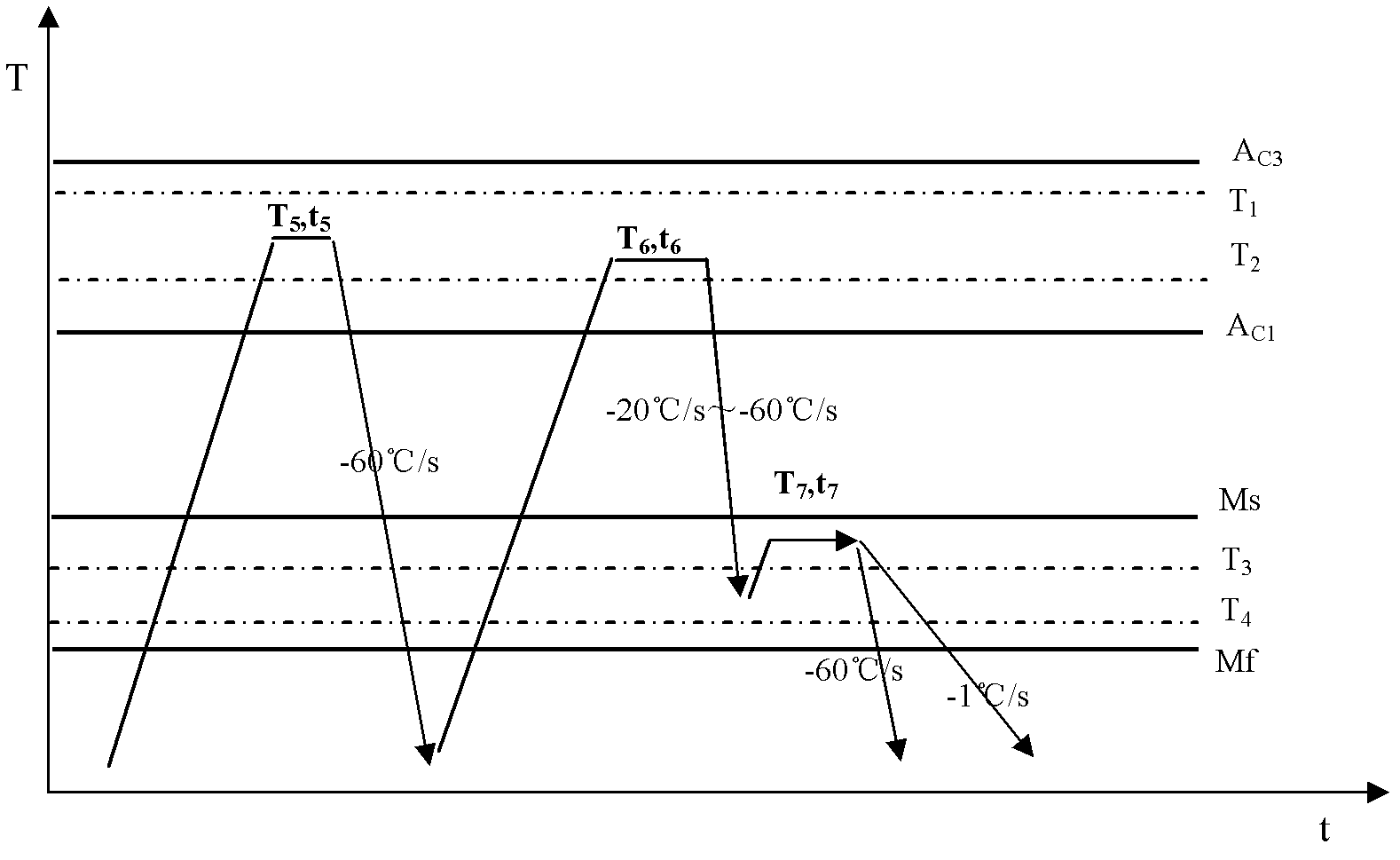

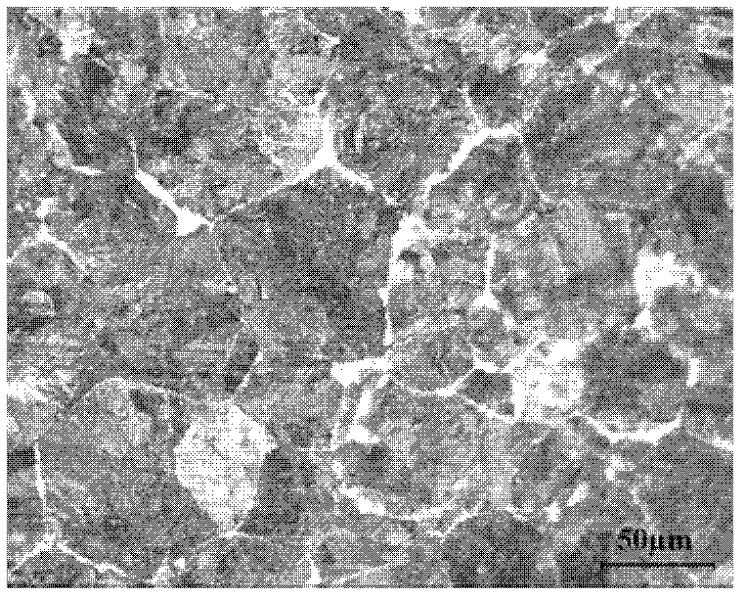

Method for preparing N80 steel-grade expansion tubes for petroleum and natural gas exploitation

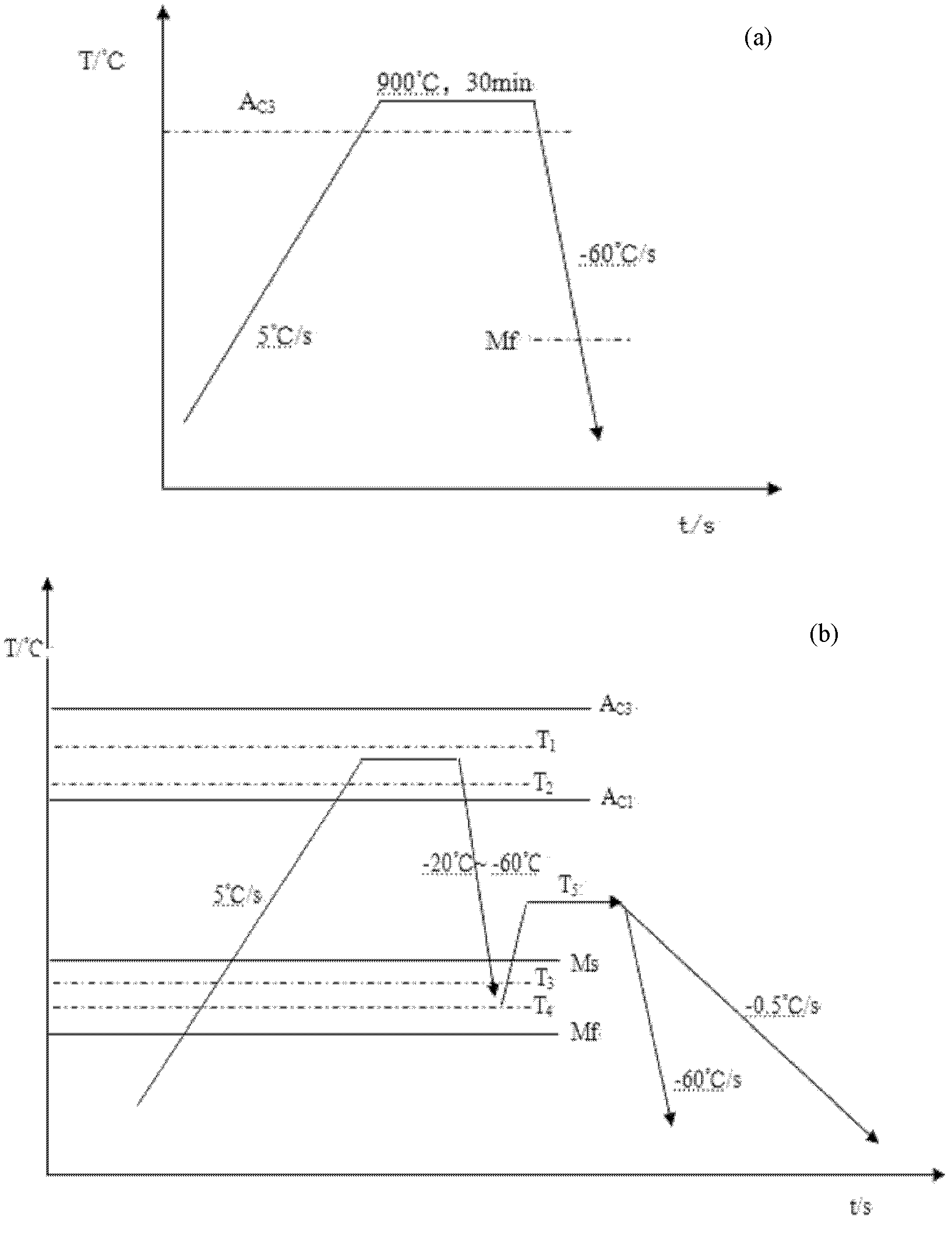

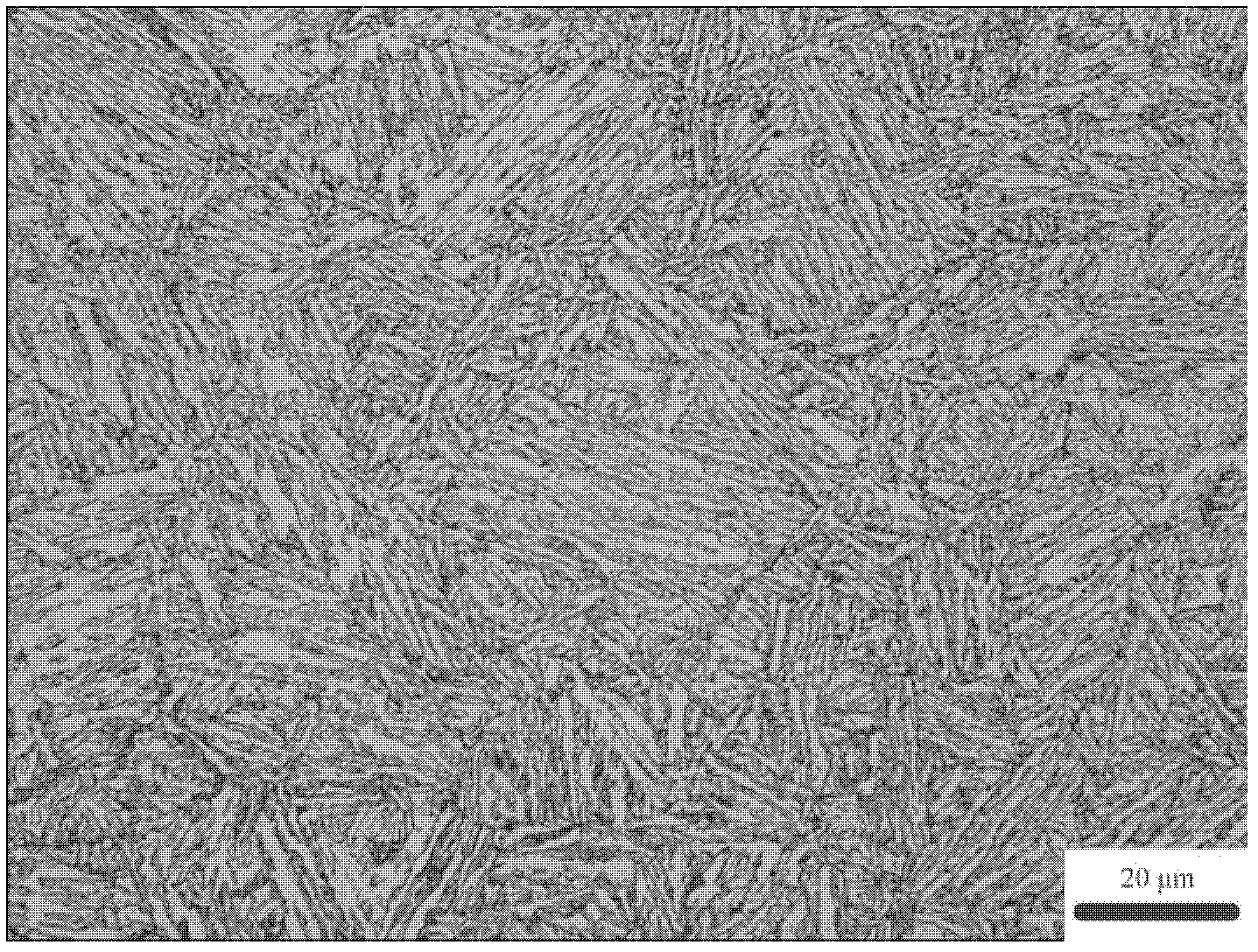

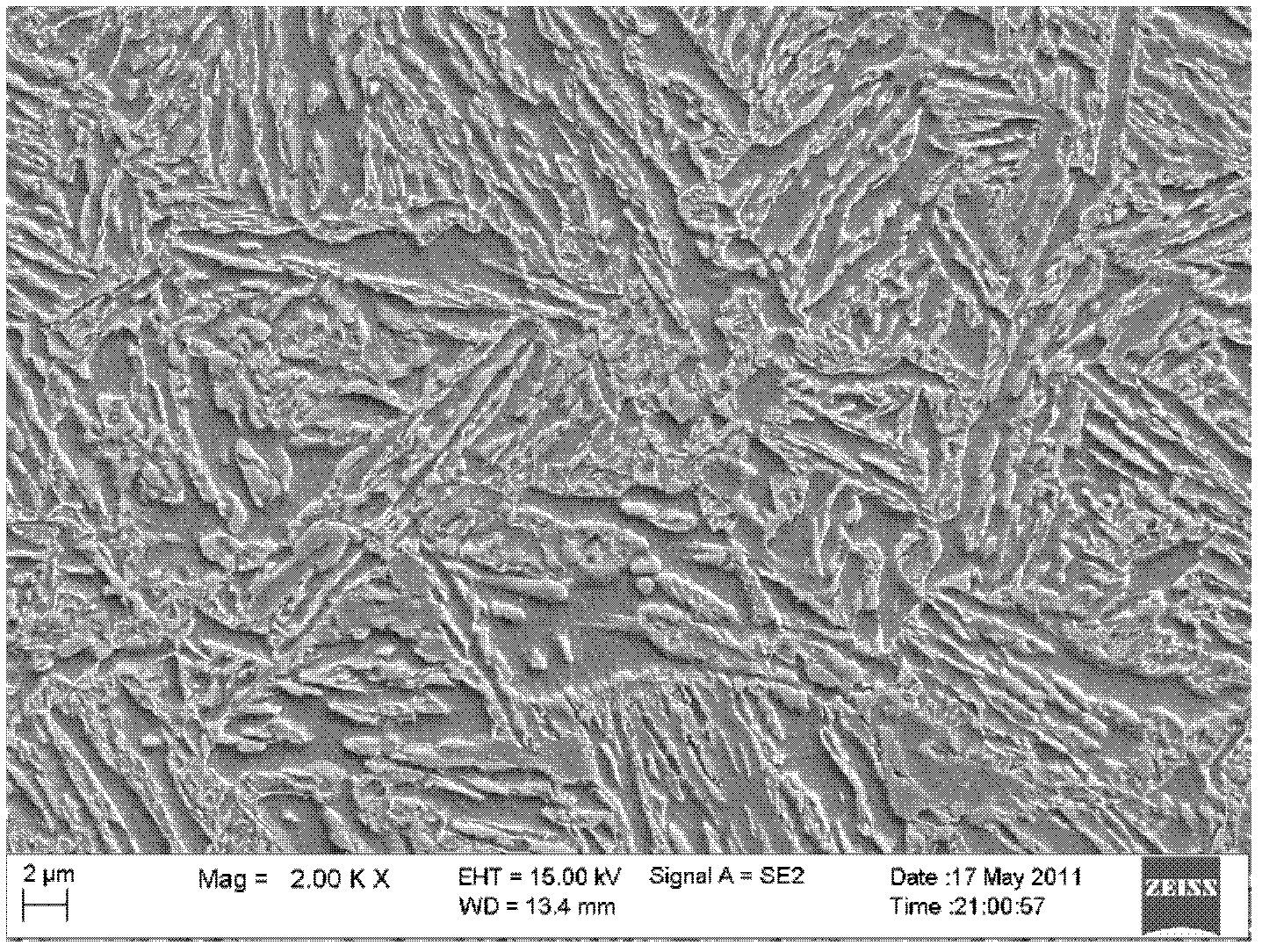

The invention discloses a method for preparing N80 steel-grade expansion tubes for petroleum and natural gas exploitation, and belongs to the field of metal materials. An N80 steel-grade expansion tube comprises the following chemical compositions in percentage by mass: 0.1 to 0.3 percent of C, 1.0 to 2.5 percent of Mn, 0.3 to 1.5 percent of Si, 0 to 1.0 percent of Al, 0.02 to 0.1 percent of Nb, 0 to 0.02 percent of Ti and the balance of Fe and inevitable impurities. After related alloy plates are obtained through smelting and rolling, the alloy plates are bent and welded into expansion tubes, and through a heat treatment process consisting of two procedures, namely two-phase region quenching and sub-temperature tempering-quenching-partitioning treatment, the expansion tubes reach the expected strength standard and plastic deformation capacity, and the mechanical properties of the tubes before and after expansion can meet the requirements of American Petroleum Institute (API) and other related standards. Test results show that the N80 steel-grade multiphase high-uniformity extended expansion tubes have high strength, plasticity, toughness and elongation, and the comprehensive mechanical properties are superior to those of the conventional dual-phase steel and Trip steel.

Owner:UNIV OF SCI & TECH BEIJING

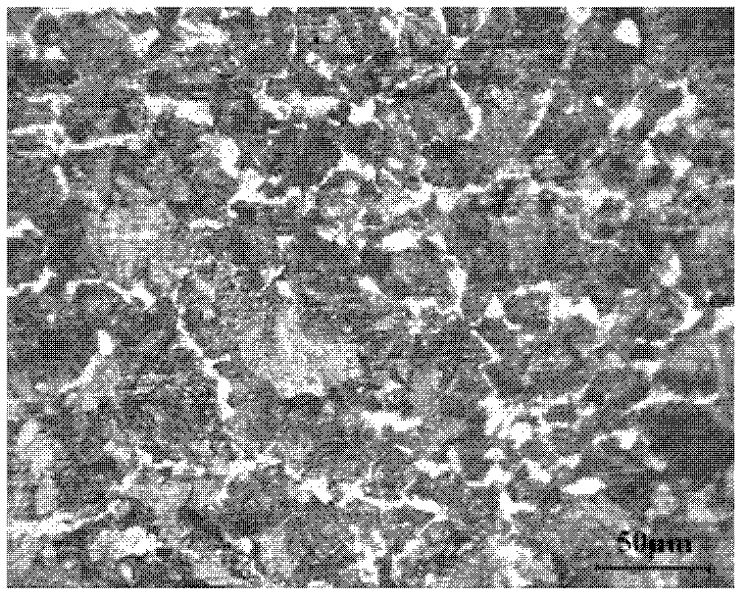

Preparation method of P110-grade expansion tube for exploiting petroleum and gas

InactiveCN102534372ALow alloy contentHigh strengthDrilling rodsDrilling casingsMetallic materialsAlloy

The invention relates to a preparation method of a P110-grade expansion tube for exploiting petroleum and gas. The expansion tube comprises the following chemical components by mass percentage: 0.10-0.30 of C, 0.70-2.0 of Mn, 0.3-1.5 of Si, 0-1.0 of Al, 0.02-0.1 of Nb, 0-0.02 of Ti and the balance of Fe and inevitable impurities. The preparation method comprises the following steps of: after performing smelting and rolling to obtain a related alloy plate, performing plate rolling to the alloy plate and welding to prepare the expansion tube, and finally, performing complete austenitizing and then carrying out heat treatment process of quenching and subsequent subtemperature tempering-quenching-partitioning to enable an expansion tube to reach expected strength criterion and plastic deformation ability and ensure the mechanical property of the tube after and before tube expansion to meet provisions of API (American Petroleum Institute) and other relevant standards. Test results show that the P110 steel grade multiphase expansion tube with high uniformity extension has high strength, plasticity, toughness and elongation rate, and has comprehensive mechanical property superior to the conventional quenching-tempering steel, trip steel and Q-P (quenching--partitioning) steel.

Owner:UNIV OF SCI & TECH BEIJING

1000Mpa-grade high-strength hot-rolled anti-bullet steel plate and making method

ActiveCN1814845ALow manufacturing costAnti-ballistic performance does not decreaseFurnace typesHeat treatment furnacesSteel platesHigh intensity

This invention relates to a kind of high strength hot-rolled bulletproof steel of 1000Mpa in the following weight percentage: C 0.17-0.21%, Si 1.5-2.2%, Mn 1.5-2.0%, P<=0.035%, S<=0.010%, Al 0.015-0.060%, N<=0.0060%, Nb 0.010-0.050%, Ti 0.010-0.060%, Ca<=0.0050%, Fe and unavoidable impurities, which is processed in the following steps: a, smelting according to the above mentioned components, casting to form slabs, b, heating the slabs to 1100-1250DEG C, hot-rolling the slabs in the austenitic area and over 80% of them are deformed and the final temperature is 800-900DEG C, d, the final rolled steel is cooled to 650-780DEG C in the speed of 50deg.C / s and air cooled for 6-15 seconds, e, cooling them to 350-450deg.C in the speed over 50deg.C / s, f, rolling them and air cooling them to room temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

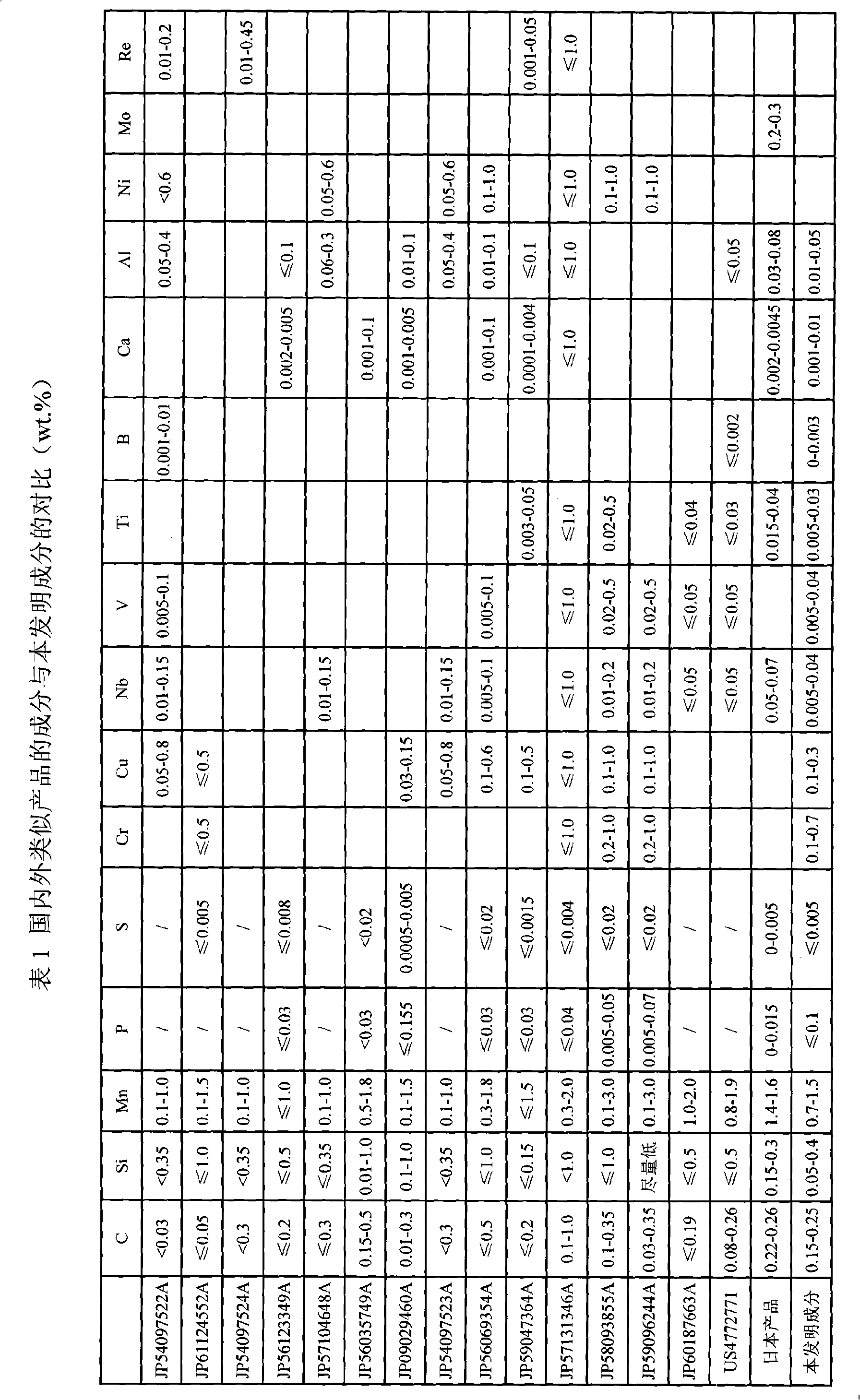

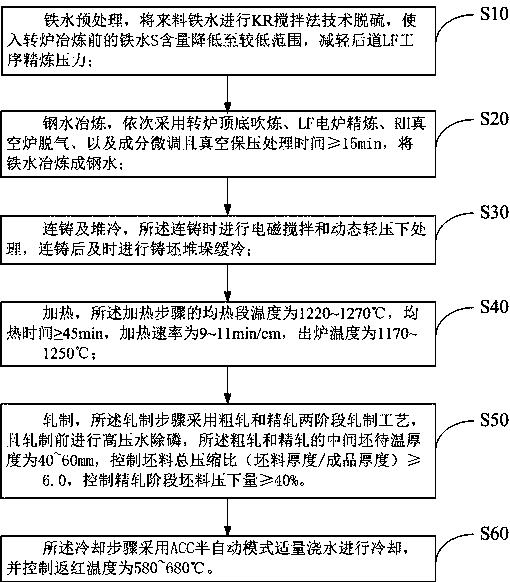

HB400-grade wear-resisting steel plate and production method thereof

The invention discloses an HB400-grade wear-resisting steel plate and a production method thereof. The steel plate comprises the following chemical components in percentage by weight: C 0.05-0.15wt%, Si 0.4-1.4wt%, Mn 0.5-2.0wt%, P <0.012wt%, S <0.003wt%, Mo 0-0.5%, Nb 0.01-0.08%, Cu 0.20-1.0%, Co 0-1.0%, B 0.0010-0.0025wt%, Al 0.02-0.04wt%, Ti 0.004-0.030wt%, and the balance of Fe and inevitable impurities, wherein the content of Mo and Nb needs to satisfy the condition that the Mo+Nb is not less than 0.023C+0.059Ti+1.71B and not more than 2.574C+0.62Mn+10.36Ti +2.11B. The invention reduces production cost by adding some cheap alloy elements; and when the value of carbon equivalent Ceq is not more than 0.45, the HB400-grade wear-resisting steel plate has good welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Grooving corrosion resistant high strength steel for ERW soldering sleeve, sleeve and production method

ActiveCN101353766AExcellent resistance to trench corrosionImprove tissue performanceTemperature control deviceChemical compositionHigh intensity

The invention provides a steel used for a guttering corrosion resistant high-strength ERW welding socket, and the chemical compositions of which by weight percentage are as follows: 0.15 percent to 0.25 percent of C, 0.05 percent to 0.4 percent of Si, 0.7 percent to 1.5 percent of Mn, less than or equal to 0.1 percent of P, less than 0.005 percent of S, 0.005 percent to 0.03 percent of Ti, 0.005 percent to 0.04 percent of Nb, 0.005 percent to 0.04 percent of V, 0.1 percent to 0.7 percent of Cr, 0.1 percent to 0.30 percent of Cu, 0 percent to 0.003 percent of B, 0.002 percent to 0.04 percent of Al and 0.001 to 0.01 percent of Ca, and the rest are Fe and other unavoidable impurities. The invention also provides a cannula prepared by adopting the steel and a manufacturing method thereof. The steel of the invention has excellent performance of guttering corrosion resistance and does not contain expensive alloying elements such as Mo and Ni and the like, therefore, the cost of the cannula is low.

Owner:BAOSHAN IRON & STEEL CO LTD

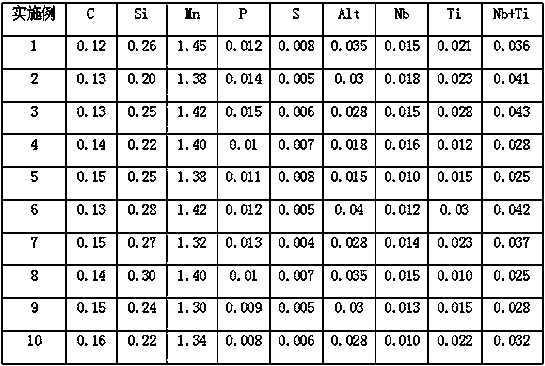

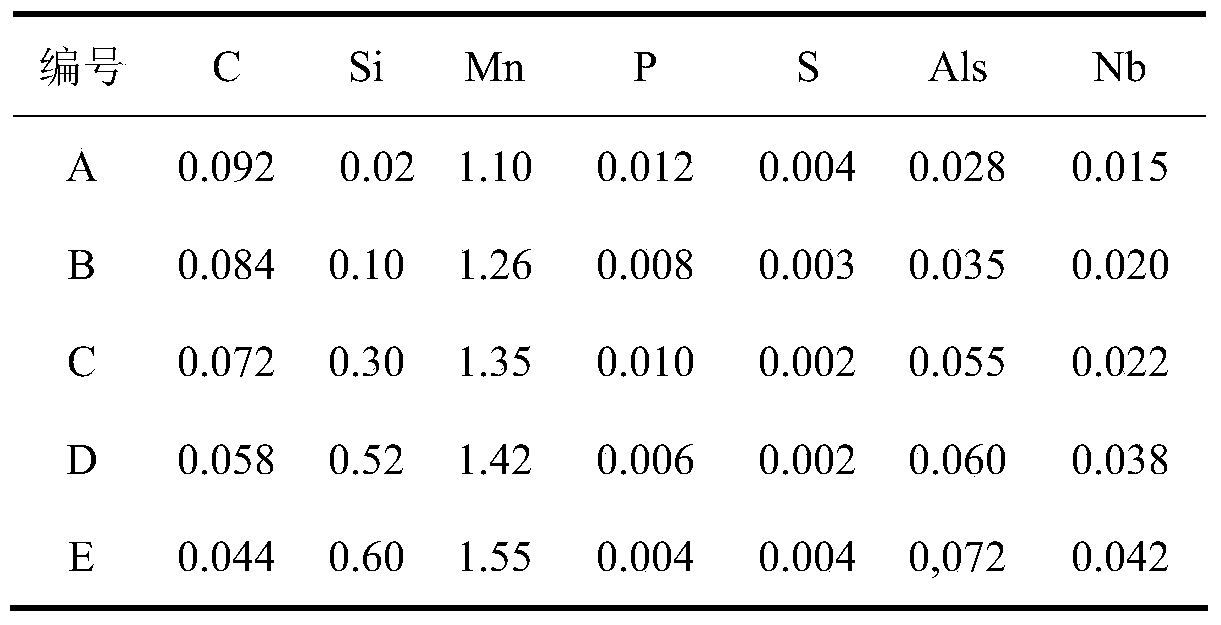

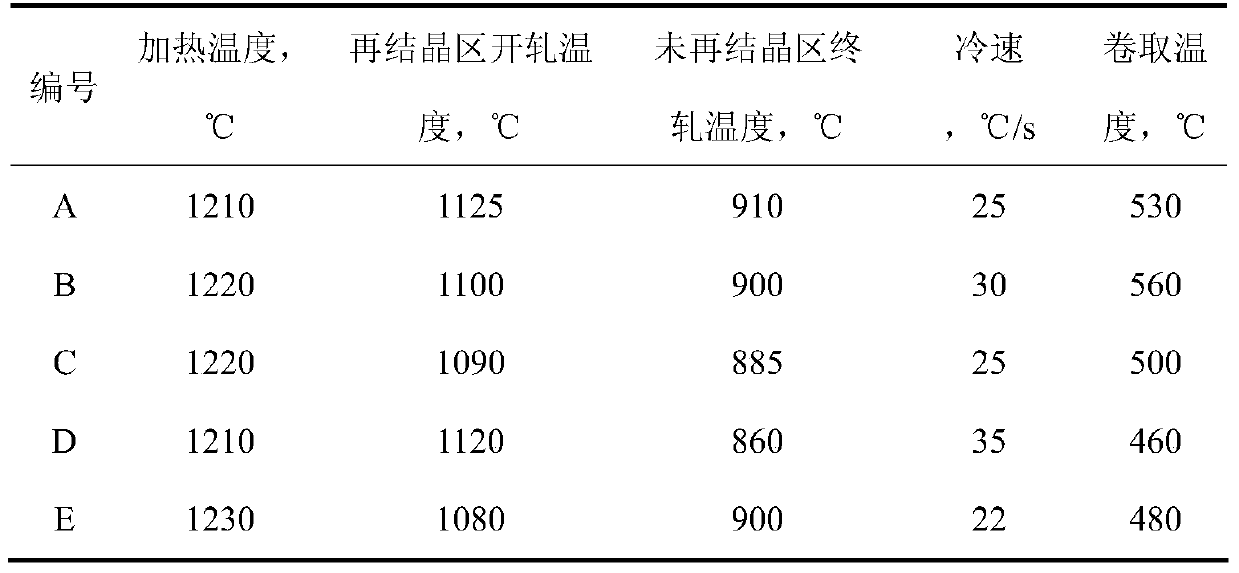

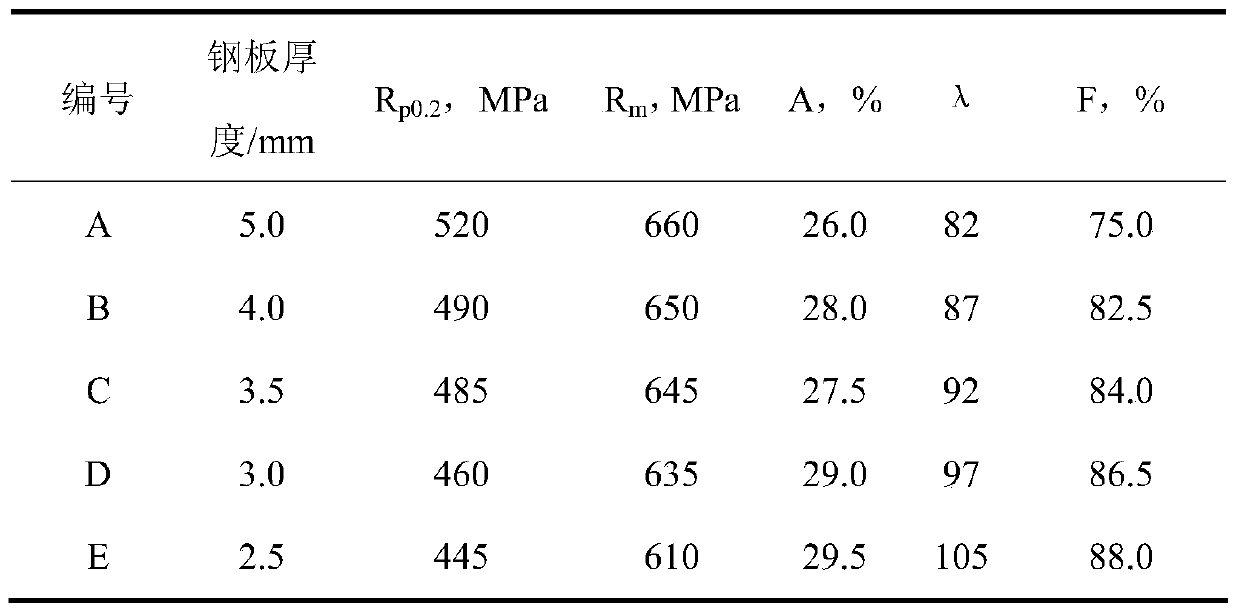

High-toughness hot-rolled 530 MPa-grade automobile cold stamping bridge shell steel plate and manufacturing method thereof

The invention discloses a high-toughness hot-rolled 530 MPa-grade automobile cold stamping bridge shell steel plate and a manufacturing method thereof. The high-toughness hot-rolled 530 MPa-grade automobile cold stamping bridge shell steel plate comprises the following components of C, S, Mn, P, S, Al, Nb, Ti and the balance Fe and impurities; the content of the elements has to meet the followingrelationship at the same time, Nb+Ti is greater than or equal to 0.025% and is less than or equal to 0.045%, CEV is equal to C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15 and is less than or equal to 0.45%; the manufacturing method is characterized in that V is not added to the component design, Mn content is properly adjusted, a certain amount of Si, Nb, Ti and the like are added, molten iron pretreatment, molten steel smelting, continuous casting, cooling, heating, rolling, cooling, finishing, inspection and the like are carried out, so that the surface quality and strength of the steel meet the cold stamping and welding processing processes of the bridge shell steel; the yield strength ReL of the steel plate is greater than or equal to 375 MPa, the tensile strength Rm is greater than or equal to 530 MPa, the elongation percentage A after fracture is greater than or equal to 26%, the impact power KV2 at 0 DEG C is greater than or equal to 180 J, the grain size is 8-10 grades, the strip-shaped gradeis 1-3 grades, and cold stamping and forming of 10-16 mm specifications can be realized.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

High-strength ERW welding socket steel, socket, method for producing same

ActiveCN101514432ALow alloy contentReduce manufacturing costChemical compositionUltimate tensile strength

The invention provides high-strength ERW welding socket steel, which comprises the following chemical components in weight percentage: 0.18 to 0.30 percent of C, 0.15 to 0.50 percent of Si, 0.9 to 1.5 percent of Mn, 0 to 0.03 percent of Ti, 0.06 to 0.25 percent of V, 0 to 0.6 percent of Cr, 0 to 0.004 percent of B, 0.002 to 0.04 percent of Al, 0 to 0.01 percent of Ca, 0 to 0.05 percent of Zr, and the balance of Fe and inevitable impurities. The invention also provides a welding socket made of the steel and a method for producing the same. Hot rolled plate coils made by the steel produced by the invention can obtain a strengthened ferritic structure at different cooling rates, so the yield strength is insensitive to the cooling rate and the manufacturability of the welding socket is ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

Alkali and corrosion resistant anchor chain steel and its production method

ActiveCN104294153AImprove alkaline corrosion resistanceLong service periodBusiness efficiencyHigh energy

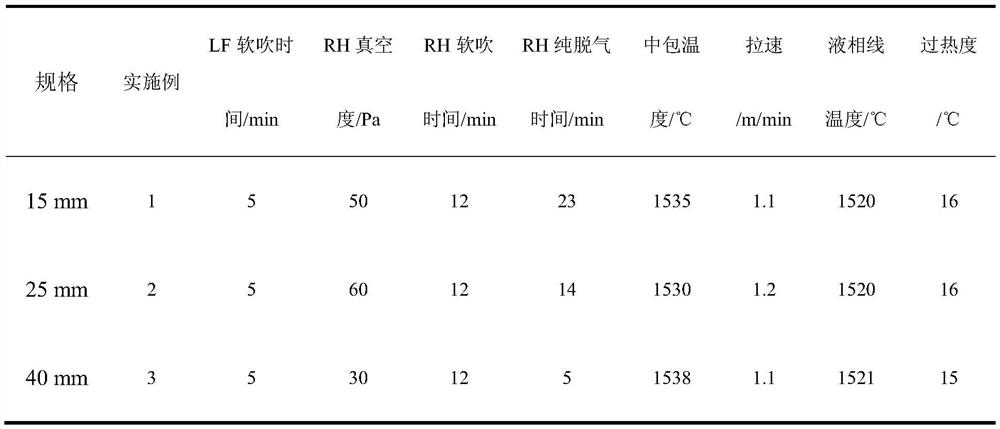

An alkali and corrosion resistant anchor chain steel comprises 0.27-0.33wt% of C, 0.15-0.55wt% of Si, 1.4-1.6wt% of Mn, 0.035wt% or less of P, 0.015wt% or less of S, 0.001-0.003wt% of B, 0.03-0.05wt% of V, 0.1-0.25wt% of Cu, 0.025-0.035wt% of Als, 0.1-0.25wt% of Ni and 0.001-0.007wt% of Ca. A production method of the anchor chain steel comprises the steps of molten iron desulphurization, converter smelting, argon blowing, LF furnace refining, RH furnace vacuum treatment, blank casting, natural pile cooling to room temperature, rough rolling, finish rolling, and air cooling to room temperature. The production method can improve the alkali resistance of steel by above 45%, allows the anchor chain steel to have a long service life under alkaline conditions, and reduces the alloy content without reducing the material performances in order to reduce the production cost; the obtained alkali resistant anchor chain steel has excellent weldability and plasticity; and a converter technology has a high energy / efficiency ratio.

Owner:武汉钢铁有限公司

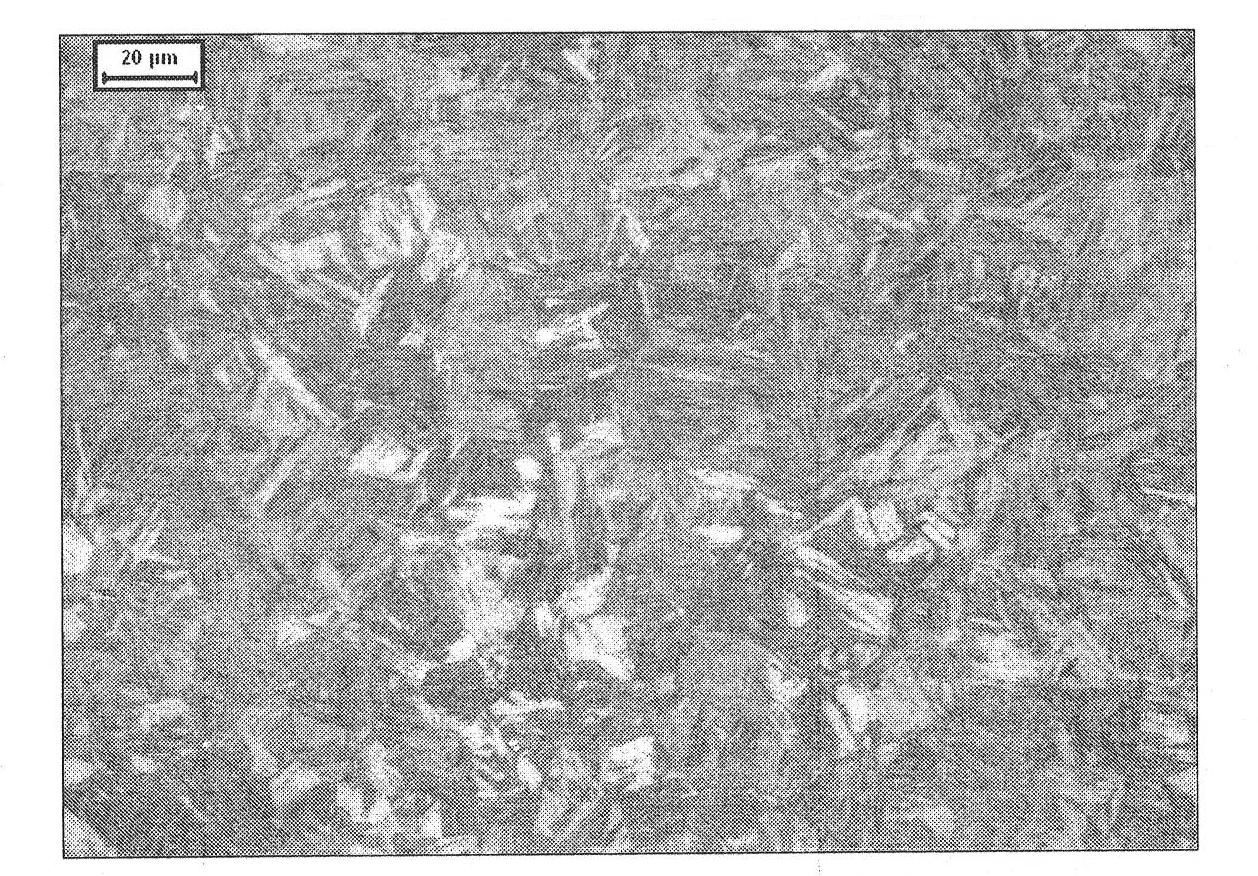

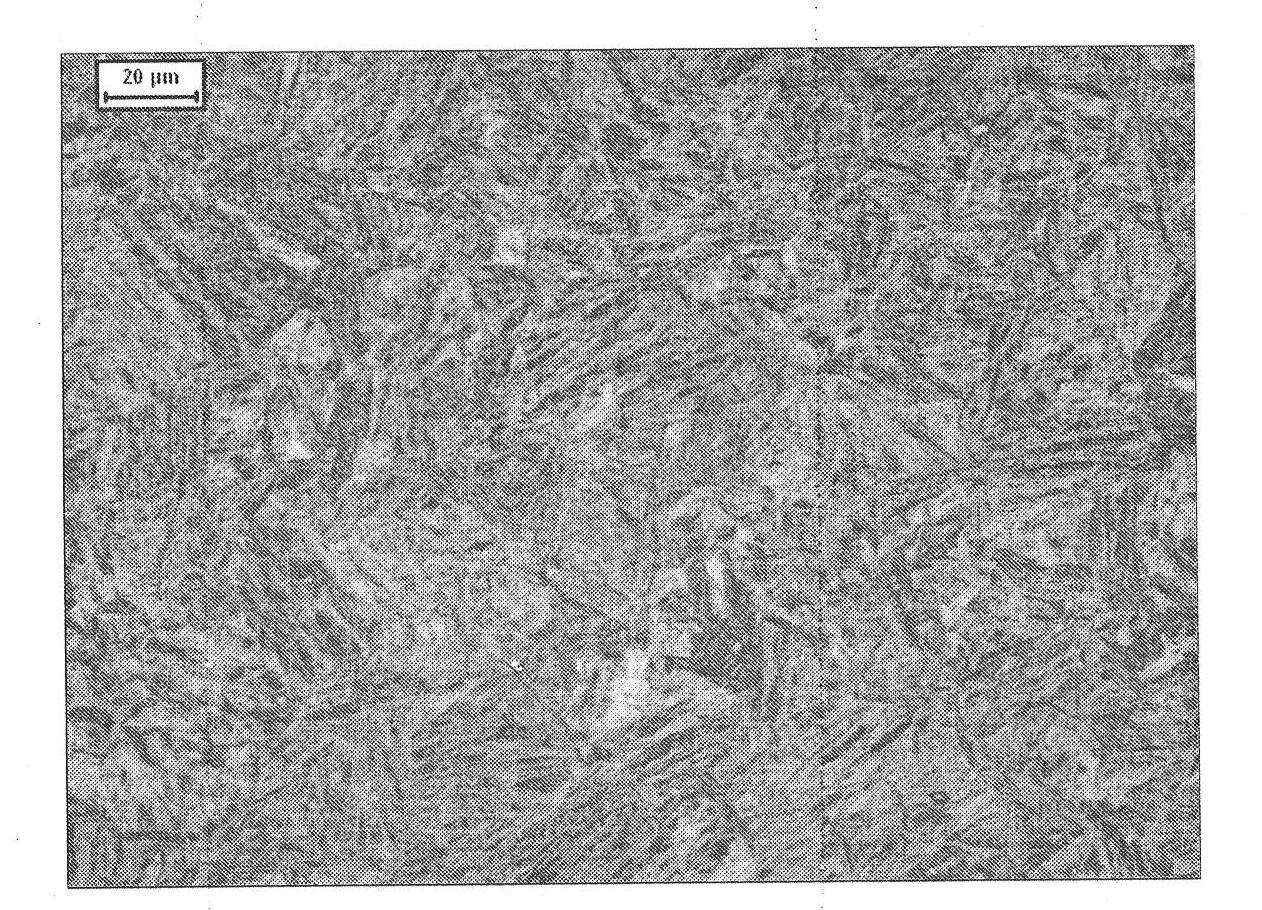

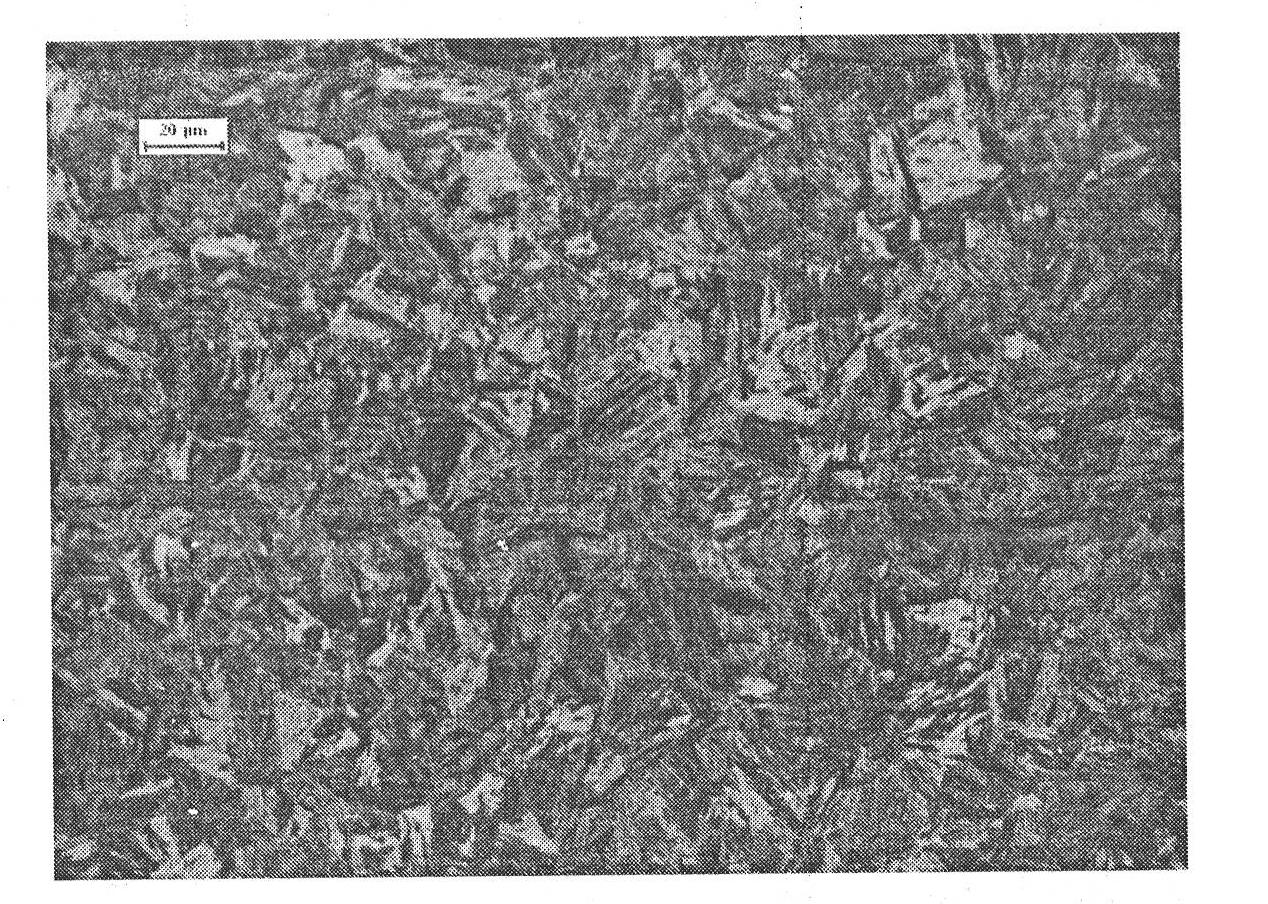

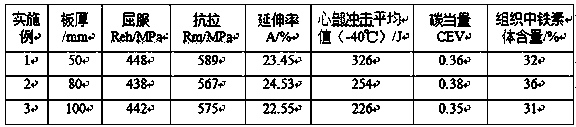

Modified EH550 super-thick steel plate for marine engineering and manufacturing method thereof

The invention discloses a modified EH550 super-thick steel plate for marine engineering and a manufacturing method thereof. The steel contains 0.08% to 0.15% of C, 0.20% to 0.55% of Si, 0.80% to 1.35%of Mn, less than or equal to 0.01% of P, less than or equal to 0.03% of S, 0.04% to 0.08% of V, 0.015% to 0.45% of Als, 0.003-0.015% of N, 0.50-0.90% of Ni, 0.20-0.40% of Cr, 0.002-0.03% of Mo, 0.02%to 0.05% of Nb, 0.20-0.40% of Cu, less than or equal to 0.04% of Ti, and the balance of Fe and unavoidable impurities. The method employs two-stage controlled rolling, the first-stage rolling temperature is 1100-1150 DEG C, the one-stage finishing rolling temperature is 990-1130 DEG C, the second-stage rolling temperature is 700-780 DEG C, and the final rolling temperature is 680-750 DEG C. The heat treatment method of quenching before sub-quenching is used, and after quenching, the steel plate is tempered, and the steel plate having a thickness of 80-100 mm is obtained. The impact toughnessof a core is more than 200J, and the comprehensive performance is uniform at different positions.

Owner:ANGANG STEEL CO LTD

Low-alloy steel used for oil well pipe with carbon dioxide corrosion resistance and manufacturing method thereof

ActiveCN102400057ASub>goodAccelerated corrosionFurnace typesHeat treatment furnacesCarbon dioxide corrosionImpurity

The invention relates to a low-alloy steel used for an oil well pipe, and the low-alloy steel comprises the following chemical components in percentage by weight: 0.20-0.40% of C, 0.10-1.0% of Si, 0.50-2.0% of Mn, 0.5-1.5% of Cr, 0.02-0.2% of V, 0.01-0.10% of Al, 0.005-0.03% of N, 0.02-0.2% of Nb, less than or equal to 0.015% of P, less than or equal to 0.005% of S and the balance of Fe and inevitable impurities, wherein the total content of the impurity elements is less than 0.05wt. The invention also relates to a manufacturing method of the low-alloy steel. The manufacturing method comprises the following steps: performing steel making at the initial tapping temperature of 1600-1700 DEG C; performing continuous casting at the initial temperature of 1530-1570 DEG C, wherein in order to reduce the centre cracks and drawhole occurrence rates of a casting blank, the pulling rate of the continuous casting is controlled to be below 2.3m / min, and banding segregation is controlled to be within the level of 2.5; beginning performing perforation rolling at the temperature of 1180-1220 while performing hot rolling on the continuous casting blank; performing final stretch reducing until the temperature is 890-910 DEG C; and after hot rolling, air-cooling a steel tube to room temperature, thus obtaining the low-alloy steel used for the oil well pipe, wherein the low-alloy steel is provided with ferrite and pearlitic structures and has carbon dioxide and chloride ion corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

High-carbon microalloying steel ball and production process thereof

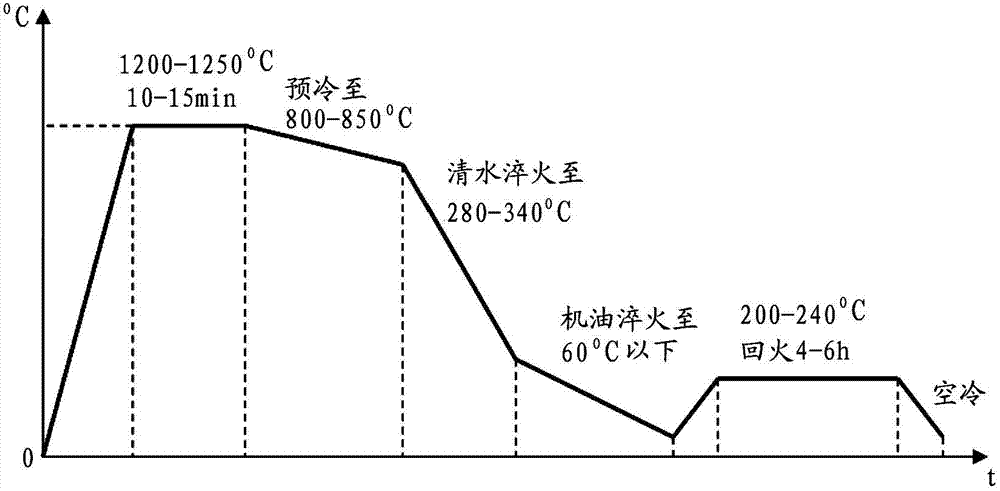

ActiveCN102758140APrevent quenching crackingAvoid problems such as quenching crackingFurnace typesHeat treatment process controlSurface layerHigh carbon

The invention discloses a production process of a high-carbon microalloying steel ball. The production process comprises the following steps of: heating a steel ball blank to be 1,200-1,250 DEG C and forging the steel ball blank to a steel ball of which the size is required; precooling the steel ball until the temperature of the surface layer of the steel ball is 800-850 DEG C; putting the steel ball into clear water at the temperature of 30-60 DEG C to quench until the temperature of surface layer of the steel ball is reduced to 280-340 DEG C, and taking out the steel ball; 1-2s later, putting the steel ball into mechanical oil at the temperature of 30-50 DEG C to quench until the temperature of surface layer of the steel ball is reduced be below 60 DEG C; taking out the steel ball and putting the steel ball into mechanical oil at the temperature of 200-240 DEG C to temper for not less than 4 hours; and taking out and finishing the steel ball to obtain a steel ball finished product, wherein according to the weight percentage, the steel ball contains 0.90-1.05 percent of C, 0.30-0.70 percent of Si, 0.80-1.20 percent of Mn, 0.25-0.40 percent of Cr and the balance being Fe and inevitable impurities. The high-carbon microalloying steel ball is prepared by using the production process, and the quenching and cracking of the steel ball can be effectively avoided; and compared with the conventional high-carbon microalloying steel ball, the prepared high-carbon microalloying steel ball has the same performance, and obviously reduces alloy contents and production cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

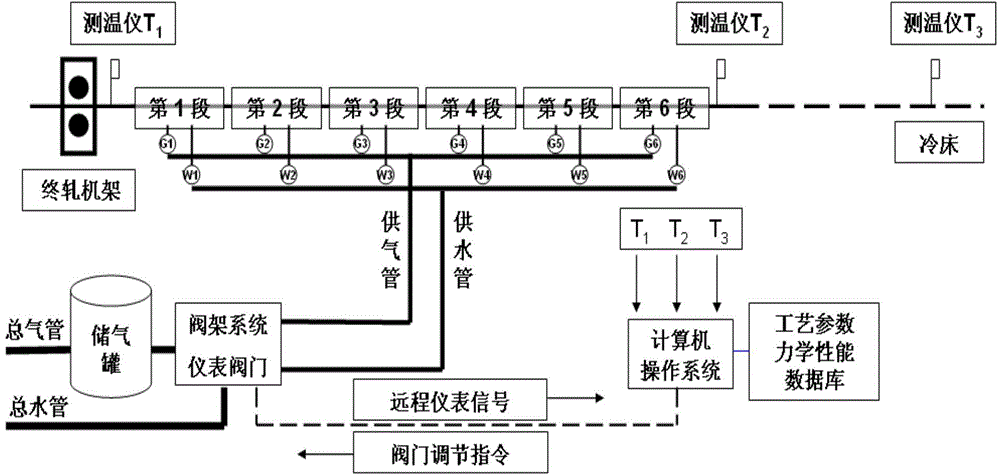

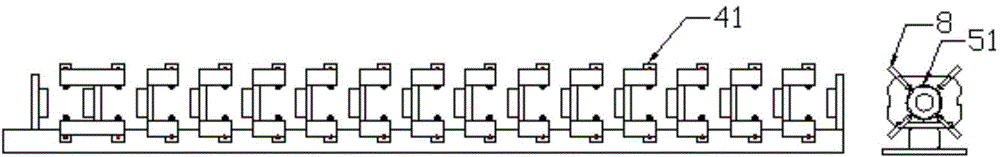

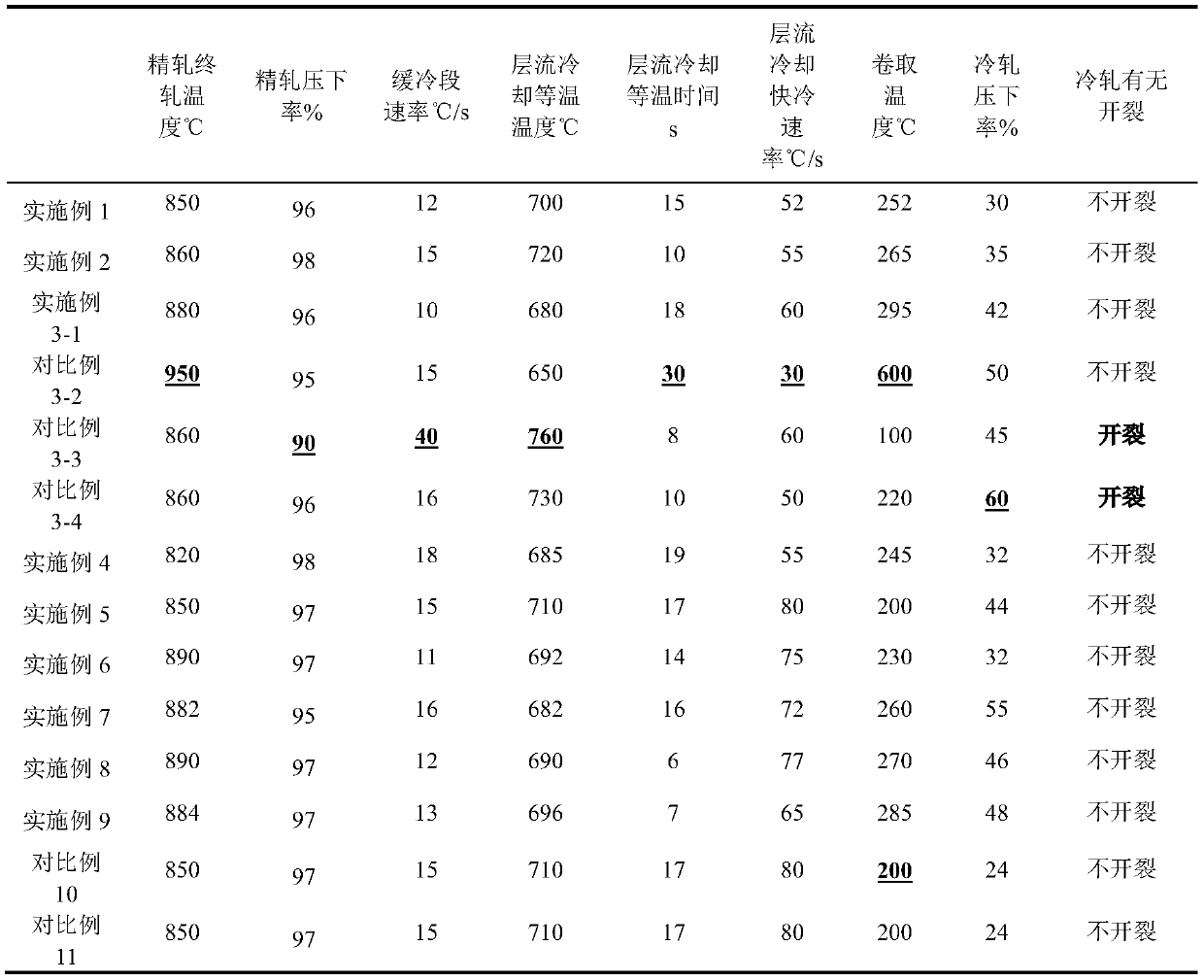

Method and device for spray evaporation cooling of hot-rolled high-strength rebar

ActiveCN104550275AEvaporative cooling high efficiencyHigh efficiency of water mist vaporization coolingTemperature control deviceWork treatment devicesEvaporationAlloy

The invention discloses a method and a device for spray evaporation cooling of a hot-rolled high-strength rebar, and belongs to the technical field of steel rolling. The device comprises a water and air supply system, six segments of a spray evaporation cooling device, infrared thermometers and a computer operating system, wherein the water and air supply system is composed of a main water pipe, a filter screen, a main air pipe, an air storage tank, a valve bracket system, a water supply pipe and an air supply pipe. Pressure gauges and flow gauges of the valve bracket system transmit pressure parameters and flow parameters of water and air supply to the computer operating system through long-distance instrument signals. According to the device for spray evaporation cooling of the hot-rolled high-strength rebar, grain refinement and bainite transformation are controlled through a grouped and segmented stepped accelerated cooling mode of spray evaporation cooling nozzles, so that strength of the hot-rolled rebar is improved remarkably and required elongation, yield strength ratio and anti-seismic property are acquired on the premise of avoiding martensite ring formation caused by conventional through water cooling, alloy content and new water consumption are reduced, and red rust on the surface of the rebar due to through water cooling is prevented.

Owner:CENT IRON & STEEL RES INST

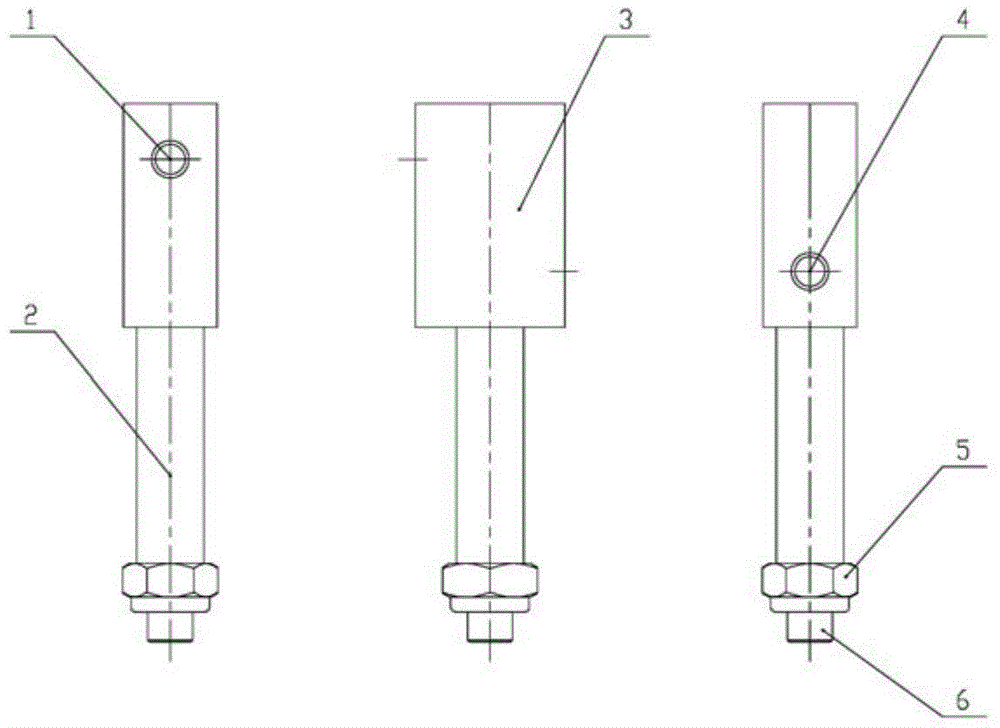

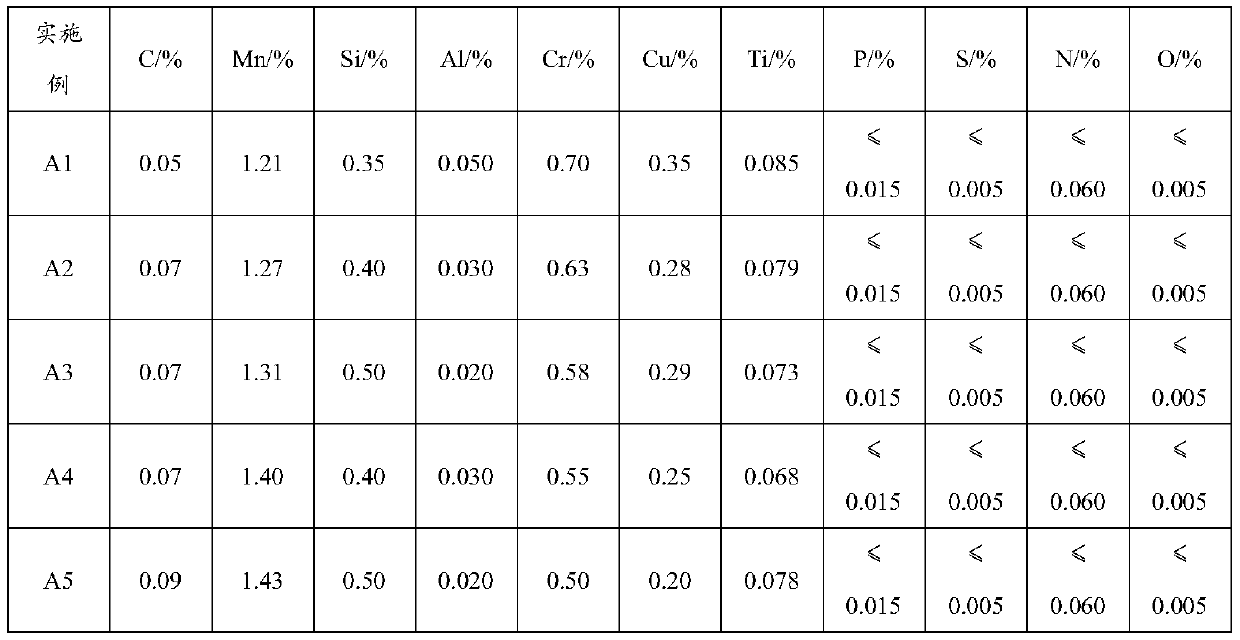

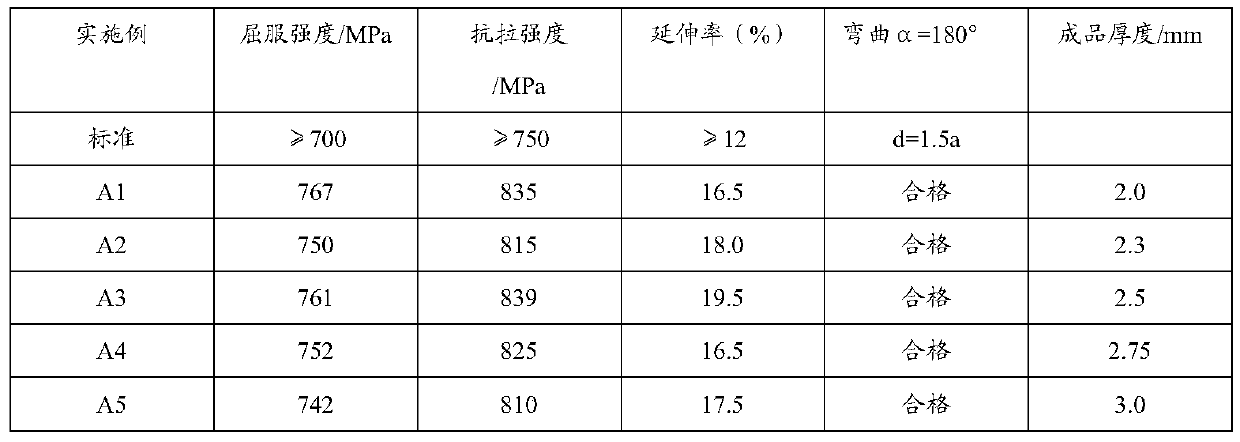

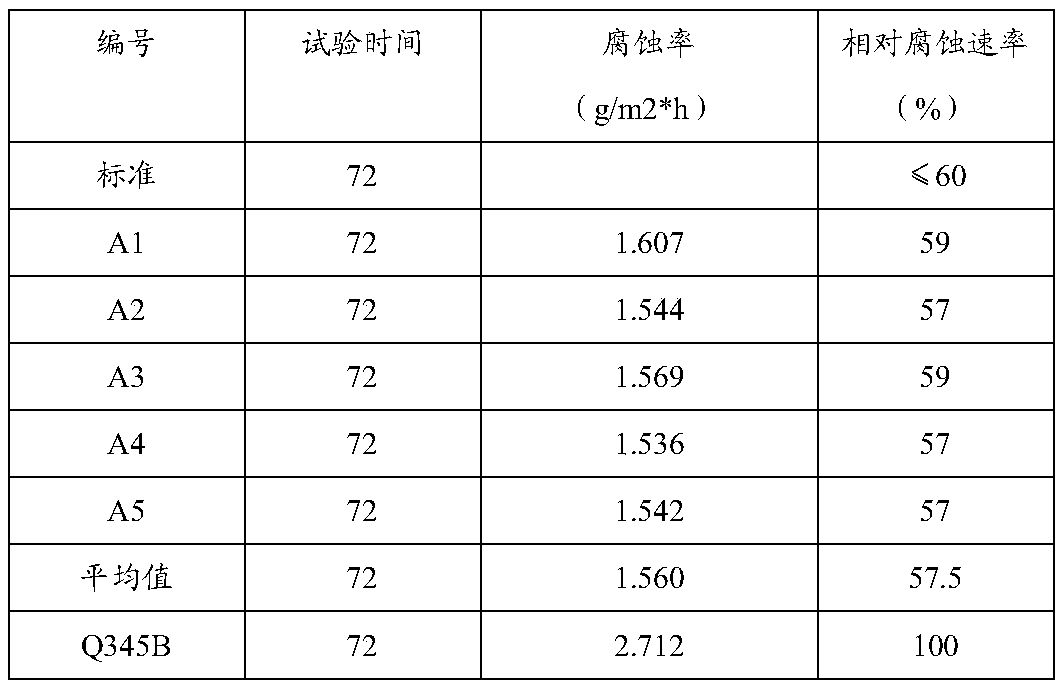

700 MPa-grade hot-rolled container steel and low-cost production method thereof

InactiveCN109881081AImprove performanceImprove corrosion resistanceTemperature control deviceMolten steelMechanical property

The invention discloses 700 MPa-grade hot-rolled container steel and a low-cost production method thereof. The hot-rolled container steel has corrosion resistance, cold bending property, and of the container steel comprises the following alloy composition of, in percentage by mass, 0.05-0.09% of C, 1.20-1.50% of Mn, 0.35-0.50% of Si, 0.020-0.050% of Al, 0.20-0.40% of Cu, 0.50-0.70% of Cr, 0.070-0.100% of Ti, not greater than 0.015% of P, not greater than 0.005% of S, not greater than 0.0060% of N and not greater than 0.005% of O. According to the 700 MPa-grade hot-rolled container steel and the low-cost production method thereof, the hot-rolled container steel component design is low in alloy content, pure in molten steel, and capable of saving the cost on the basis of ensuring excellent performance; and the high compression ratio is achieved, and the structure and the performance of finished products are improved; and in terms of mechanical property, various indexes meet the requirements, and the surplus amount is relatively sufficient.

Owner:BENGANG STEEL PLATES

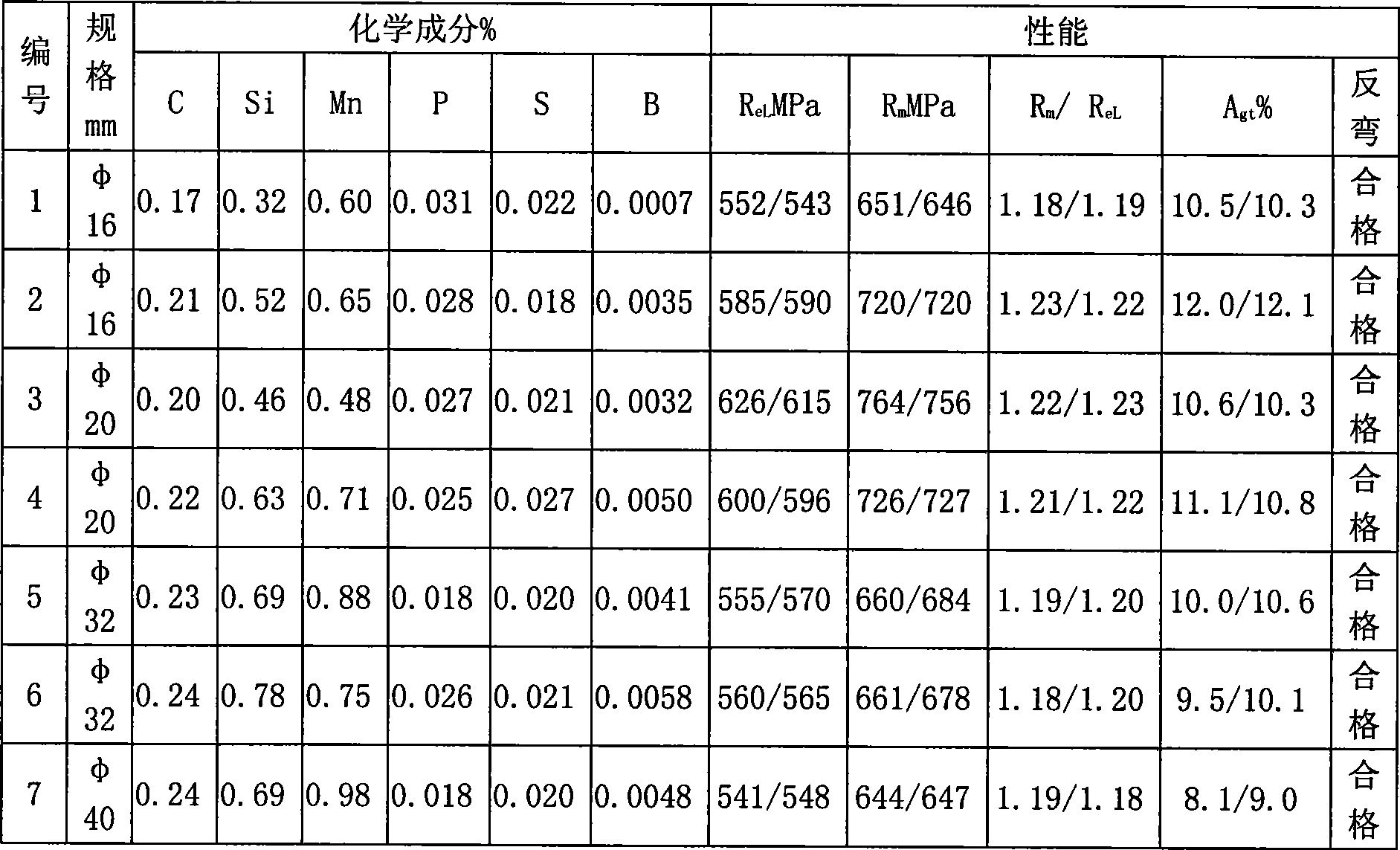

Steel for boron micro-alloying waste heat treatment steel bar

The invention provides a steel for a boron microalloying afterheat-treating steel bar, comprising the chemical compositions with the following mixture ratio (by weight percent): 0.15-0.25% of C, not higher than 0.80% of Si, 0.45-1.00% of Mn, not higher than 0.045% of P, not higher than 0.045% of S, 0.0005-0.006% of B, and the balance of Fe and impurity elements. The steel for the steel bar is smelted and continuously cast to a steel billet on common steelmaking equipment, and then is rolled on a common steel bar mill, which is followed by post-rolling afterheat treatment, rapid surface quenching is carried out by a cooling device and self tempering is implemented using the heat transmitting from inside to outside of the core of the steel bar. The steel bar produced by the invention can further lower alloy content of a 20MnSi afterheat-treating steel bar, save alloy resources, lower production cost, overcome the defects of high technical requirements to the cooling device, large control difficulty of cooling procedures and low production efficiency of a Q235 general carbon steel afterheat-treating steel bar.

Owner:MAANSHAN IRON & STEEL CO LTD

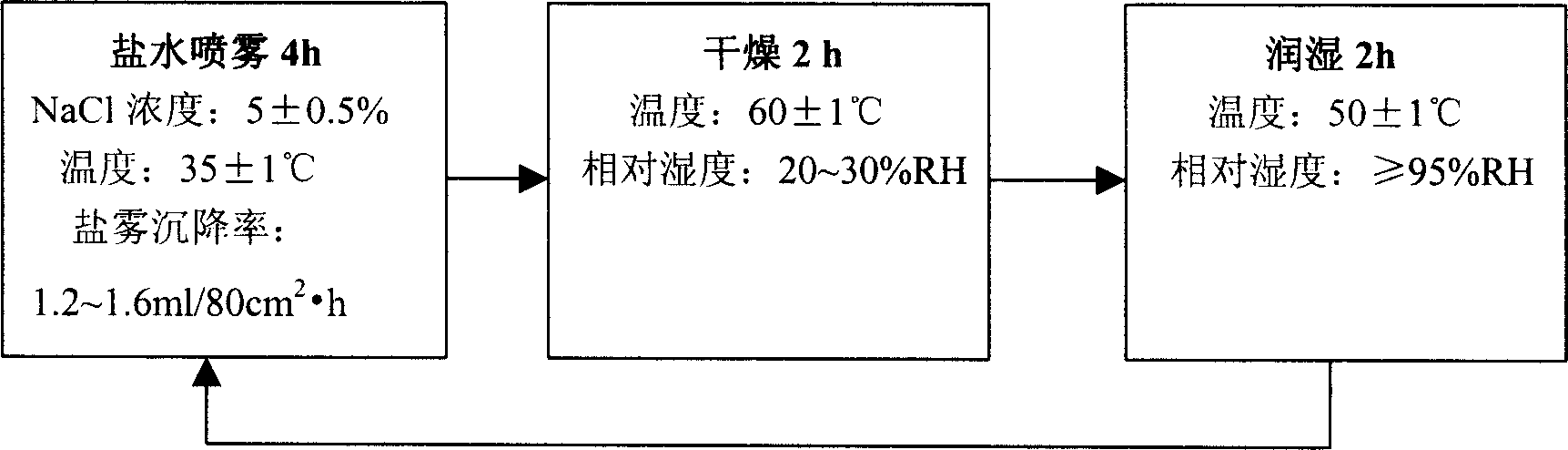

Anti-corrosive alloy coating for power transmission tower and fastener and preparation process of anti-corrosive alloy coating

ActiveCN103834890ASimple hot-dip plating processShort immersion timeHot-dipping/immersion processesAlloy coatingTower

The invention relates to an anti-corrosive alloy coating for a power transmission tower and a fastener and a preparation process of the anti-corrosive alloy coating. The anti-corrosive alloy coating is prepared by pickling, aided plating, drying, hot dipping, air cooling and other technological processes. The coating comprises the following components: 0.01 to 2.5% of Al, 0.01 to 0.5% of Mg, 0.06 to 2% of Re, 0.02 to 1.5% of Cu, 0.05 to 0.3% of Cr, 0.005 to 0.01% of Nb, 0.005 to 0.01% of Ni, 0.002 to 0.06% of B, and the balance of Zn. The alloy coating is used for prolonging the anticorrosive lifetimes of steel for the power transmission tower and the fastener under a complex salt-spray environment, and prolonging the anticorrosive lifetimes more than 10 times that of an industrial hot galvanizing pure-zinc product on the premise that the thickness of the coating is not increased.

Owner:STATE GRID CORP OF CHINA +2

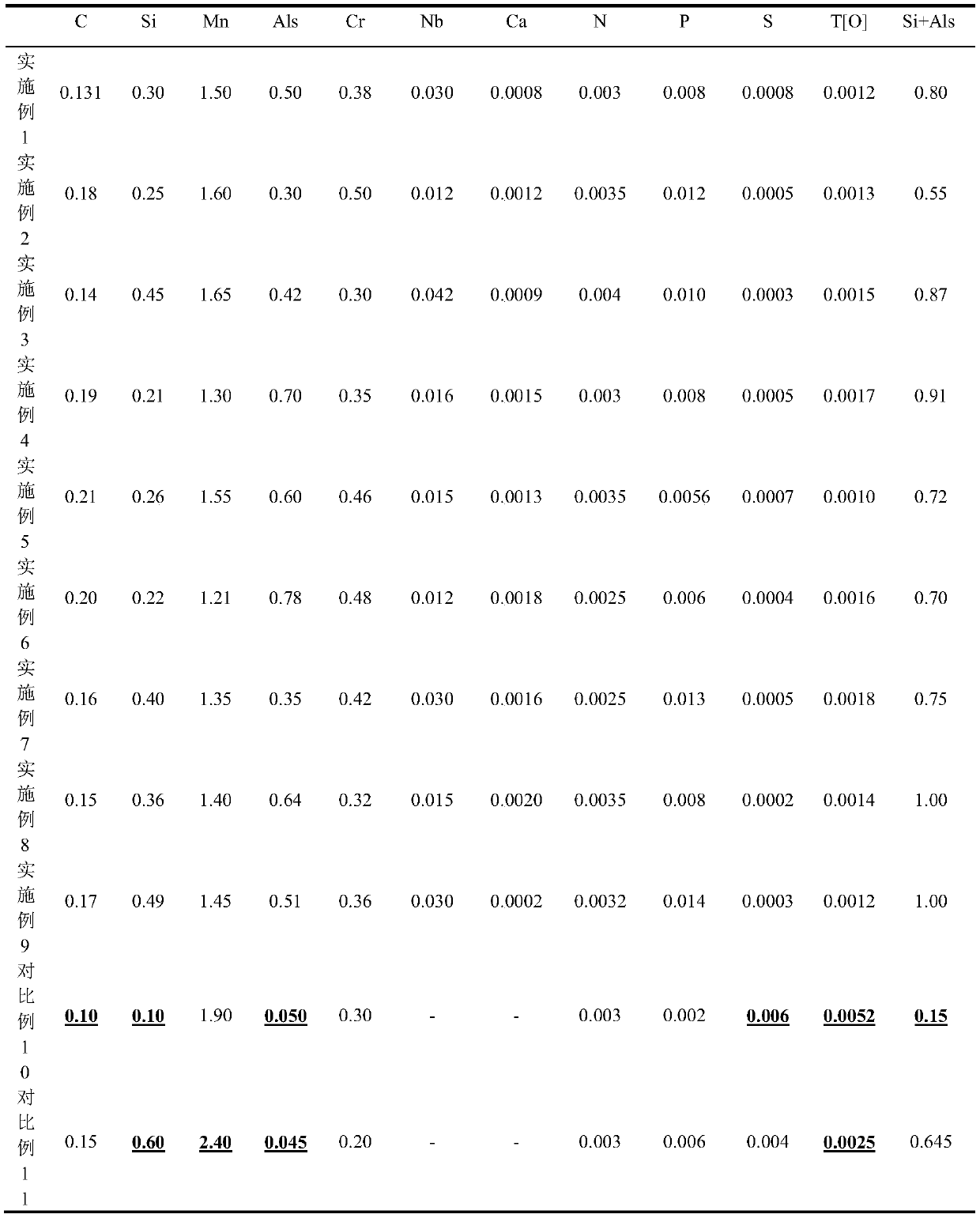

1000 MPa-grade good-cold-machining-property low-cost cold-rolling dual-phase steel and manufacturing method thereof

The invention discloses 1000 MPa-grade good-cold-machining-property low-cost cold-rolling dual-phase steel and a manufacturing method thereof, and belongs to the technical field of iron and steel smelting. The 1000 MPa-grade good-cold-machining-property low-cost cold-rolling dual-phase steel comprises the following chemical components of, according to the mass percentage, 0.13-0.22% of C, 1.20-1.70% of Mn, 0.20-0.50% of Si, 0.30-0.80% of Als, less than or equal to 0.015% of P, less than or equal to 0.0010% of S, less than or equal to 0.004% of N, 0.20-0.50% of Cr, 0.010-0.05% of Nb, 0.0005-0.0025% of Ca, less than or equal to 0.002% of T[O], and the balance Fe and unavoidable impurities; and the sum of the mass percentage of Si and Als is greater than or equal to 0.50% and is less than orequal to 1.00%. The manufacturing method comprises the steps of a steel making technology, an LF refining technology, a RH refining technology, a continuous casting technology, a hot rolling technology, a cooling technology, a winding technology, an acid pickling technology, a cold rolling technology, an annealing technology and a leveling technology. On the basis that the design of the relativelylow content of alloy elements is selected, the rolling technologies and the cooling technology are combined, so that the requirement of a prepared product on a production technology production line is not high on the basis that the prepared product has the relatively high intensity and cold bending property.

Owner:武汉钢铁有限公司

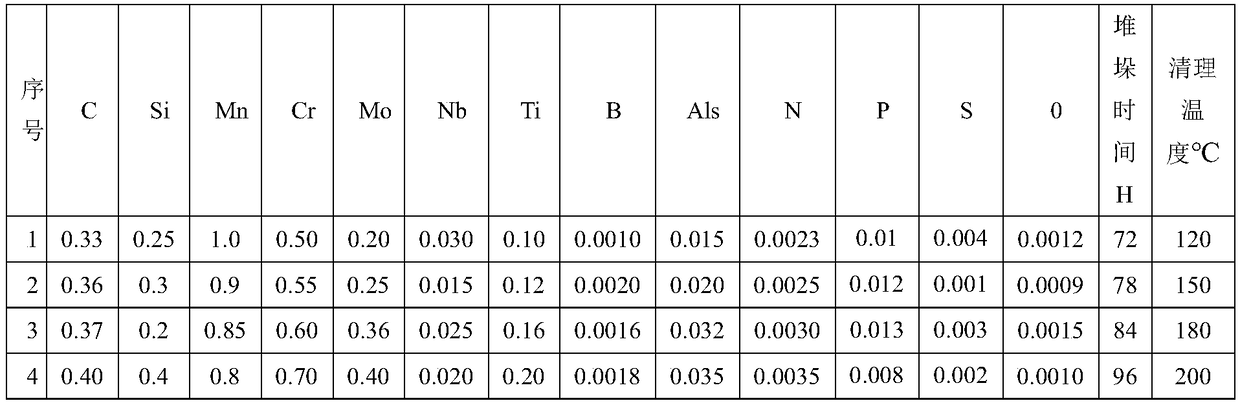

Heat-resistant wear-resistant steel plate and production method thereof

The invention discloses a heat-resistant wear-resistant steel plate and a production method thereof. The heat-resistant wear-resistant steel plate consists of the following components in percentage byweight: 0.33%-0.40% of C, 0.2%-0.4% of Si, 0.80%-1.00% of Mn, 0.5-0.7% of Cr, 0.2-0.4% of Mo, 0.015%-0.03% of Nb, 0.0005-0.0022% of B, 0.10%-0.20% of Ti, 0.015%-0.045% of Als and the balance of Fe and inevitable impurities; and impurity elements in steel are controlled as follows: less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.0040% of [N] and less than or equal to 0.0020% of [O]. According to the heat-resistant wear-resistant steel plate and the production method thereof provided by the invention, the steel plate has surface hardness greater than HB400 after being tempered at a temperature lower than 500 DEG C; the production method is simple, and does not need special compound equipment; and residual stress is low, cracks are not liable togenerate, components are simple and common, and the cost is low.

Owner:ANGANG STEEL CO LTD

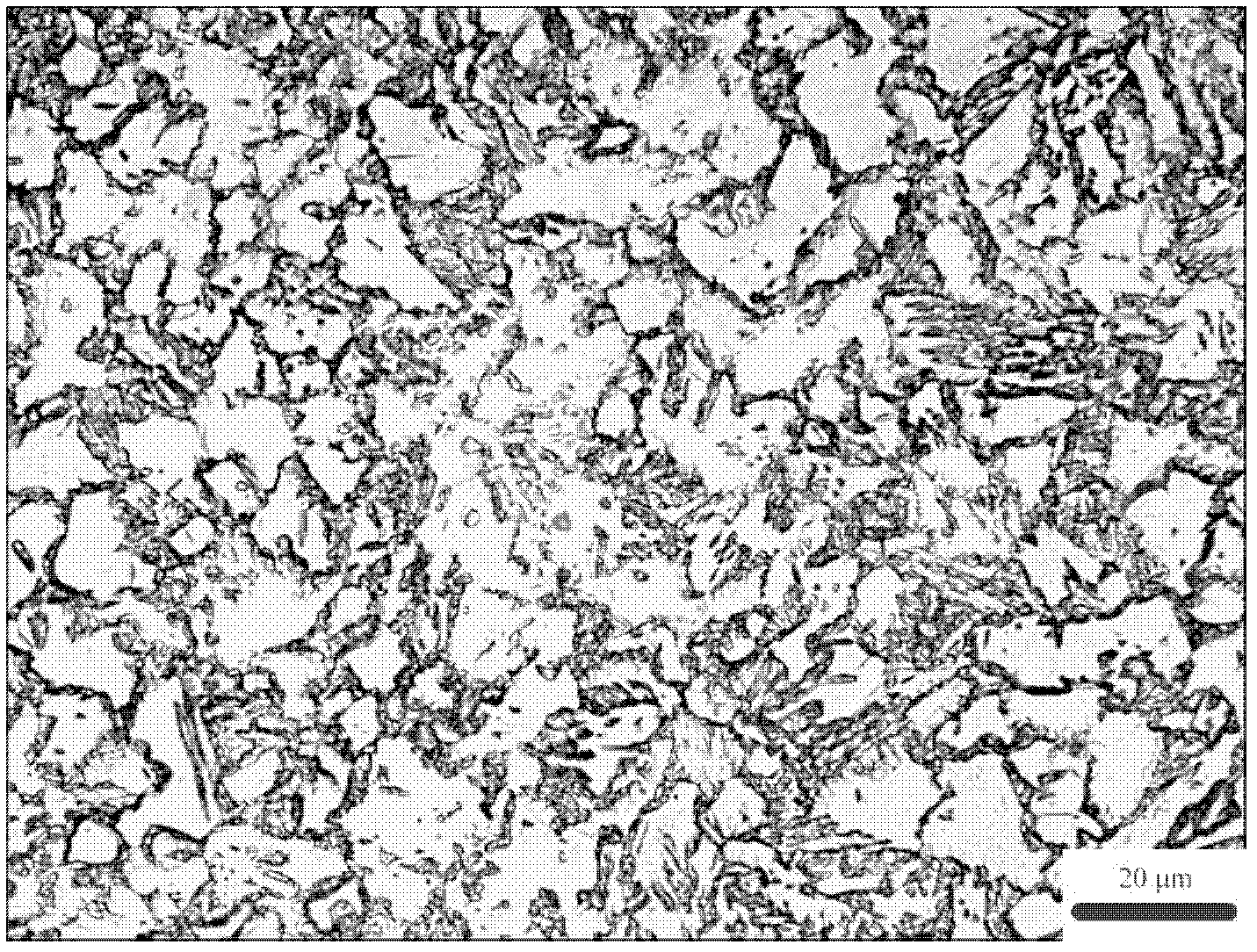

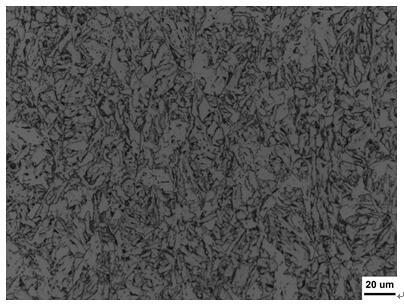

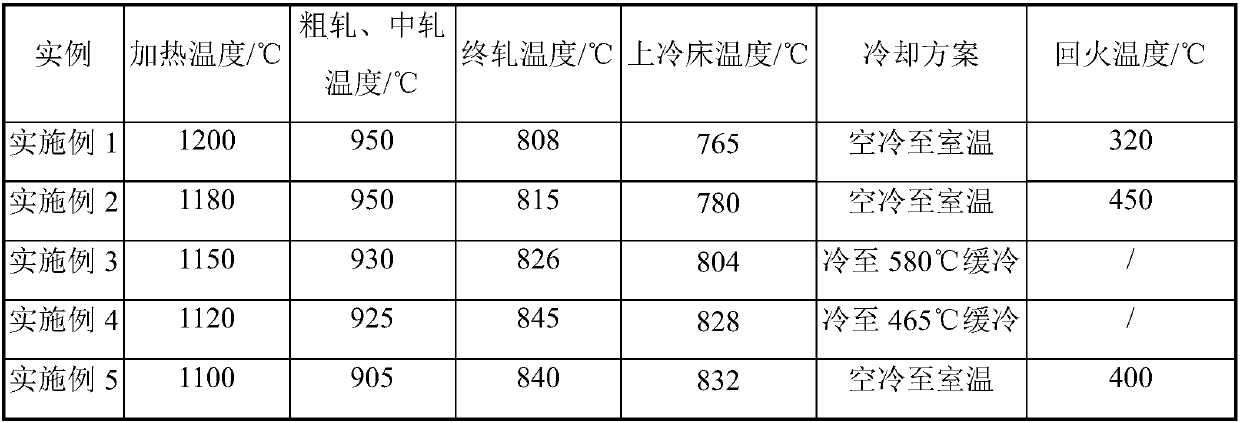

Production method of polyphase structure high tenacity ship plate steel EH40

The present invention discloses a production method of polyphase structure high tenacity ship plate steel EH40. The steel includes the following chemical compositions by weight percentage: carbon=0.04-0.08, silicon 0.15-0.35, manganese=1.50-1.60, phosphorus less than and equal to 0.015, sulfur less than and equal to 0.005, niobium less than and equal to 0.02-0.03, titanium less than and equal to 0.008-0.02, aluminum=0.015-0.05, nickel=0.30-0.40, and the remaining of Fe and inevitable impurities. The process steps include smelting, continuous casting, rolling, relaxation and cooling. The methodof the present invention breaks through the limitation of compression ratio for rolling continuously cast bloom by the traditional TMCP process without additional thermal treatment process; high tenacity steel plate with a low temperature impact requirement of below -40 DEG C is produced, the maximum thickness may reach 100 mm, and the product can be widely applied to manufacturing of thick plates in various fields such as shipbuilding, maritime work, wind power, bridge, architecture and engineering machinery; and the method of the present invention can be realized by using the current equipment and process condition of a steel mill, which does not increase investment and equipment upgrading, and further improve the production efficiency and realizes energy conservation and consumption reduction.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

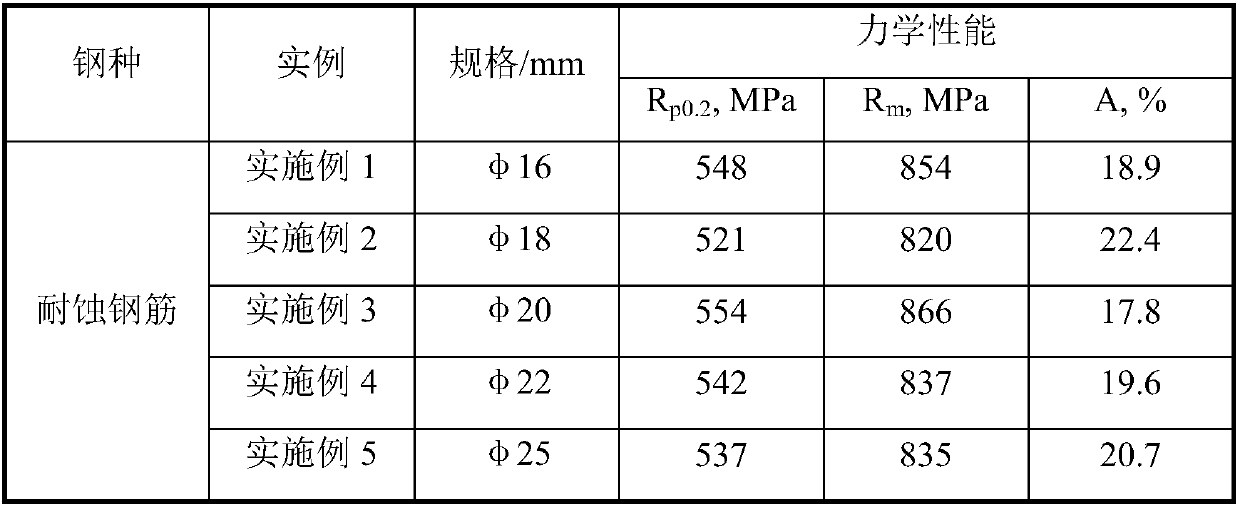

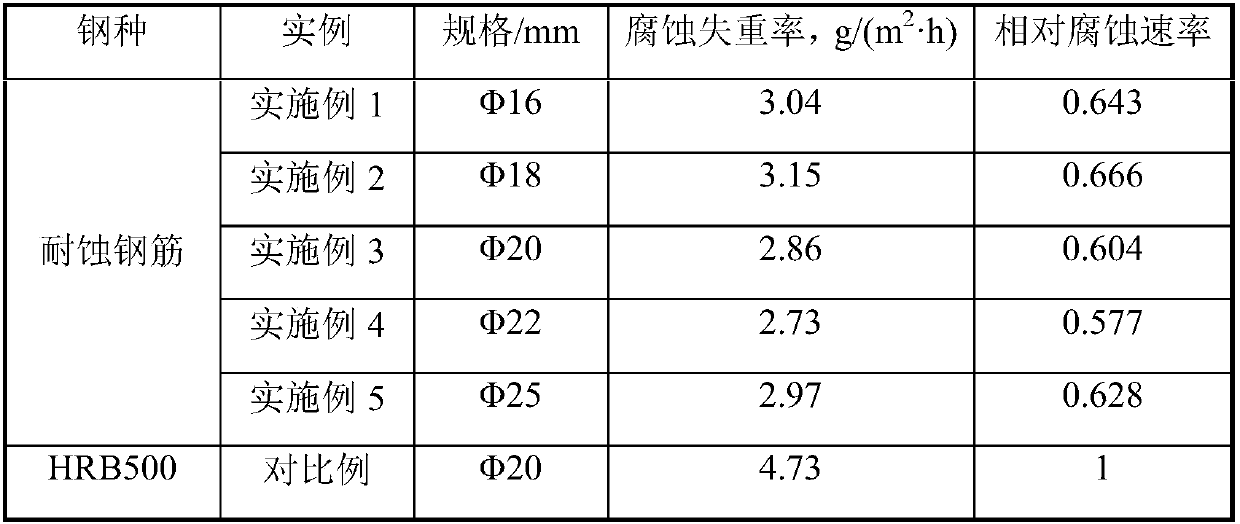

Corrosion-resisting rebar with yield strength in 500 MPa grade and production method

InactiveCN107723603AIncrease corrosion rateGood toughening effectProcess efficiency improvementChemical compositionRebar

The invention discloses a corrosion-resisting rebar with the yield strength in 500 MPa grade and a production method, and belongs to the technical field of corrosion-resisting steel for construction.The rebar comprises, by weight, the chemical components including 0.05-0.10% of C, 0.30-0.60% of Si, 1.20-1.50% of Mn, 1.00-1.50% of Cr, 0.10-0.20% of Ni, 0.20-0.40% of Cu, 0.10-0.20% of Mo, 0.06-0.10% of V, 0.010-0.025% of Ti, 0.035% or less of P, 0.010% or less of S and the balance Fe and inevitable residual impurity elements. According to the rebar, by adding small amounts of the alloying elements and fully using each individual element and the synergistic action among the elements, the corrosion resistance performance of the rebar is improved; the production method of the rebar comprises the steps of conventional smelting and casting and adoption of a controlled rolling and controlled cooling technology on a bar mill; noble metal elements in the rebar are low in contents, the toughness, the weldability and the corrosion resistance performance of the rebar are excellent, resources are saved, and the production cost is low.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

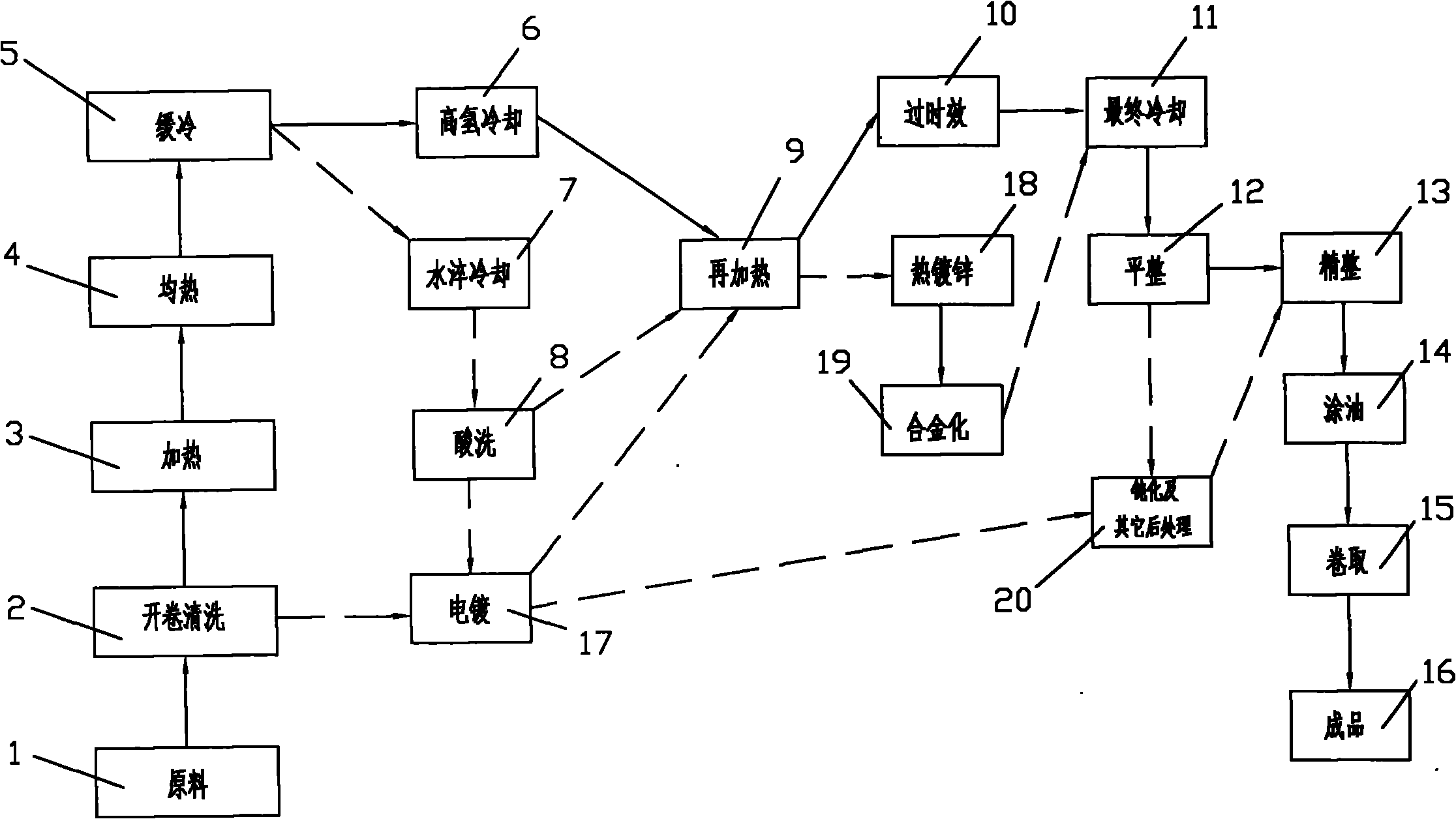

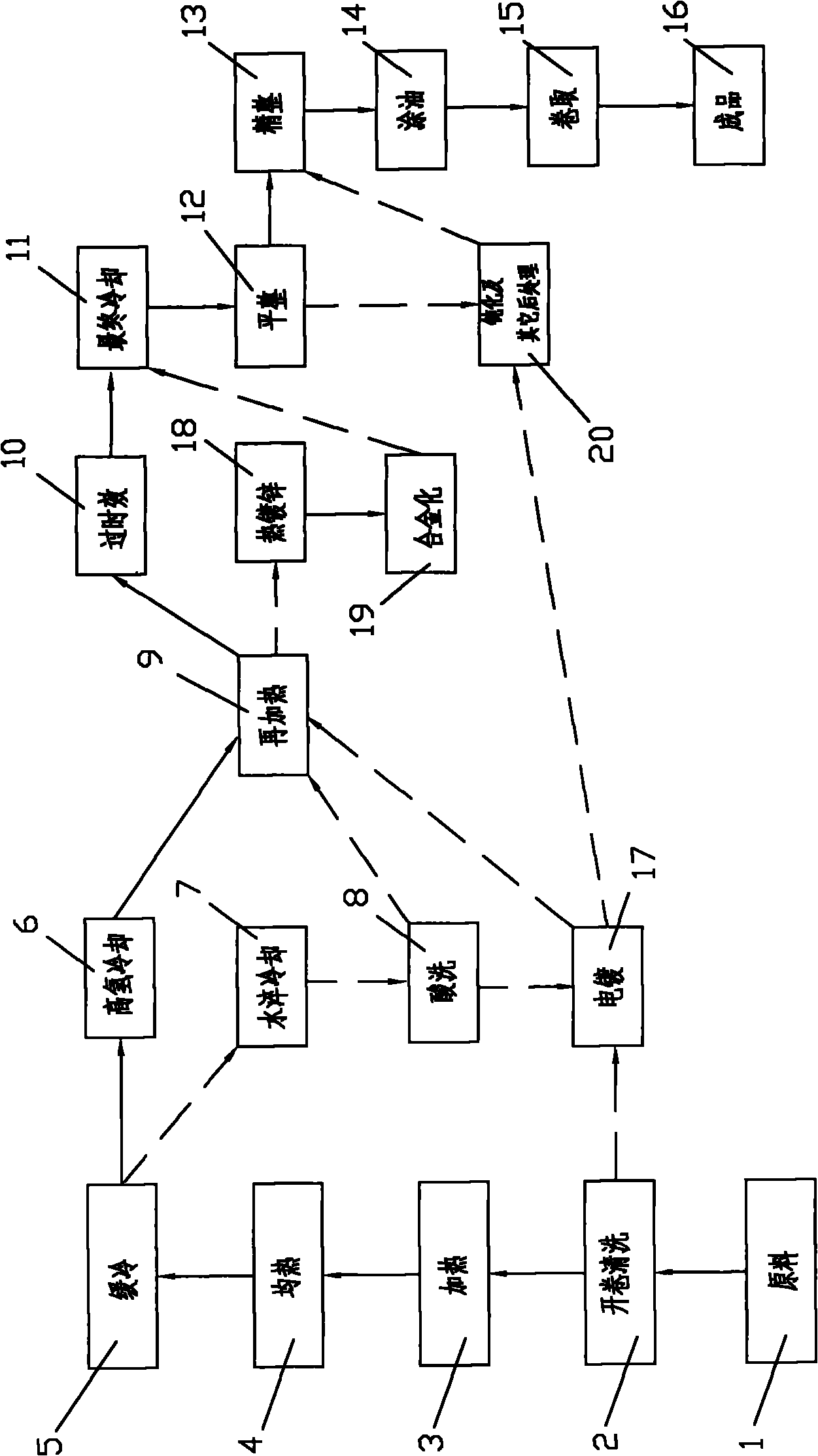

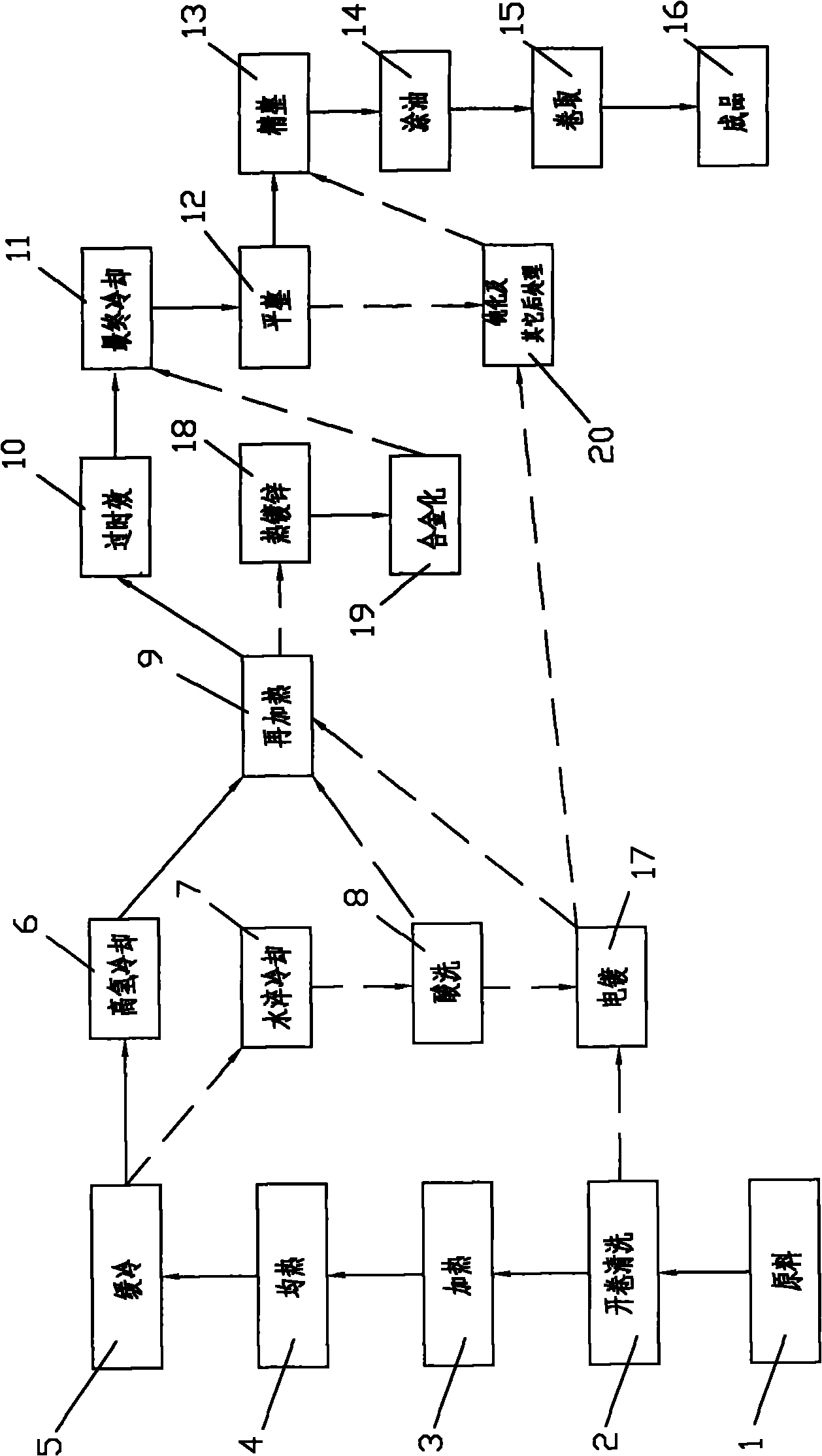

Flexible strip steel treating line suitable for producing various high-strength steel

ActiveCN101812579ARich varietyMeet actual needsHot-dipping/immersion processesElectrolysis componentsStrip steelSlow cooling

The invention discloses a flexible strip steel treating line suitable for producing various high-strength steel. The flexible strip steel treating line comprises an uncoiling working position, a washing working position, a heating working position, a soaking working position and a slow cooling working position, a jet cooling working position or a water quenching cooling working position in turn, wherein a reheating working position and then an overaging working position or a hot galvanizing working position and a cladding alloying and annealing working position are arranged after the jet cooling working position; a moveable bypass channel is arranged to connect the reheating working position and the overaging working position respectively; a final cooling working position and a flatting working position are connected after the overaging working position and the hot galvanizing working position; then, a finishing working position and an oil coating working position, or a passivating working position and other post-treatment working positions are connected; the finishing working position and the oil coating working position are connected to a coiling working position to finish a finished product; an acid cleaning working position and an electroplating working position are arranged corresponding to the water quenching and cooling working position; the reheating working position can be connected after the acid cleaning working position directly; an uncoiling and washing working position can be directly connected before the electroplating working position; and the bypass channel or a switching device is arranged after the electroplating working position to respectively and correspondingly connect the reheating working position or directly connect the passivating working position and the other post-treatment working positions.

Owner:BAOSHAN IRON & STEEL CO LTD

600 MPa-grade highly-chambered steel plate for automotive chassis and manufacturing method thereof

The invention provides a 600 MPa-grade highly-chambered steel plate for automotive chassis. Steel of the steel plate is composed of, in percentage by weight, 0.04-0.10% of C, Si smaller than 0.70%, 1.0-1.6% of Mn, 0.02-0.08% of Als, 0.01-0.05% of Nb, P smaller than 0.015%, S smaller than 0.005% and the balance Fe and inevitable impurities. The invention further provides a manufacturing method of the steel plate. The method comprises the steps of heating continuous casting sheet billets with the thickness ranging from 80 mm to 230 mm to 1220+ / -20 DEG C, and preserving the temperature for 1.8-3 hours; carrying out two-stage rolling, wherein the rolling temperature of the recrystallizing region is higher than 1050 DEG C, the thickness of intermediate billets ranges from 35 mm to 60 mm, the finish rolling temperature of the non-recrystallizing region ranges from 840 DEG C to 920 DEG C, and the thickness of finished products ranges from 2.0 mm to 6.0 mm; carrying out continuous laminar flow cooling after finish rolling, wherein the cooling rate is 20-40 DEG C / s and the coiling temperature ranges from 450 DEG C to 580 DEG C. According to the invention, the steel plate is high in alloy content and low in cost, the hot rolling process is simple, the rolling performance of the steel plate is uniform, and the matching performance between the strength and the hole chambering rate is good.

Owner:ANGANG STEEL CO LTD

Steel plate for polar ocean engineering and preparation method of steel plate

ActiveCN112048665AGood welding performanceLow costManufacturing convertersFurnace typesSlow coolingCorrosion resistant

The invention discloses a steel plate for polar ocean engineering and a preparation method of the steel plate. The steel plate is prepared from the components in percentage by mass: 0.06%-0.09% of C,0.20%-0.35% of Si, 1.48%-1.63% of Mn, 0.020%-0.035% of Nb, 0.010%-0.020% of Ti, 0.020%-0.035% of V, 0.08%-0.17% of Ni, 0.015%-0.040% of Als, less than or equal to 0.013% of P and less than or equal to0.005% of S. The preparation method of the steel plate comprises the steps: primarily smelting, refining and casting are conducted, a casting blank is obtained, and then slow cooling is conducted; the slowly-cooled casting blank is heated and then rolled, and the steel plate is obtained; and the steel plate is cooled. The type of steel has excellent comprehensive properties such as high strength,low temperature resistance, easy welding, corrosion resistance and the like, and is good in low-temperature aging impact toughness.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com