700 MPa-grade hot-rolled container steel and low-cost production method thereof

A production process and container technology, applied in the direction of temperature control, etc., can solve the problems of high alloying cost, good corrosion resistance, good cold bending performance, etc., achieve the effect of low alloy content, excellent performance, and promote lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present invention is described in detail by the following examples:

[0018] 1. Steelmaking

[0019] 1. Hot metal pretreatment process

[0020] S ≤ 0.006% into the furnace for pretreatment, remove the slag; use fine scrap steel.

[0021] 2. Converter process

[0022] The converter pulls carbon once and avoids spot blowing; high manganese, ferrosilicon, and ferromolybdenum are used for tapping; argon purges the ladle before tapping to control the tapping port and avoid scattered flow, and the Als of the ladle is controlled at 0.025-0.035%.

[0023] 3. Refining process

[0024] The LF refining process is adopted, and the gas content is strictly controlled. It is required to maintain a slight positive pressure in the LF treatment process, strictly control the increase of N in LF, and the amount of N increase is required to be ≤10ppm; LF uses active lime and fluorite to make reducing slag with good fluidity, strictly controls the intensity of argon blowing, and avoi...

Embodiment 2

[0033] In the same process as in Example 1, 5 groups of experimental parameters were done below.

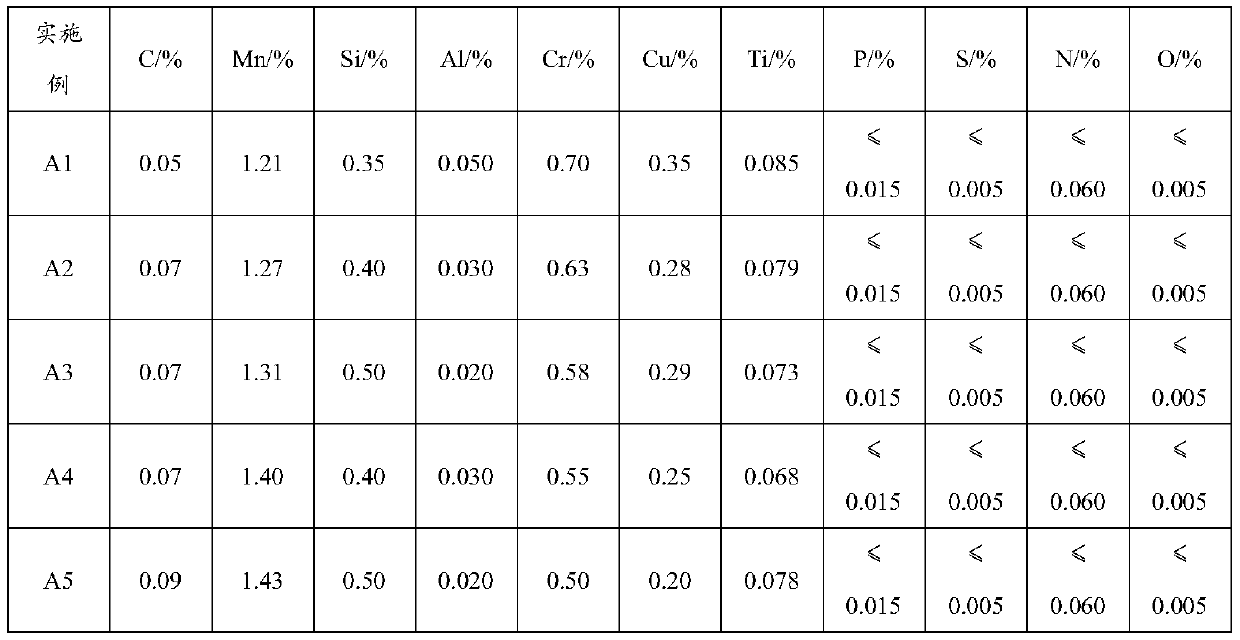

[0034] Chemical composition table of example steel

[0035]

[0036] Rolling process of table 2 example steel

[0037] Example

Slab Thickness / mm

Inlet and finish rolling temperature / ℃

Finishing temperature / ℃

Curling temperature / ℃

A1

230

1255

1100

865

565

A2

230

1248

1081

872

558

A3

230

1233

1095

870

580

A4

230

1252

1077

877

574

A5

230

1237

1067

866

575

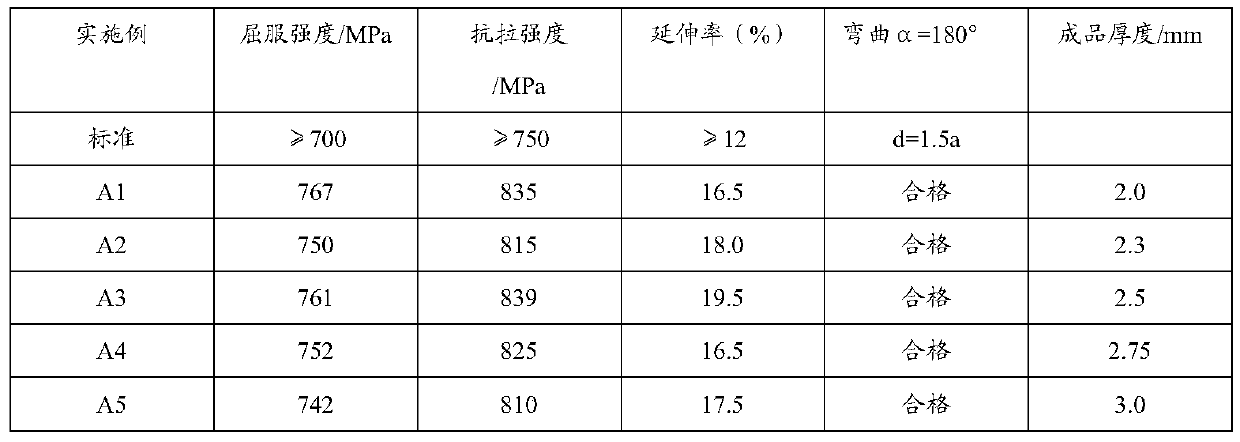

[0038] The mechanical property of table 3 example steel:

[0039]

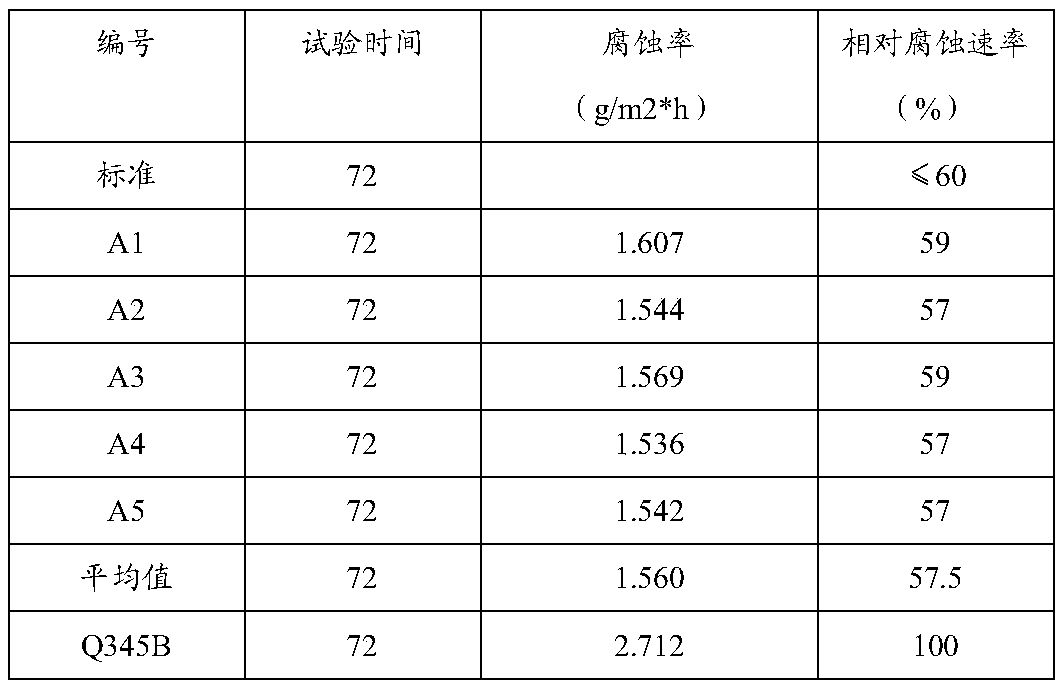

[0040] Corrosion performance of table 4 example steel

[0041] 72 hours relative corrosion test

[0042]

[0043] It can be seen from Table 1-Table 4 that the products of this process can meet the standard in terms of strength and cold bending performance, have sufficient margin and can meet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com