Alkali and corrosion resistant anchor chain steel and its production method

An alkali-resistant, anchor chain steel technology, applied in the production field of low-alloy steel, can solve the problems of high overall alloy composition setting, internal cracks in the material, reduced transverse plasticity and toughness index, etc., to achieve excellent welding performance and plasticity, reduce Alloy content, the effect of reducing production costs

Active Publication Date: 2015-01-21

武汉钢铁有限公司

View PDF7 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This technology has the following problems: ⅰ carbon equivalent is high, which affects welding performance; ⅱ the production cost of electric furnace is higher than that of converter; Otherwise, the material will undergo structural transformation during placement, resulting in structural stress, resulting in internal cracks in the material; ⅳThe steel’s alkali resistance is similar to that of ordinary anchor chain steel in an alkaline environment

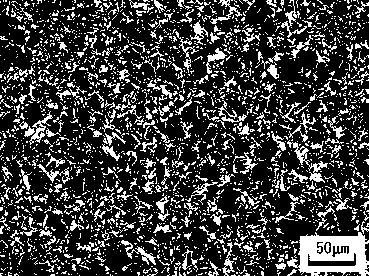

The disadvantage is that the chromium content is an element that is easy to segregate. The dendrite segregation generated during the solidification process affects the overall corrosion resistance. At the same time, the dendrite segregation is easy to produce a banded structure, and the banded structure will cause the mechanical properties of the steel to be directional. Reduce the transverse plasticity and toughness of the steel; in addition, the alkali resistance of the steel is similar to that of ordinary anchor chain steel in an alkaline environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

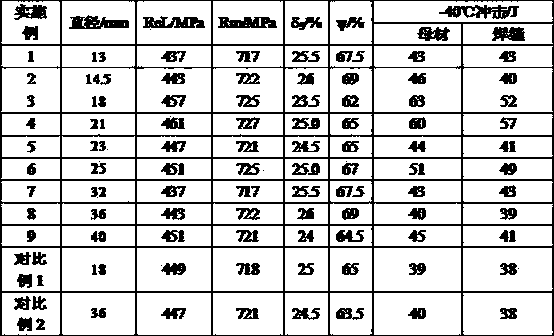

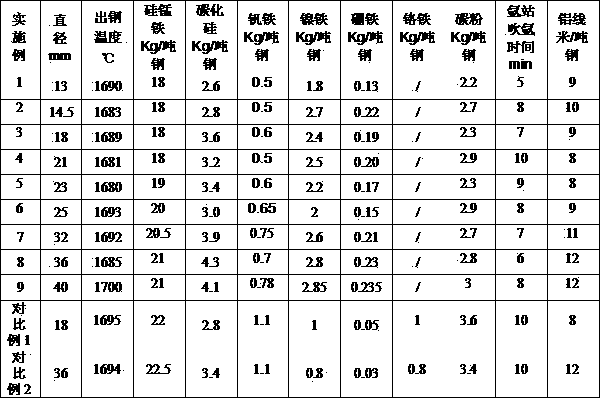

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

An alkali and corrosion resistant anchor chain steel comprises 0.27-0.33wt% of C, 0.15-0.55wt% of Si, 1.4-1.6wt% of Mn, 0.035wt% or less of P, 0.015wt% or less of S, 0.001-0.003wt% of B, 0.03-0.05wt% of V, 0.1-0.25wt% of Cu, 0.025-0.035wt% of Als, 0.1-0.25wt% of Ni and 0.001-0.007wt% of Ca. A production method of the anchor chain steel comprises the steps of molten iron desulphurization, converter smelting, argon blowing, LF furnace refining, RH furnace vacuum treatment, blank casting, natural pile cooling to room temperature, rough rolling, finish rolling, and air cooling to room temperature. The production method can improve the alkali resistance of steel by above 45%, allows the anchor chain steel to have a long service life under alkaline conditions, and reduces the alloy content without reducing the material performances in order to reduce the production cost; the obtained alkali resistant anchor chain steel has excellent weldability and plasticity; and a converter technology has a high energy / efficiency ratio.

Description

Technical field The invention relates to the technical field of production of low alloy steel, and is particularly suitable for a production method of alkali corrosion resistant anchor chain steel with a diameter of not more than 40 mm. Background technique Anchor chain is an important component in ships and marine engineering. It is a high-strength, high-tech product and is widely used in mooring positioning of large ships. The service conditions are harsh and long-term immersion in seawater, so not only high strength and good toughness are required, but also good seawater corrosion resistance and abrasion resistance are required. Anchor chain steel is the raw material used to make the chain, so its quality requirements are self-evident. When the anchor chain is used in the Dead Sea or other alkaline seas, it will face corrosion in an alkaline environment. The current research on the corrosion of anchor chain steel is mainly acidic seawater corrosion. There are few reports on...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/16

CPCC22C38/02C22C38/04C22C38/06C22C38/08C22C38/12C22C38/16

Inventor 徐志东周新龙龙莉范植金吴杰徐志

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com