1000 MPa-grade good-cold-machining-property low-cost cold-rolling dual-phase steel and manufacturing method thereof

A cold working, low-cost technology, applied in cold-rolled dual-phase steel, low-cost cold-rolled dual-phase steel and its manufacturing field, can solve the problem that the plasticity and cold-bending properties cannot meet the requirements, the difficulty of continuous casting and rolling, and the alloying elements Add less questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

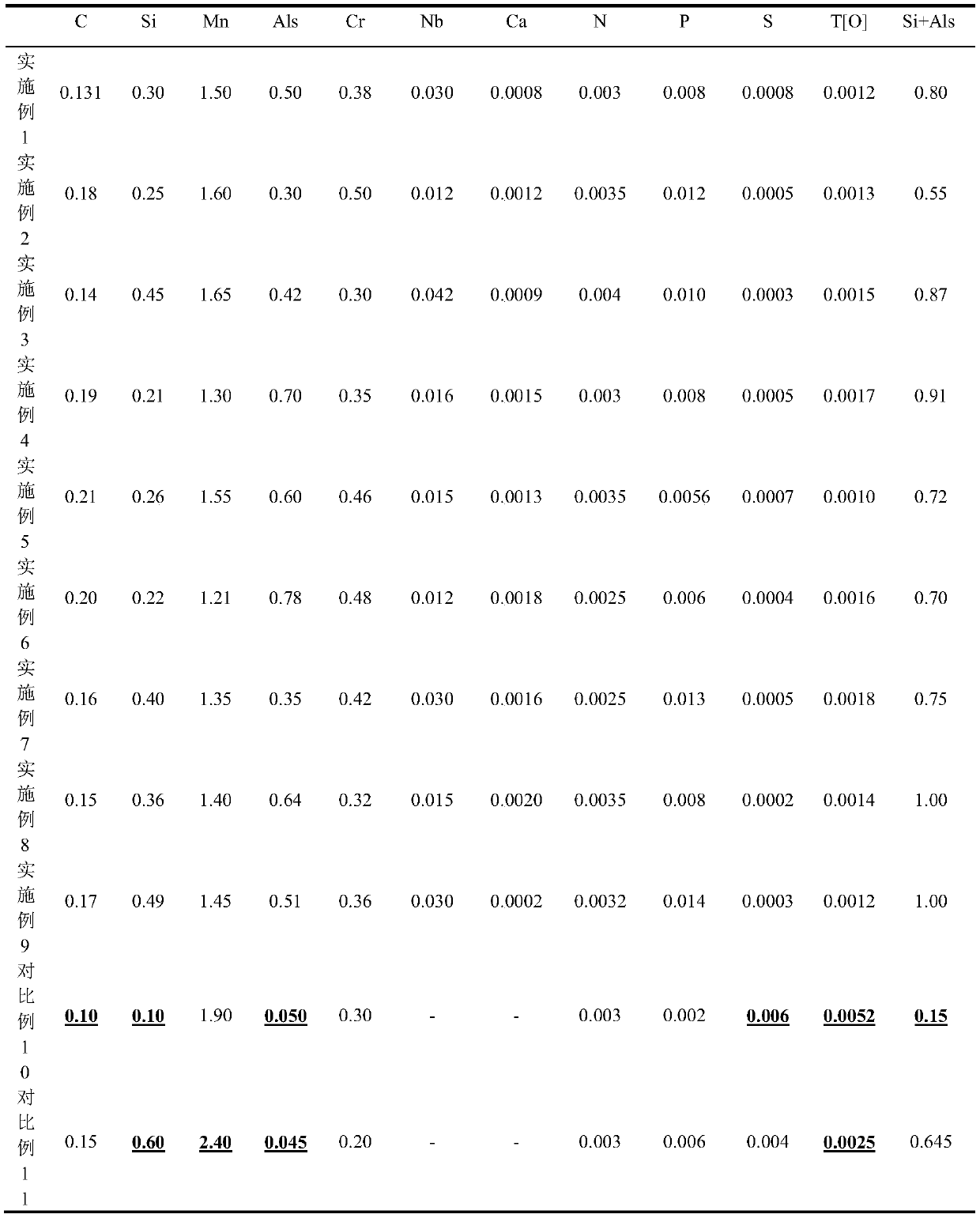

[0093] The invention discloses a method for preparing a low-cost cold-rolled dual-phase steel with good 1000MPa-level cold working performance, wherein the alloy elements designed in Table 1 are used for smelting;

[0094] Table 1 each embodiment of the present invention and comparative example list of main components

[0095]

[0096] In above-mentioned table 1, 10 and 11 are the composition of comparative example, C, Si, Als, (Si+Als), Mn and T[O] of comparative example 10 are not in the scope of the present invention, Si, Als, Als of comparative example 11, (Si+Als), Mn, Nb, S, Ca, and T[O] are outside the scope of the present invention.

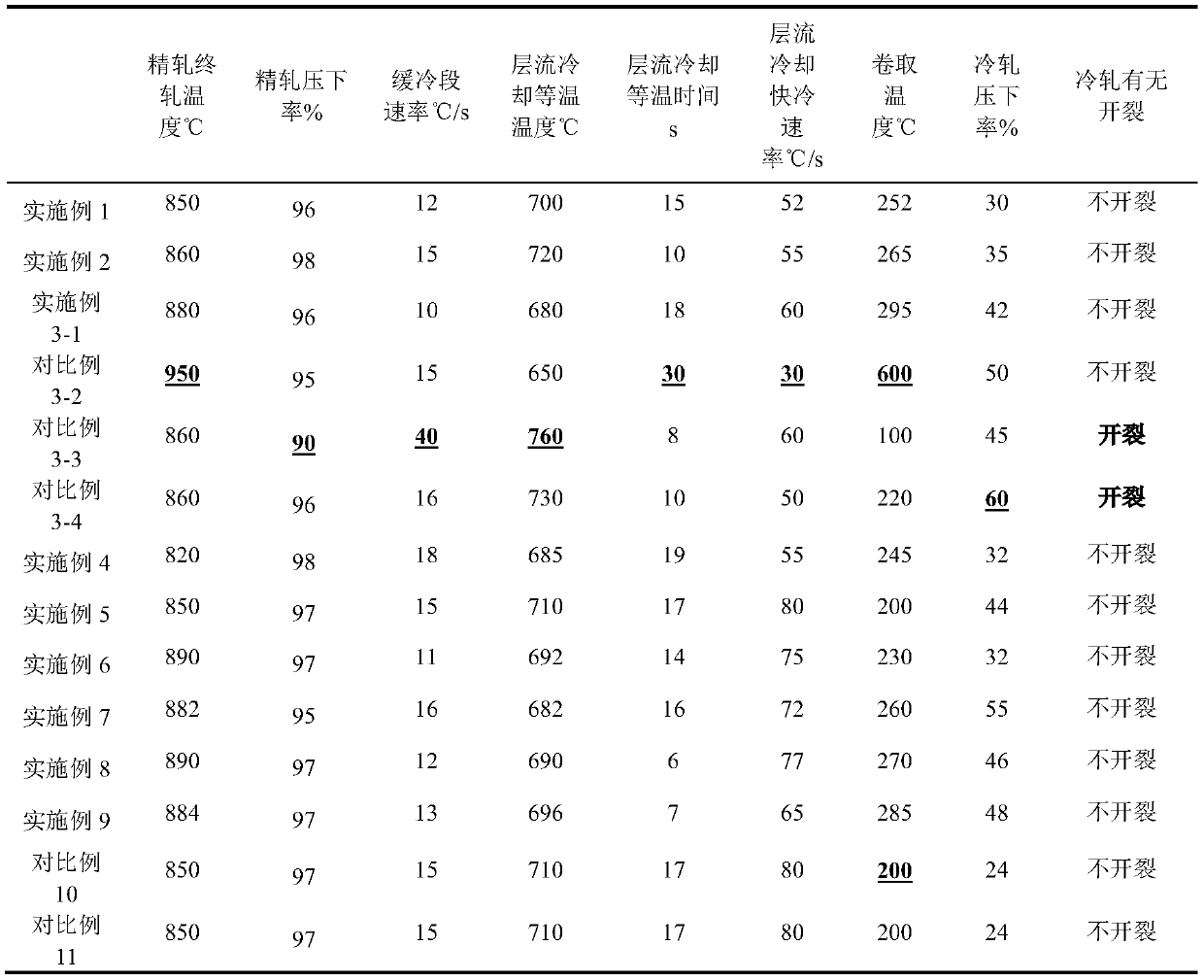

[0097] The cold-rolled dual-phase steel of the present invention includes steelmaking,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com