Low-alloy steel used for oil well pipe with carbon dioxide corrosion resistance and manufacturing method thereof

A low-alloy, oil-well technology, used in manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., to achieve the effects of good chloride ion corrosion performance, improved corrosion resistance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

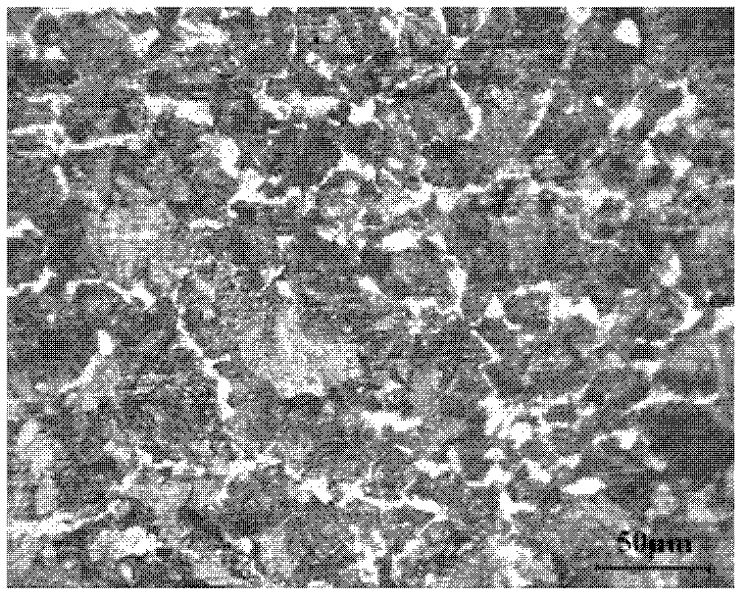

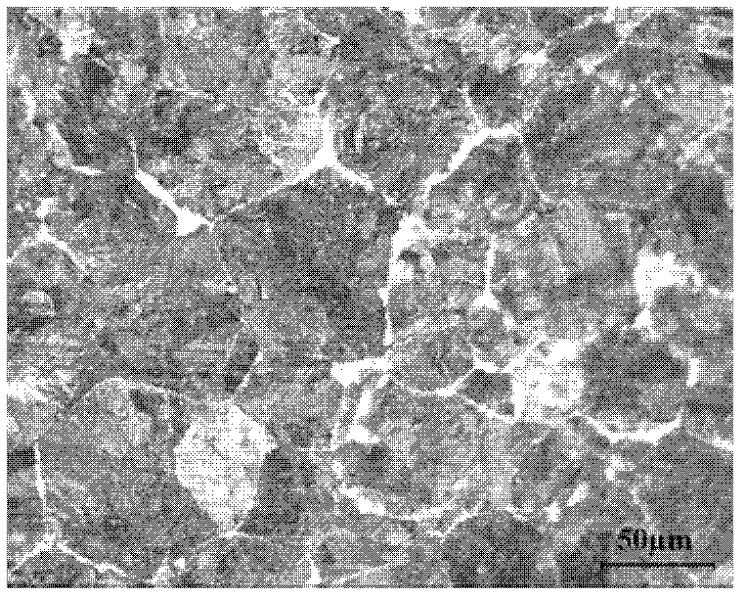

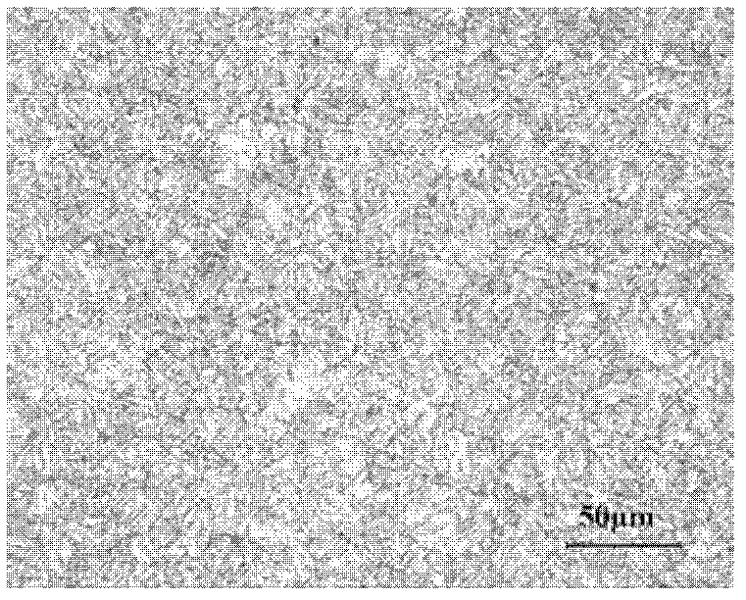

Image

Examples

Embodiment

[0040] Table 1 Alloy steel of the present invention and the chemical composition of existing alloy steel, wt%

[0041]

[0042] Table 1 shows the chemical composition of the test steels, wherein A1-A6 are alloy steels of the present invention, and B1-B2 are reference steels, all of which are N80 oil pipes commonly used in oil fields at present. The key process parameters of the production process of control steel B1-B2 are briefly as follows: the tapping temperature at the beginning of steelmaking is about 1650°C, the starting temperature of continuous casting is about 1550°C, the piercing and rolling at about 1200°C for hot rolling of the continuous casting slab, and the final tension The temperature after diameter reduction is about 900°C. After hot rolling, the steel pipe is air-cooled to room temperature without subsequent heat treatment. In the production of steel A1-A6 of the present invention, the same process and parameters as B1-B2 are used in the front stage, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com