Production method of polyphase structure high tenacity ship plate steel EH40

A production method and technology of multi-phase structure, applied in the field of metallurgy, can solve the problems of prolonged production cycle, coarse grains, poor toughness, etc., and achieve the effects of shortening the delivery cycle, reducing the alloy content and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

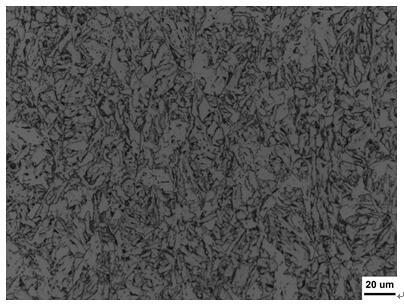

Image

Examples

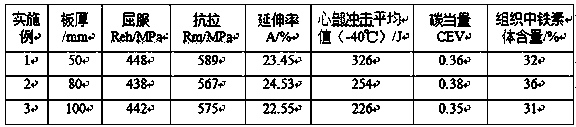

Embodiment 1

[0020] A production method of multi-phase structure high toughness ship plate steel EH40, the chemical composition weight percentage of the steel is: carbon=0.06, silicon=0.22, manganese=1.56, phosphorus=0.008, sulfur=0.0016, niobium=0.025, titanium= 0.014, aluminum = 0.046, nickel = 0.36, and the rest are Fe and unavoidable impurities. The process steps include: smelting: converter tapping [C]=0.0032, adopting LF+RH refining process, LF furnace refining full-process argon blowing, white slag retention time 22min, RH vacuum degassing treatment, outgoing molten steel [N]=38 ppm , [H]=1.2ppm; continuous casting adopts full protection casting, slab thickness is 300mm, slab low center segregation C class 0.5.

[0021] The used cast slab is rolled into EH40 ship plate with a thickness of 50mm. The heating temperature is 1152°C, and two-stage rolling is adopted. The first stage rough rolling finish rolling temperature is 1031°C, the intermediate billet is 120mm, and the second stage...

Embodiment 2

[0023] A production method of multi-phase structure high toughness ship plate steel EH40, the chemical composition weight percentage of the steel is: carbon = 0.07, silicon = 0.22, manganese = 1.56, phosphorus = 0.008, sulfur = 0.0018, niobium = 0.026, titanium = 0.015, aluminum = 0.044, nickel = 0.37, and the rest are Fe and unavoidable impurities. The key process steps include: smelting: converter tapping [C]=0.0036, adopting LF+RH refining process, LF furnace refining full-process argon blowing, white slag retention time 21min, RH vacuum degassing treatment, outbound molten steel [N]=36ppm , [H]=1.5ppm; continuous casting adopts full protection casting, tundish slab thickness is 300mm, slab low center segregation C class 0.5.

[0024] In this example, the cast slab is used to roll the EH40 ship plate with a thickness of 80 mm. The heating temperature is 1188 ° C. Two-stage rolling is adopted. The first stage rough rolling finish rolling temperature is 1042 ° C, the intermed...

Embodiment 3

[0026]A production method of multi-phase structure high-toughness ship plate steel EH40, the chemical composition weight percentage of the steel is: carbon = 0.05, silicon = 0.25, manganese = 1.55, phosphorus = 0.009, sulfur = 0.0017, niobium = 0.028, titanium = 0.015, aluminum = 0.046, nickel = 0.37, and the rest are Fe and unavoidable impurities. The key process steps include: smelting: converter tapping [C]=0.0024, adopting LF+RH refining process, argon blowing throughout the LF furnace refining, white slag retention time 20min, RH vacuum degassing treatment, outbound molten steel [N]=36ppm , [H]=1.5ppm; continuous casting adopts full protection casting, tundish slab thickness is 300mm, slab low center segregation C class 0.5.

[0027] In this example, the EH40 ship plate with a thickness of 100 mm is rolled from cast slabs, and the heating temperature is 1195 ° C. Two-stage rolling is adopted. The rough rolling and finishing rolling temperature of the first stage is 1002 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com