High-carbon microalloying steel ball and production process thereof

A technology of micro-alloying and production technology, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of unusable steel balls, unrecyclable, expensive alloy elements, etc., to avoid quenching cracking, best promotion significance, alloy Content and production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

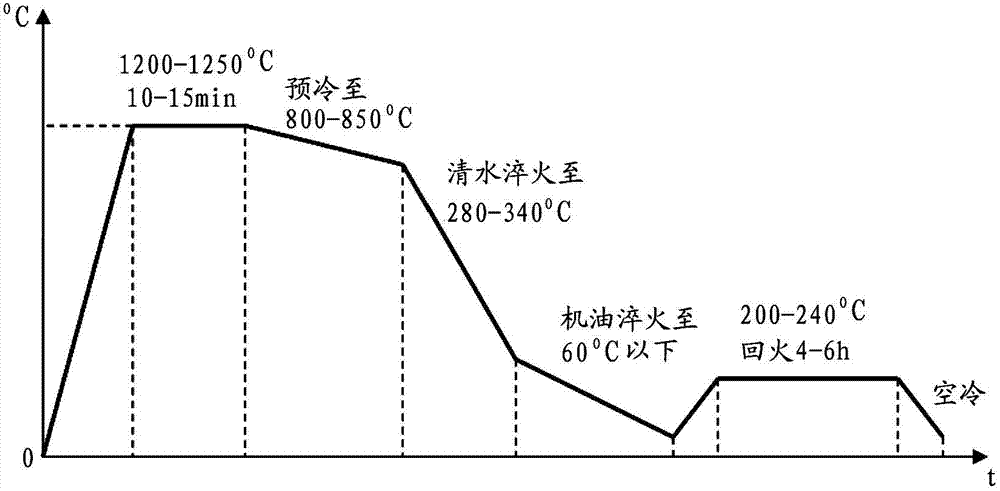

Embodiment 1

[0031] Converter smelting, LF furnace refining, continuous casting, slab cleaning, slab heating, square steel rolling and other processes to obtain steel slabs with the following chemical composition: C: 1.02%, Si: 0.55%, Mn: 0.92% , Cr: 0.30% and the balance of Fe and unavoidable impurities. Use a gas heating furnace to rapidly heat up the steel ball billet to 1200°C and hold it for 10 minutes, then take out a steel ball with a diameter of 100mm forged in a 500kg air hammer, and put it into a clean water tank at 35°C when the surface temperature of the steel ball drops to 835°C. Take it out after rolling quenching for about 38s. At this time, the surface temperature of the steel ball is about 310°C. Within 2s, quickly put the steel ball into No. 10 high-speed engine oil at 45°C and roll quenching for 40s. At this time, the surface temperature of the steel ball is 55°C. ℃, and then take out the steel ball and put it in No. 50 machine oil at 220 ℃ for tempering. The tempering t...

Embodiment 2

[0033] Converter smelting, LF furnace refining, continuous casting, slab cleaning, slab heating, square steel rolling and other processes are used to obtain steel ball blanks with the following chemical composition: C: 0.95%, Si: 0.61%, Mn: 0.88% , Cr: 0.35% and the balance of Fe and unavoidable impurities. Use a gas heating furnace to rapidly heat up the steel ball billet to 1230°C and hold it for 9 minutes, then take out a steel ball with a diameter of 100mm forged in a 500kg air hammer, and put it into a clean water tank at 42°C when the surface temperature of the steel ball drops to 812°C. Take it out after rolling quenching for about 43s. At this time, the surface temperature of the steel ball is about 297°C. Within 2s, quickly put the steel ball into No. 10 high-speed engine oil at 48°C and roll quenching for 40s. At this time, the surface temperature of the steel ball is 57°C. ℃, and then take out the steel ball and place it in No. 50 machine oil at 220 ℃ for tempering....

Embodiment 3

[0035] Converter smelting, LF furnace refining, continuous casting, slab cleaning, slab heating, square steel rolling and cut-to-length sawing are used to obtain steel ball billets with the following chemical composition: C: 0.98%, Si: 0.55% , Mn: 1.05%, Cr: 0.35%, and the balance of Fe and unavoidable impurities. Use a gas heating furnace to rapidly heat up the steel ball billet to 1220°C and keep it warm for 10 minutes, then take out a steel ball with a diameter of 120mm forged in a 500kg air hammer, and put it into a 40°C clear water tank when the surface temperature of the steel ball drops to 820°C. Take it out after rolling quenching for about 50s. At this time, the surface temperature of the steel ball is about 290°C. Quickly put the steel ball into No. 10 high-speed engine oil at 35°C within 2s. After rolling quenching for 50s, the surface temperature of the steel ball is 52°C. ℃, and then take out the steel ball and put it in No. 50 machine oil at 220 ℃ for tempering. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com