Method for preparing lanthanum strontium manganite/copper calcium titanate composite magnetoelectric ceramic material by virtue of sol-gel method

A technology of strontium lanthanum manganate and copper calcium titanate, which is applied in the manufacture of circuits, electrical components, inductors/transformers/magnets, etc., can solve the problems of easy introduction of impurities and influence on the purity of target products, and achieve low prices and reliable components. control, strong regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

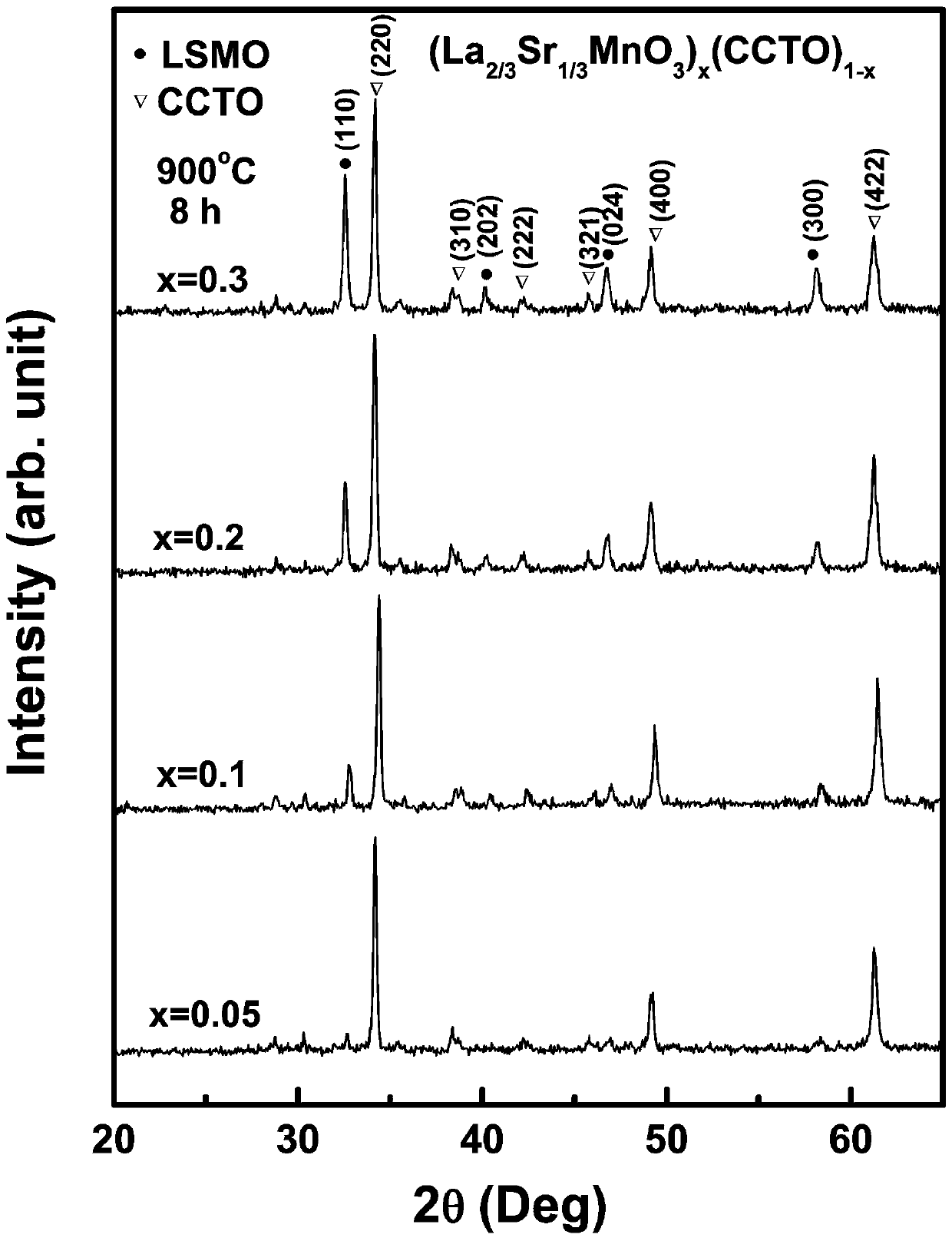

[0019] Example 1: A method for preparing strontium lanthanum manganate / copper calcium titanate composite magnetoelectric ceramic materials by a sol-gel method, using the sol-gel method to prepare strontium lanthanum manganate or LSMO precursor powder and copper titanate respectively Calcium and CCTO precursor powder, LSMO and CCTO precursor powder are mixed and then added with a binder, mixed evenly and pressed into a ceramic body, and the ceramic body is sintered to obtain strontium lanthanum manganate / copper calcium titanate, that is, LSMO-CCTO composite Magnetoelectric ceramic samples.

[0020] Specific steps are as follows:

[0021](1) Preparation of strontium lanthanum manganate or LSMO precursor powder: A. Weigh 29.16 g of lanthanum nitrate, 7.13 g of strontium nitrate and 50.68 g of citric acid, and use deionized water as a solvent to completely dissolve the three raw materials to obtain a white Transparent mixed solution A1; Measure 35.79 g of manganese nitrate soluti...

Embodiment 2

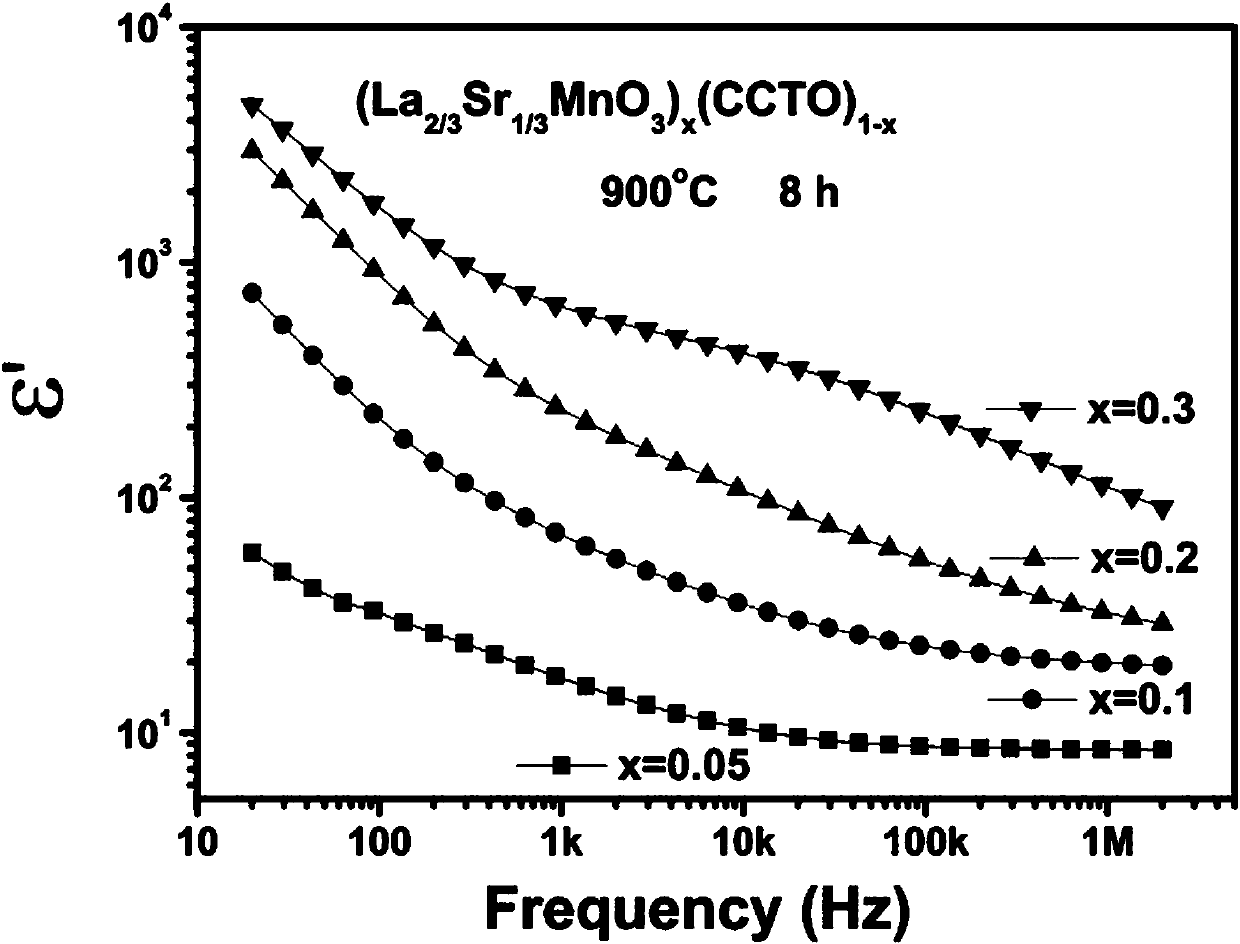

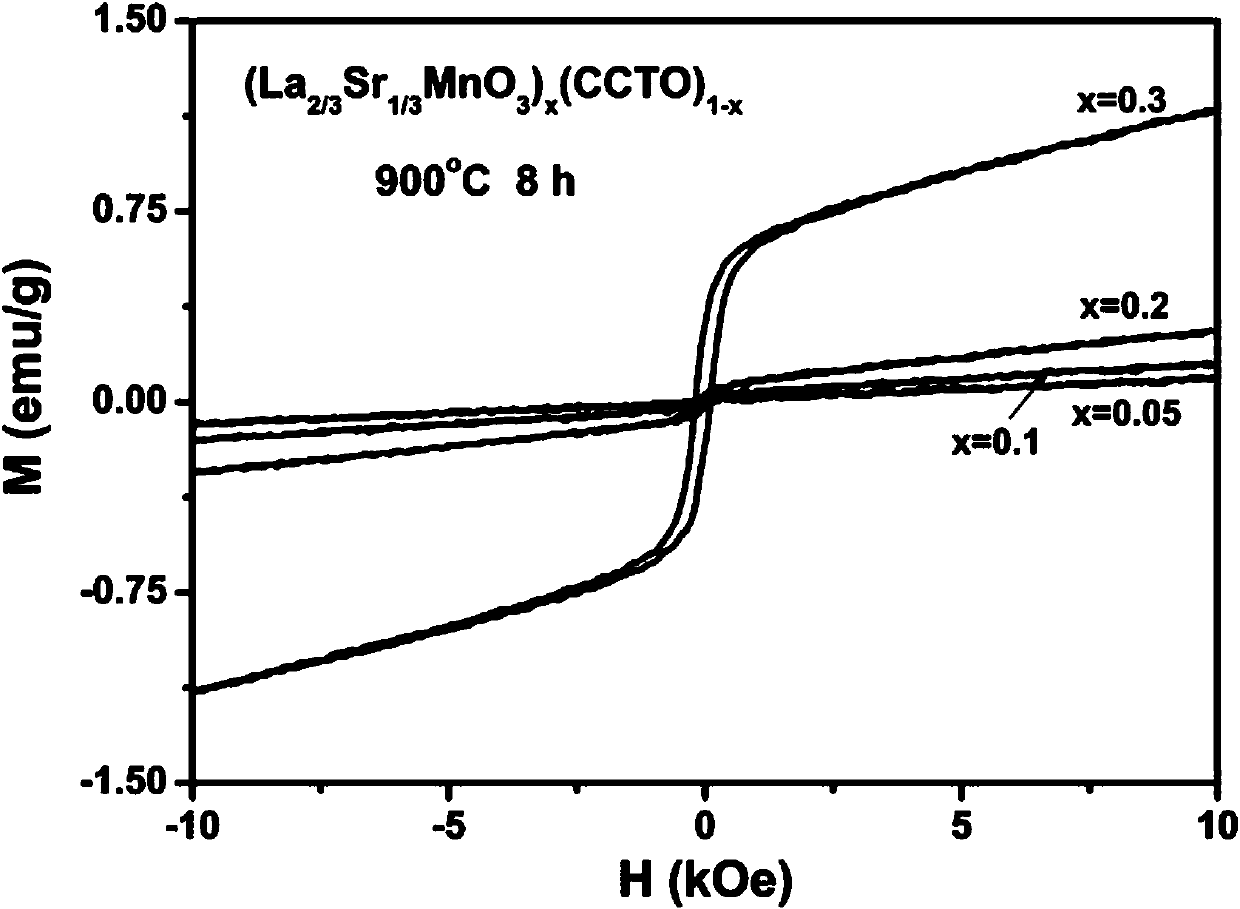

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio between LSMO and CCTO is different (x=0.2), and 2 g and 8 g are weighed respectively. After dielectric performance testing, it is found that compared with the embodiment 1. The dielectric constant of the sample decreases, and the decrease is relatively large. It was found through the magnetic performance test that compared with Example 1, the magnetic properties of the sample also decreased significantly, down to 0.28 emu / g.

Embodiment 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mass ratio between LSMO and CCTO is different (x=0.1), and 1 g and 9 g are weighed respectively. After dielectric performance testing, it is found that compared with the embodiment 1 and 2, the dielectric constant of the sample continued to decrease. It is found that compared with Examples 1 and 2, the samples show almost no magnetic characteristics after magnetic property testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com