Flexible zinc oxide schottky diode and its preparation method

A technology of Schottky diodes and zinc oxide, which is applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, semiconductor devices, etc., can solve problems such as multi-crystal grains and interfaces, device stability consistency, and poor flexibility. Achieve the effects of less intercrystalline interface, avoid device working stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

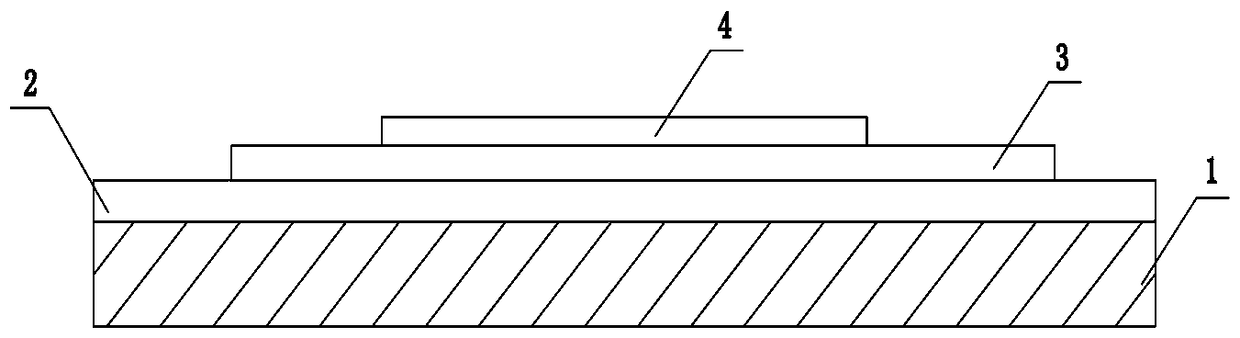

[0023] This embodiment provides a method for preparing a flexible zinc oxide Schottky diode, comprising the following steps:

[0024] Dissolving zinc nitrate hexahydrate in methoxyethanol to prepare a zinc nitrate organic solution with a zinc ion molar concentration of 0.1 mol / L; then slowly adding acetylacetone of the same molar amount as the zinc ion to the zinc nitrate organic solution for magnetic stirring After 2 hours, a clear and transparent solution A was formed;

[0025] Dissolve polytetravinylphenol in 2-methoxyethanol solution and magnetically stir for 2 hours to form a polytetravinylphenol organic solution with a mass concentration of 20 g / L; Adding the polytetravinylphenol organic solution to the clear and transparent solution A for magnetic stirring for 4 hours to obtain the precursor solution;

[0026] The precursor solution is dropped on the ITO conductive layer with a polyethylene flexible substrate, spin-coated with a desktop coater for 30 seconds, the rotat...

Embodiment 2

[0032] This embodiment provides a method for preparing a flexible zinc oxide Schottky diode. The specific steps are roughly the same as those in Embodiment 1, except that:

[0033] In this embodiment, zinc nitrate is used as a solute and methoxyethanol as a solvent to configure a zinc nitrate organic solution with a zinc ion concentration of 0.15 mol / L, and then glycine and The urea was magnetically stirred for 3 hours to form the clear and transparent solution A.

[0034] The structure of the flexible ZnO Schottky diode prepared by the above preparation method in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0036] This embodiment provides a method for preparing a flexible zinc oxide Schottky diode. The specific steps are roughly the same as those in Embodiment 1, except that:

[0037] In this embodiment, the precursor solution is spin-coated on the ITO conductive layer of the flexible substrate, heat treated at 250° C. for 15 minutes, and the above steps of spin coating and heat treatment are repeated to form a 200-nm-thick polycarbonate layer on the ITO conductive layer. Vinylphenol hybrid ZnO films were annealed at 250°C for 5 hours.

[0038]The structure of the flexible ZnO Schottky diode prepared by the above preparation method in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com