A kind of sol-hydrothermal preparation process of tetragonal barium titanate powder

A phase barium titanate and preparation process technology, applied in titanate, chemical instruments and methods, alkaline earth metal titanate and other directions, can solve the problem of high synthesis temperature, achieve low synthesis temperature, high sintering activity and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

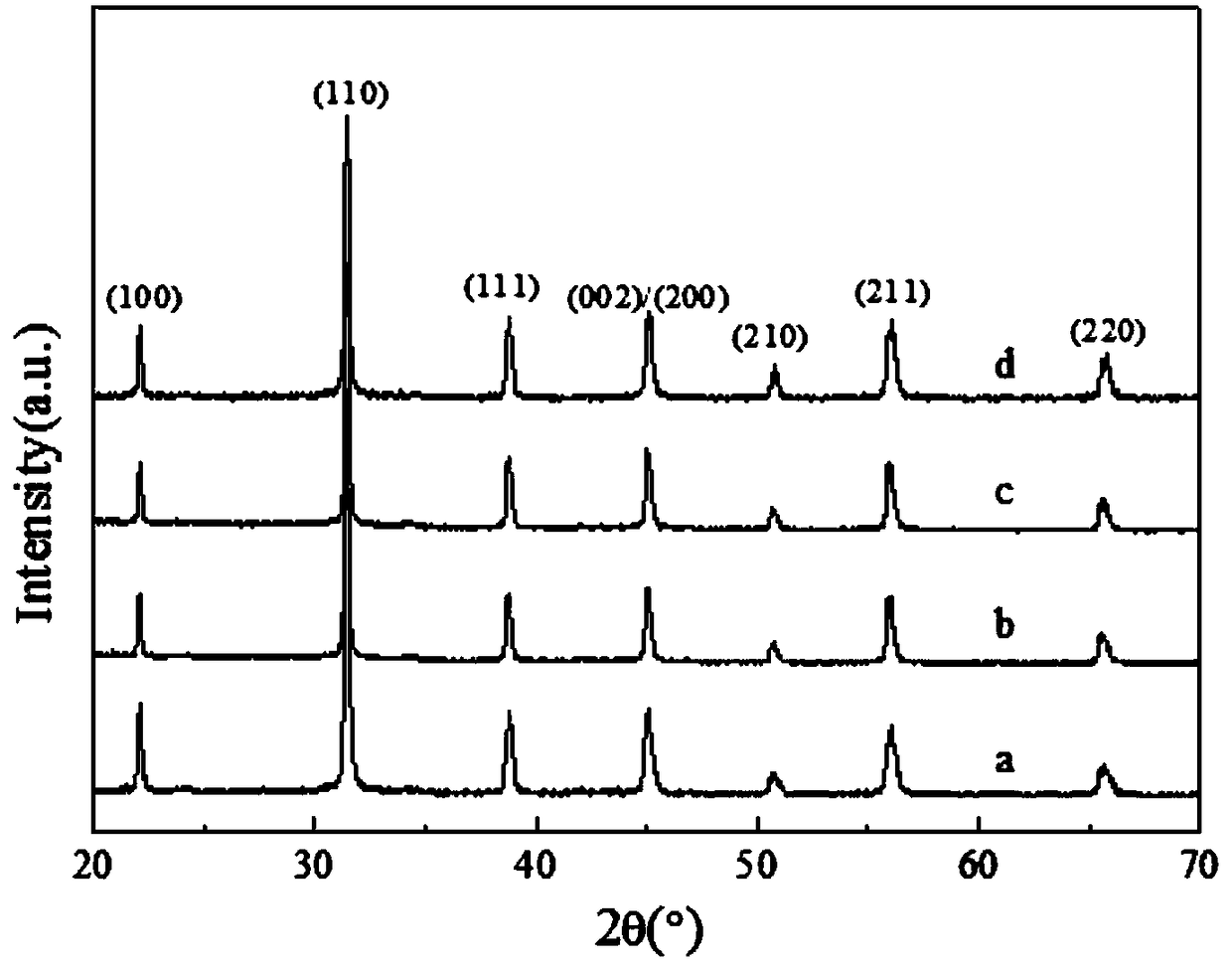

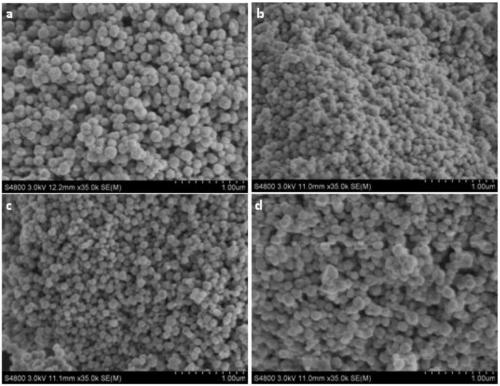

Embodiment 1

[0035] According to the molar ratio of titanium source and barium source as 1:1, weigh 11.0005 g of tetrabutyl titanate, add glacial acetic acid and absolute ethanol, and control the volume ratio of tetrabutyl titanate, glacial acetic acid and absolute ethanol to 1 :2:3, magnetically stirred to obtain a tetrabutyl titanate solution; then weighed 7.8971g of barium chloride, added 40mL of distilled water and heated and stirred to completely dissolve to obtain a barium acetate solution; the barium chloride solution was added dropwise to titanate In the tetrabutyl ester solution, heat at 50°C and magnetically stir to obtain a uniform light yellow transparent sol; then, add a mineralizer 4mol / L NaOH solution to the above sol, adjust the pH value to ≥ 13, and continue to stir to obtain a white Barium titanate precursor suspension; add the obtained precursor suspension into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 24 hours, and cool the reaction ket...

Embodiment 2

[0037]According to the molar ratio of titanium source and barium source as 1:1, weigh 9.9990 g of tetrabutyl titanate, add glacial acetic acid and absolute ethanol, and control the volume ratio of tetrabutyl titanate, glacial acetic acid and absolute ethanol to 1 :2:3, magnetically stirred to obtain a tetrabutyl titanate solution; then weighed 7.5061g of barium acetate, added 40mL of distilled water and heated and stirred to completely dissolve to obtain a barium acetate solution; the barium acetate solution was added dropwise to tetrabutyl titanate In the ester solution, heat at 50°C and magnetically stir to obtain a uniform light yellow transparent sol; then, add a mineralizer 4mol / L NaOH solution to the above sol, adjust the pH value to ≥ 13, and continue stirring to obtain white titanic acid Barium precursor suspension: Add the obtained precursor suspension into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 12 hours, and cool the reaction kett...

Embodiment 3

[0039] According to the molar ratio of titanium source and barium source as 1:1, weigh 10.9004 g of tetrabutyl titanate, add glacial acetic acid and methanol, and control the volume ratio of tetrabutyl titanate, glacial acetic acid and absolute ethanol to 1:2 : 3, magnetically stirred to obtain tetrabutyl titanate solution; then weighed 7.8252g barium chloride, added 40mL distilled water and heated and stirred to completely dissolve to obtain barium chloride solution; barium chloride solution was added dropwise to tetrabutyl titanate In the butyl ester solution, heat at 50°C and magnetically stir to obtain a uniform light yellow transparent sol; then, add a mineralizer 4mol / L NaOH solution to the above sol, adjust the pH value to ≥ 13, and continue to stir to obtain white titanium Barium acid precursor suspension; add the obtained precursor suspension into a hydrothermal reaction kettle, conduct a hydrothermal reaction at 100°C for 48 hours, and cool the reaction kettle to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com