Patents

Literature

523results about "Thermistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

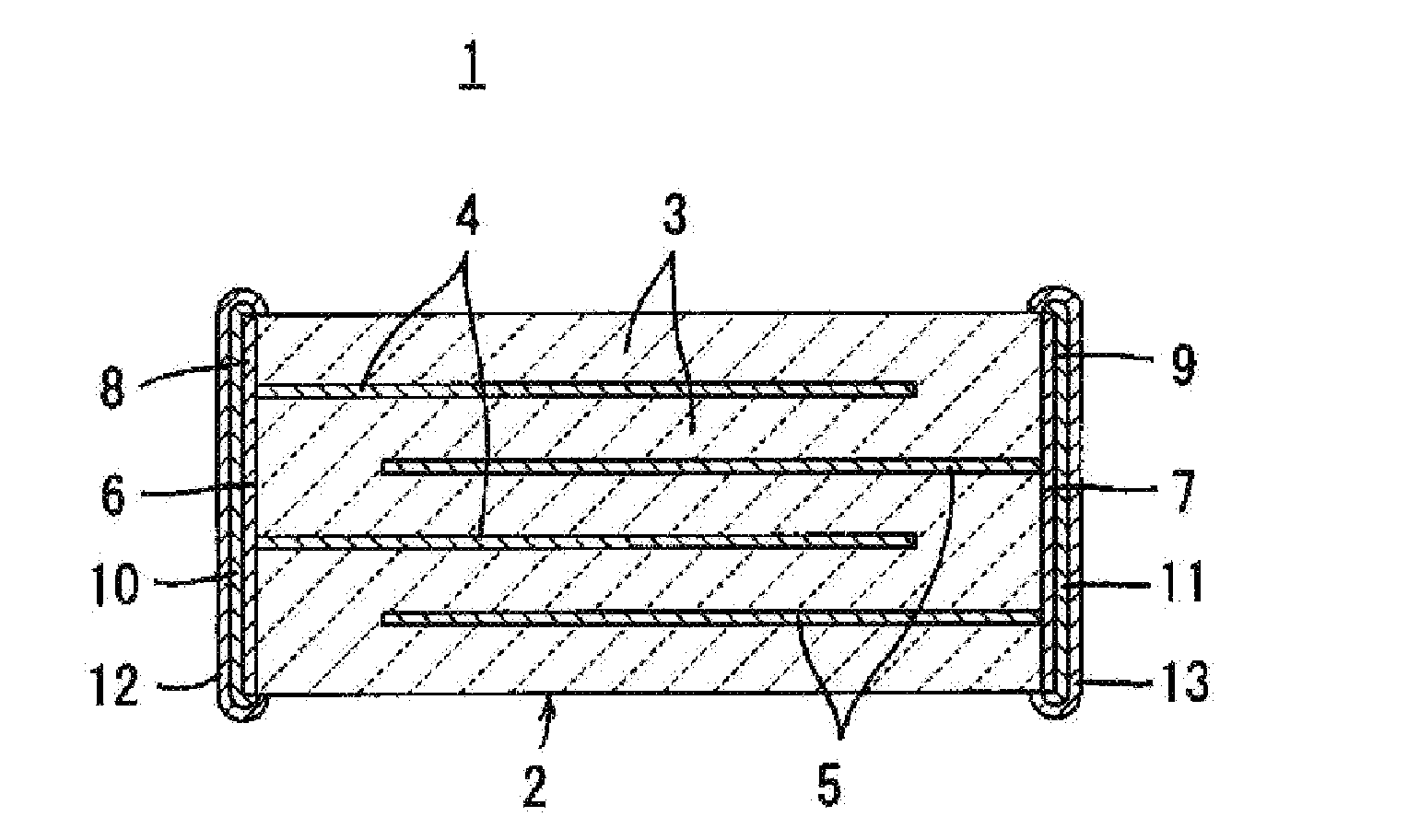

Plated terminations

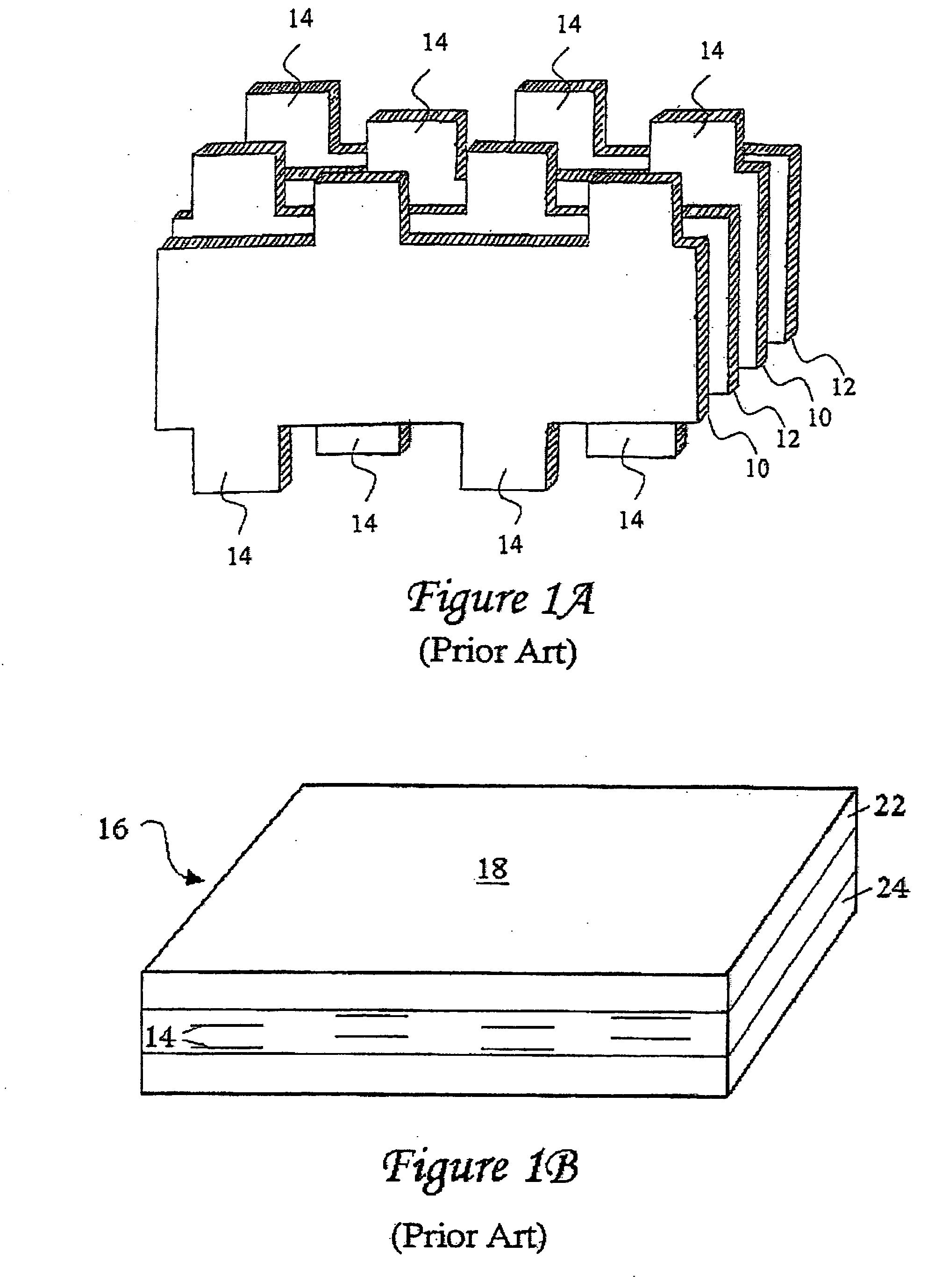

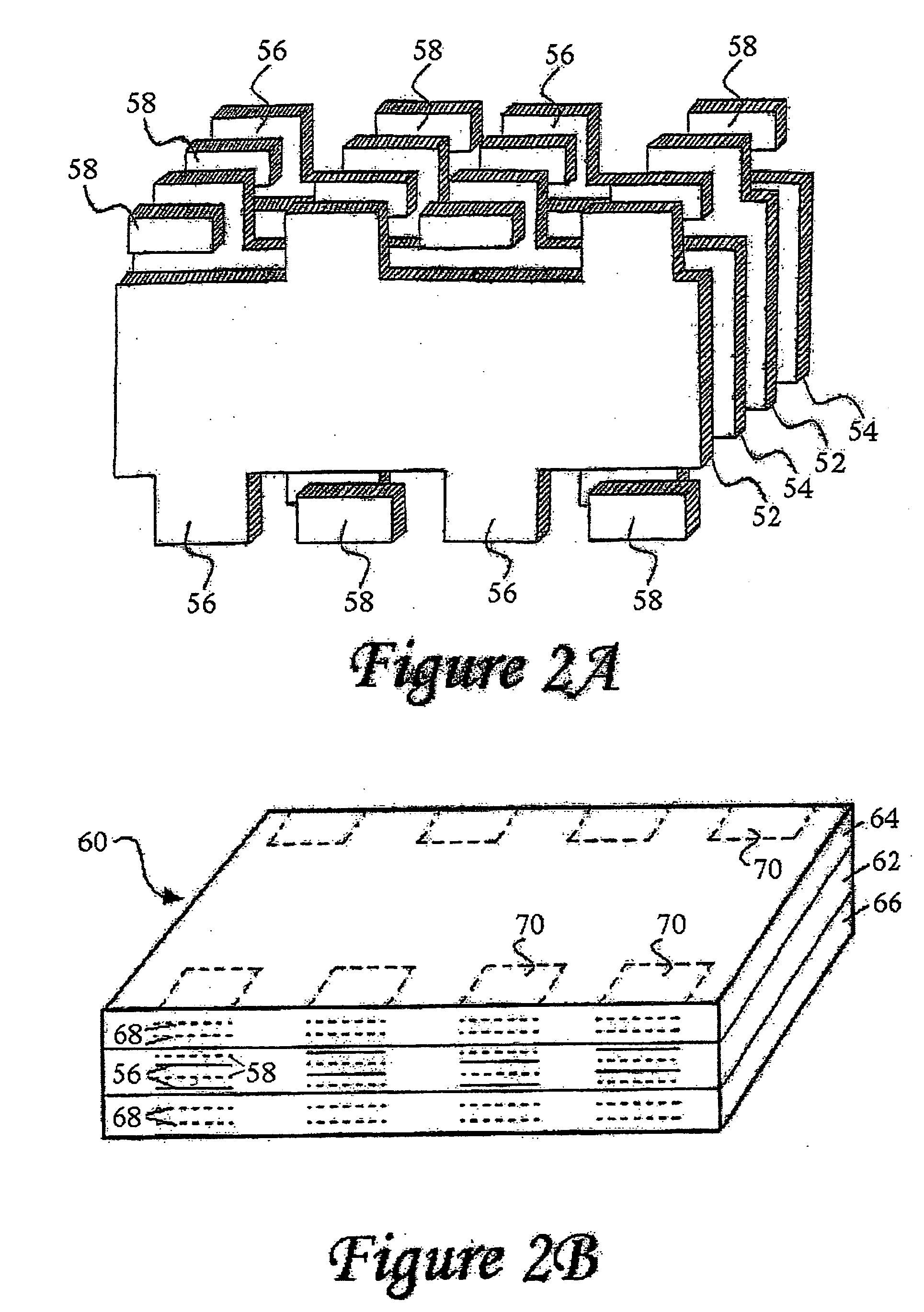

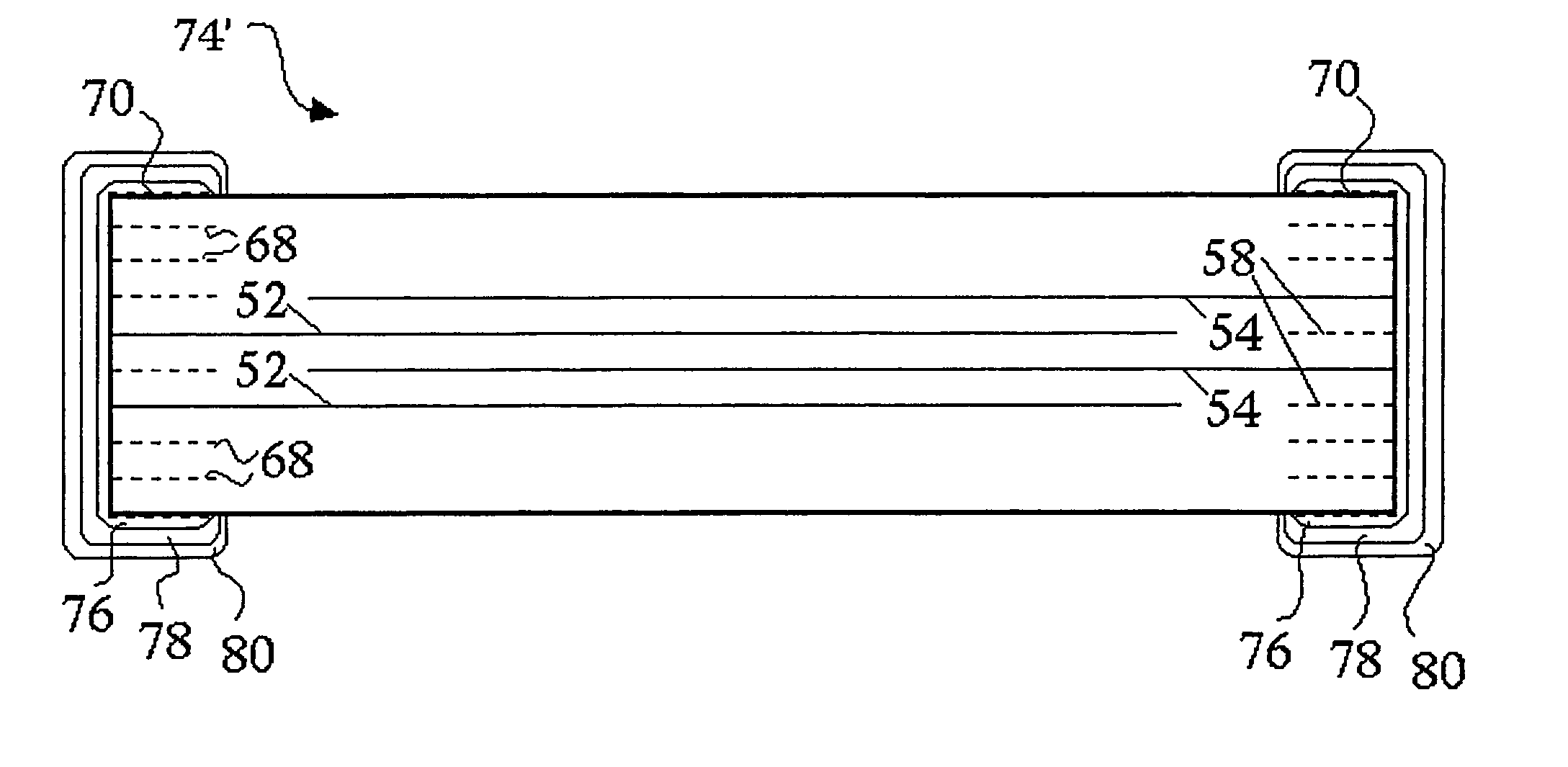

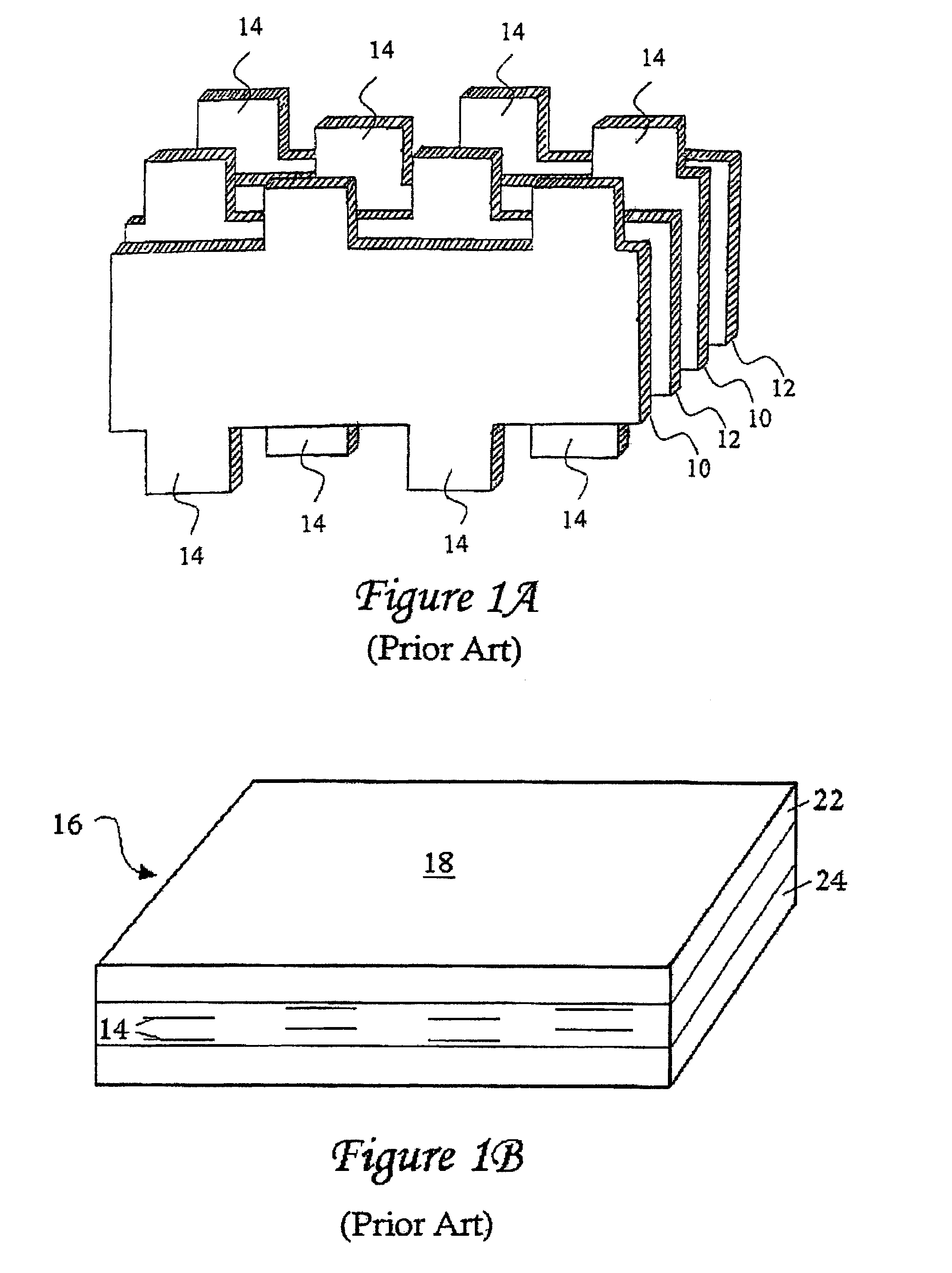

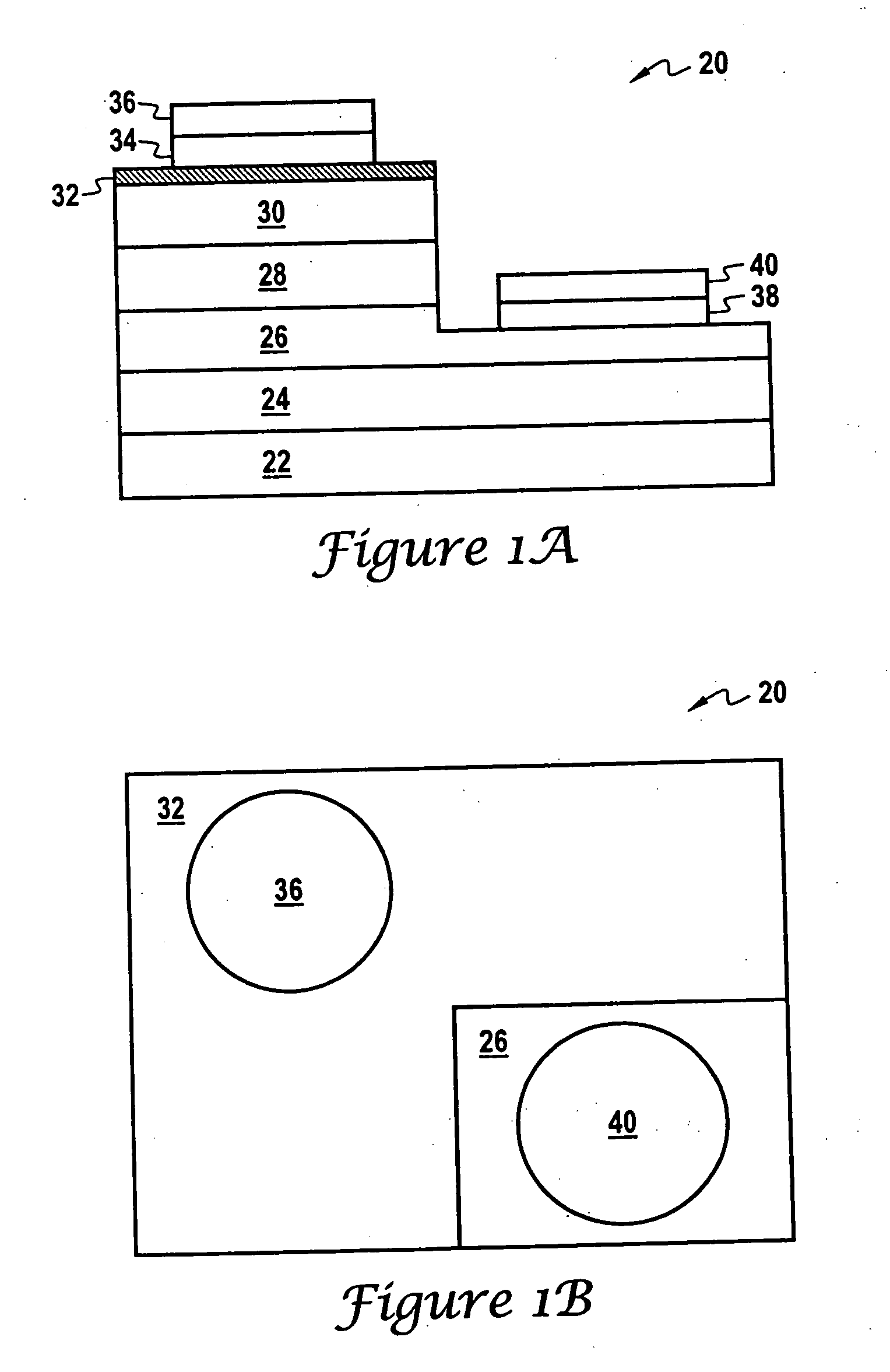

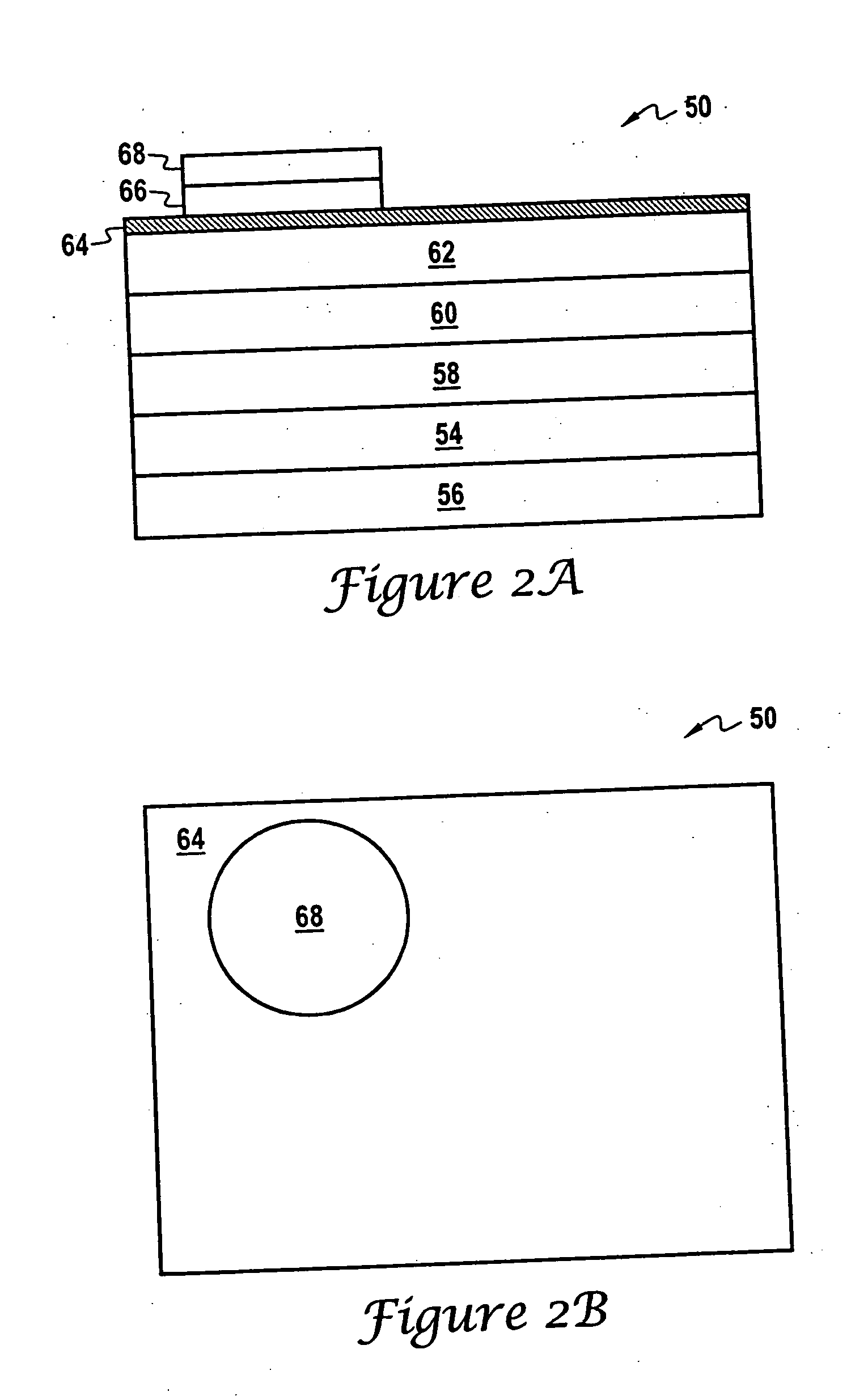

InactiveUS6960366B2Improved termination featureEliminate and greatly simplifyResistor terminals/electrodesFinal product manufactureTermination problemEngineering

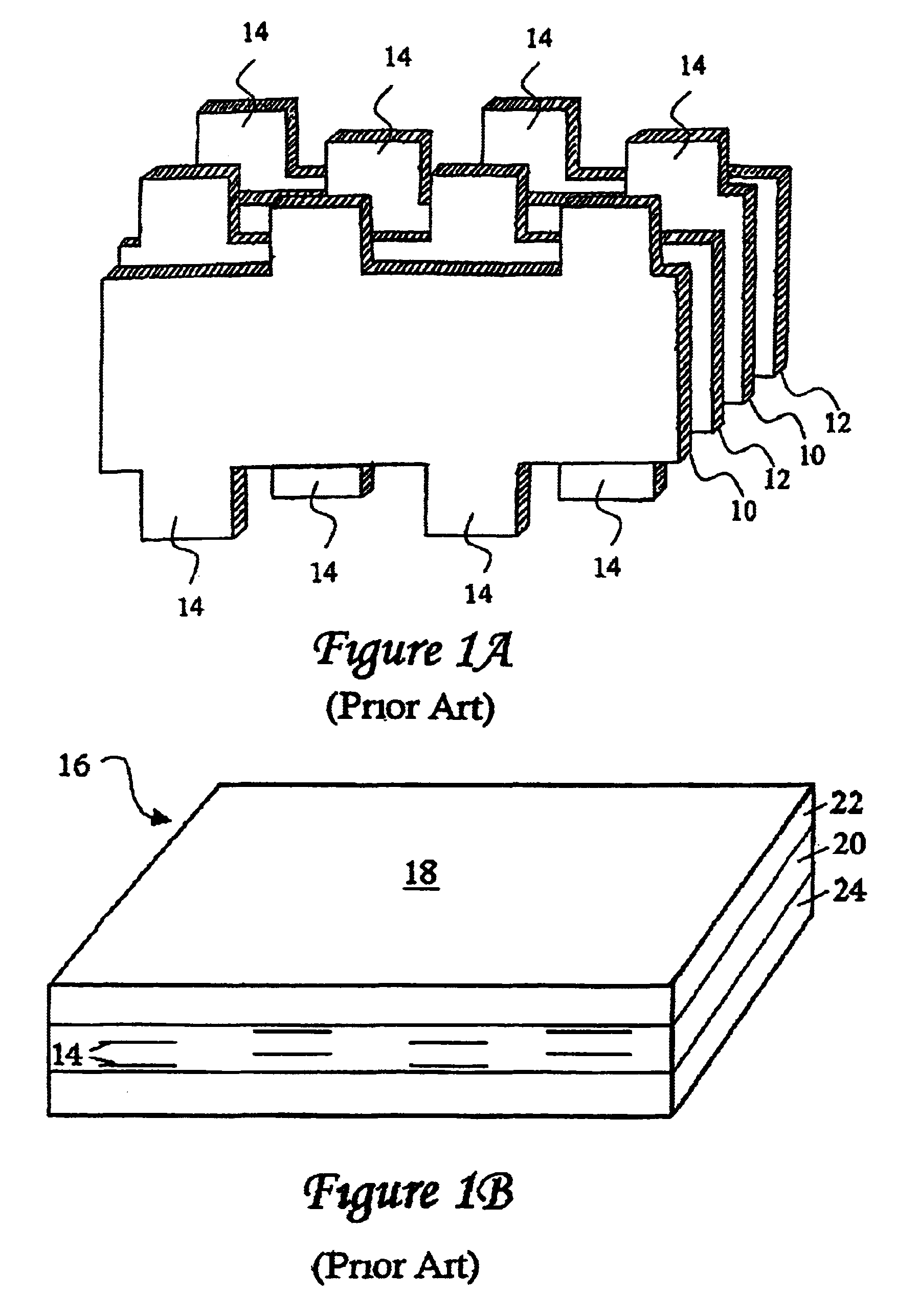

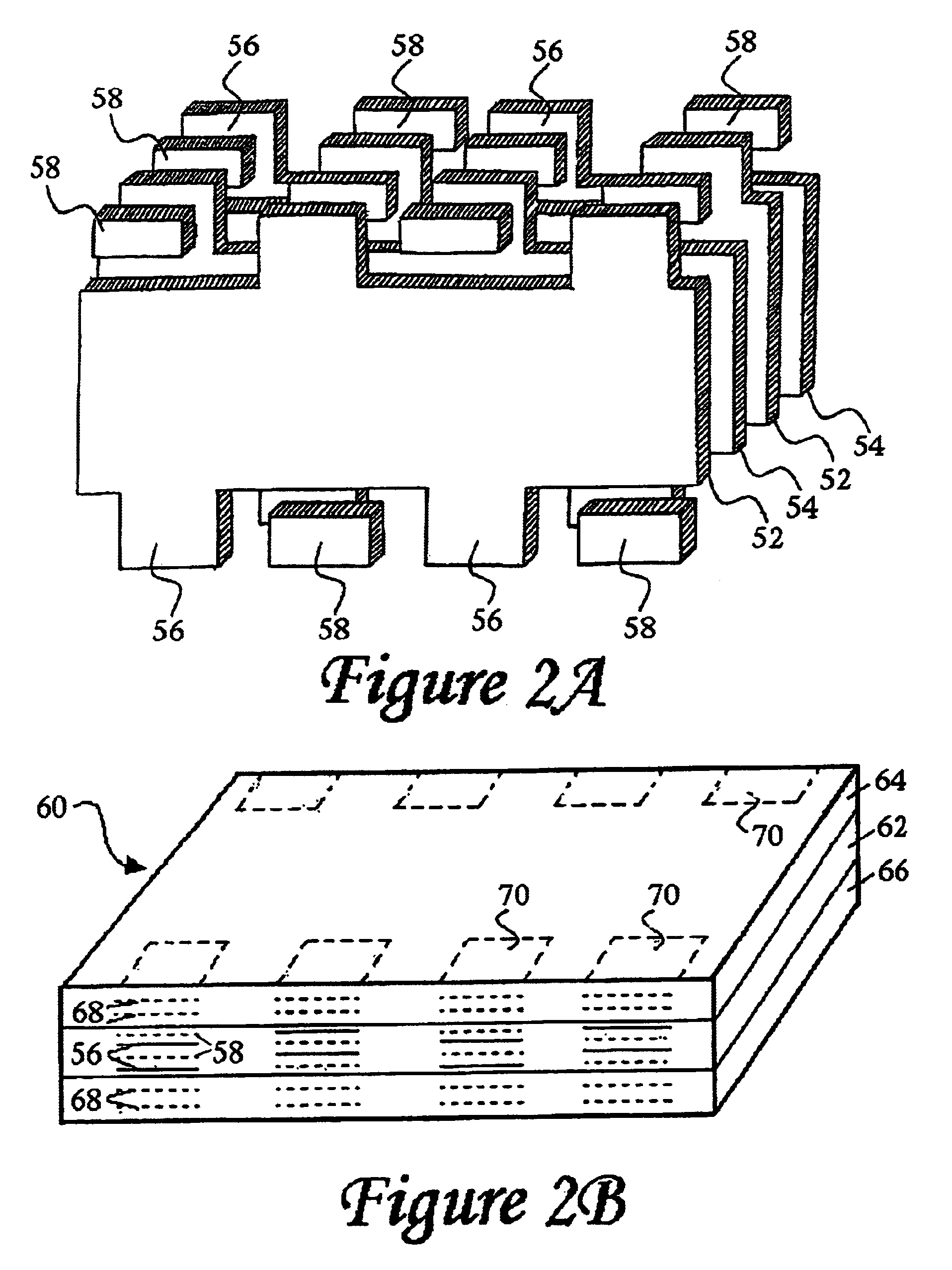

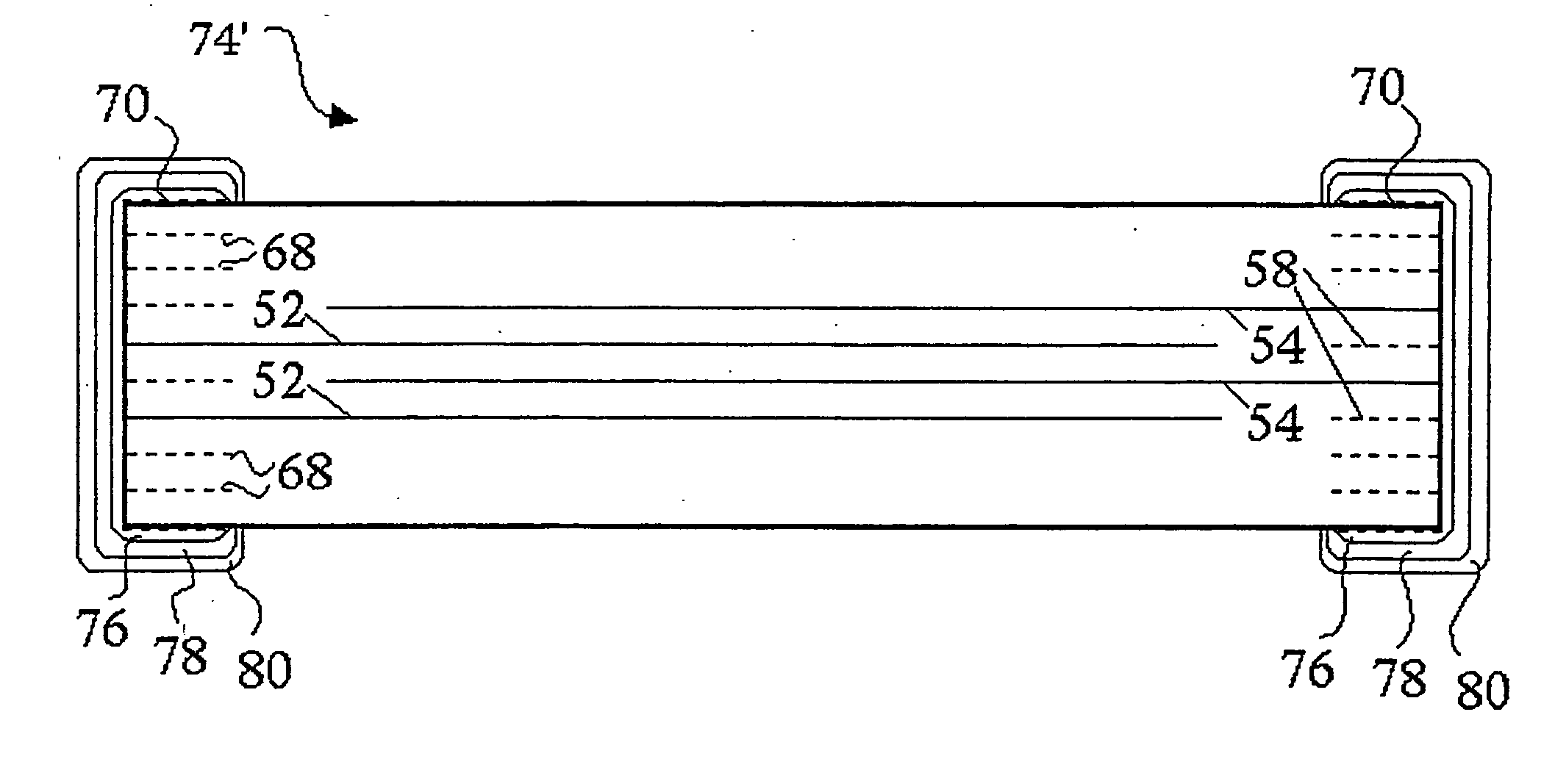

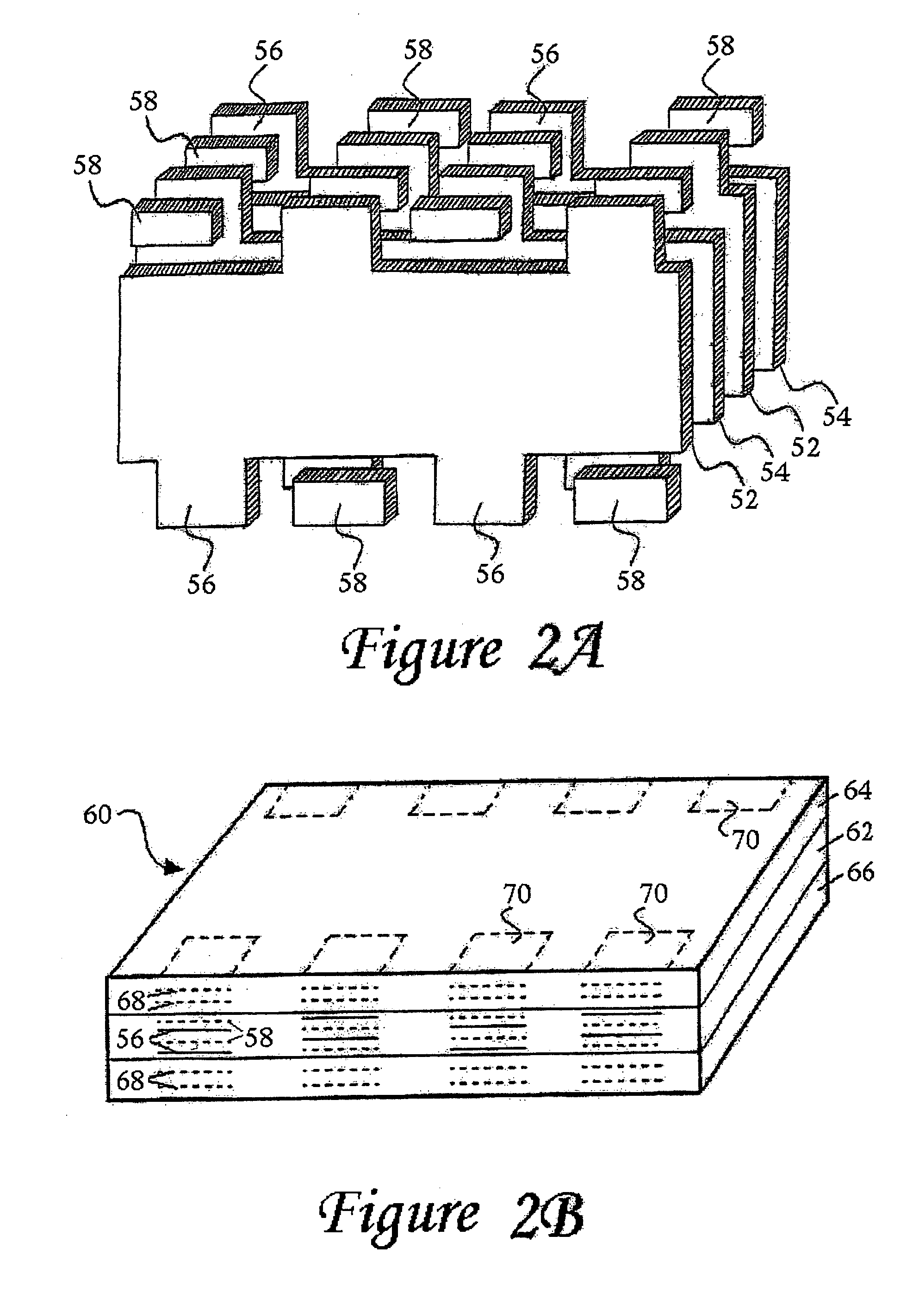

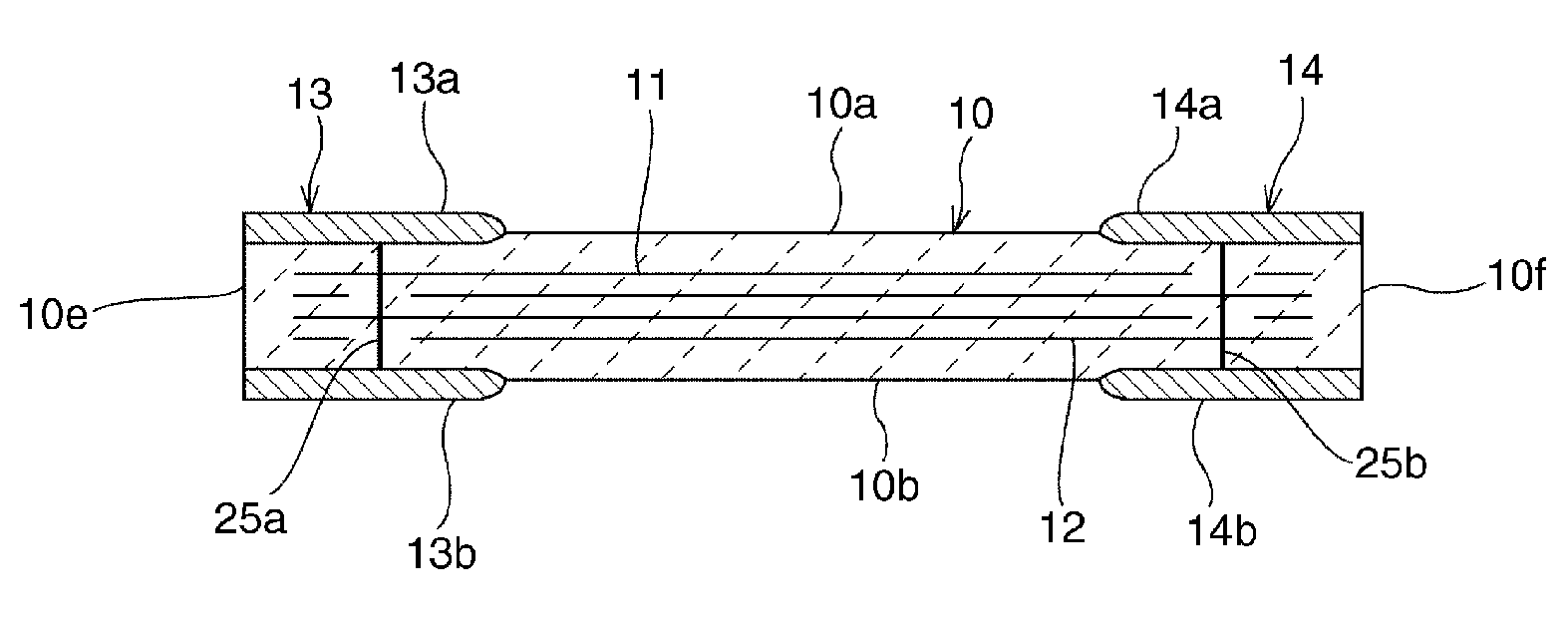

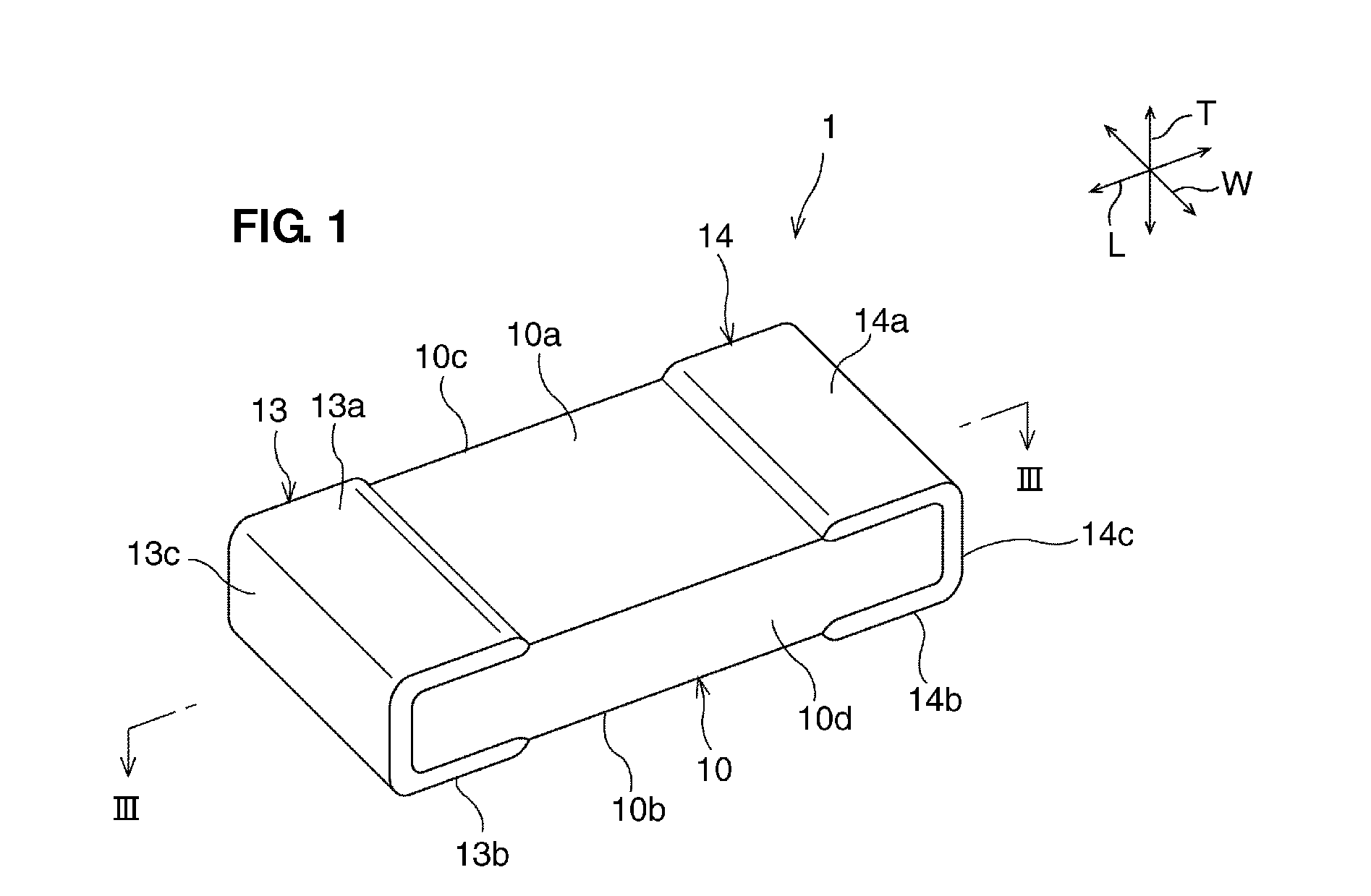

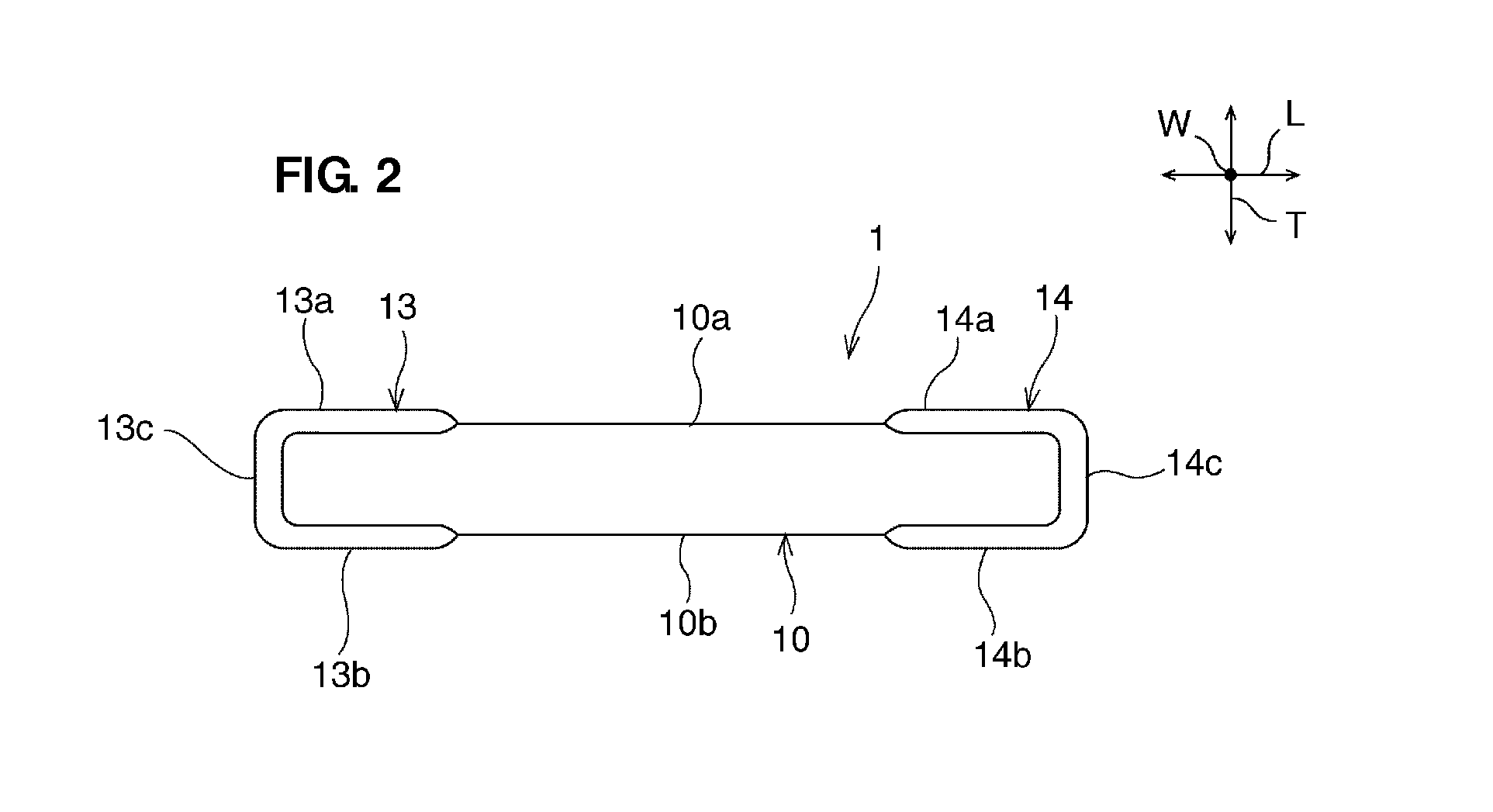

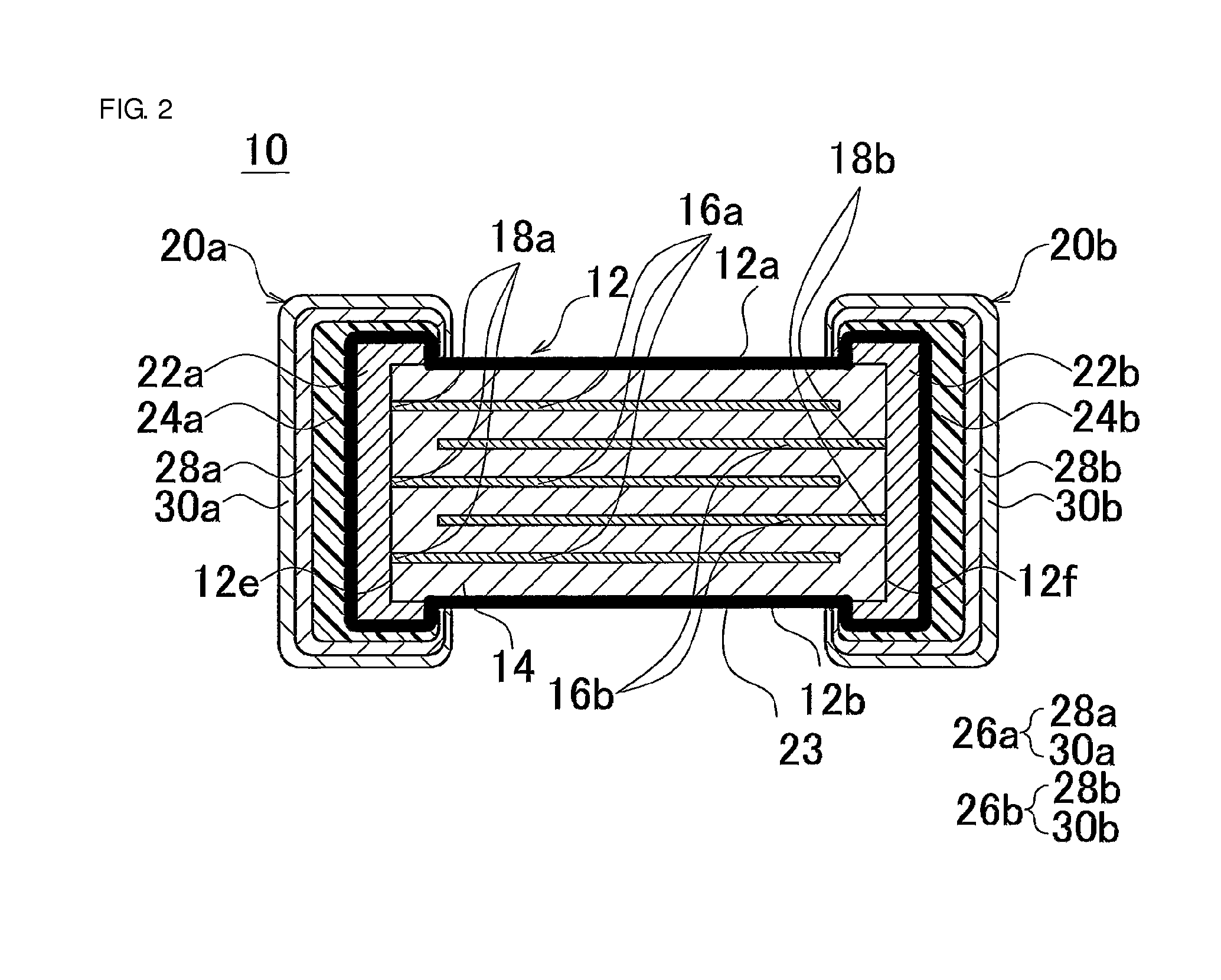

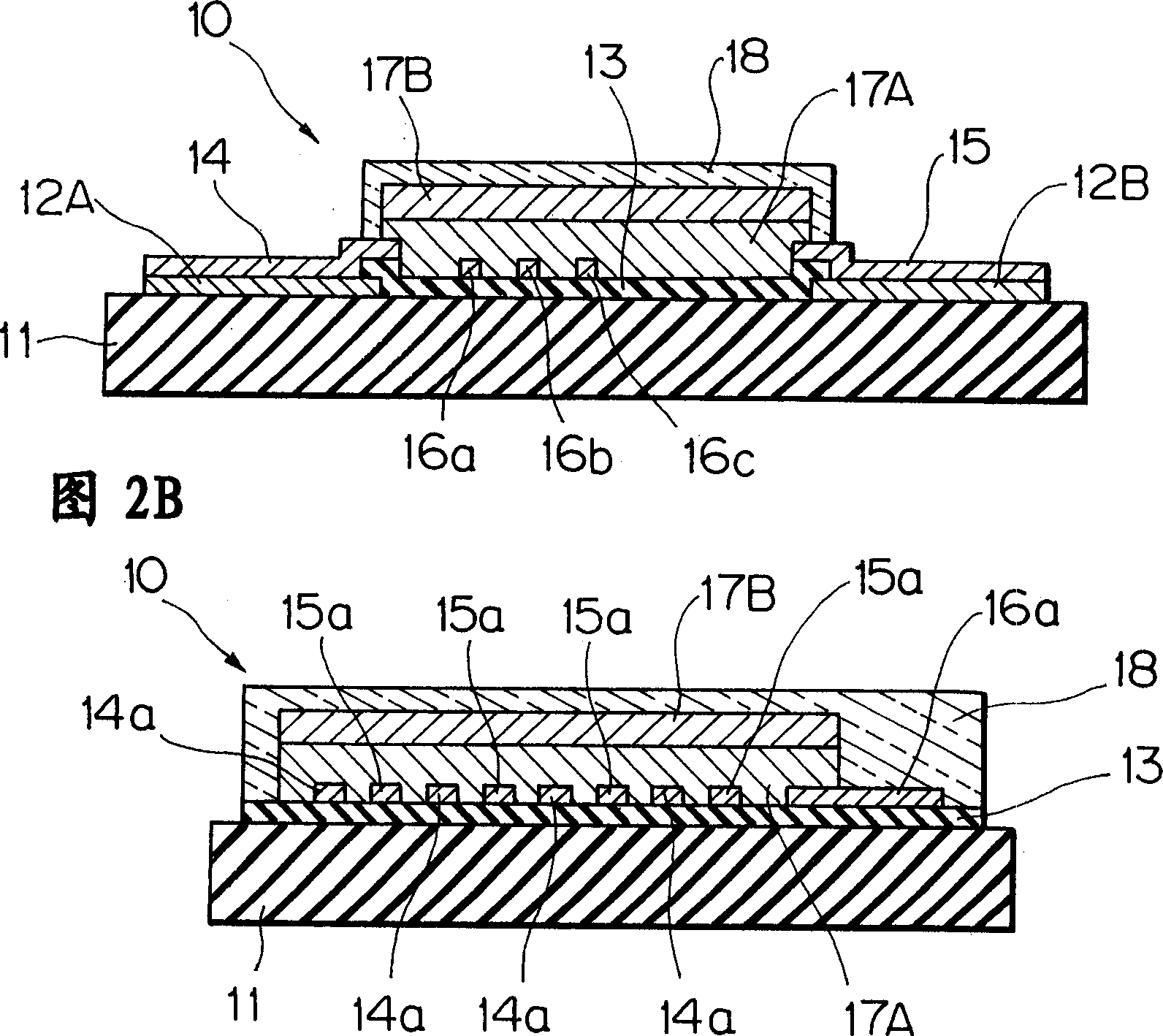

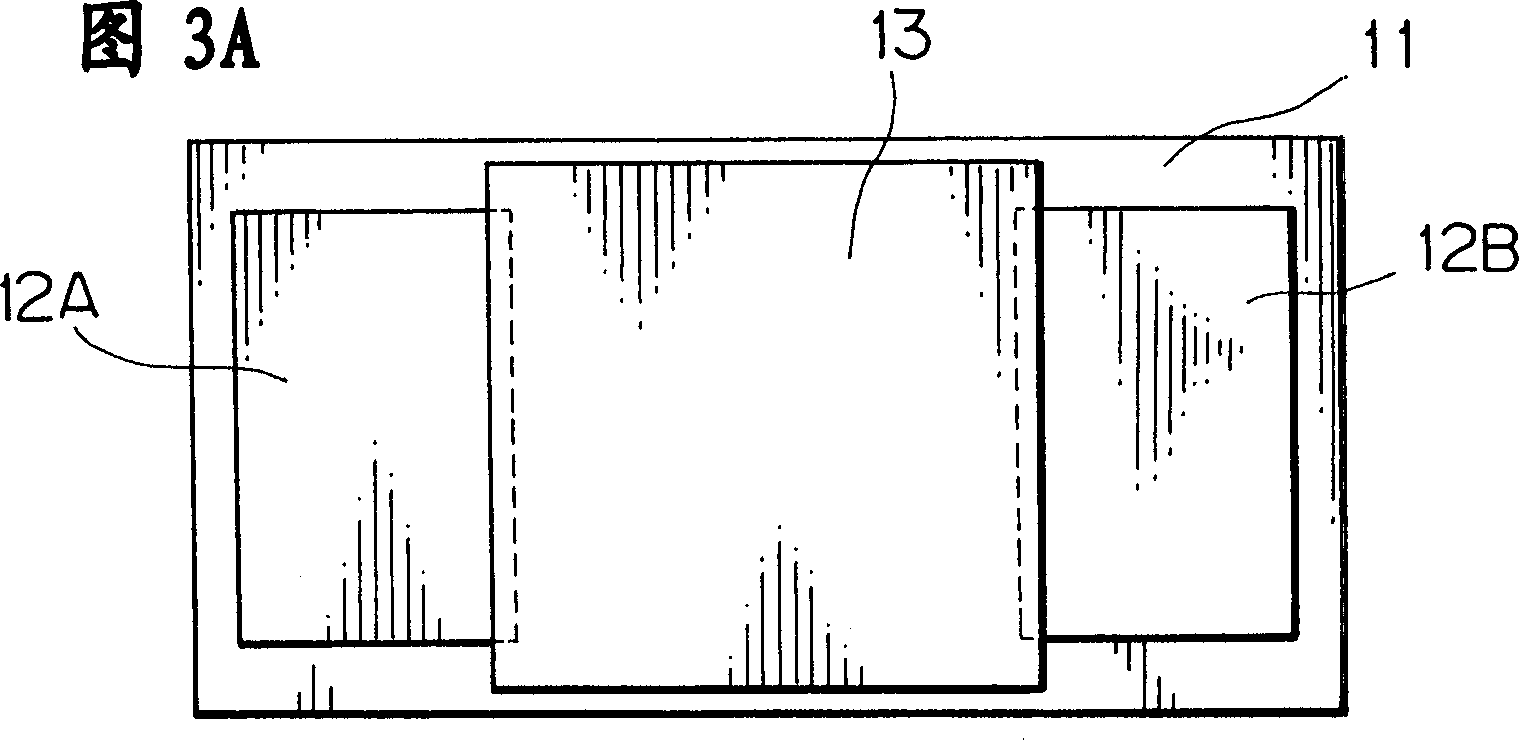

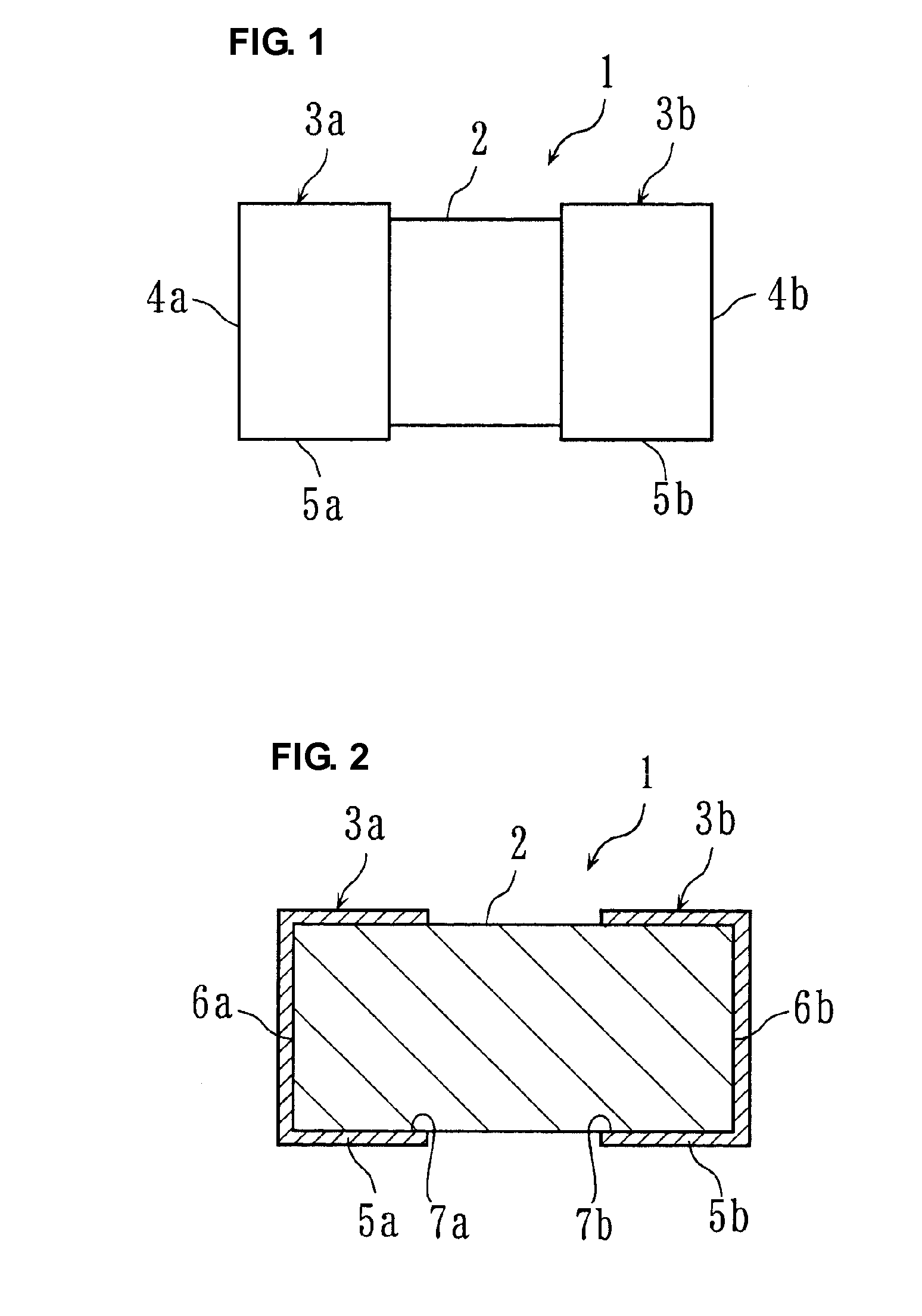

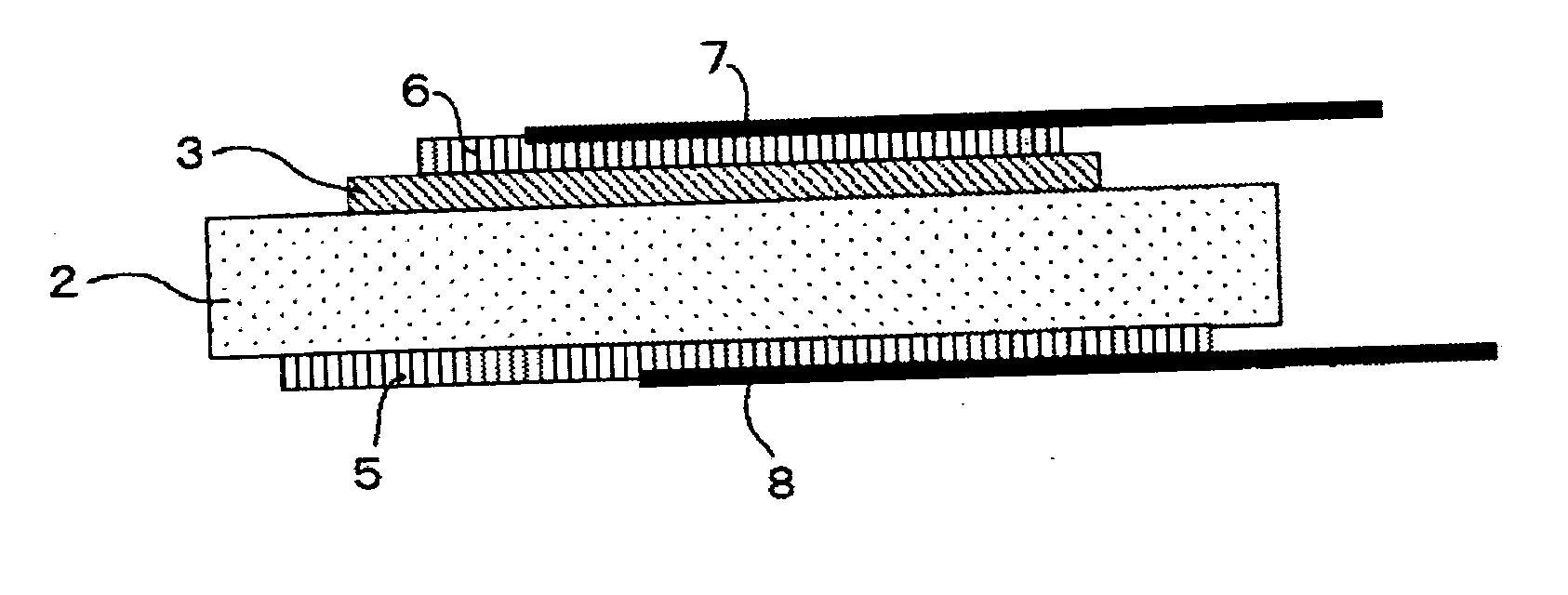

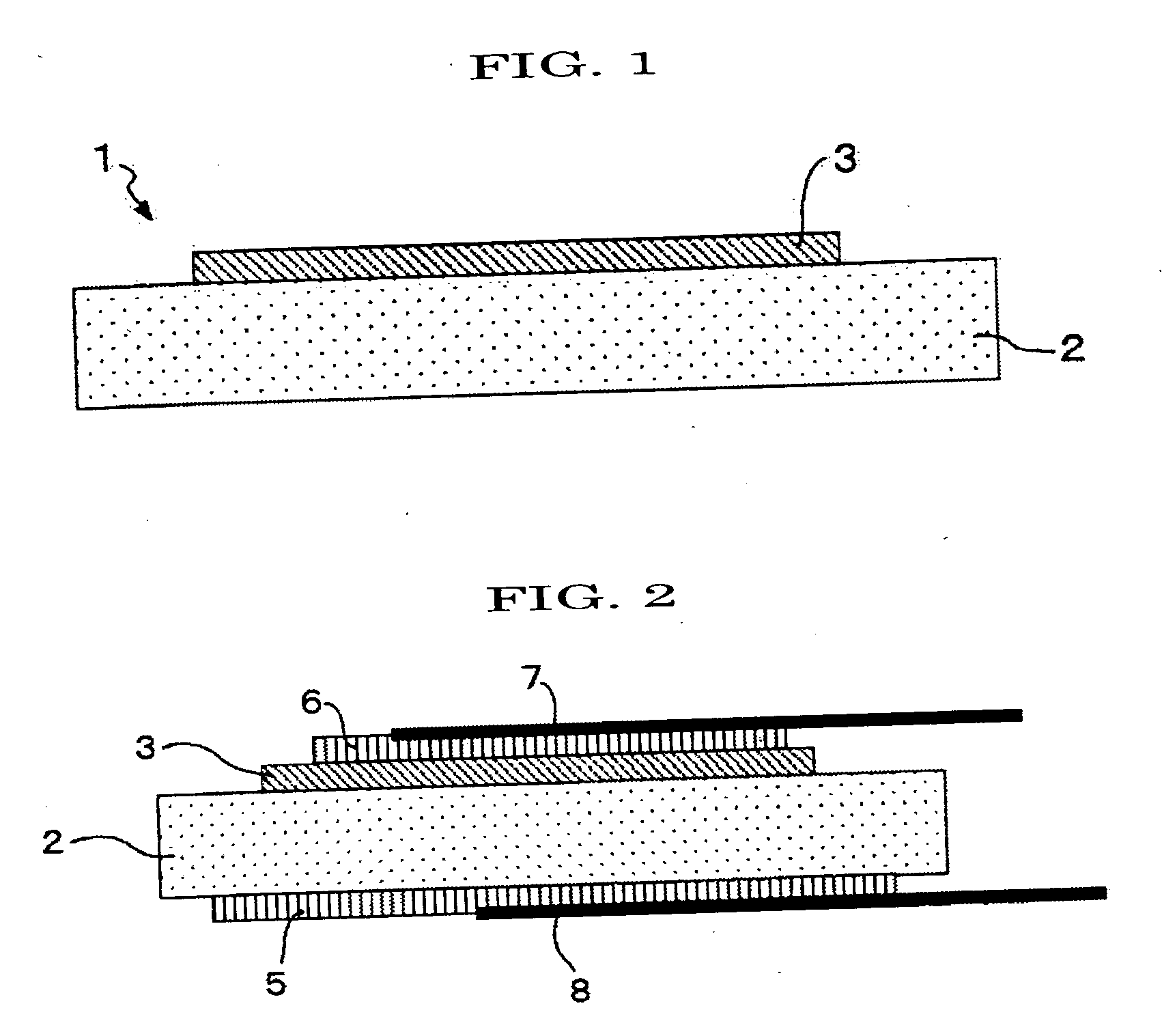

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on one or both of top and bottom surfaces of a monolithic structure can facilitate the formation of selective wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

Plated terminations

InactiveUS20050046536A1Improved termination featureEliminate and greatly simplifyWave amplification devicesResistor terminals/electrodesTermination problemEngineering

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on top and bottom sides of a monolithic structure can facilitate the formation of wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

Plated terminations

InactiveUS7154374B2Improved termination featureEliminate or greatly simplify thick-film stripesResistor terminals/electrodesSemiconductor/solid-state device detailsTermination problemEngineering

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on top and bottom sides of a monolithic structure can facilitate the formation of wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

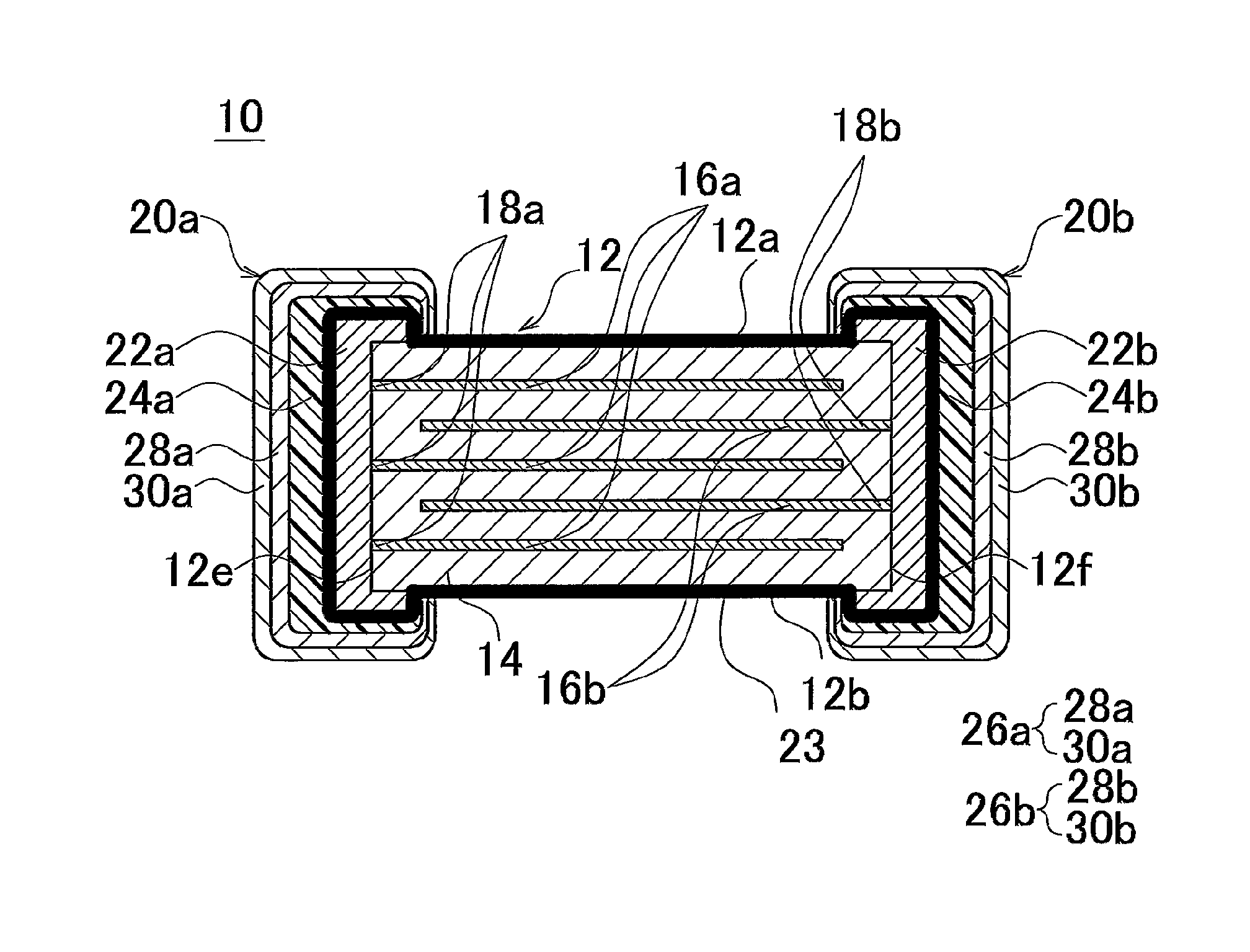

Multilayer electronic component and method for manufacturing the same

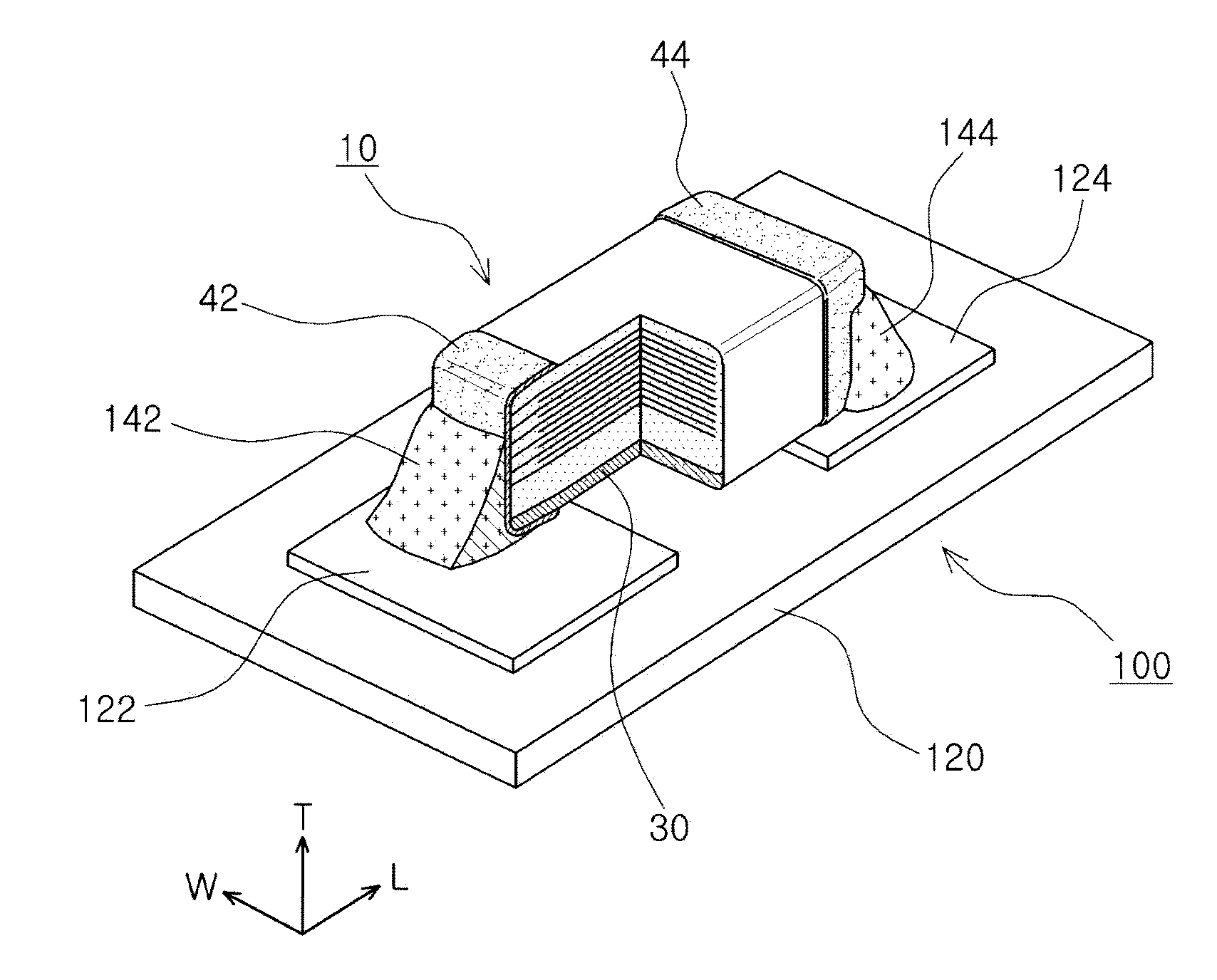

ActiveUS20080210564A1Reduction in lifeFixed capacitor electrodesStacked capacitorsEngineeringElectronic component

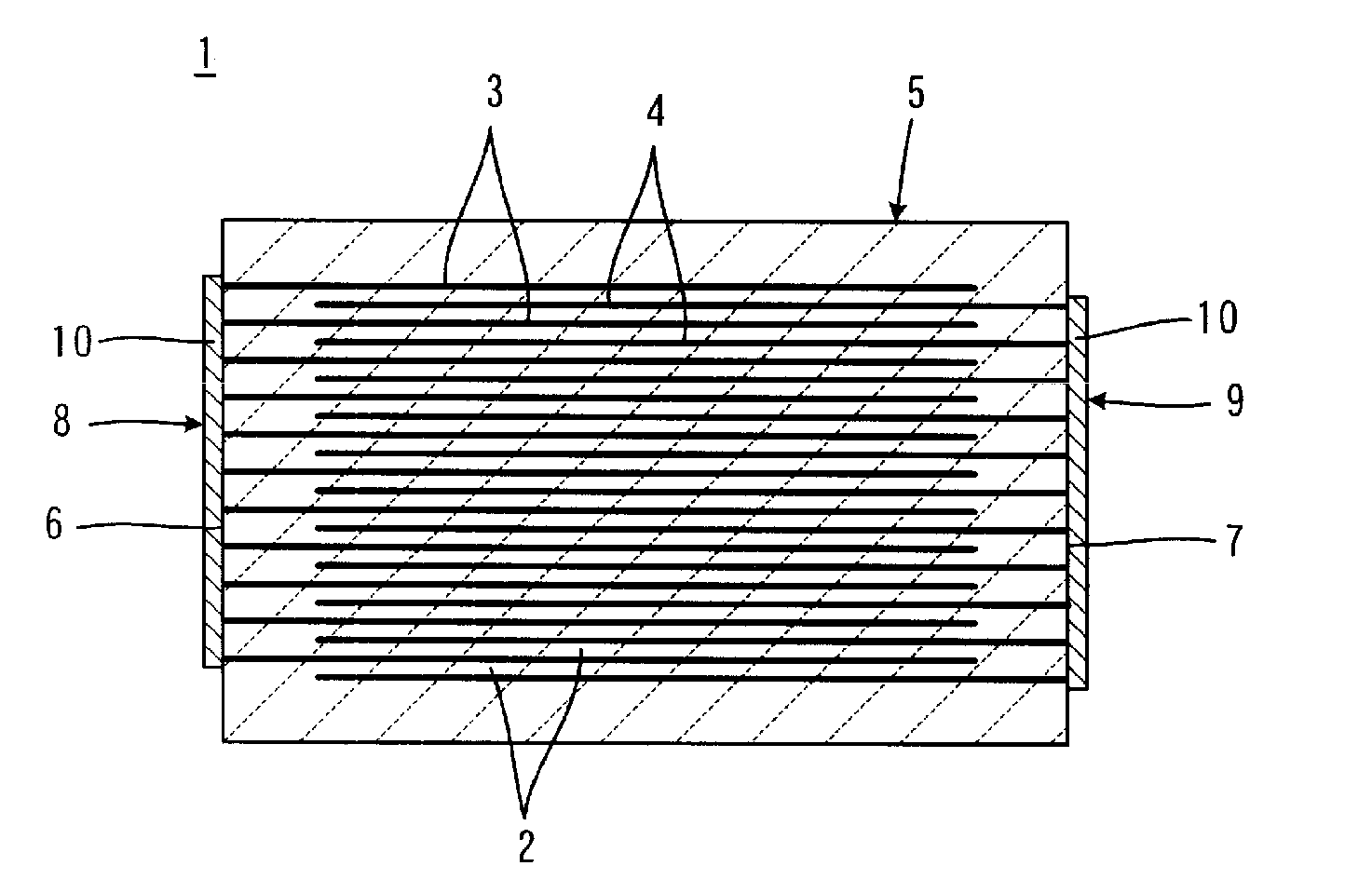

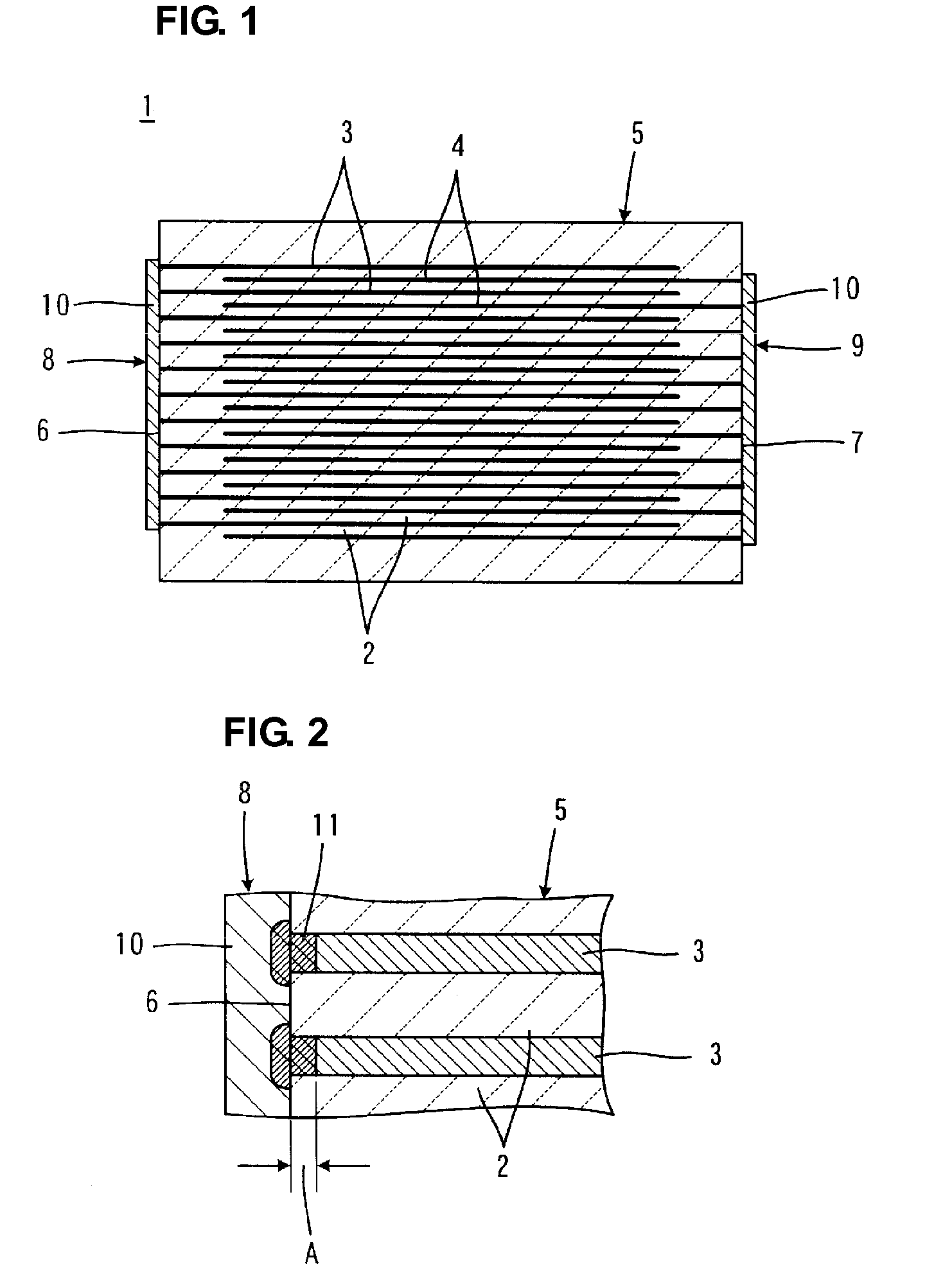

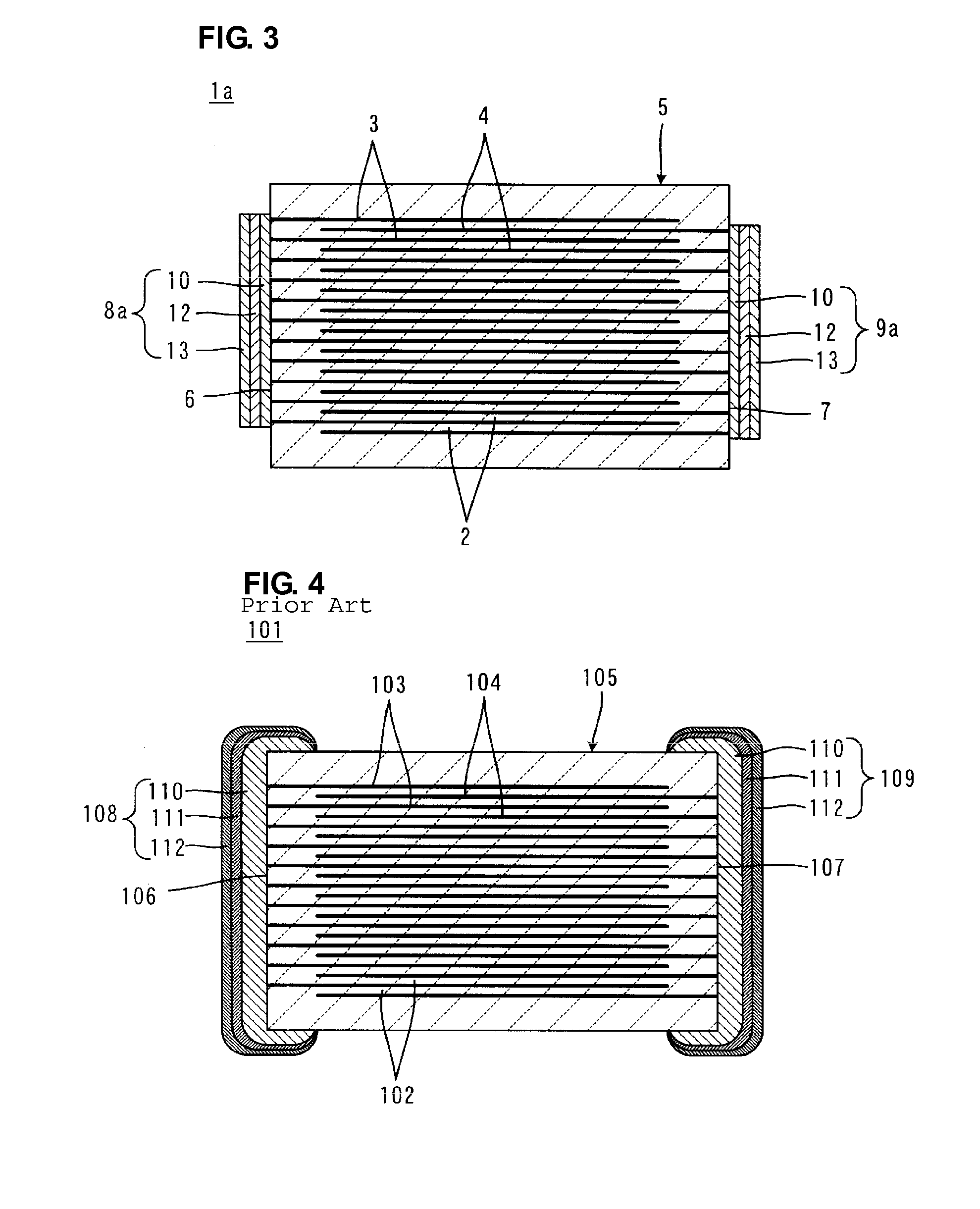

A method for manufacturing a multilayer electronic component, includes the steps of preparing a laminate including a plurality of insulating layers laminated to each other and a plurality of internal electrodes formed along interfaces between the insulating layers, edges of the internal electrodes being exposed at a predetermined surface of the laminate, and forming an external electrode on the predetermined surface so as to electrically connect the edges of the internal electrodes, which are exposed at the predetermined surface of the laminate. The step of forming an external electrode includes a plating step of forming a continuous plating film by depositing plating deposits on the edges of the internal electrodes exposed at the predetermined surface of the laminate which is prepared in the step of preparing a laminate and by performing plating growth of the plating deposits so as to be connected to each other, and a heat treatment step of performing a heat treatment on the laminate provided with the plating film formed thereon at an oxygen partial pressure of about 5 ppm or less and at a temperature of about 600° C. or more.

Owner:MURATA MFG CO LTD

Method of fabricating vertical structure LEDs

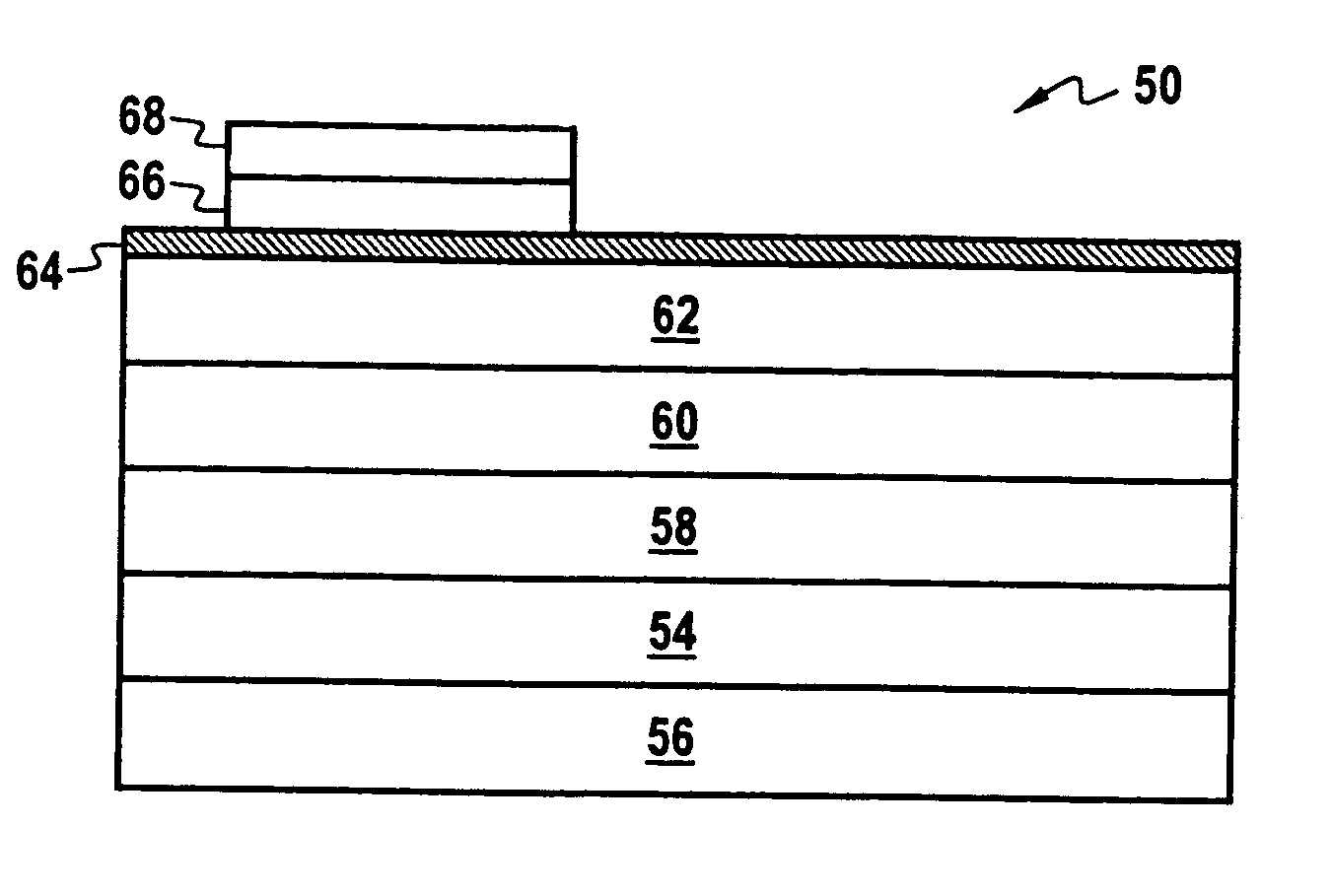

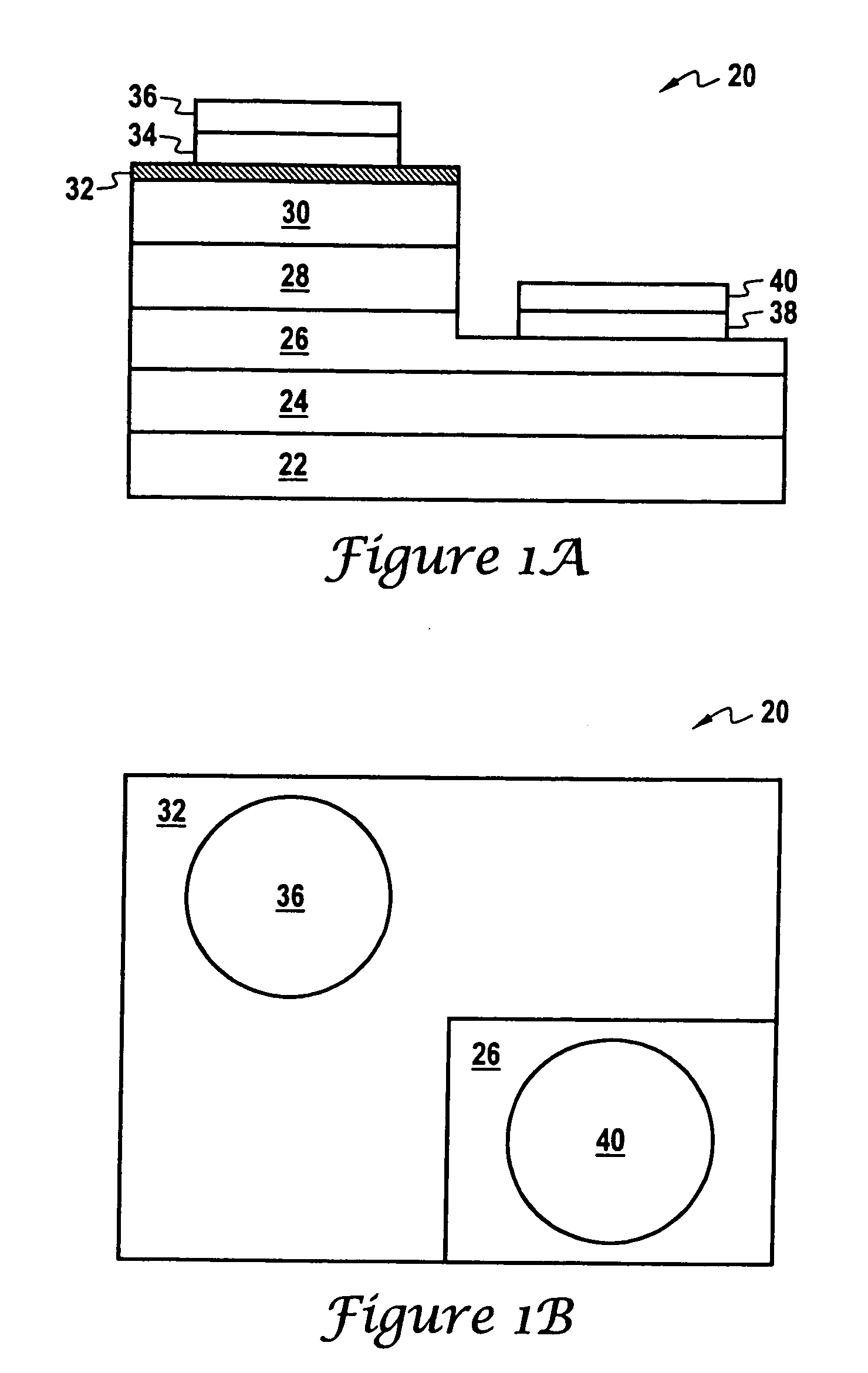

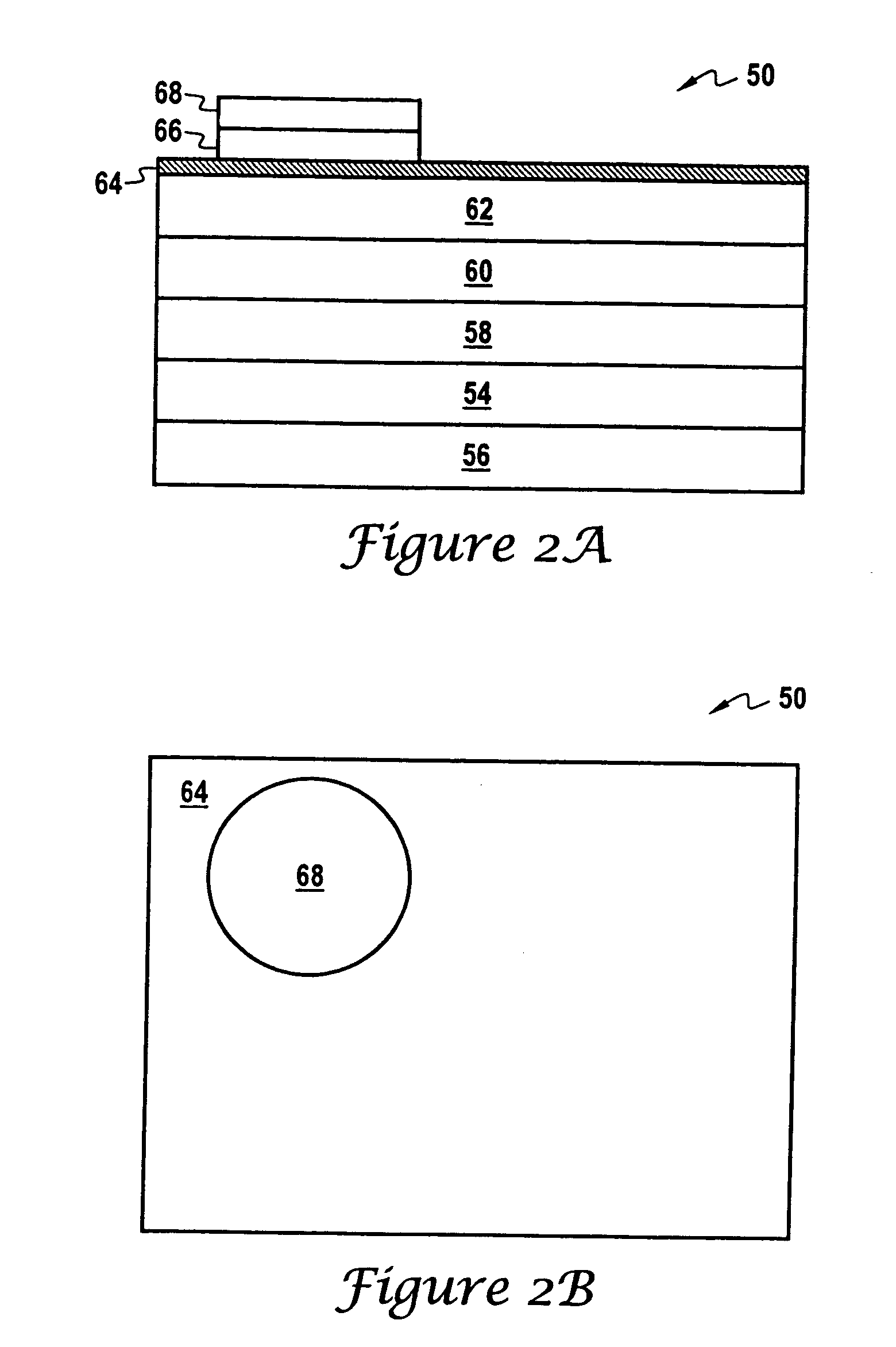

InactiveUS20050098792A1Avoid damageSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialReactive-ion etching

A method of fabricating semiconductor devices, such as GaN LEDs, on insulating substrates, such as sapphire. Semiconductor layers are produced on the insulating substrate using normal semiconductor processing techniques. Trenches that define the boundaries of the individual devices are then formed through the semiconductor layers and into the insulating substrate, beneficially by using inductive coupled plasma reactive ion etching. The trenches are then filled with an easily removed layer. A metal support structure is then formed on the semiconductor layers (such as by plating or by deposition) and the insulating substrate is removed. Electrical contacts, a passivation layer, and metallic pads are then added to the individual devices, and the individual devices are then diced out.

Owner:SUZHOU LEKIN SEMICON CO LTD

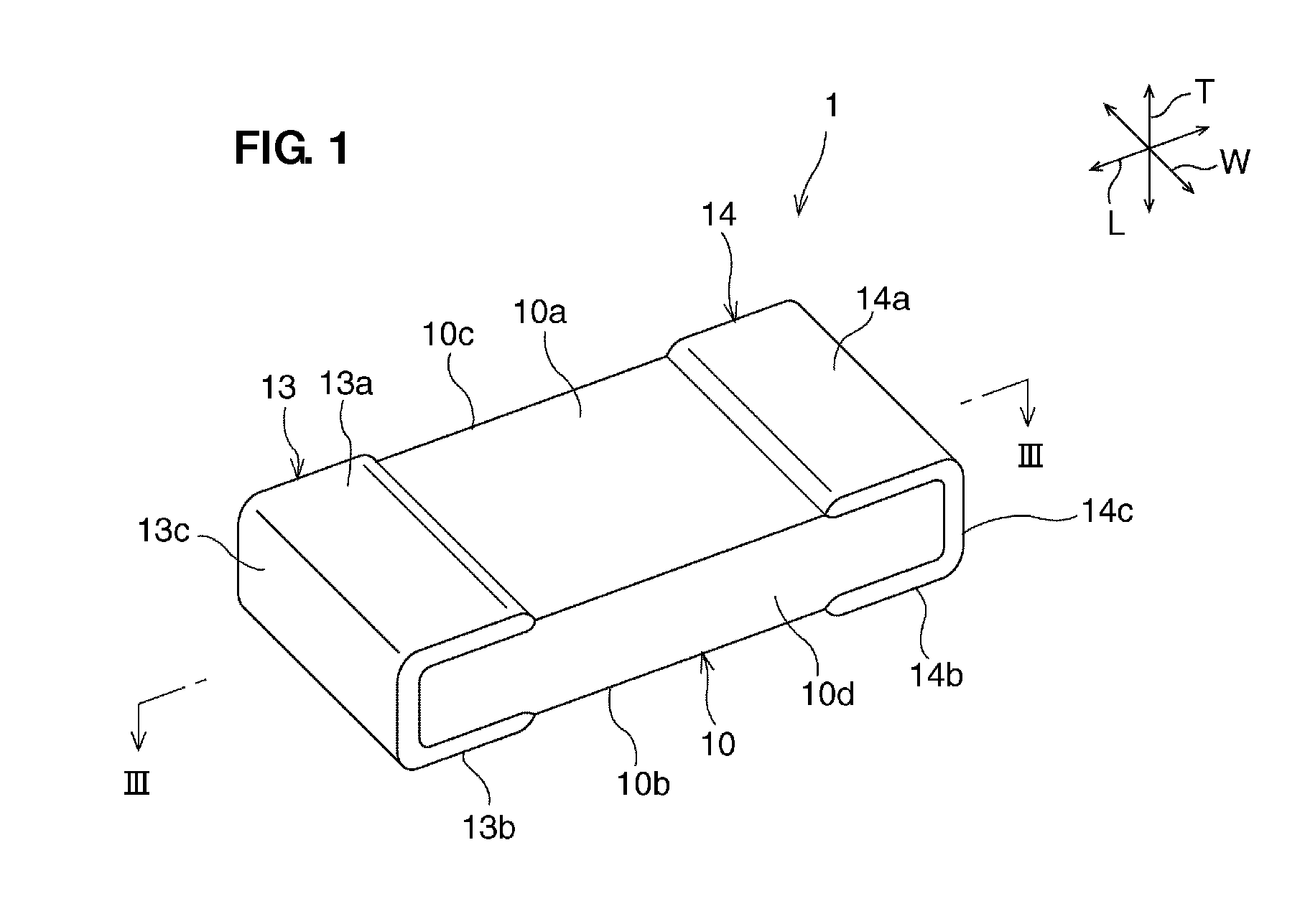

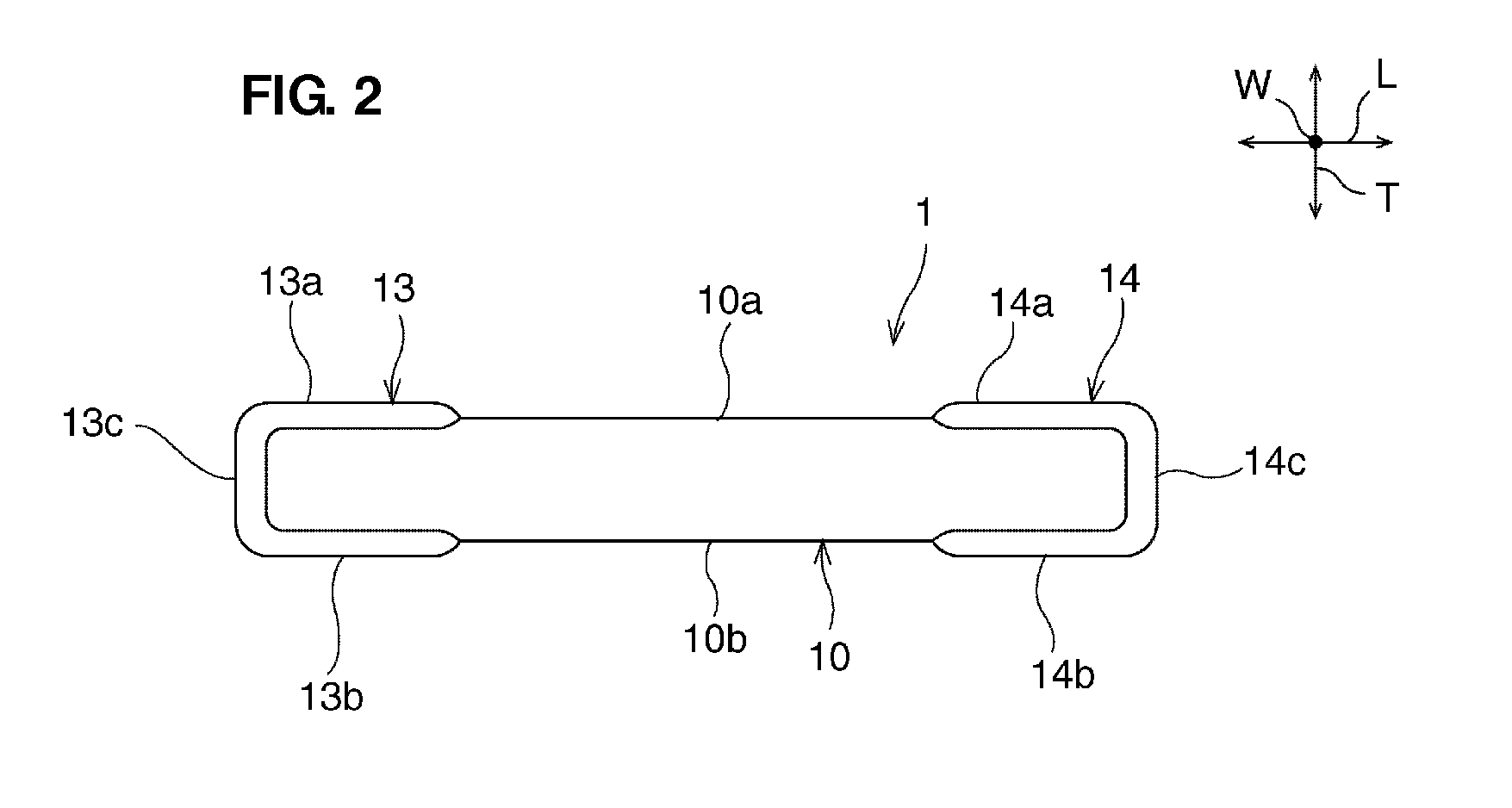

Laminated chip electronic component, board for mounting the same, and packing unit thereof

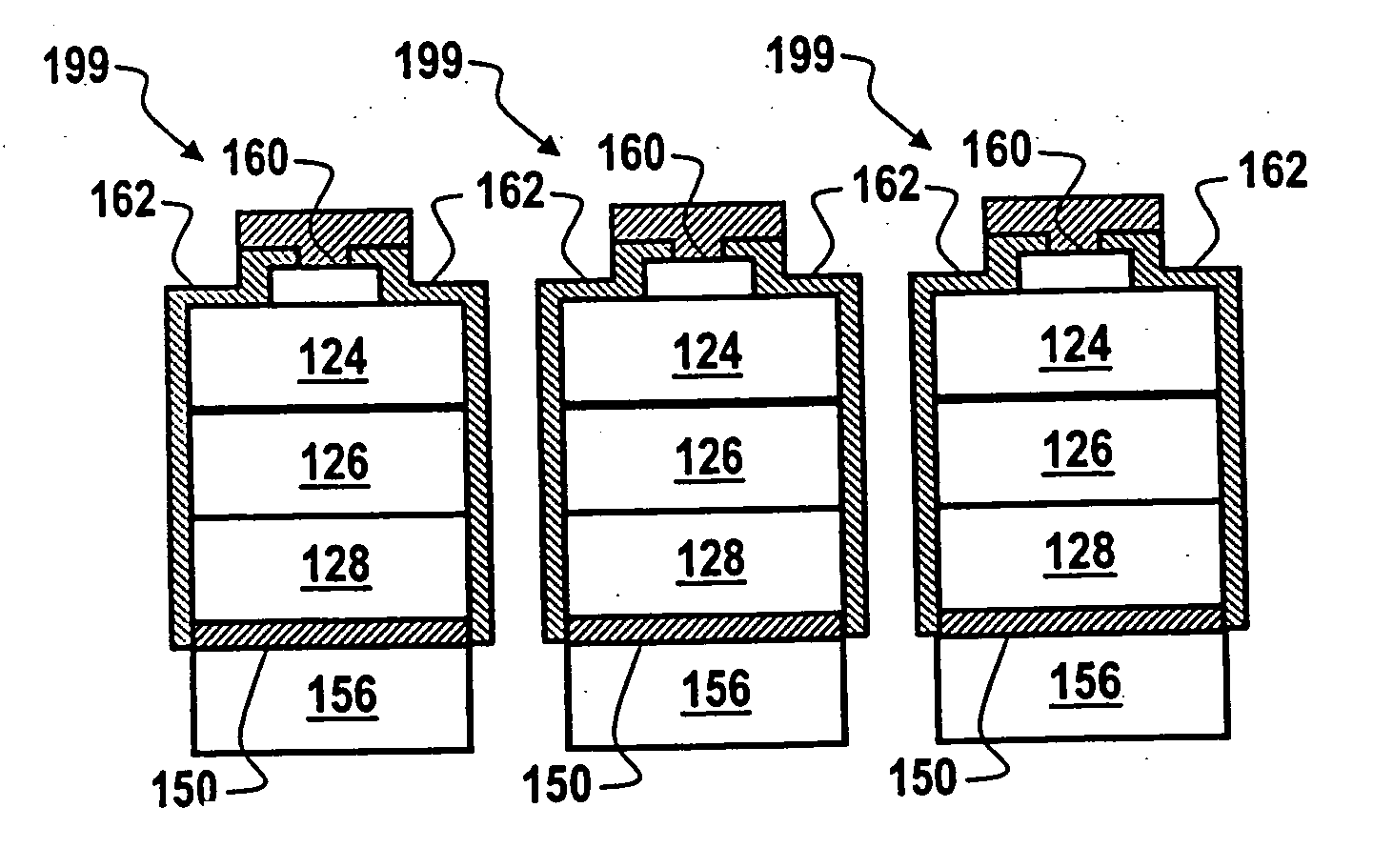

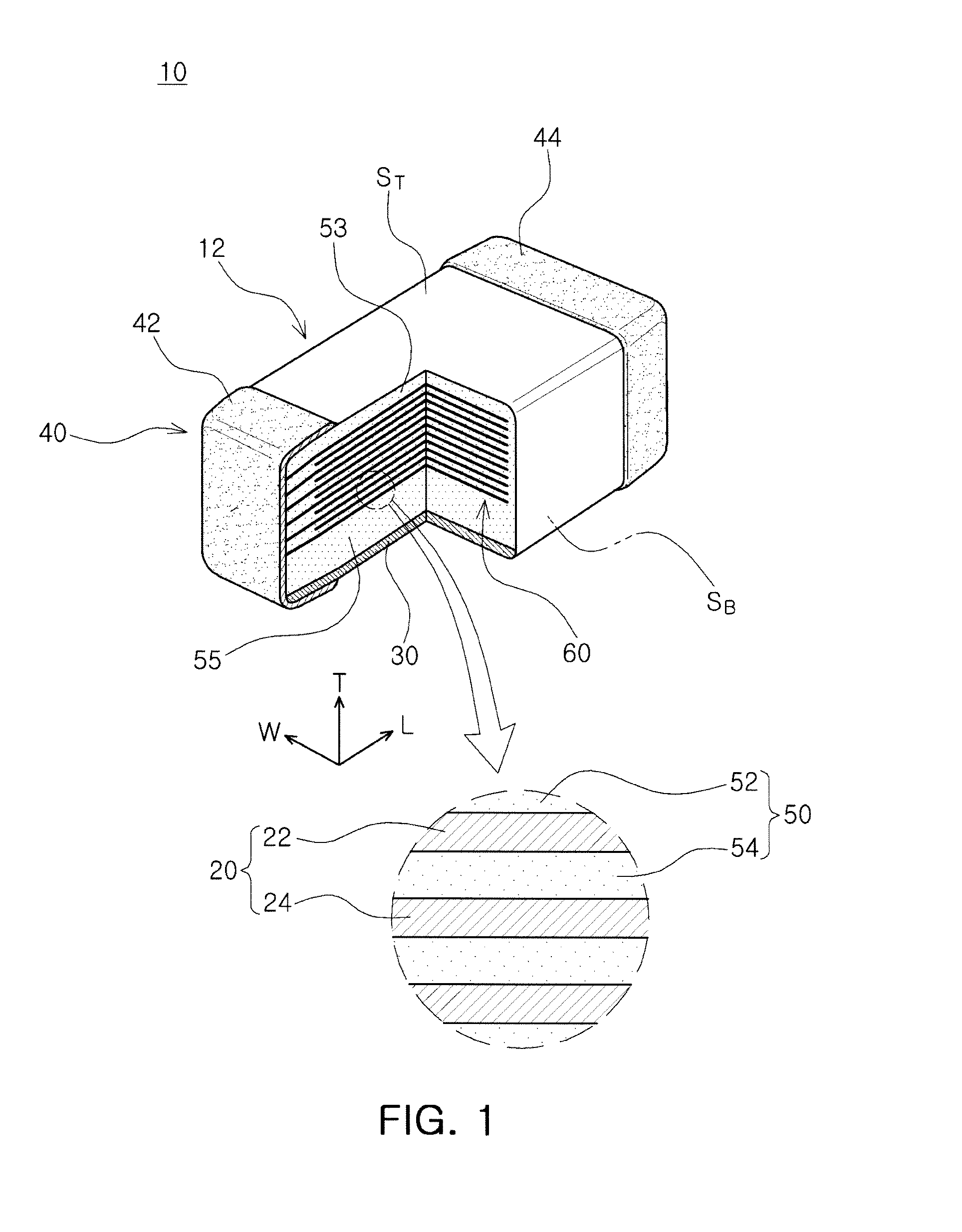

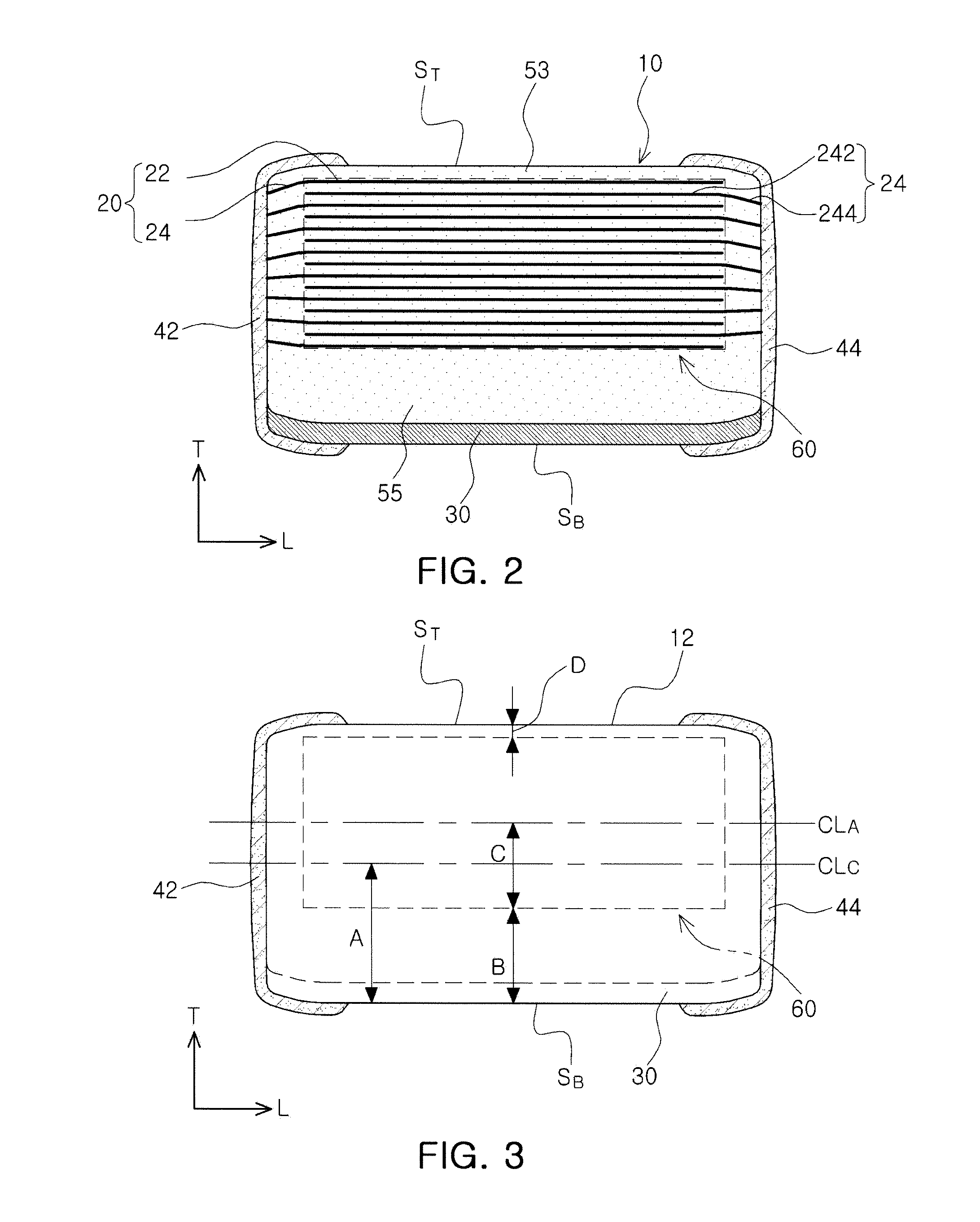

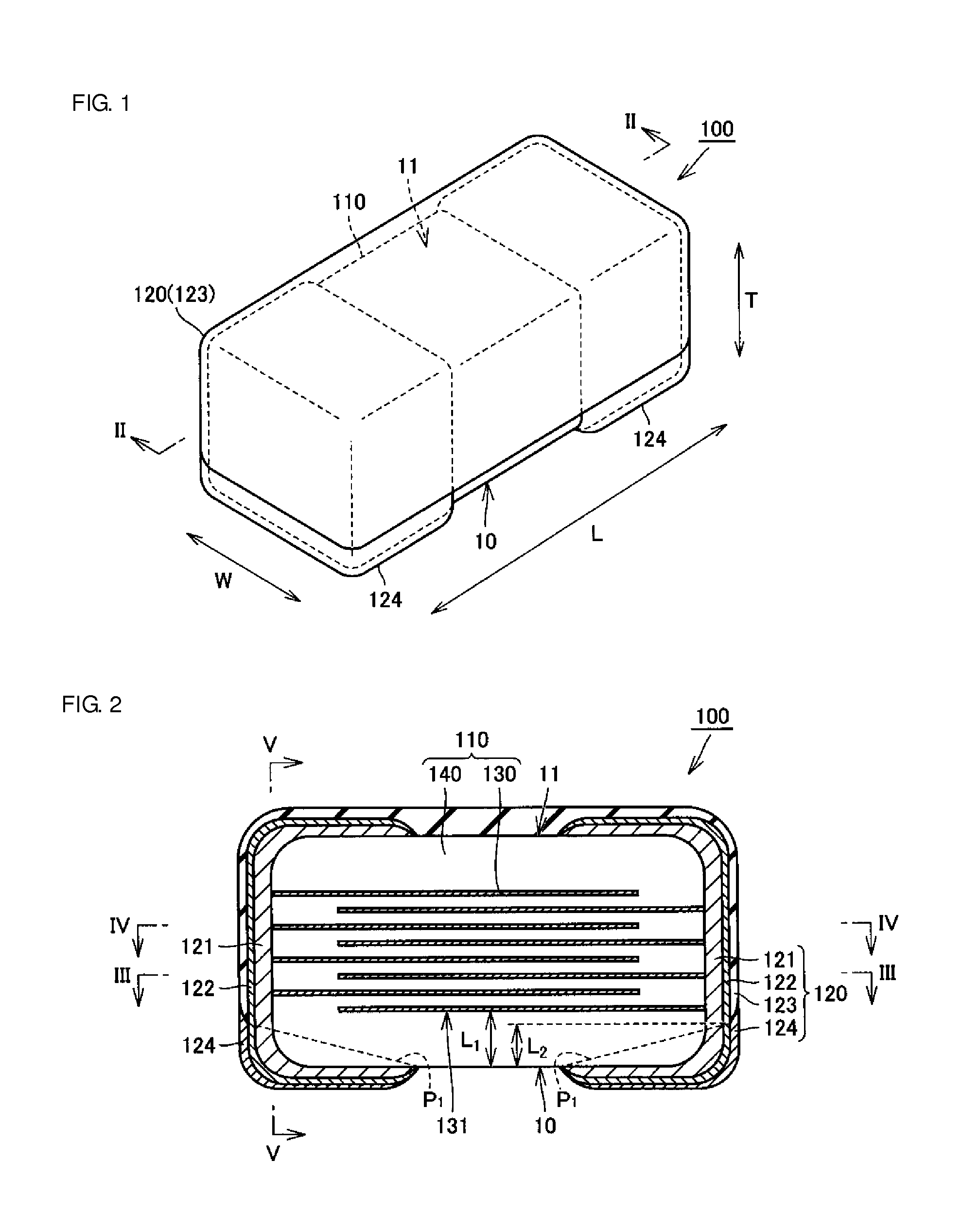

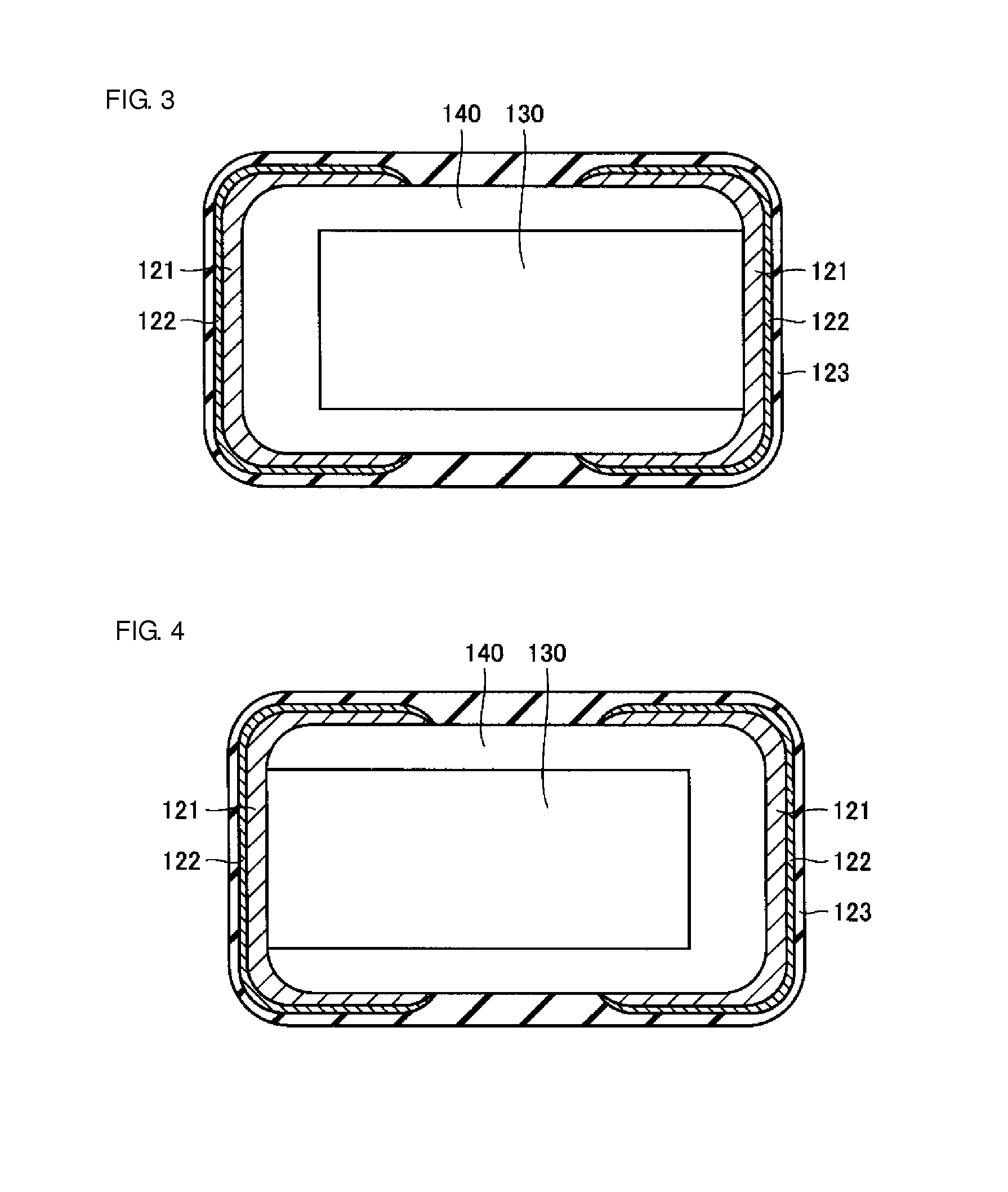

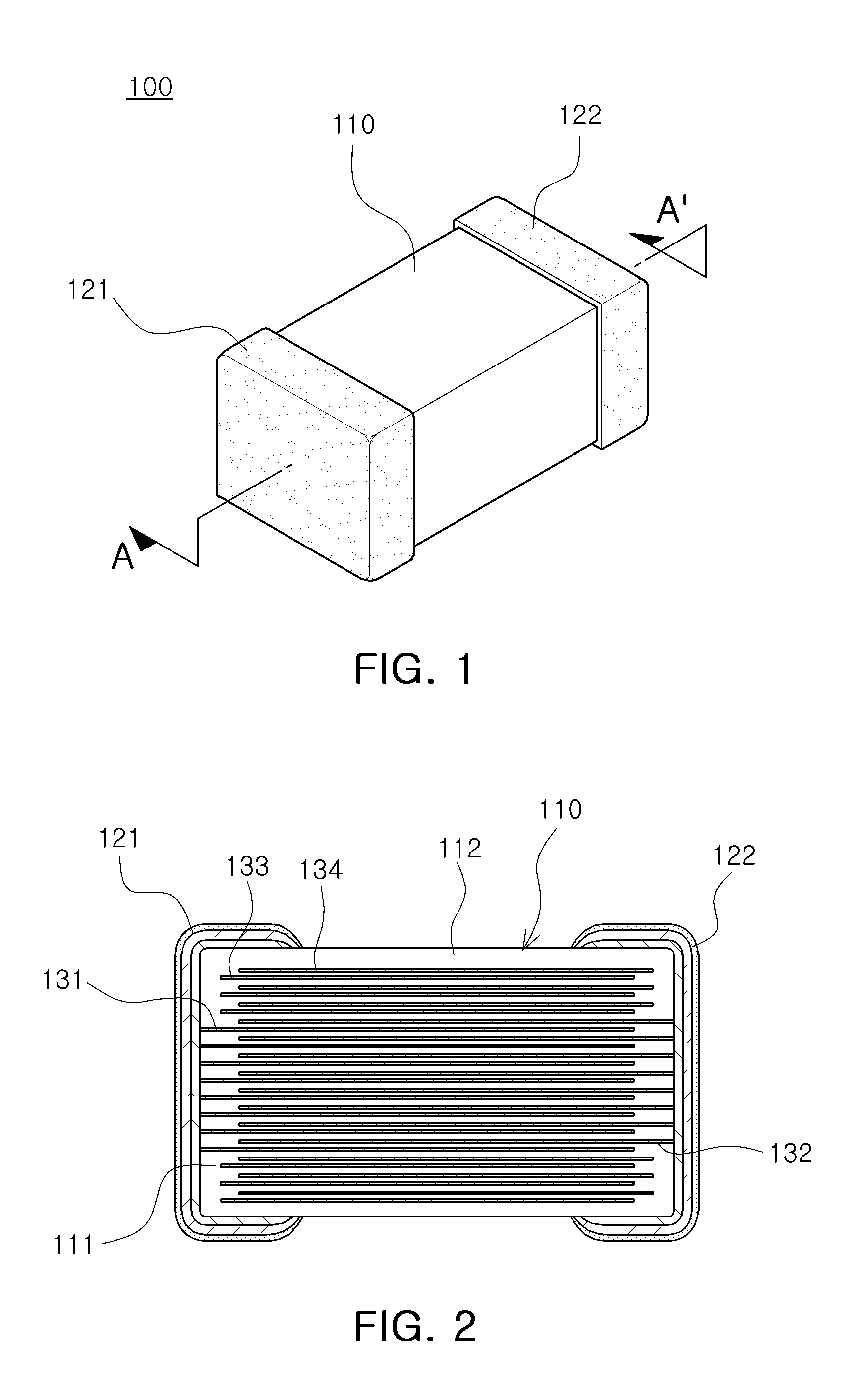

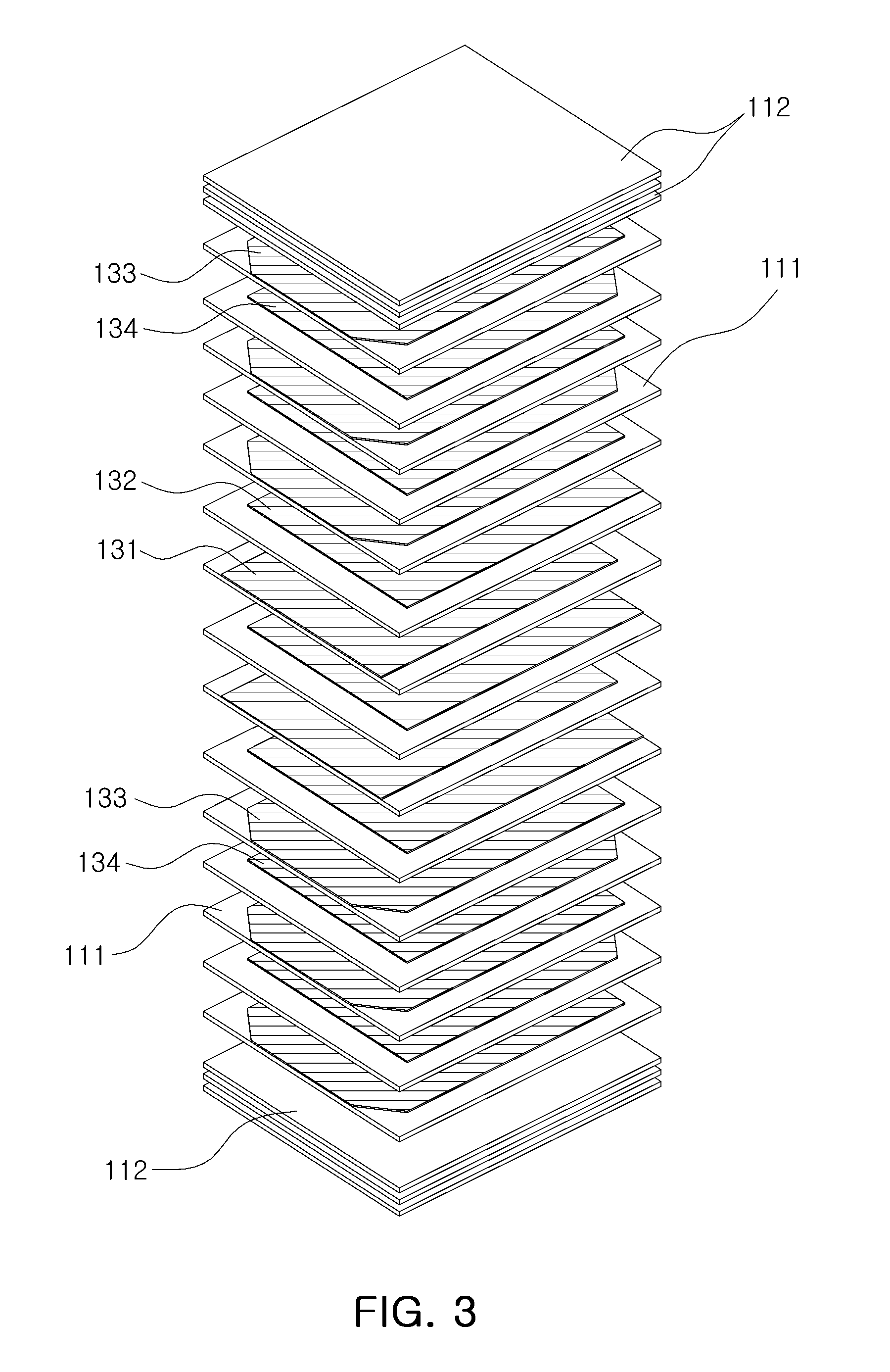

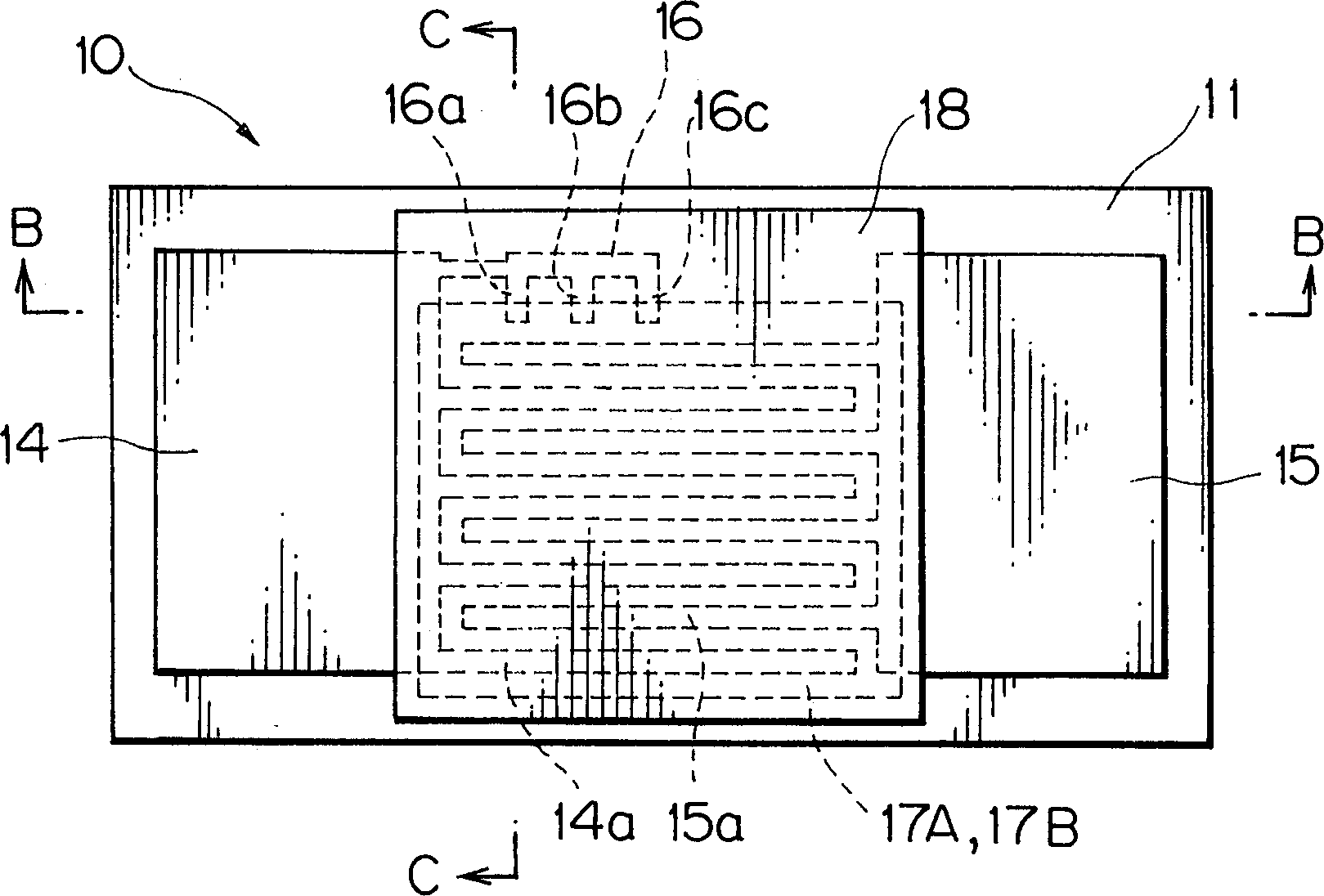

ActiveUS20140083755A1Reduce noisePiezoelectric/electrostriction/magnetostriction machinesFinal product manufactureCapacitanceElectronic component

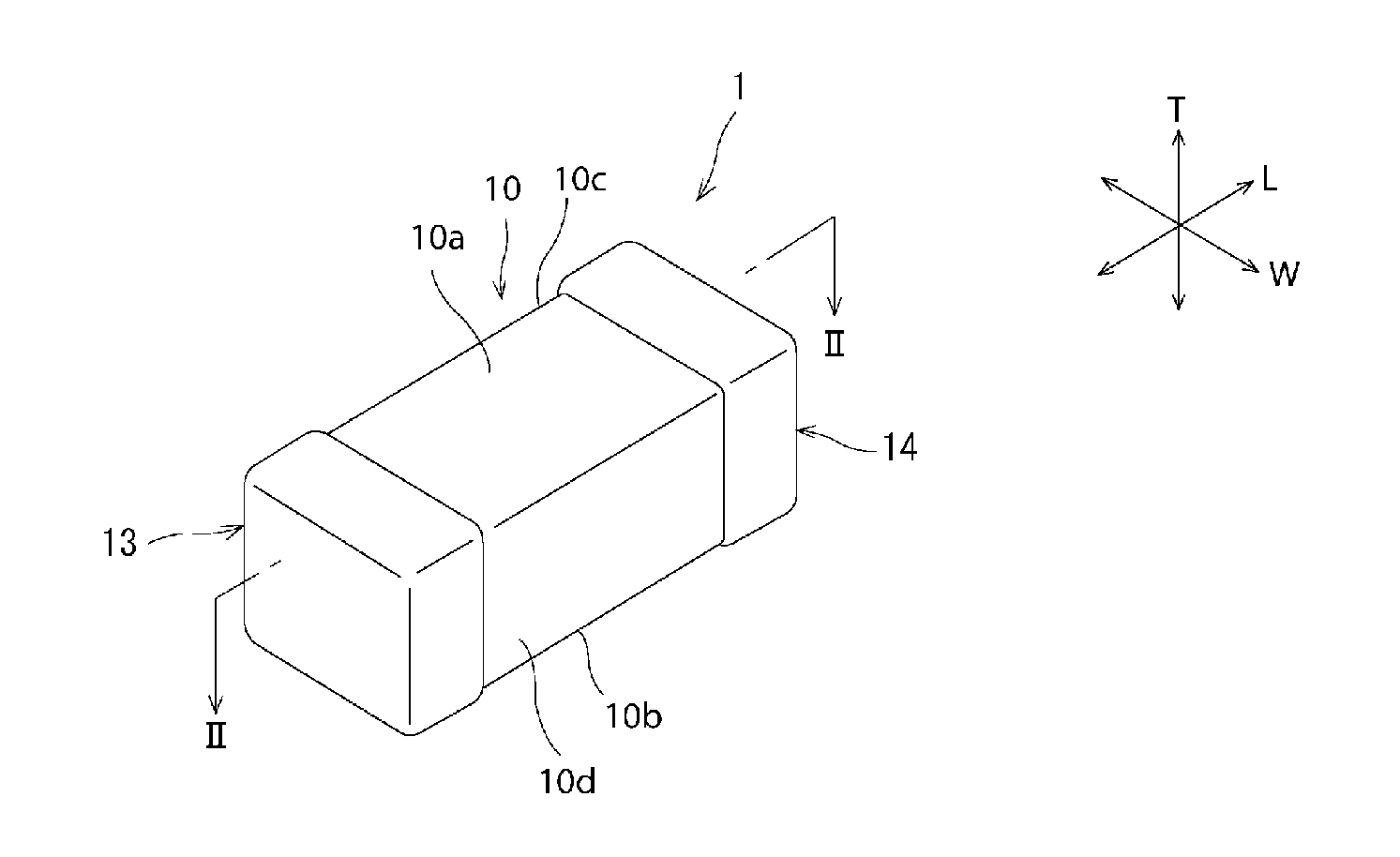

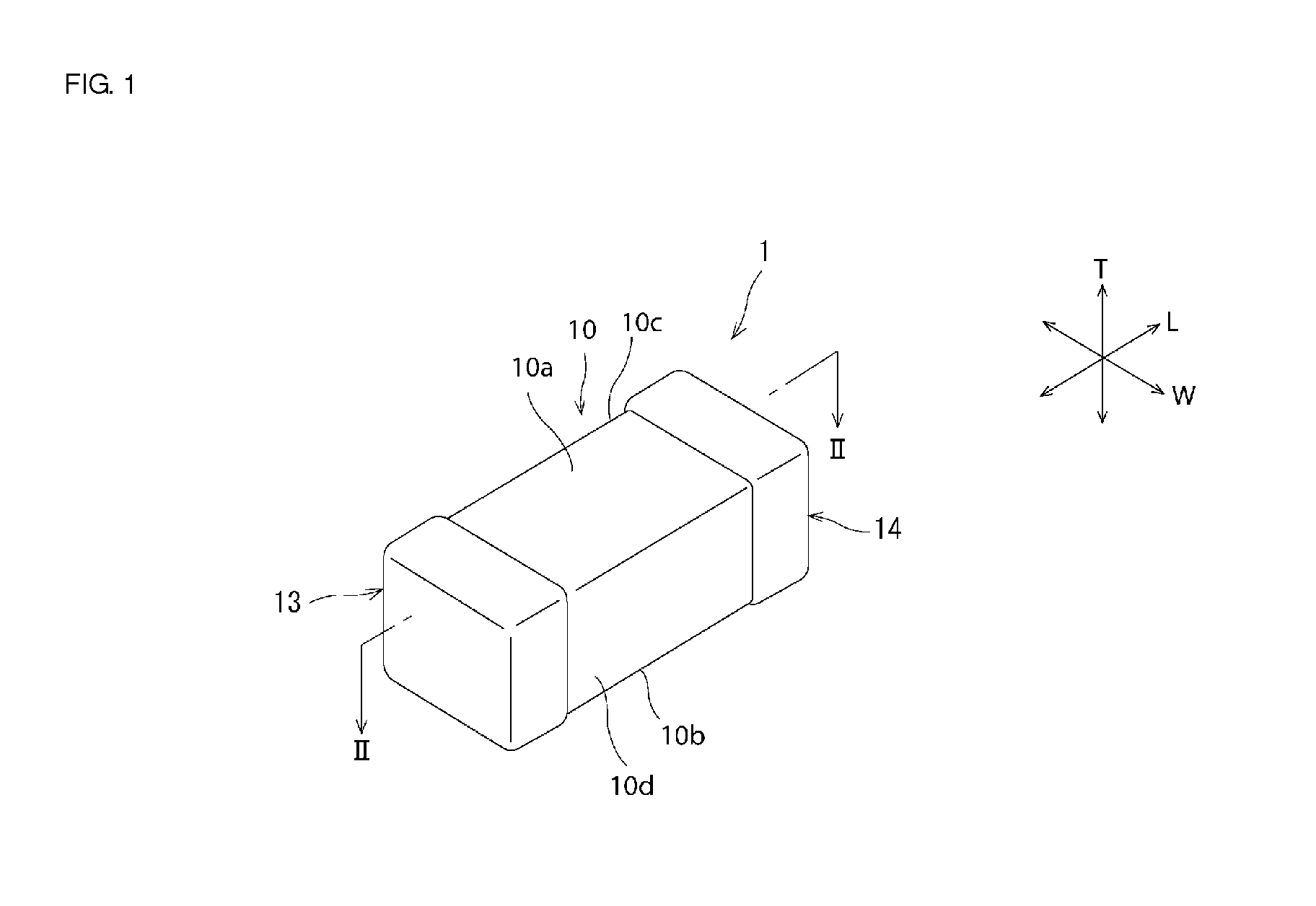

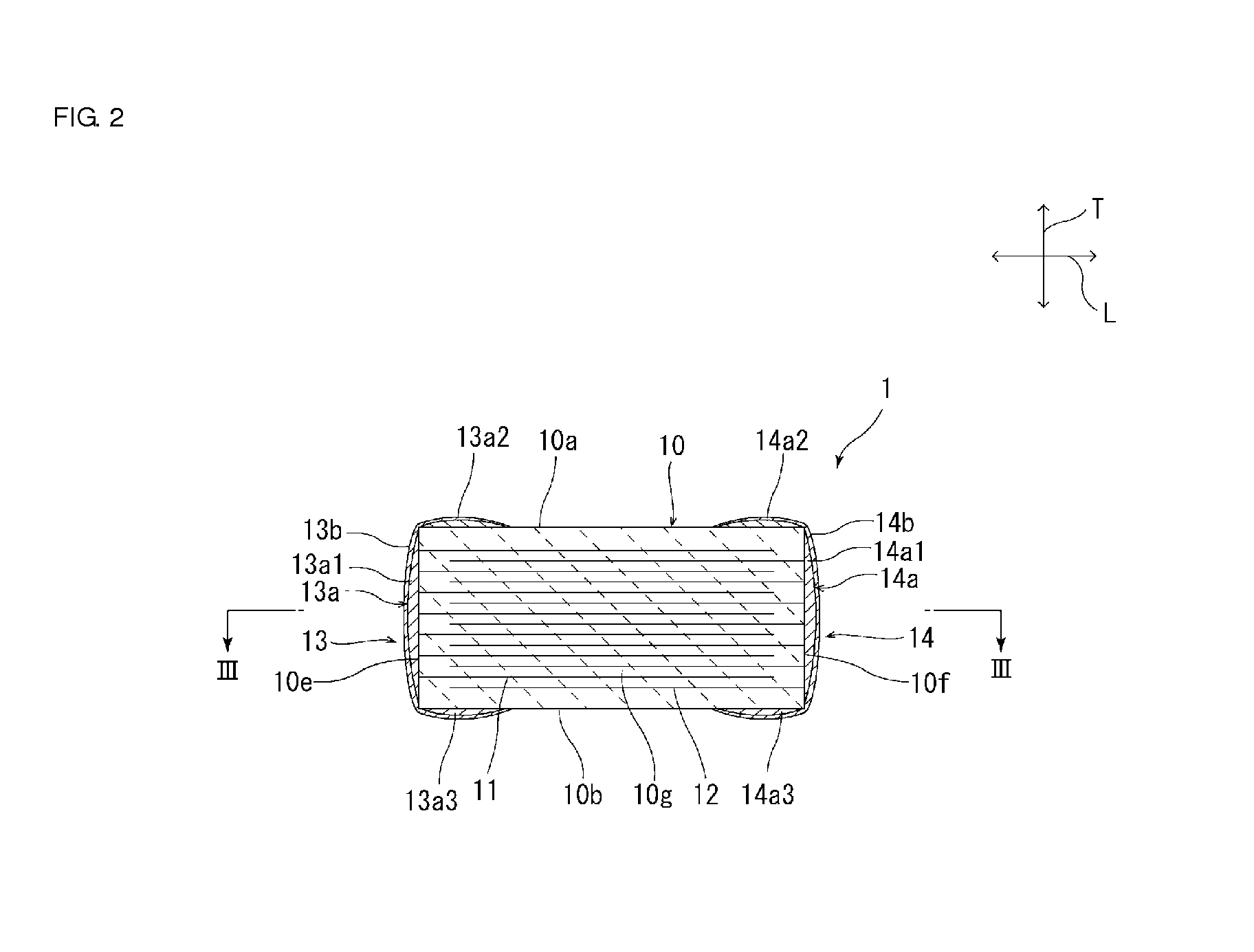

A laminated chip electronic component includes: a ceramic body including internal electrodes and dielectric layers; external electrodes formed to cover both end portions of the ceramic body in a length direction; an active layer in which the internal electrodes are disposed in an opposing manner, while having the dielectric layers interposed therebetween, to form capacitance; and upper and lower cover layers formed on upper and lower portions of the active layer in a thickness direction, the lower cover layer having a thickness greater than that of the upper cover layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method of fabricating vertical structure LEDs

InactiveUS20060071230A1Avoid damageSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialReactive-ion etching

A method of fabricating semiconductor devices, such as GaN LEDs, on insulating substrates, such as sapphire. Semiconductor layers are produced on the insulating substrate using normal semiconductor processing techniques. Trenches that define the boundaries of the individual devices are then formed through the semiconductor layers and into the insulating substrate, beneficially by using inductive coupled plasma reactive ion etching. The trenches are then filled with an easily removed layer. A metal support structure is then formed on the semiconductor layers (such as by plating or by deposition) and the insulating substrate is removed. Electrical contacts, a passivation layer, and metallic pads are then added to the individual devices, and the individual devices are then diced out.

Owner:SUZHOU LEKIN SEMICON CO LTD

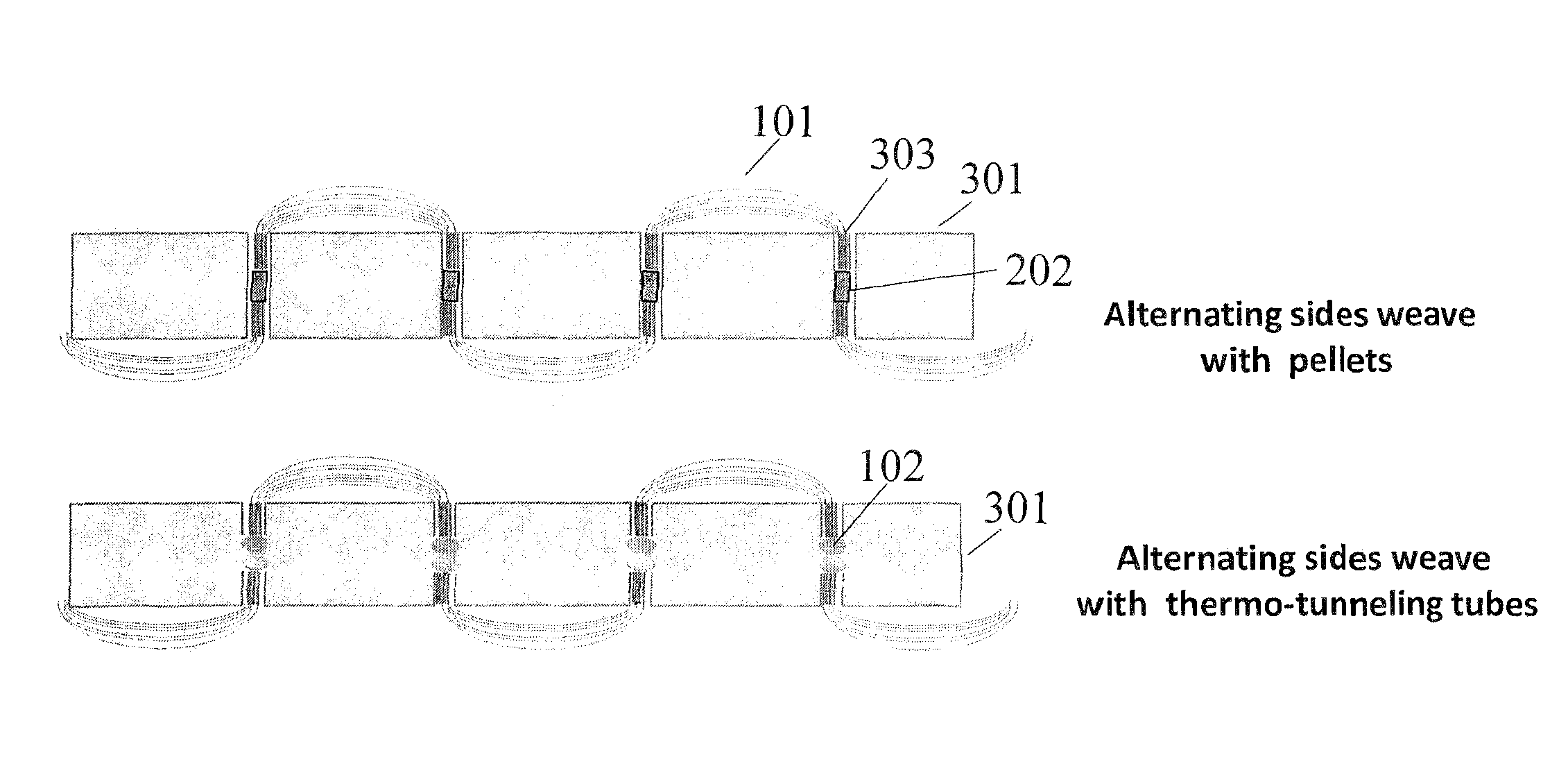

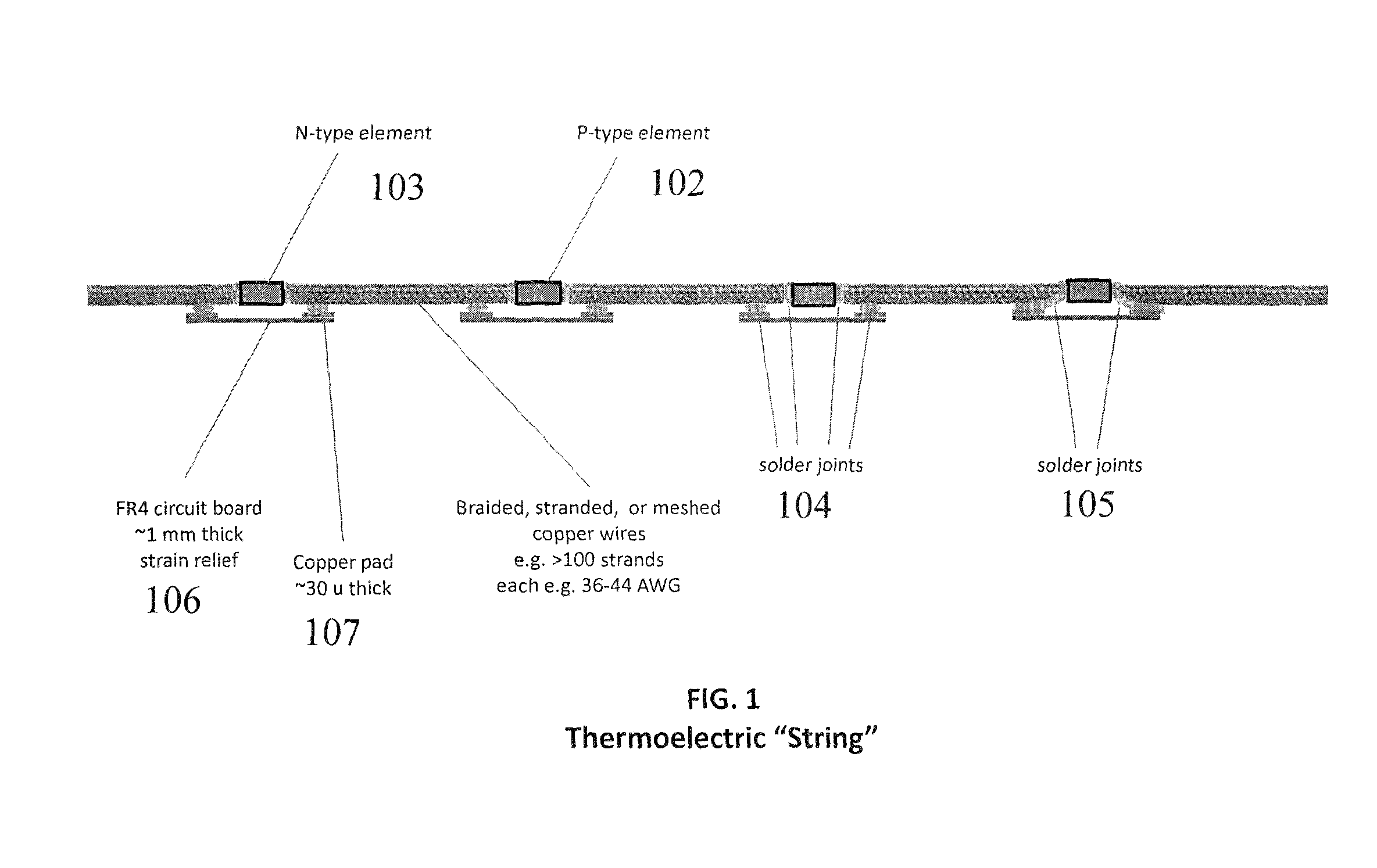

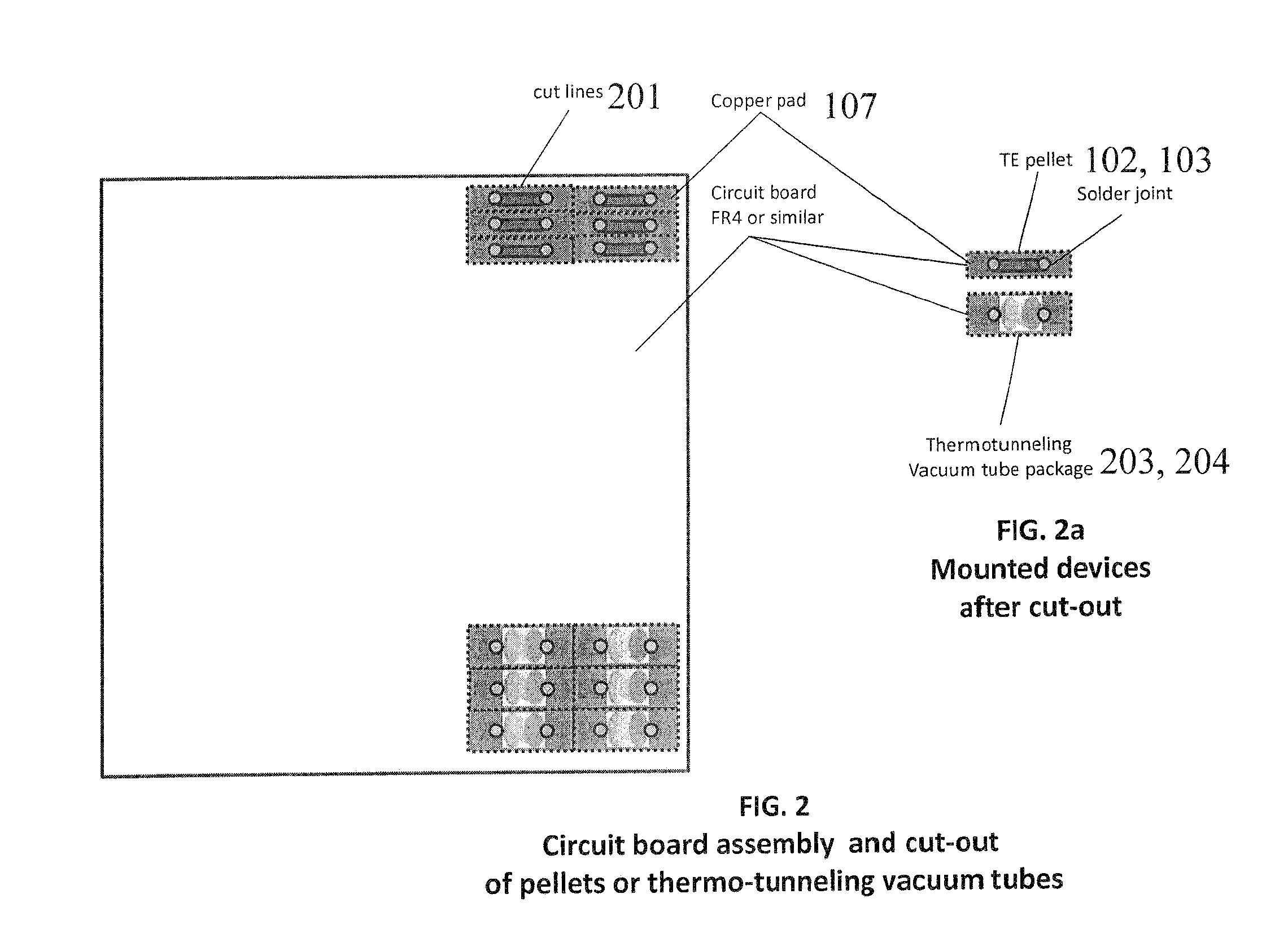

Distributed thermoelectric string and insulating panel

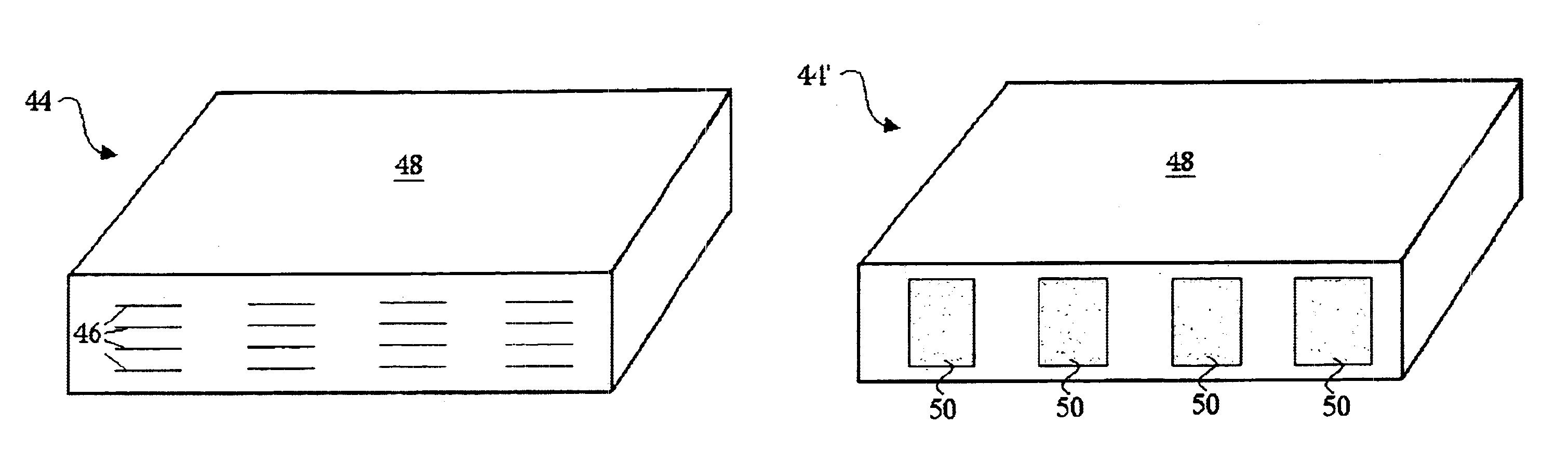

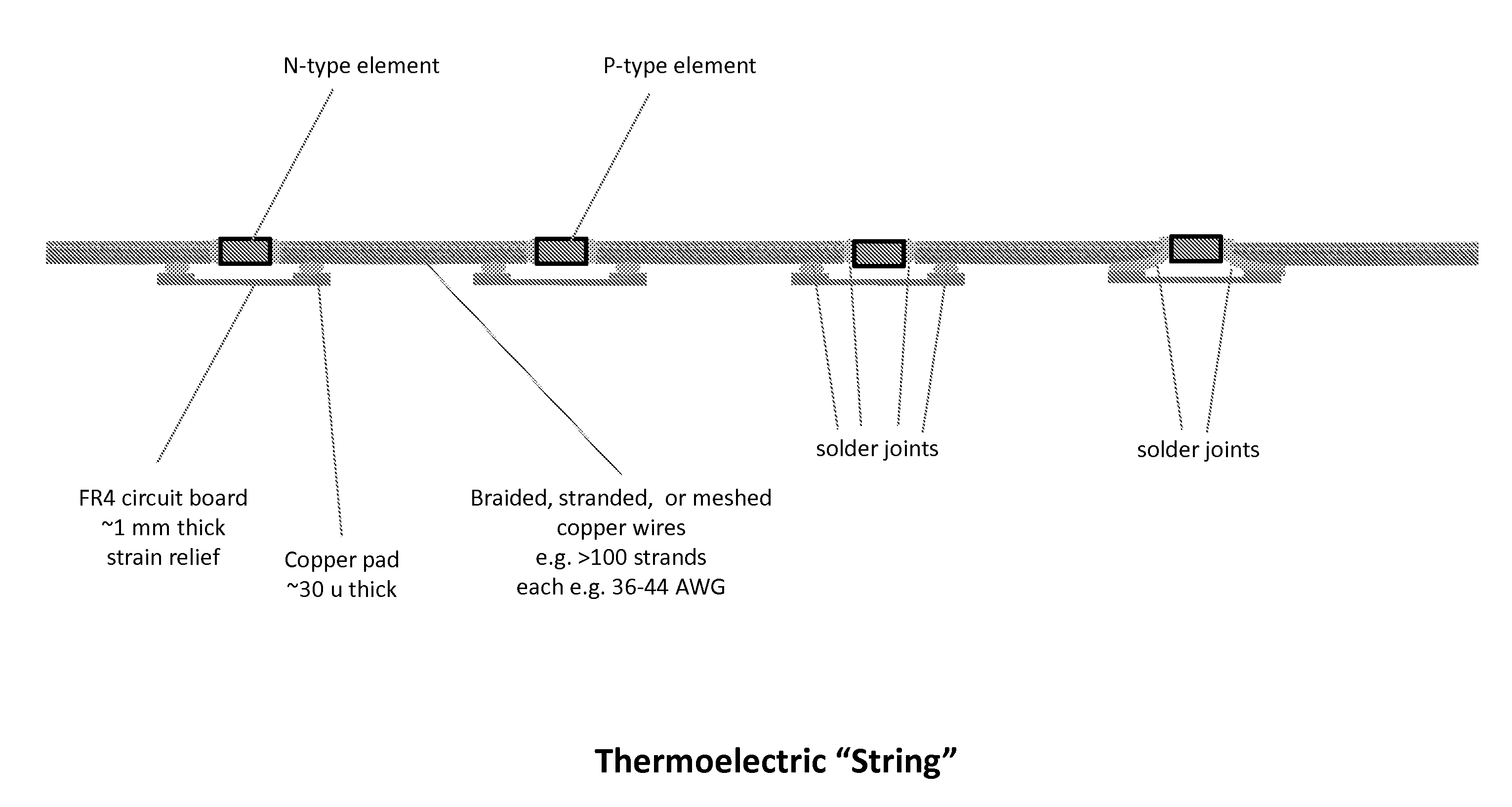

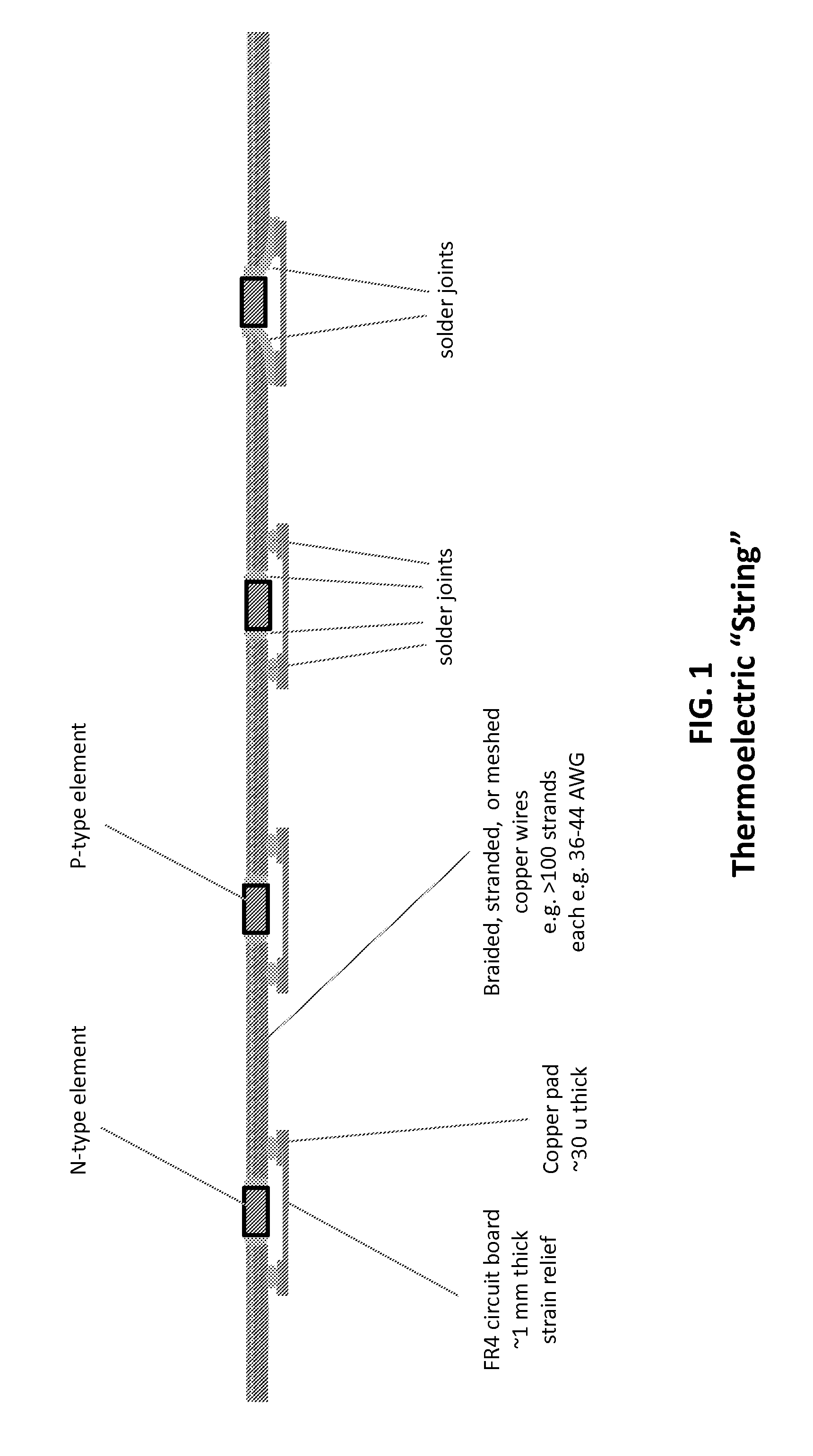

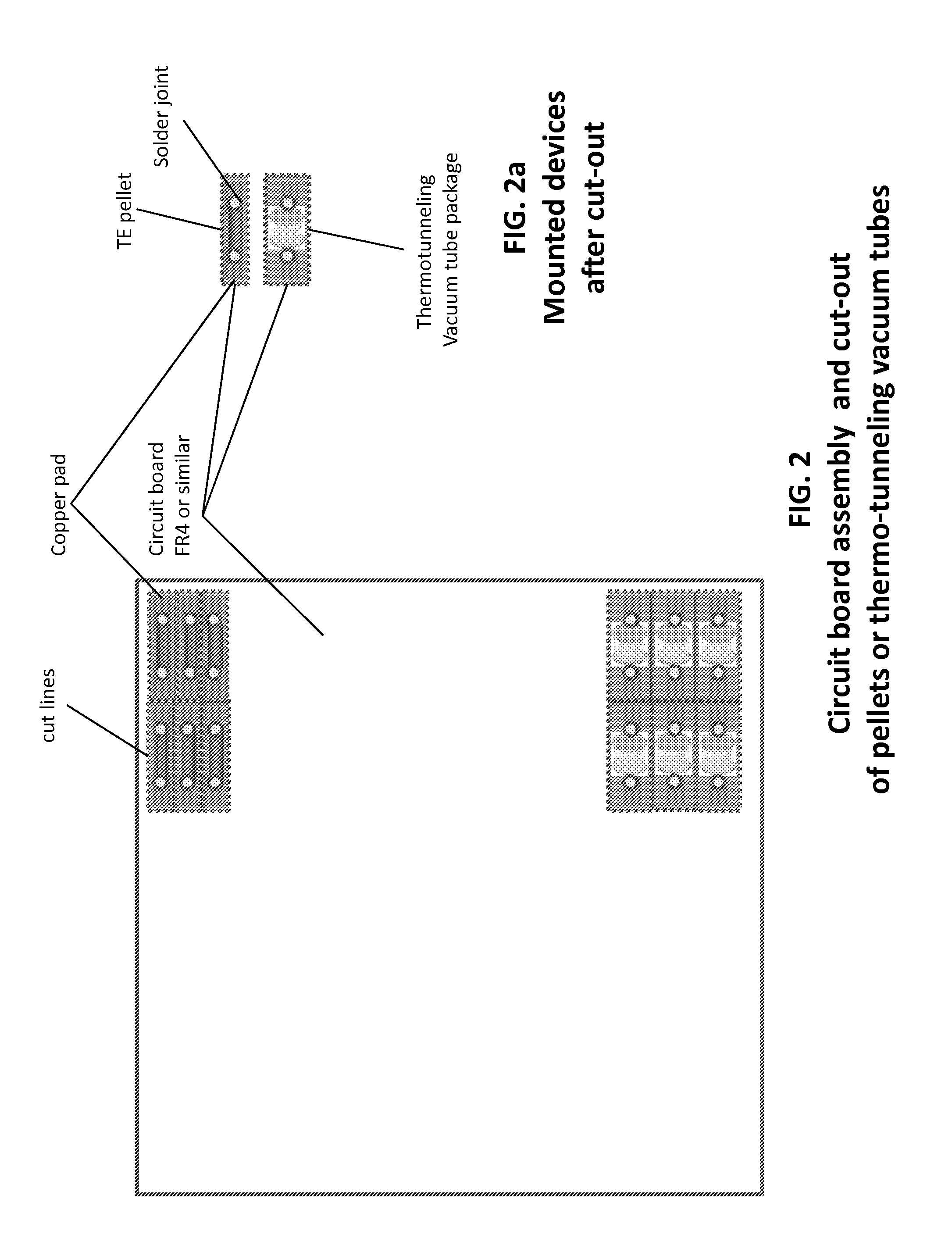

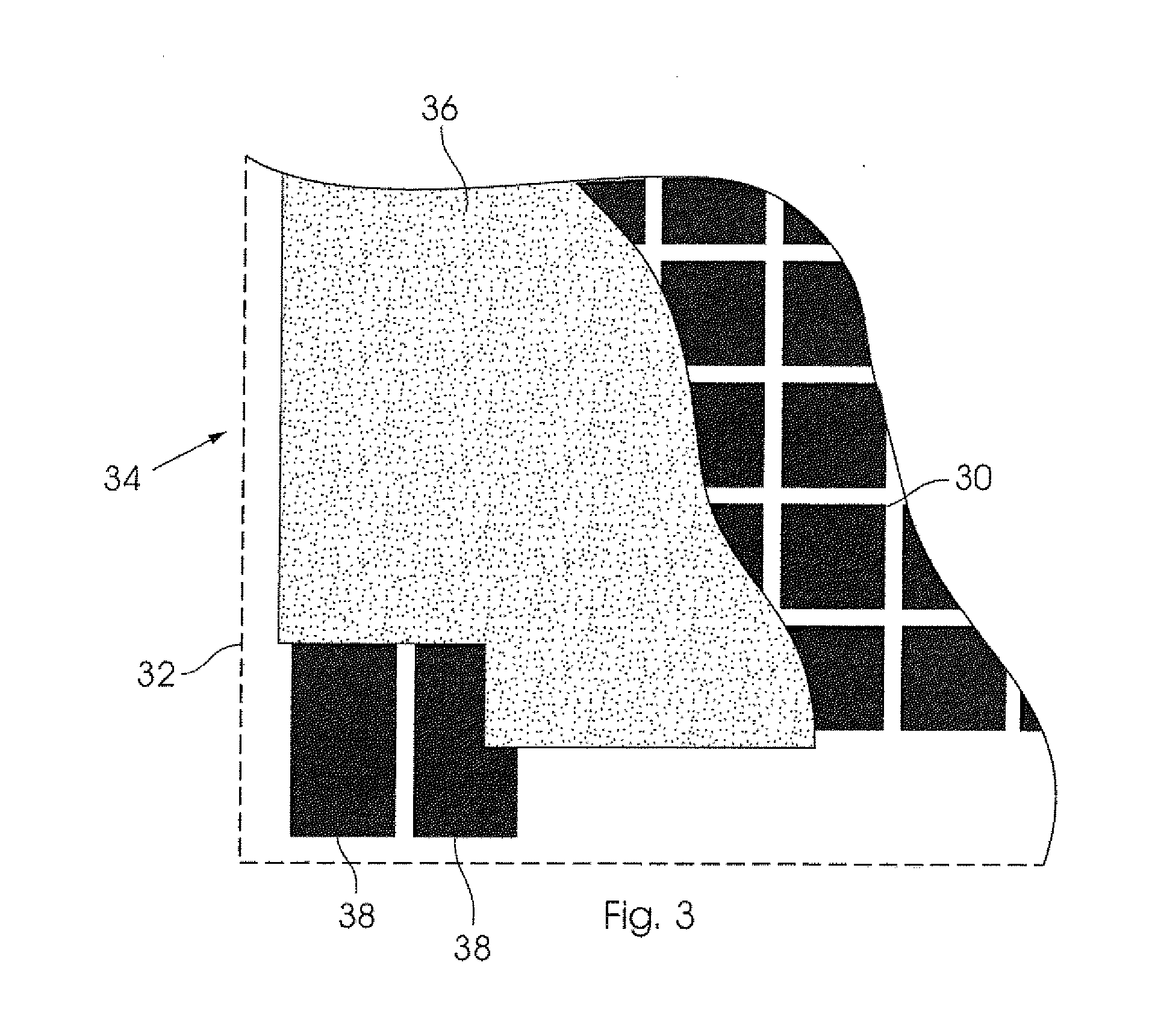

ActiveUS20120060885A1Reduce energy consumptionConserve costOther resistor networksThermoelectric device with peltier/seeback effectCold sideElectrical conductor

Inexpensive, lightweight, flexible heating and cooling panels with highly distributed thermoelectric elements are provided. A thermoelectric “string” is described that may be woven or assembled into a variety of insulating panels such as seat cushions, mattresses, pillows, blankets, ceiling tiles, office partitions, under-desk panels, electronic enclosures, building walls, refrigerator walls, and heat conversion panels. The string contains spaced thermoelectric elements which are thermally and electrically connected to lengths of braided, meshed, stranded, foamed, or otherwise expandable and compressible conductor. The elements and a portion of compacted conductor are mounted within the insulating panel On the outsides of the panel, the conductor is expanded to provide a very large surface area of contact with air or other medium for heat absorption on the cold side and for heat dissipation on the hot side.

Owner:LEAR CORP

Method of manufacturing ceramic electronic component, ceramic electronic component, and wiring board

ActiveUS20120018205A1Minimize changesCharacteristic is prevented and minimizedResistor terminals/electrodesFinal product manufactureConductive pasteMetallurgy

A method of manufacturing a ceramic electronic component prevents variations in characteristics even when the ceramic electronic component is embedded in a wiring board. Ceramic green sheets containing an organic binder having a degree of polymerization in a range from about 1000 to about 1500 are prepared. A first conductive paste layer is formed on a surface of each of the ceramic green sheets. The ceramic green sheets are laminated to form a raw ceramic laminated body. A second conductive paste layer is formed on a surface of the raw ceramic laminated body. The raw ceramic laminated body formed with the second conductive paste layer is fired.

Owner:MURATA MFG CO LTD

Electronic component and method for manufacturing the same

ActiveUS20150084487A1Contact member manufacturingPiezoelectric/electrostriction/magnetostriction machinesInsulation layerOptoelectronics

In an electronic component, an outer electrode includes a sintered layer including a sintered metal, a reinforcement layer not containing Sn but including Cu or Ni, an insulation layer, and a Sn-containing layer. The sintered layer extends from each end surface of an element assembly onto at least one main surface thereof to cover each end surface of the element assembly. The reinforcement layer extends on the sintered layer and covers the sintered layer entirely. The insulation layer is directly provided on the reinforcement layer at each end surface of the element assembly, extends in a direction perpendicular or substantially perpendicular to a side surface of the element assembly, and defines a portion of a surface of the outer electrode. The Sn-containing layer covers the reinforcement layer except for a portion of the reinforcement layer that is covered by the insulation layer, and defines another portion of the surface of the outer electrode.

Owner:MURATA MFG CO LTD

Ceramic electronic component and method for manufacturing the same

ActiveUS20110290542A1Improve reliabilityFixed capacitor electrodesFixed capacitor dielectricSurface layerMetallurgy

A ceramic electronic component includes a ceramic element assembly and external electrodes. The external electrodes are disposed on the ceramic element assembly. The external electrodes include an underlying electrode layer and a first Cu plating film. The underlying electrode layer is disposed on the ceramic element assembly. The first Cu plating film is disposed on the underlying electrode layer. The underlying electrode layer includes a metal that is diffusible in Cu and a ceramic bonding material. The metal that is diffusible in Cu is diffused in at least a surface layer in the underlying electrode layer side of the first Cu plating film.

Owner:MURATA MFG CO LTD

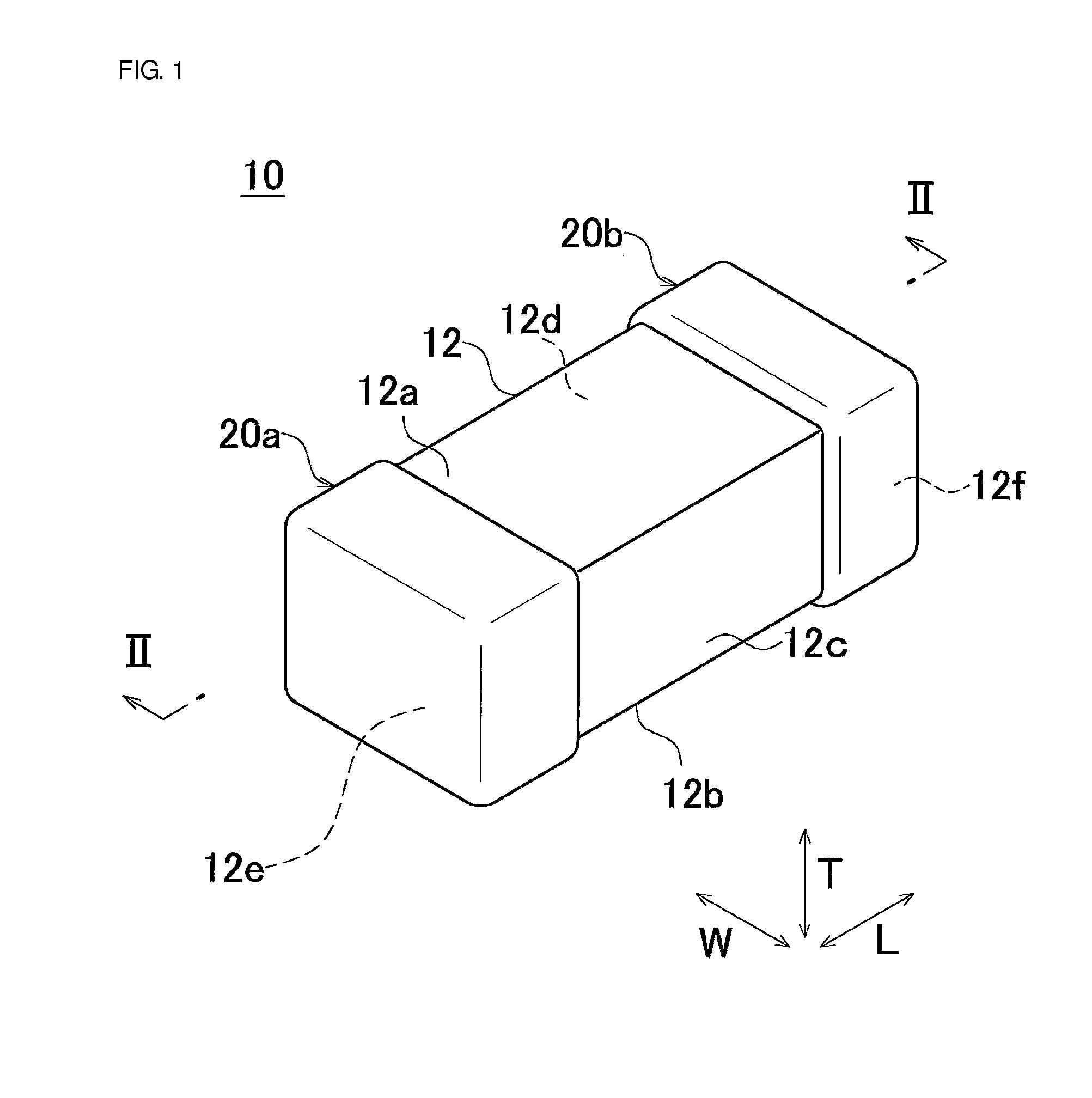

Ceramic electronic component

ActiveUS20150054388A1High melting pointLow melting pointPiezoelectric/electrostriction/magnetostriction machinesCurrent responsive resistorsBond interfaceAlloy

A ceramic electronic component includes an electronic component body and first and second metal terminals. The electronic component body includes a bare ceramic body and first and second outer electrodes. The first and second outer electrodes of the electronic component body are connected respectively to the first and second metal terminals by solders containing Sn as a main constituent. An alloy layer containing Ni—Sn is provided in at least a portion of a bonding interface between adjacent two of the first and second metal terminals and the first and second outer electrodes.

Owner:MURATA MFG CO LTD

Ceramic electronic component

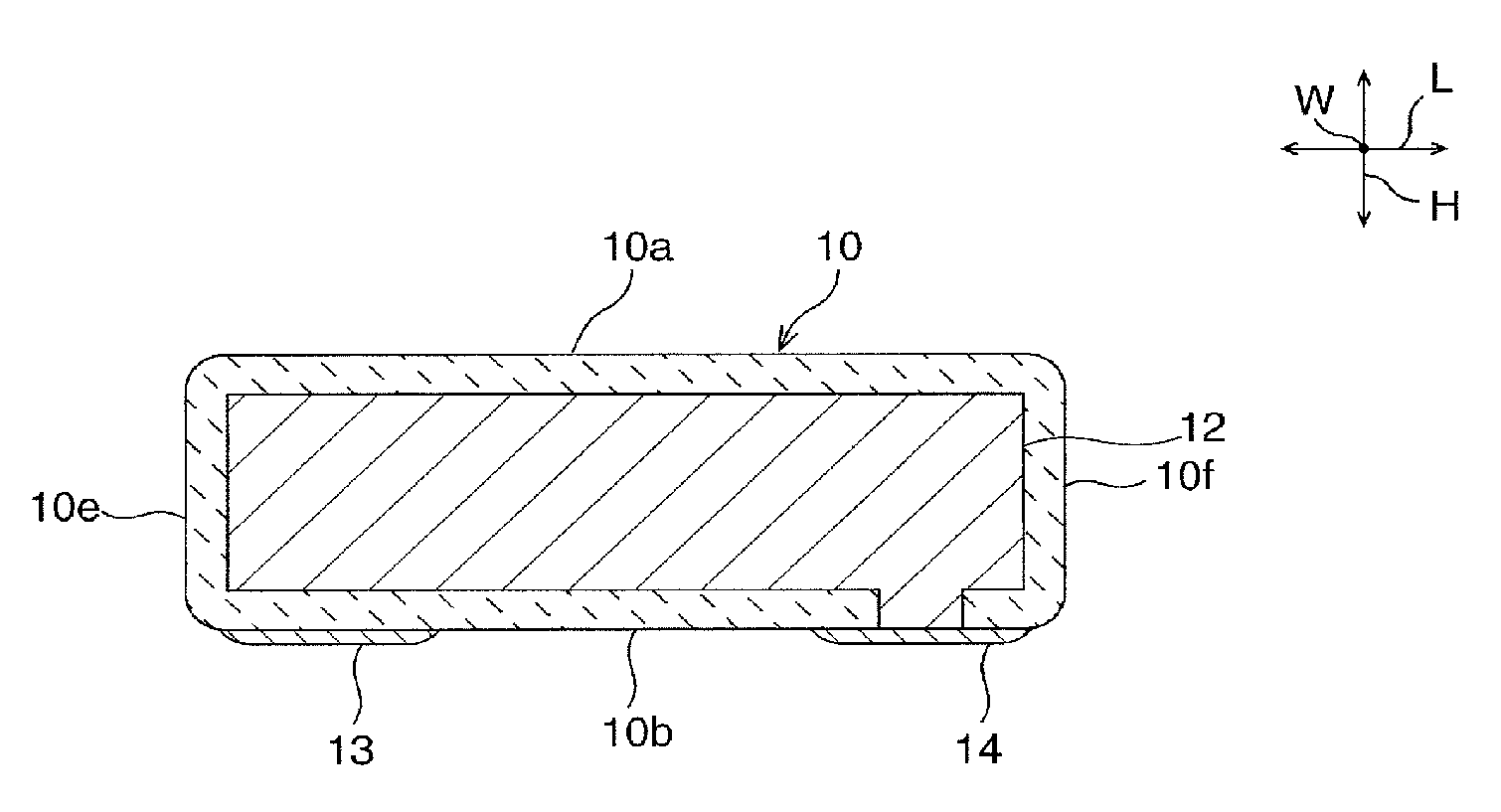

ActiveUS20160099106A1Avoid crackingReduce residual stressPiezoelectric/electrostriction/magnetostriction machinesFixed capacitor electrodesElectrical conductorMetallurgy

A ceramic electronic component includes a laminated body including ceramic layers and conductor layers stacked alternately; and first and second external electrodes provided on portions of the laminated body. Each of the first and second external electrodes includes a sintered metal layer provided on the laminated body, a conductive resin layer covering the sintered metal layer, and a plated layer covering the conductive resin layer. The maximum length of the sintered metal layer provided on the second principal surface is shorter than the maximum length of the sintered metal layer provided on each of the first and second side surfaces.

Owner:MURATA MFG CO LTD

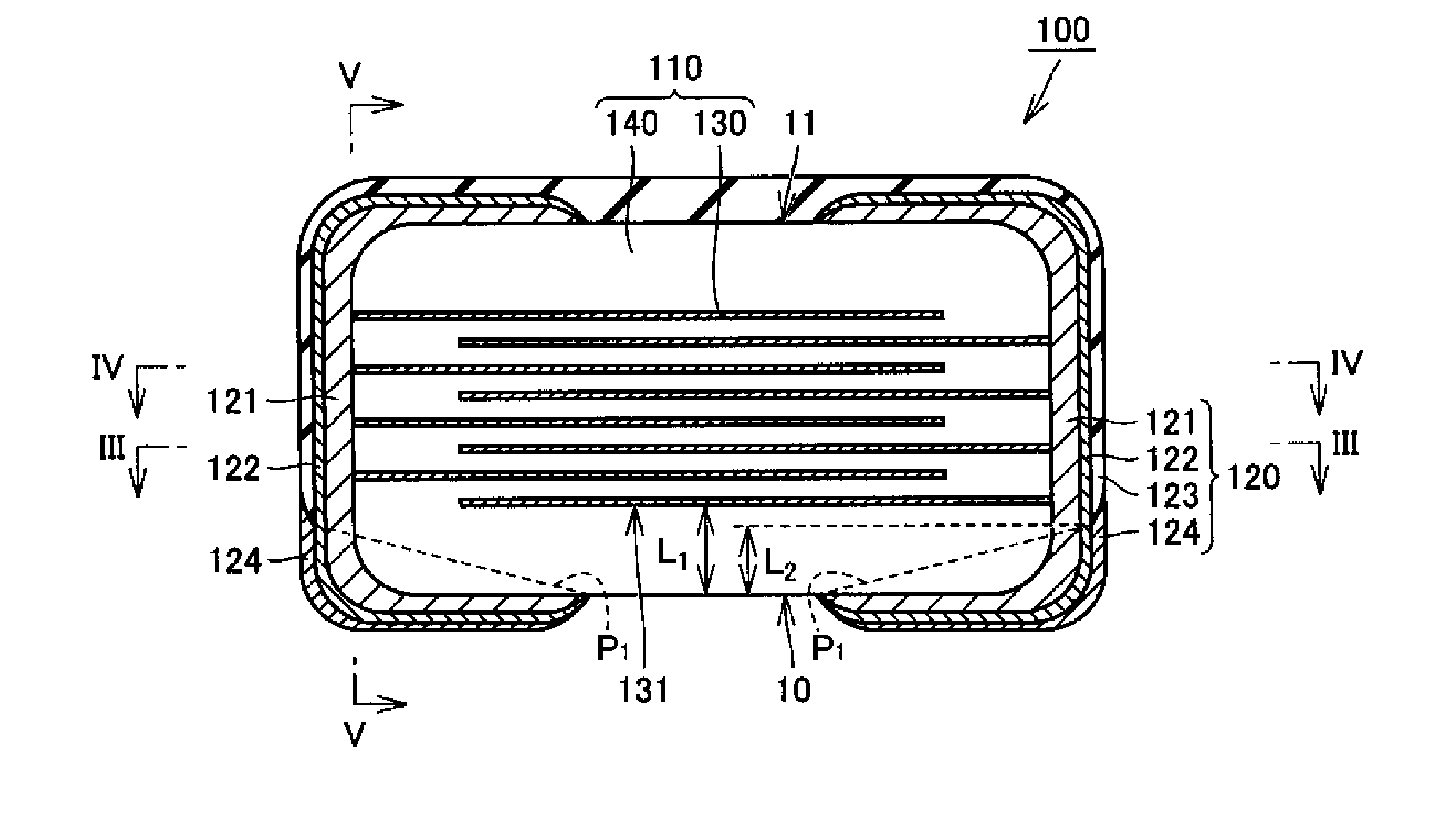

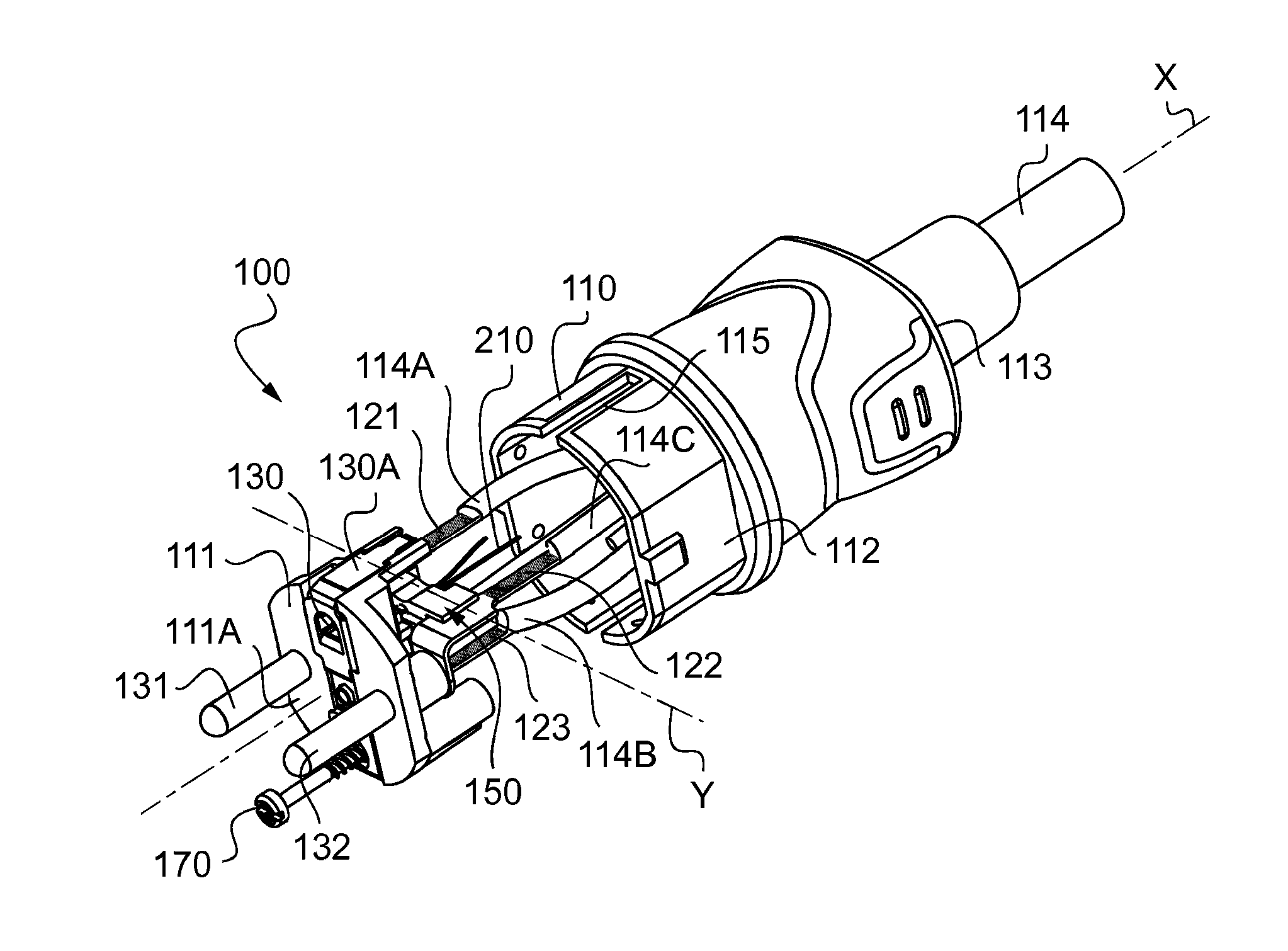

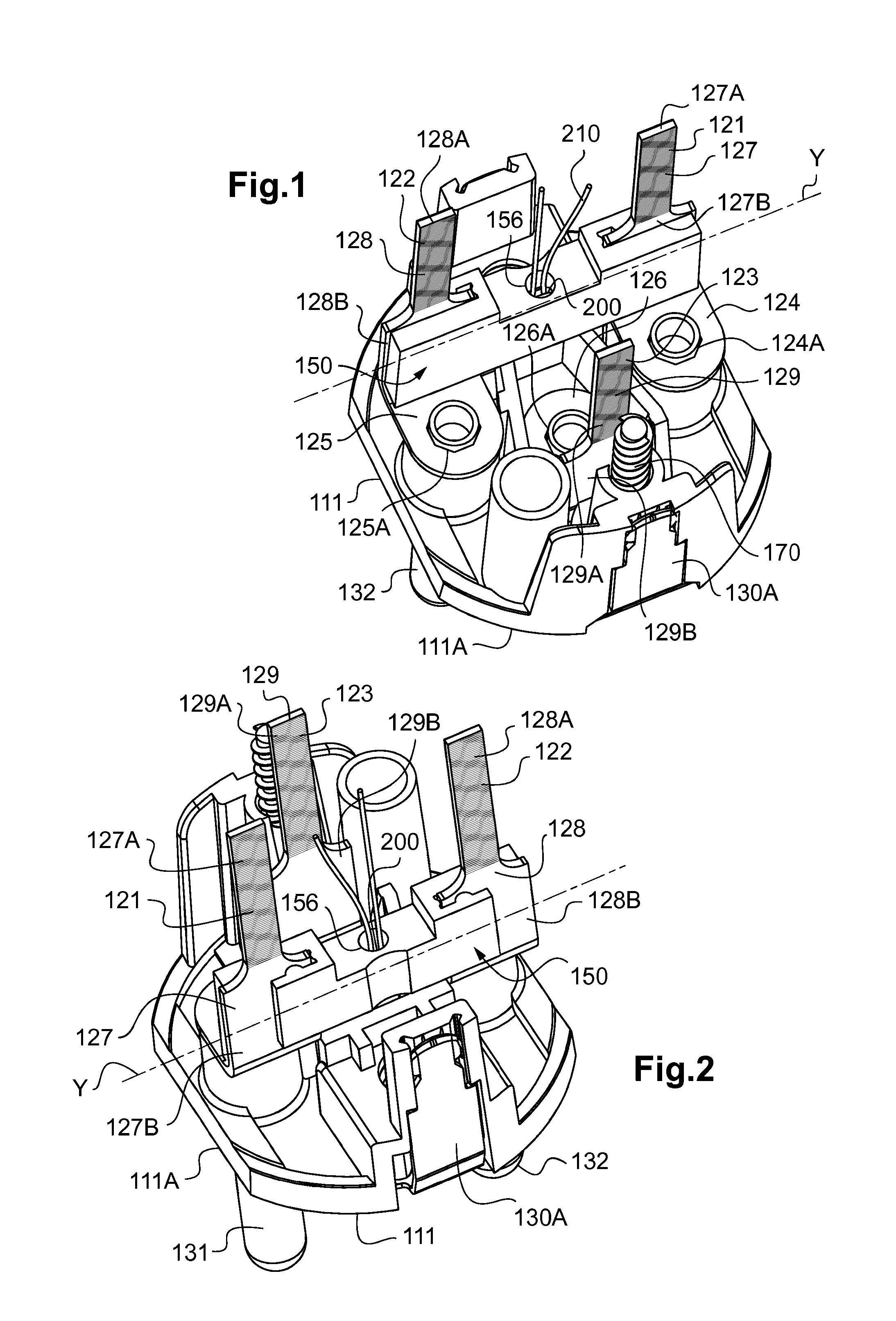

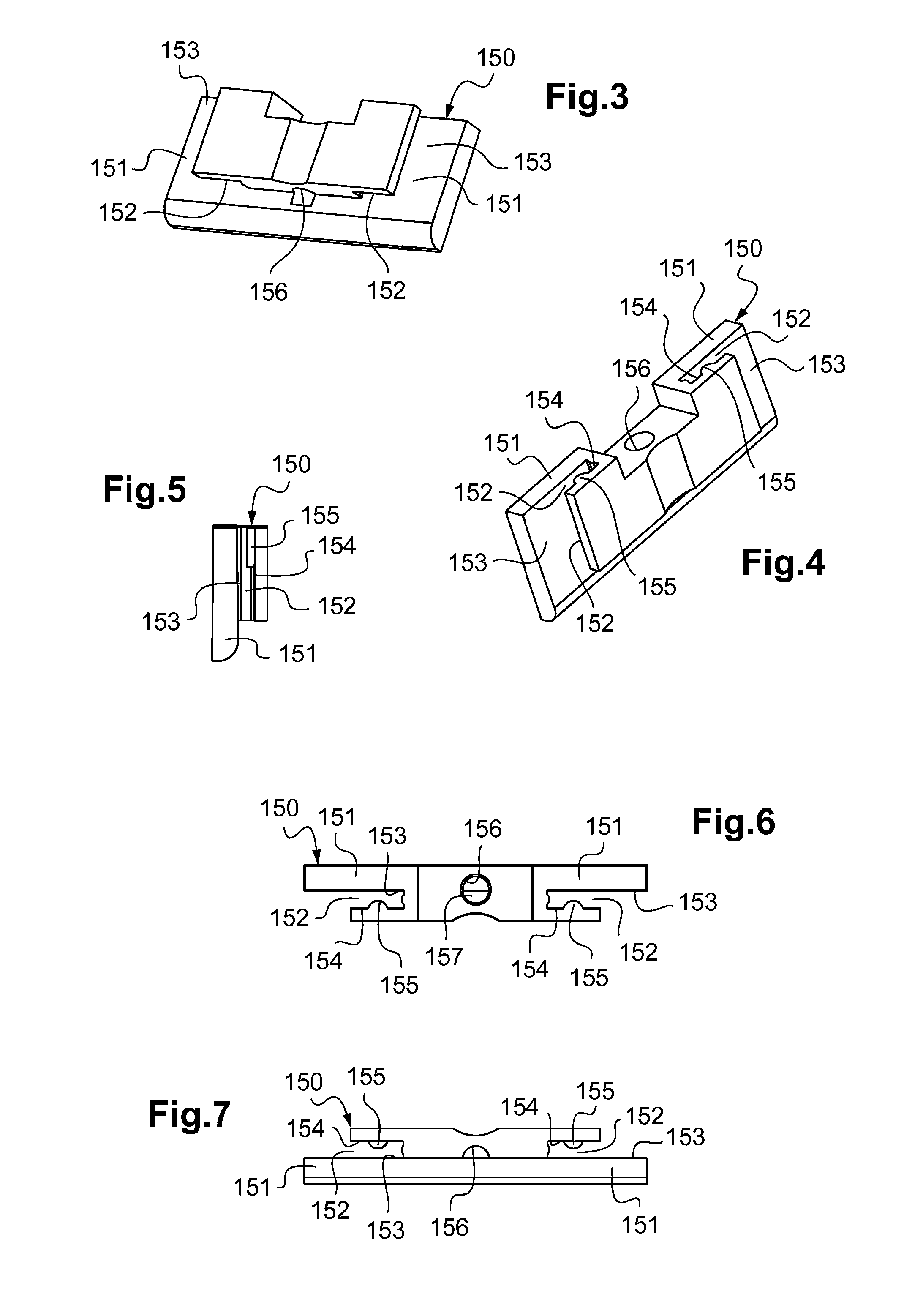

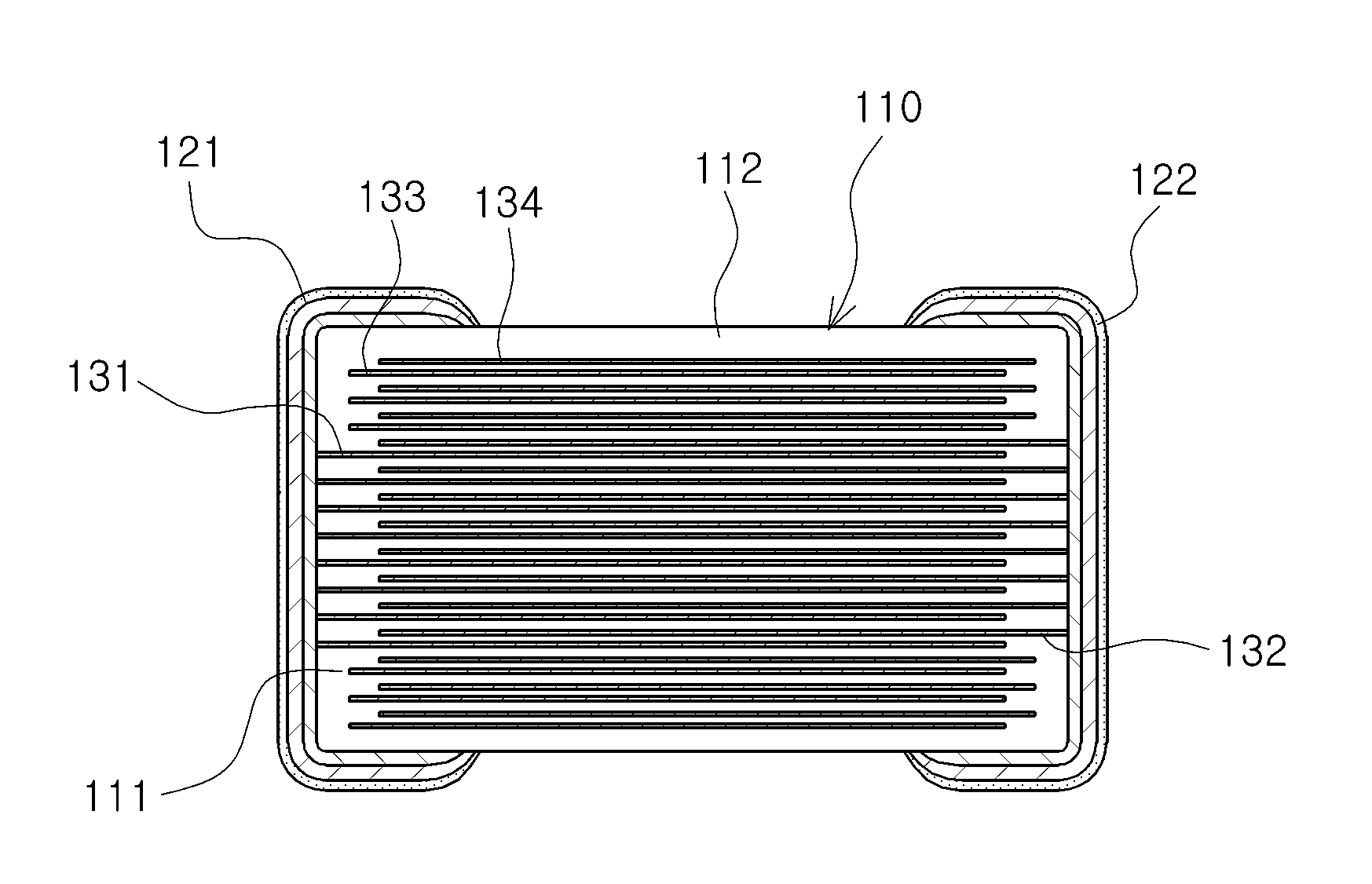

Electrical apparatus comprising a temperature sensor housed in a support element

ActiveUS20160104978A1Precise positioningEasily reproducibleThermometer detailsTemperature measurement in motorsElectricityElectrical connection

The invention relates to an electrical apparatus (100) comprising an electrically insulating body (110) housing at least two electrical connection elements (121, 122, 123), and a temperature sensor (200). According to the invention, the temperature sensor is received in a thermally conductive and electrically insulating support element (150) which is separate from said body and mounted inside said body, so as to extend between said electrical connection elements, set back from the outer faces of said body.

Owner:LEGRAND SNC

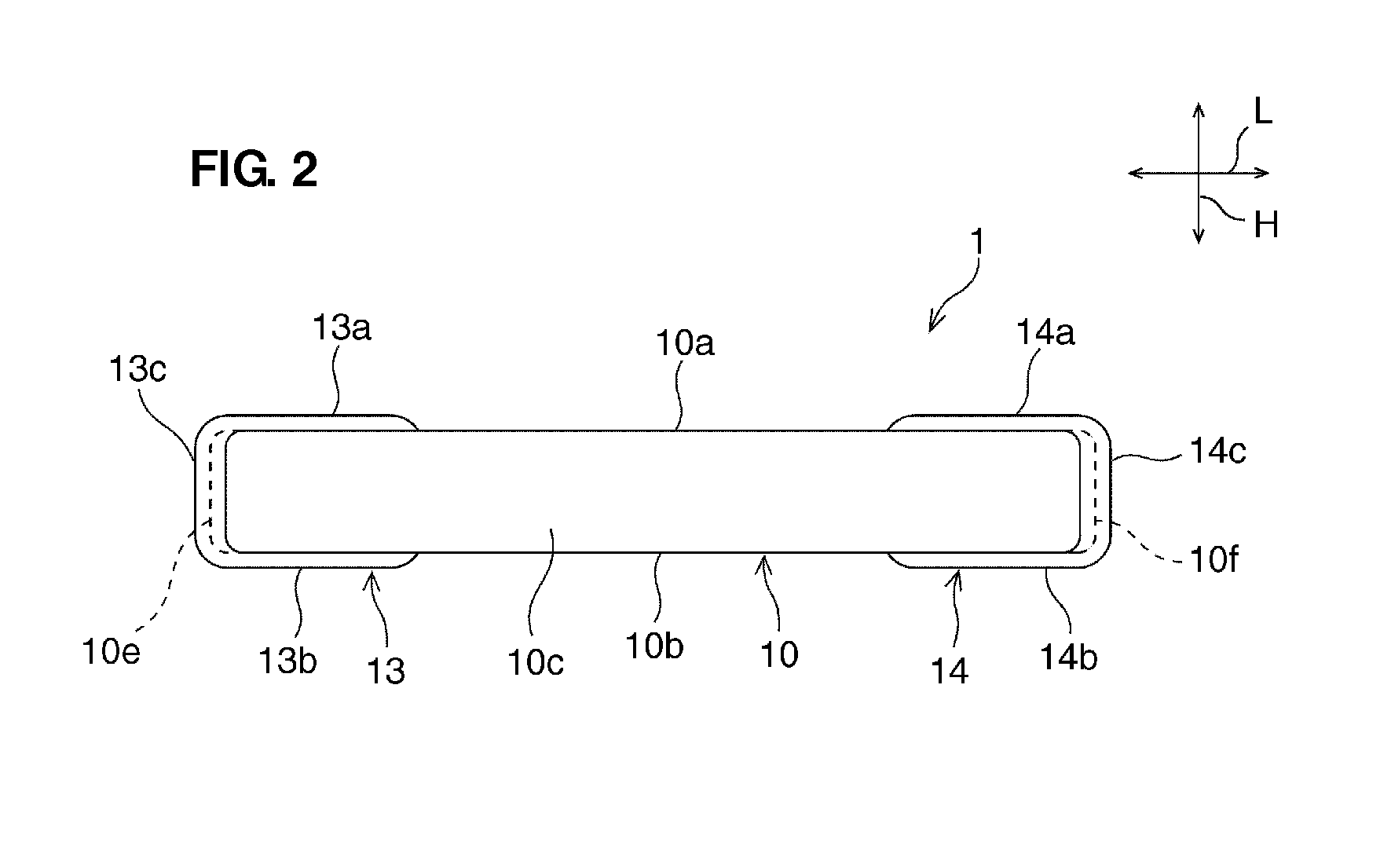

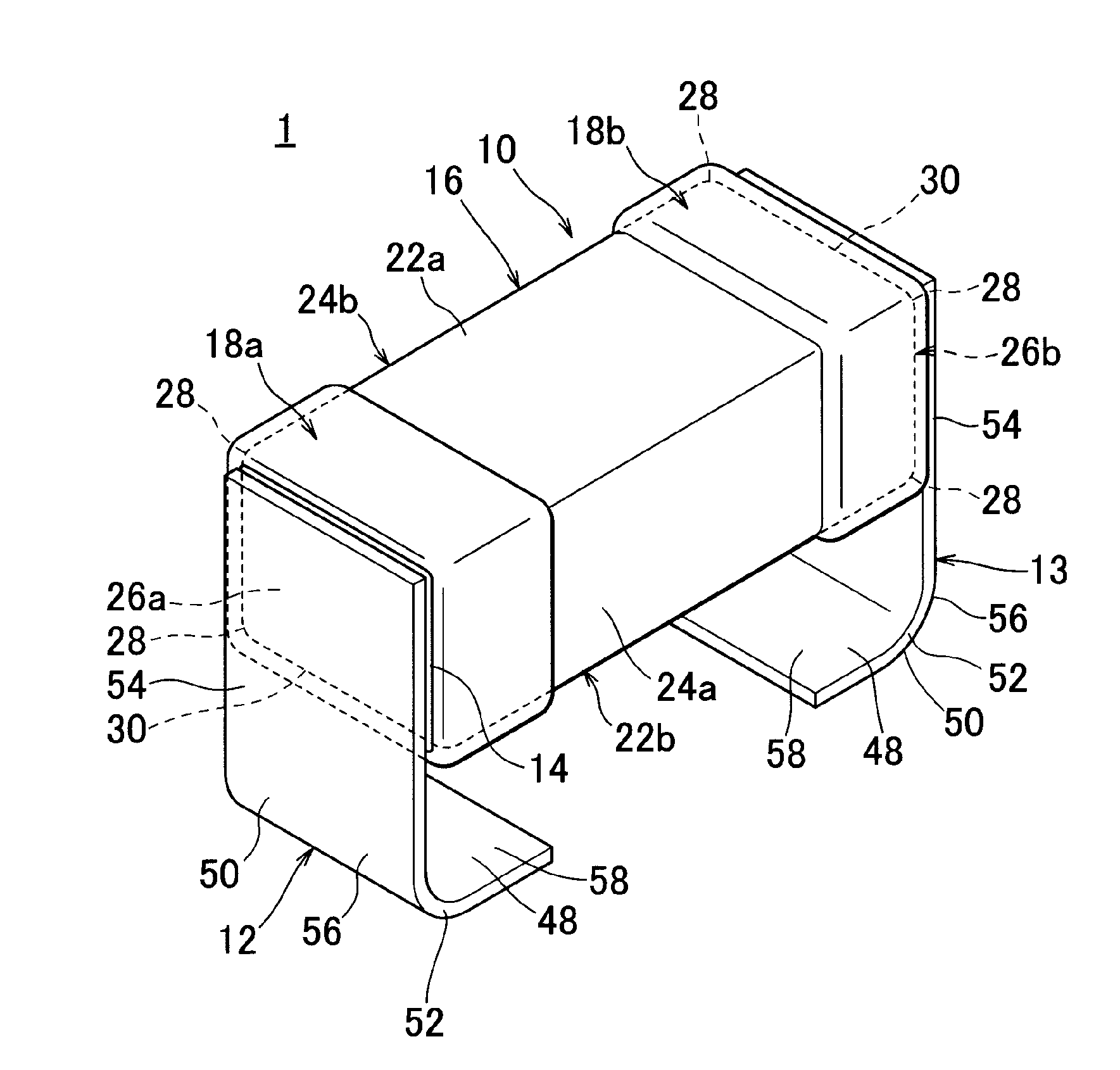

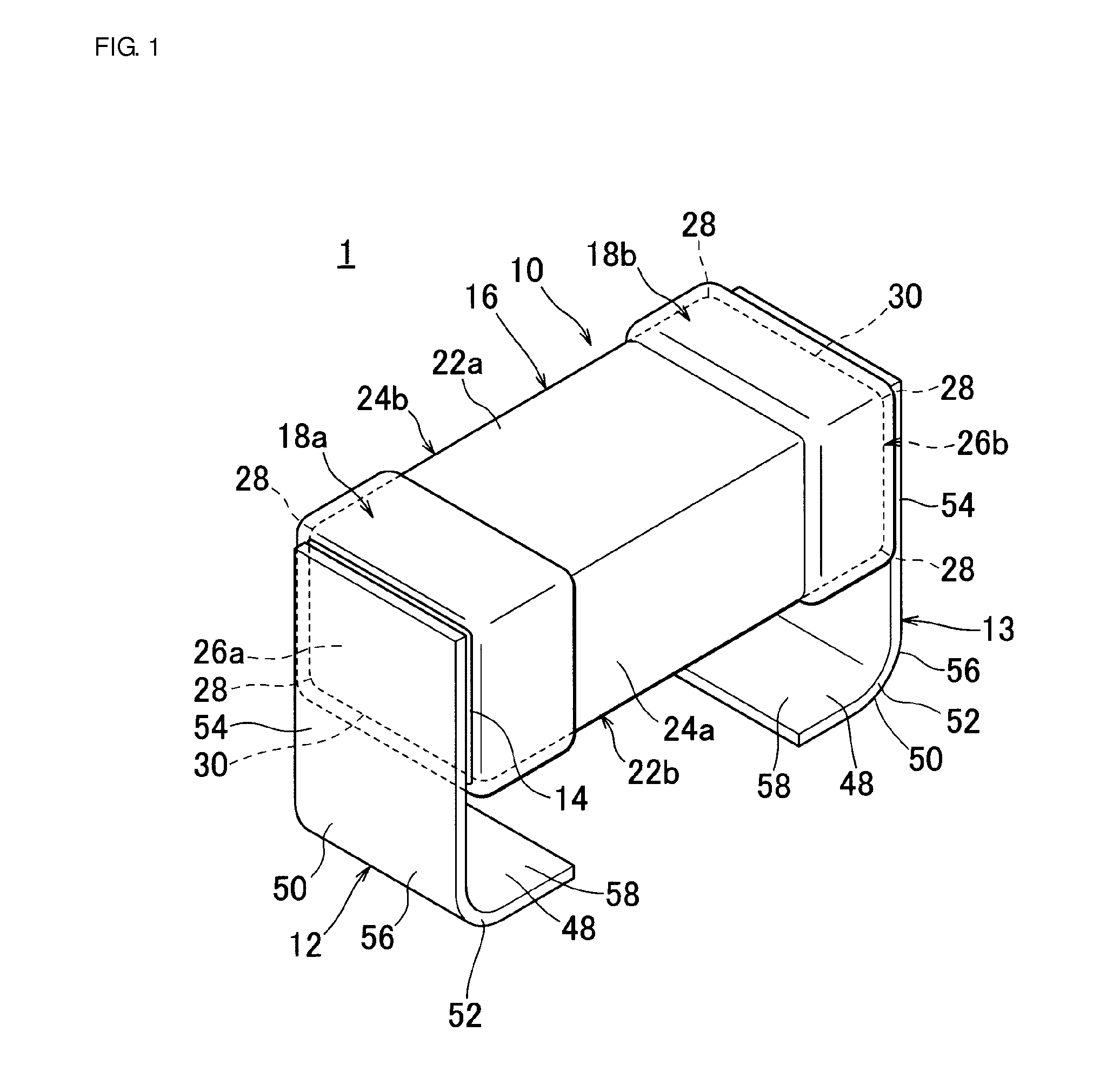

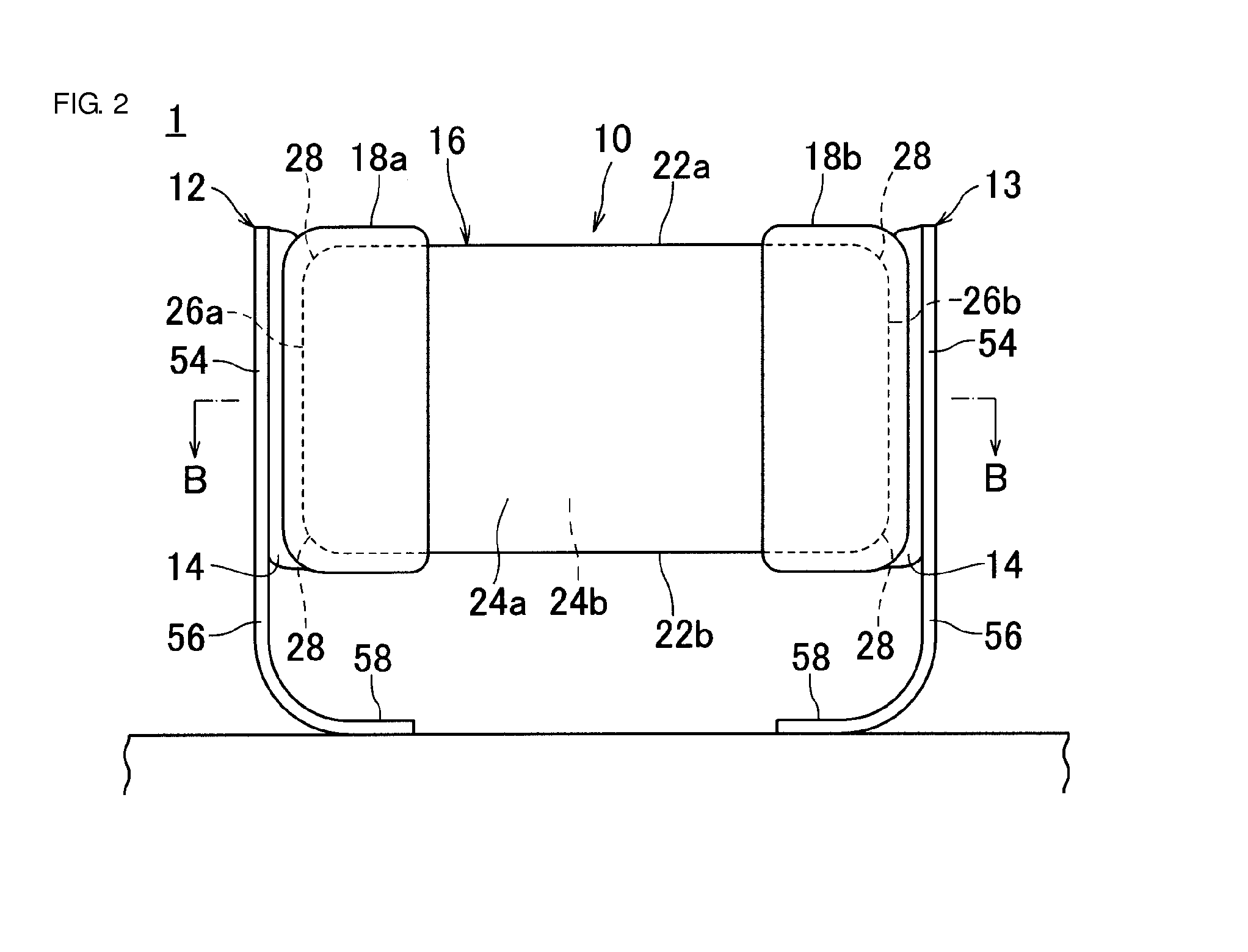

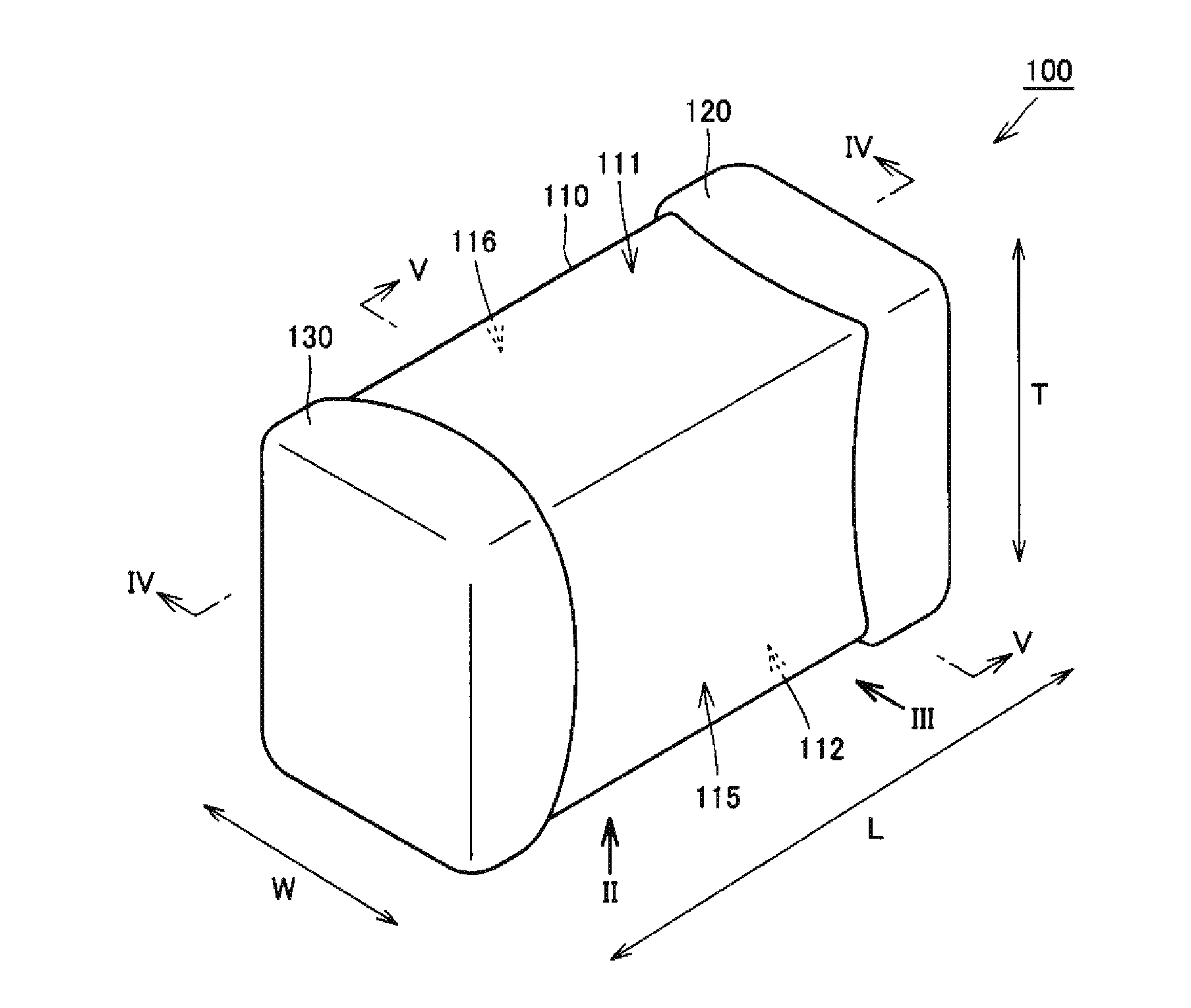

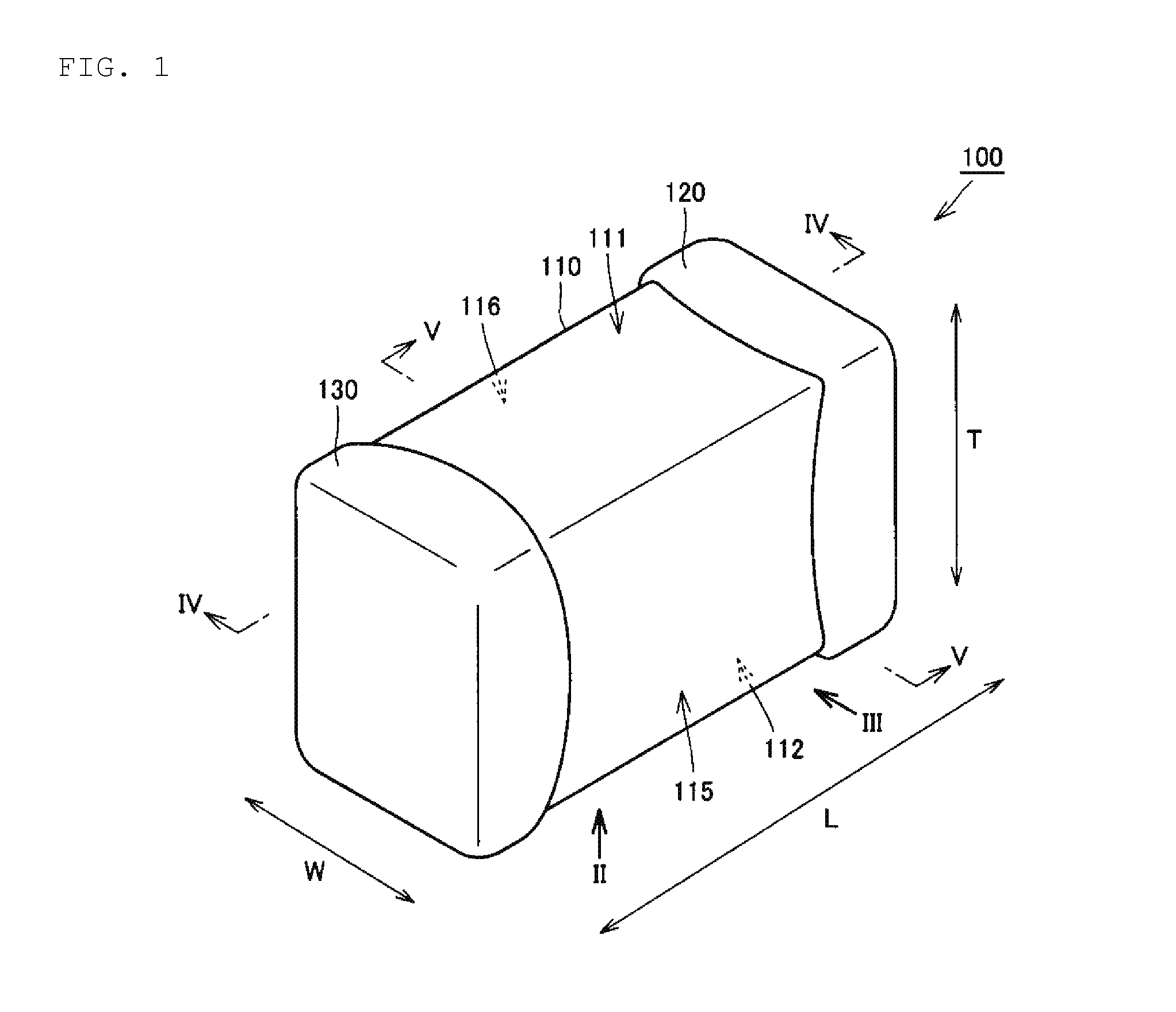

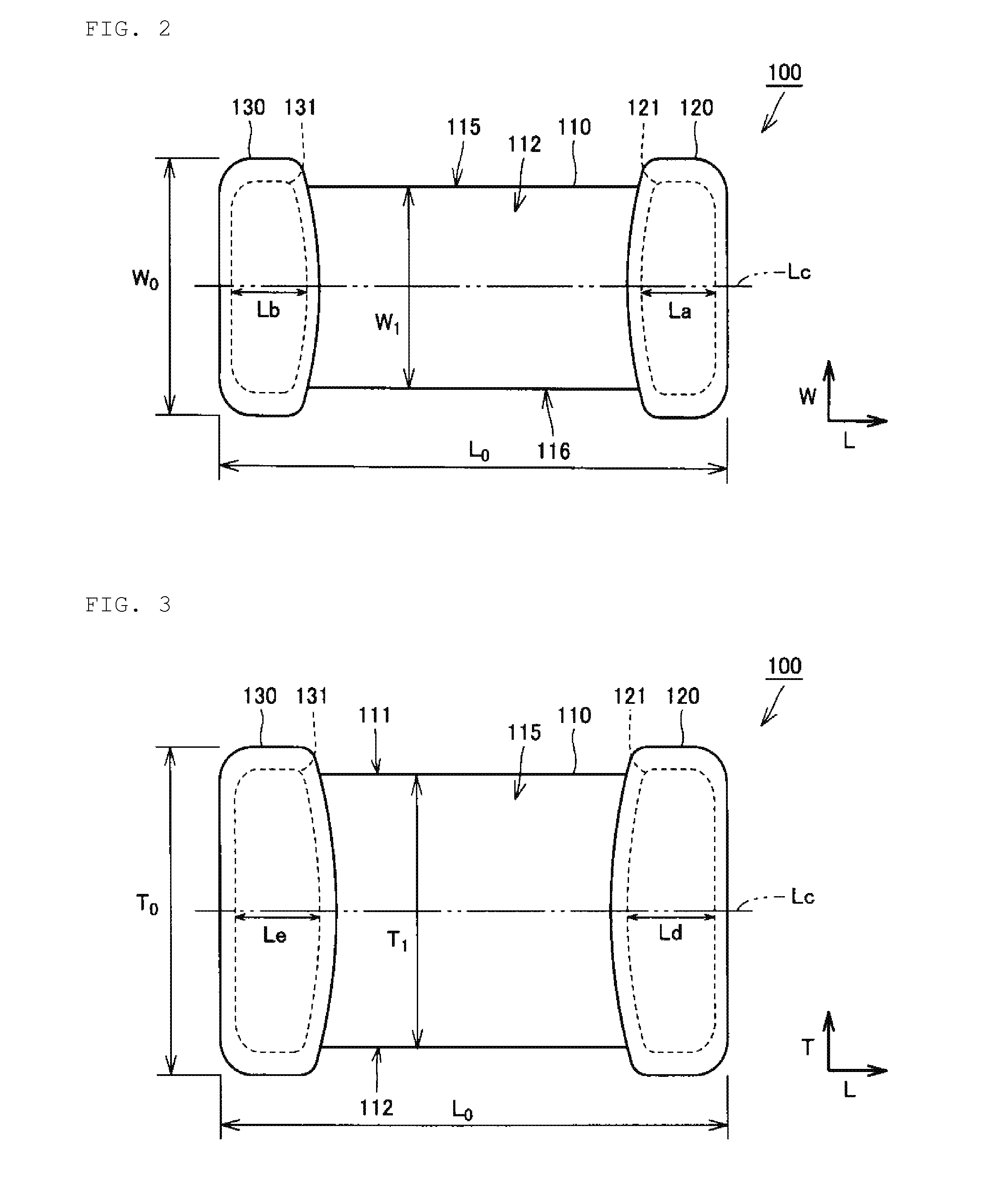

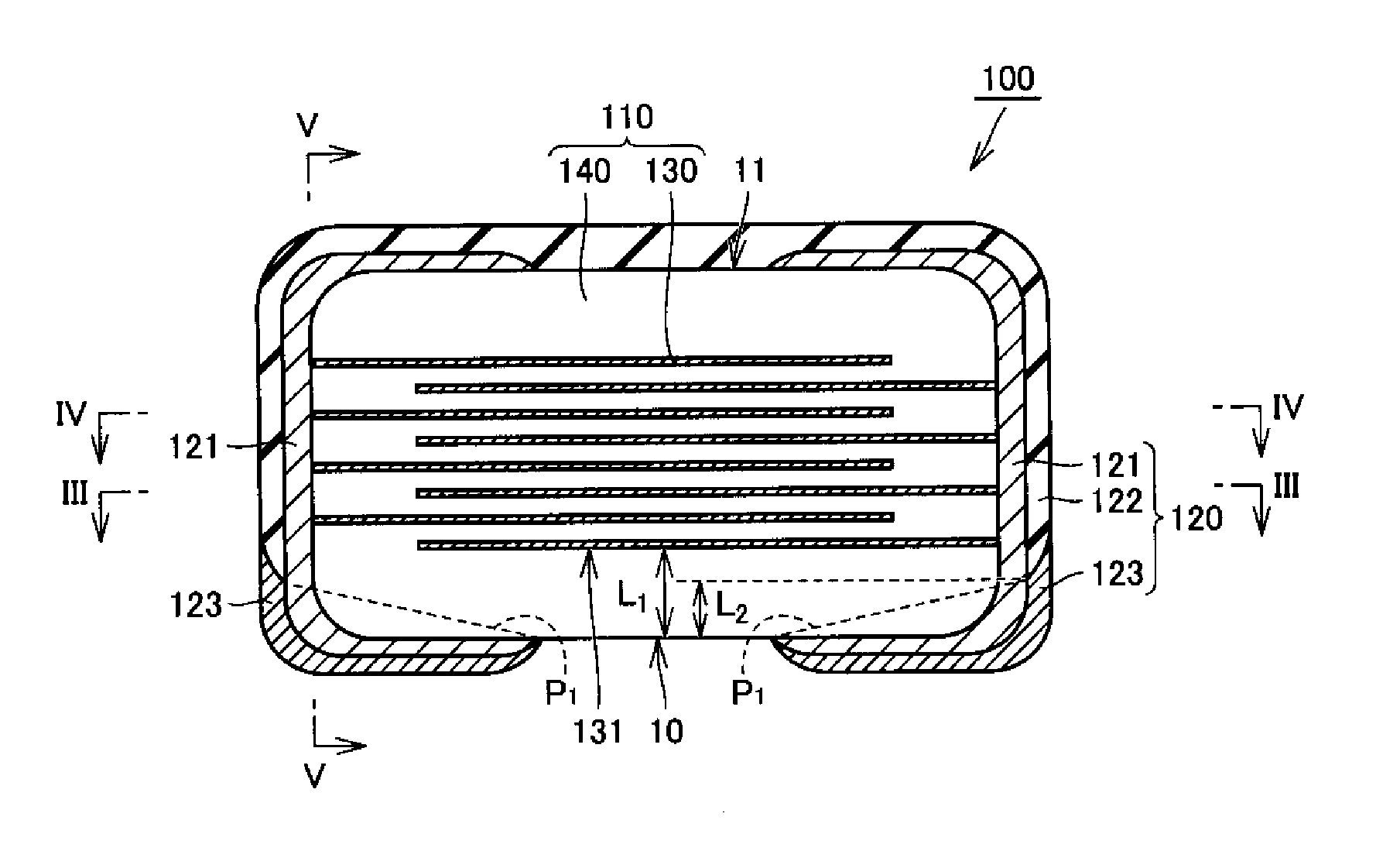

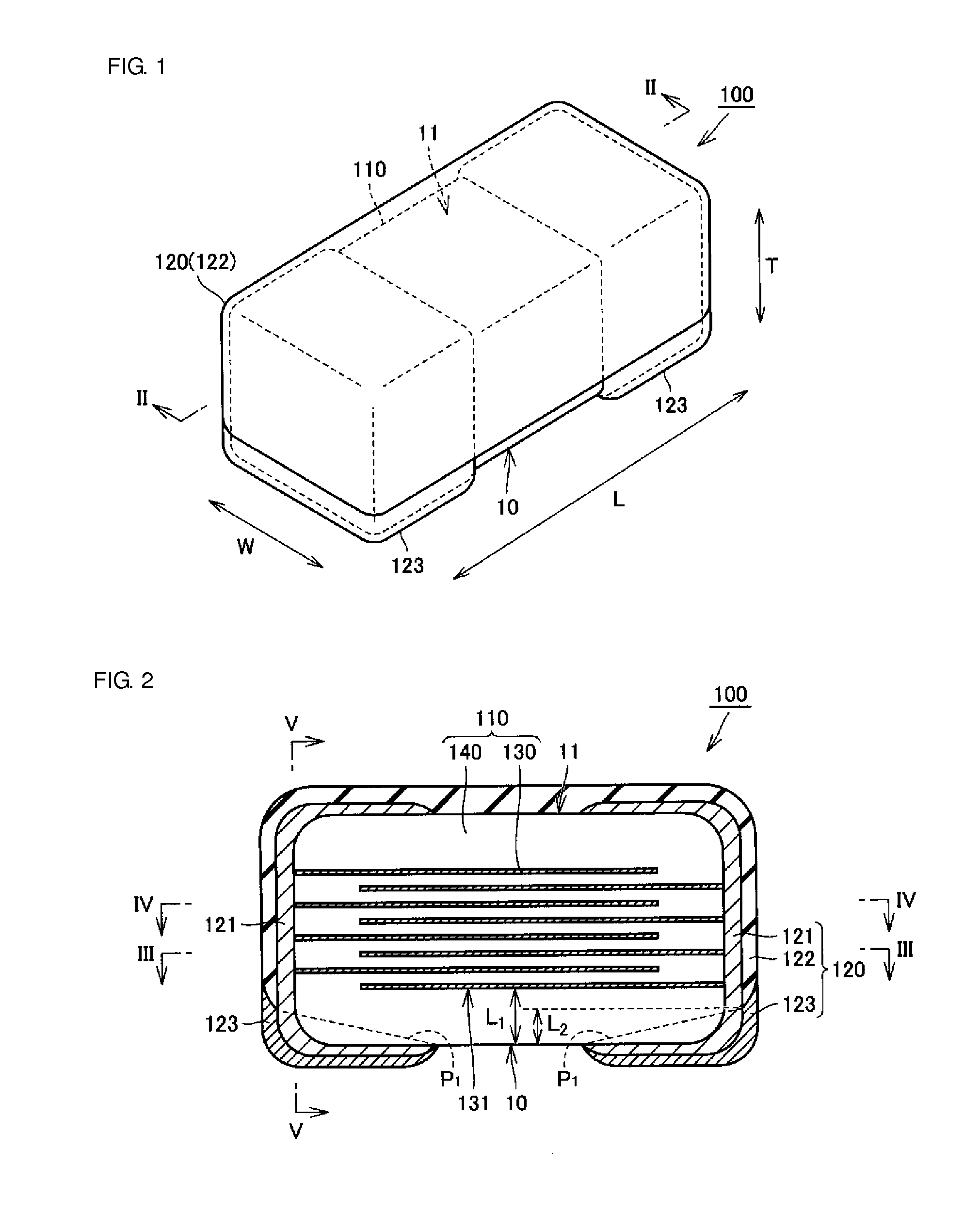

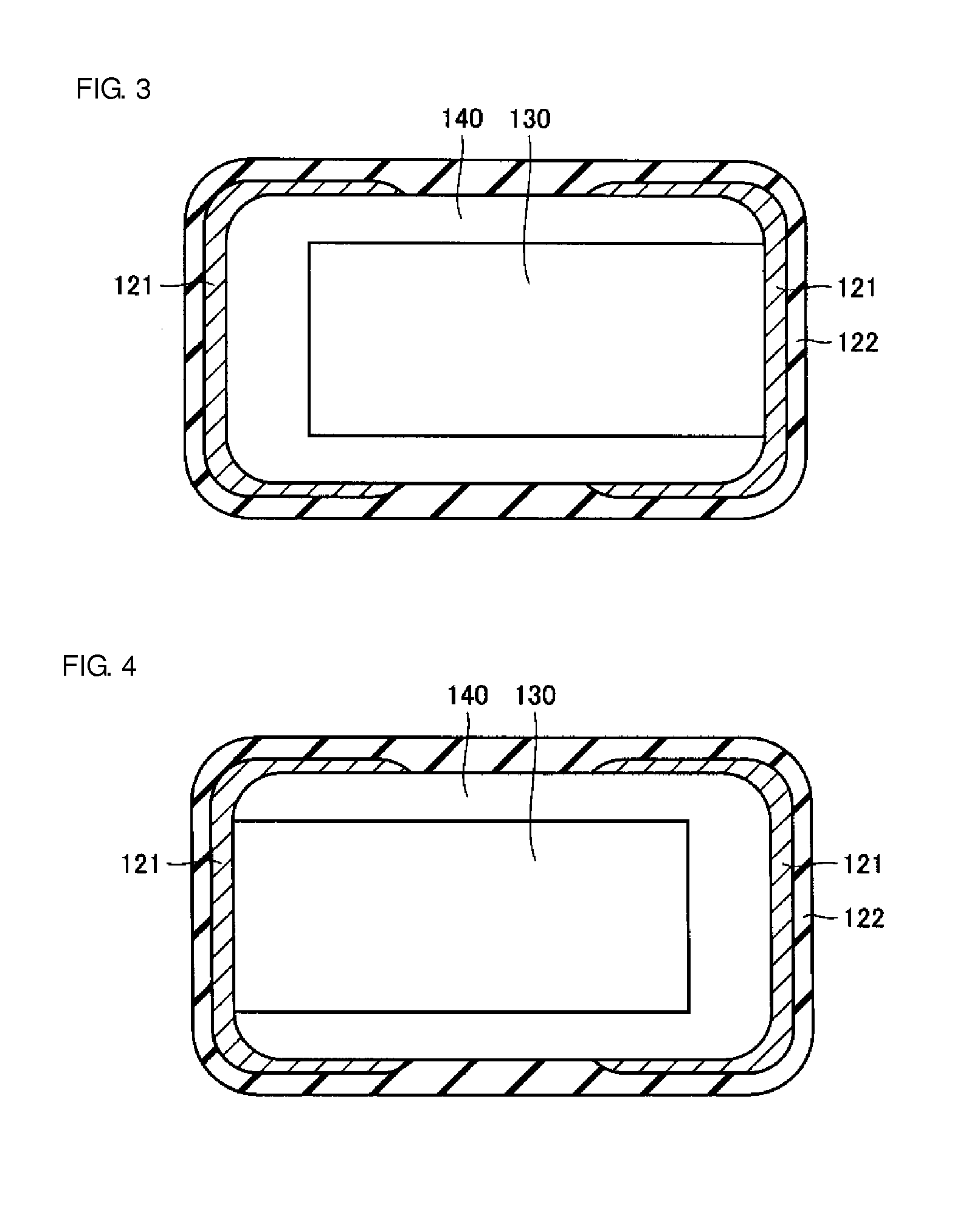

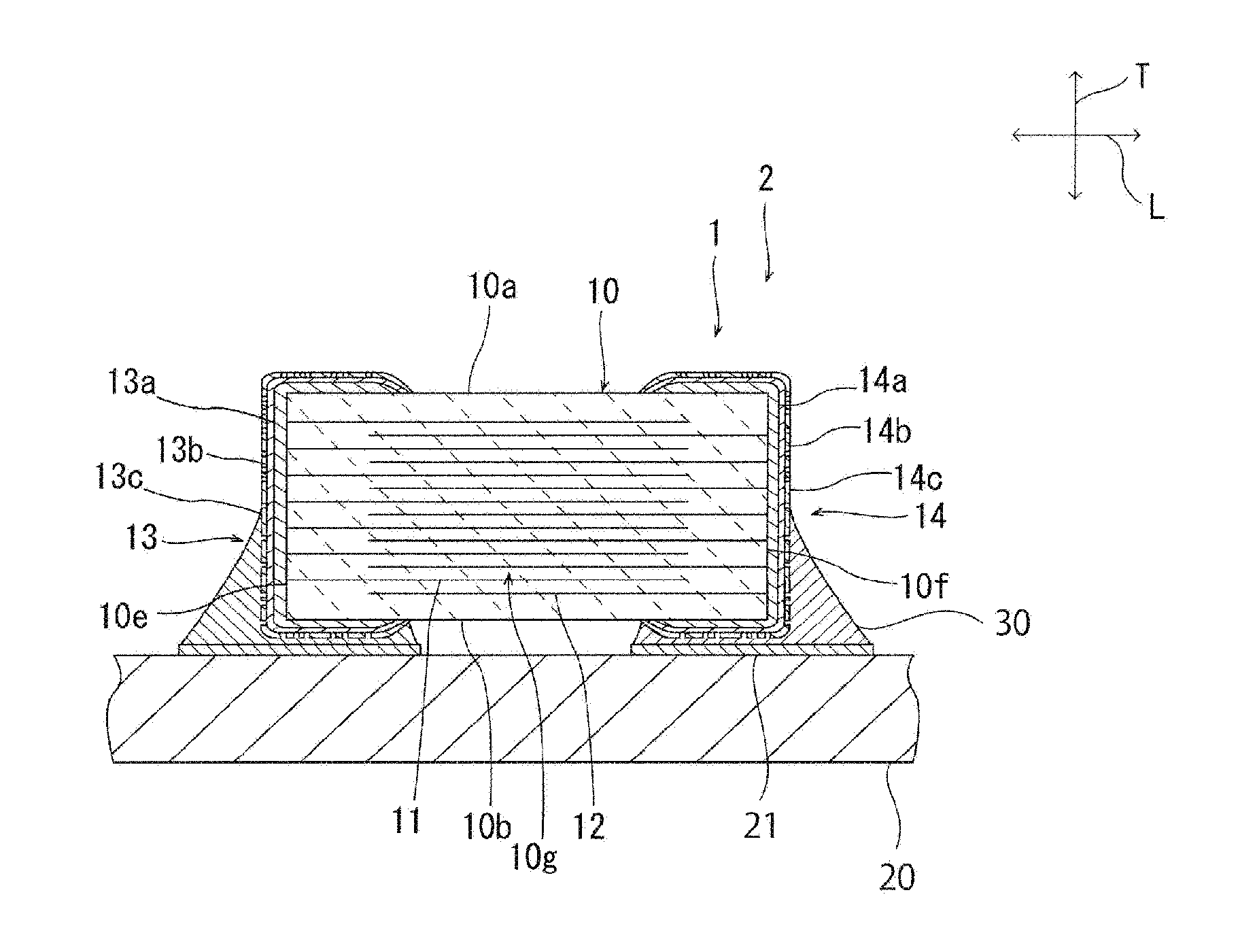

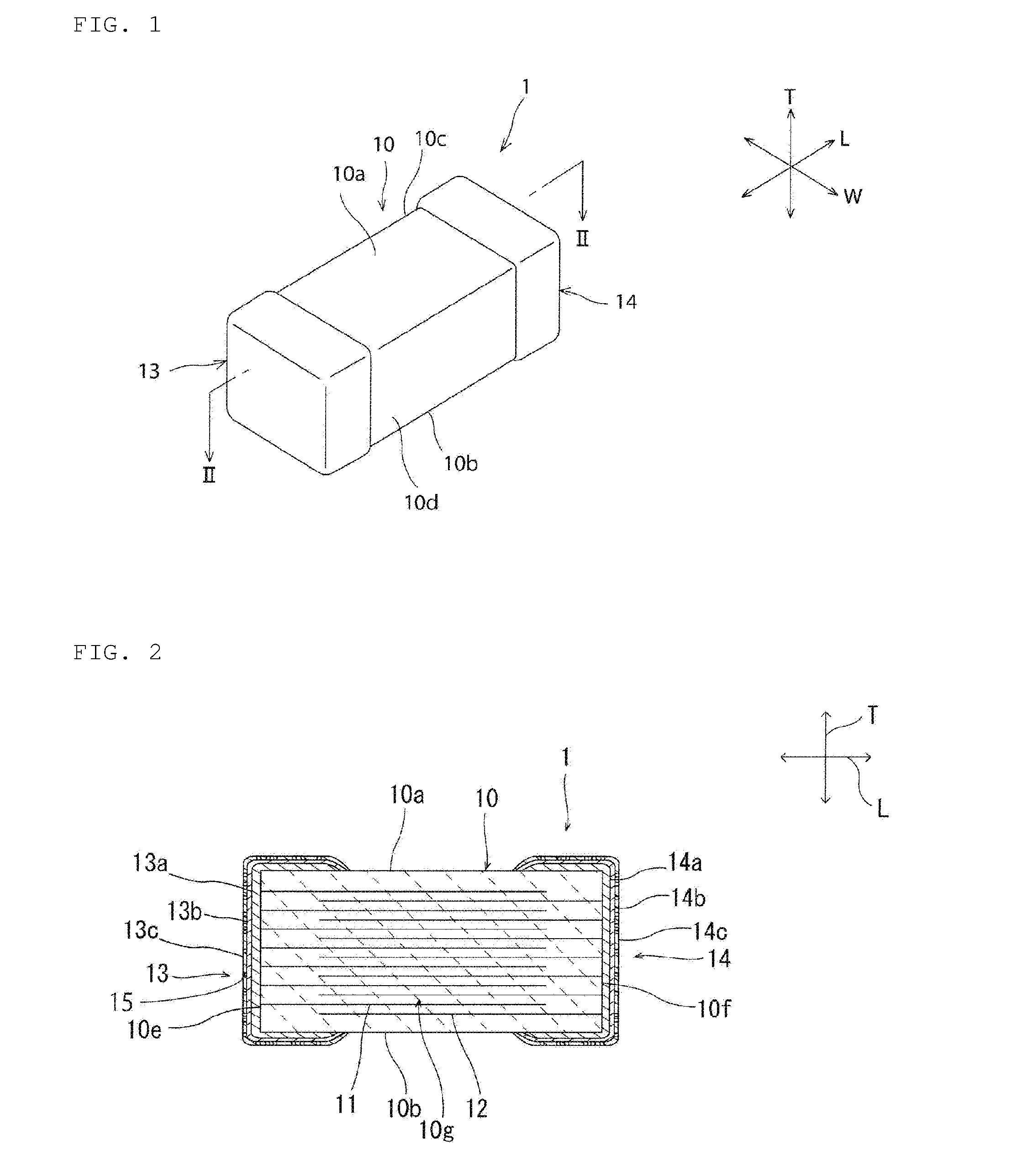

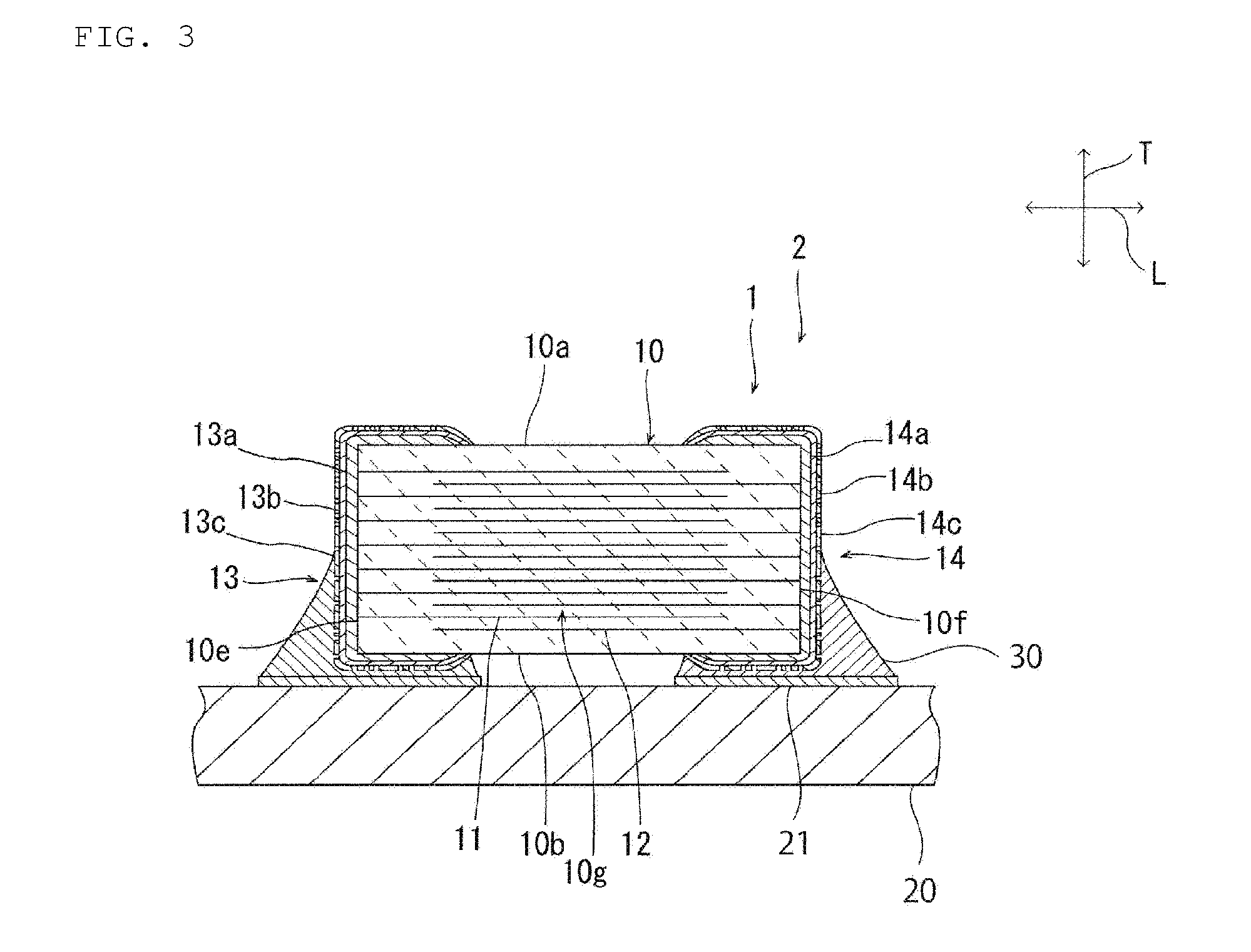

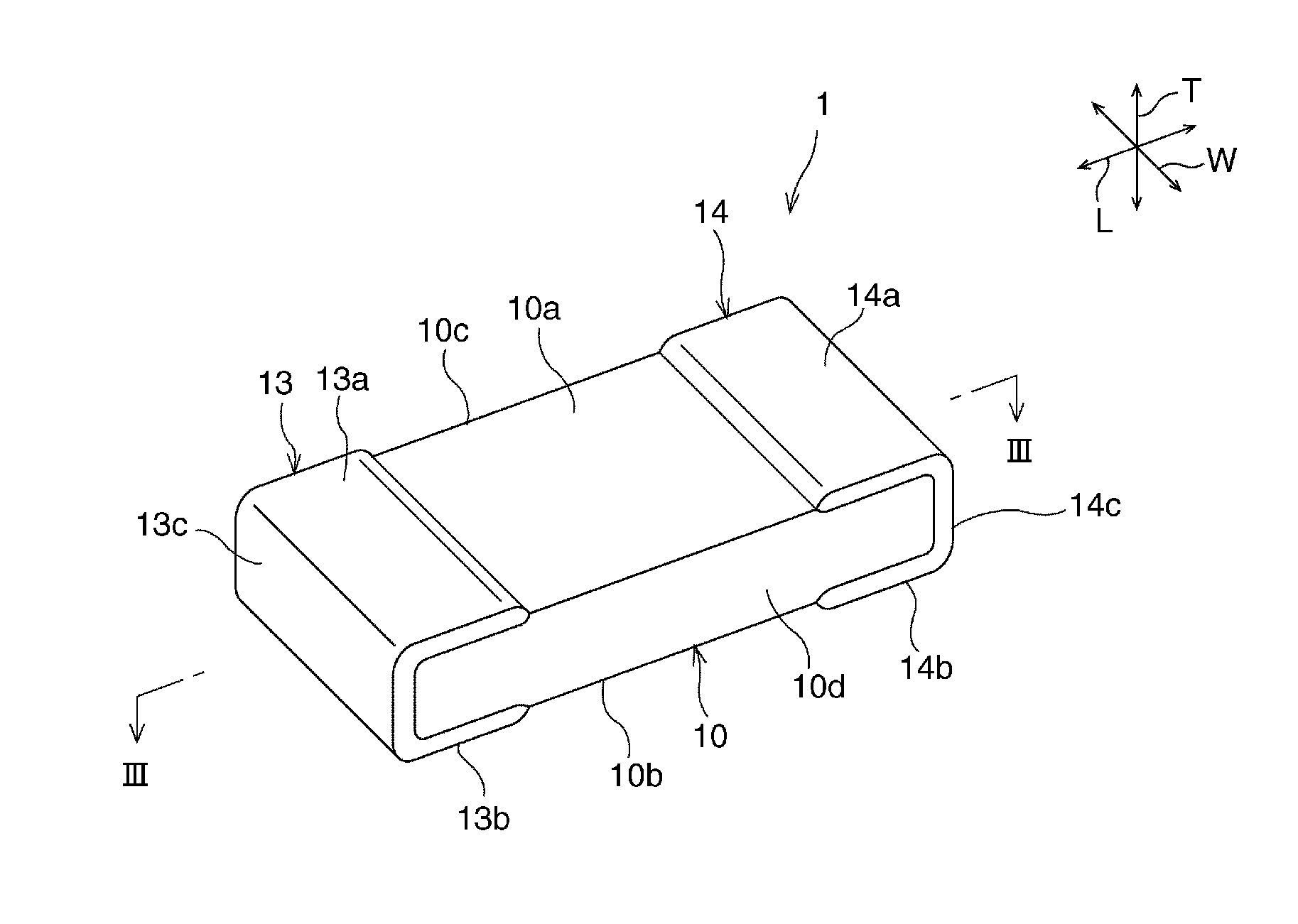

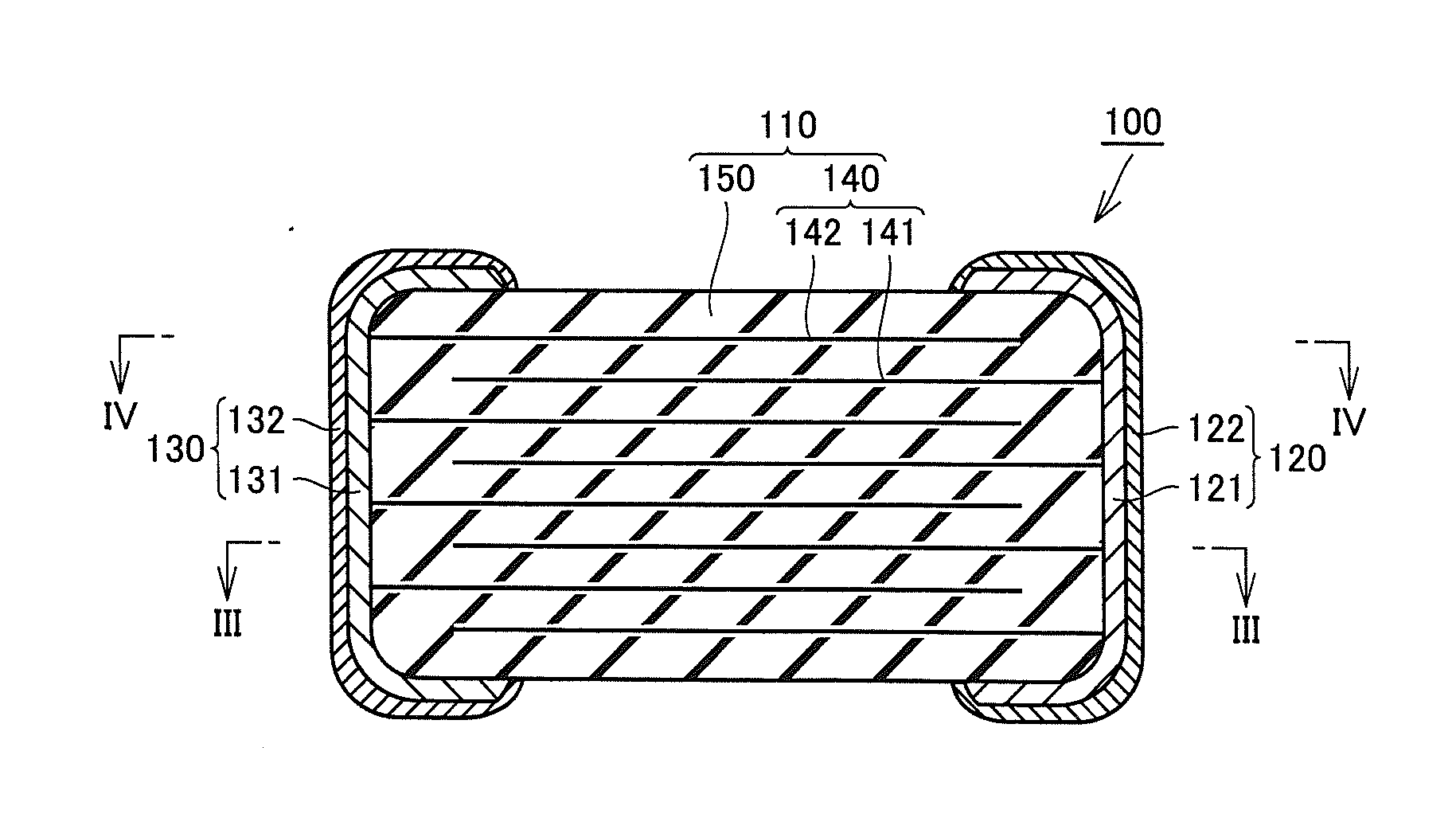

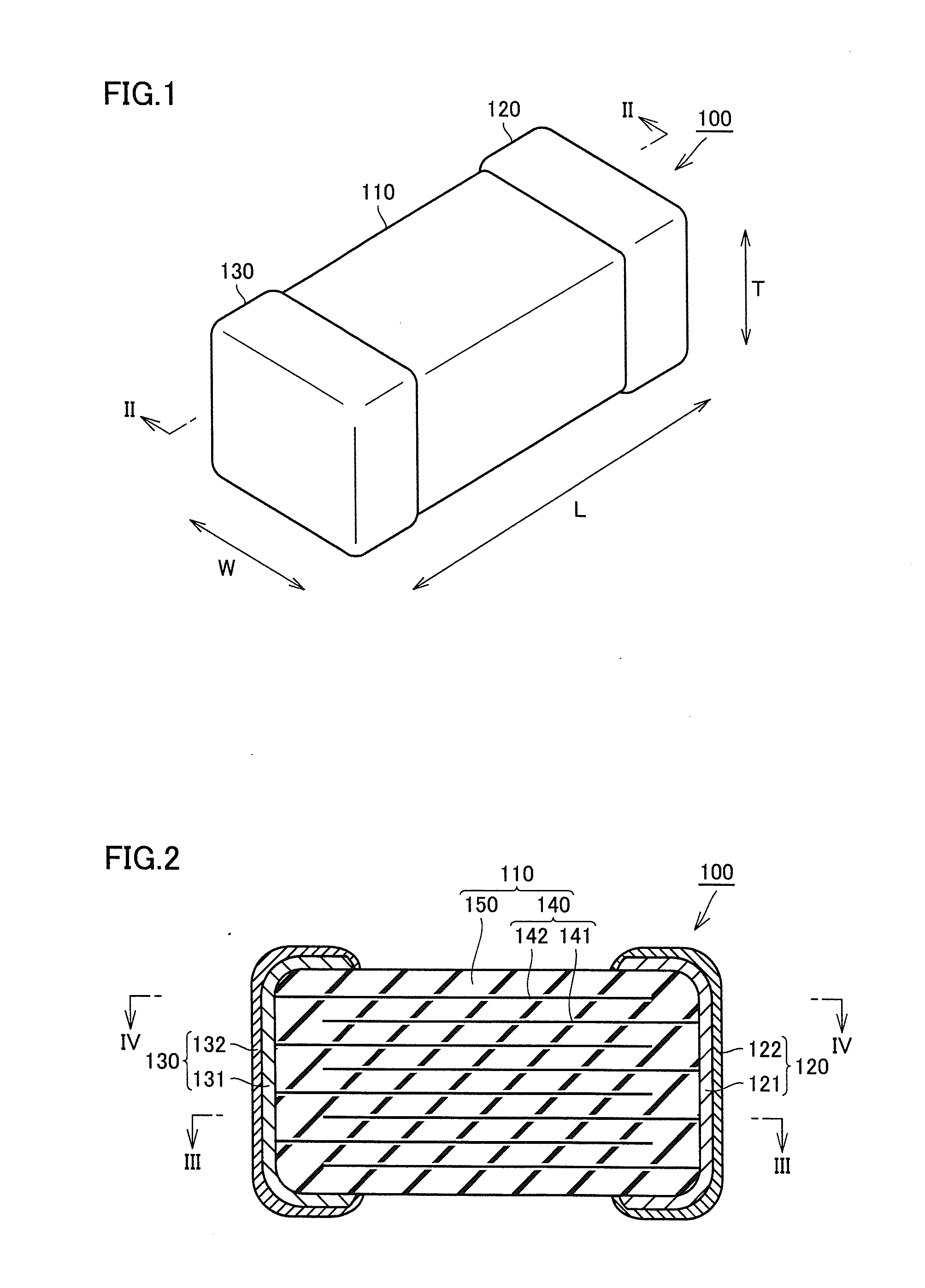

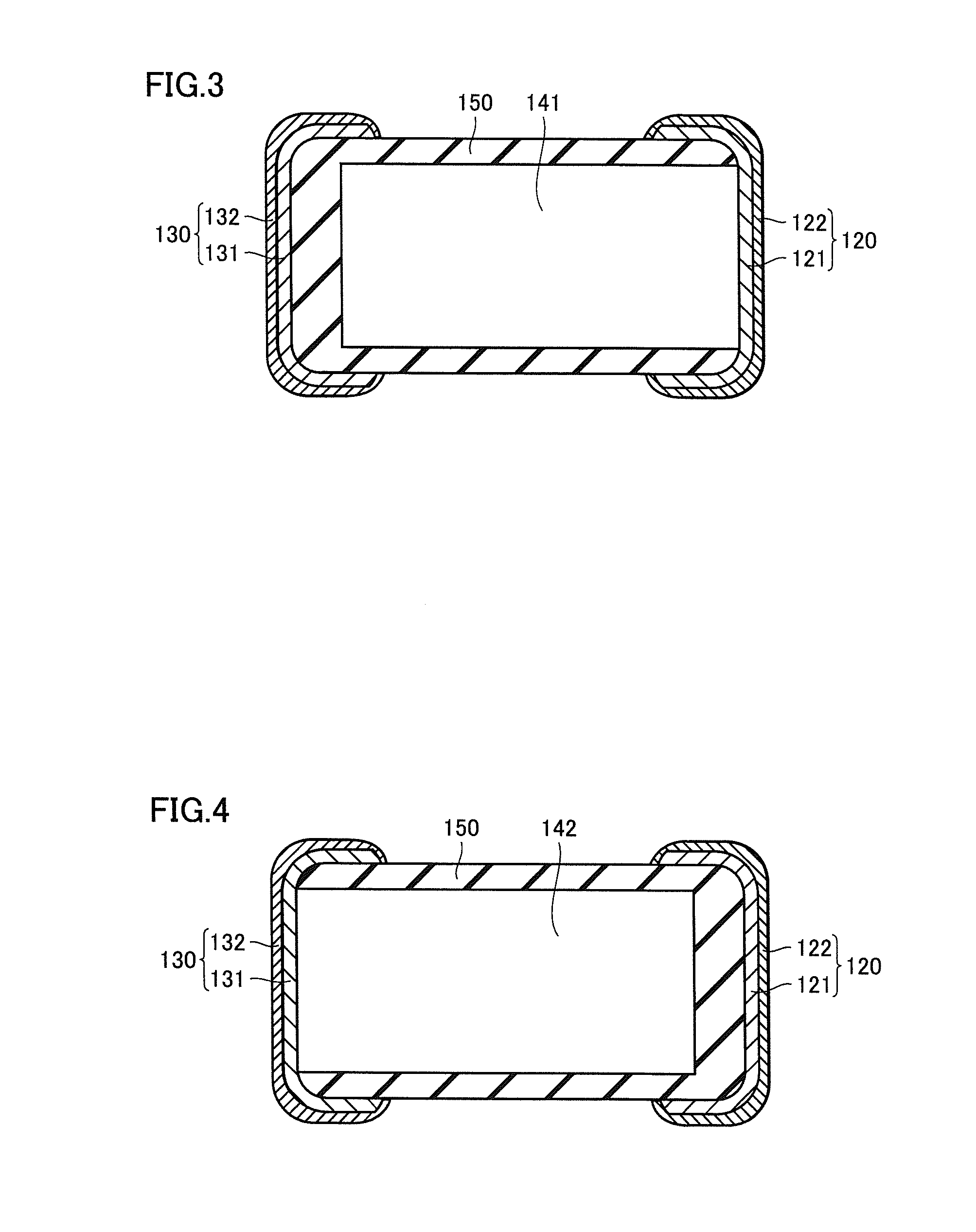

Multilayer ceramic electronic component

ActiveUS20160172110A1Prevents solder splatterPiezoelectric/electrostriction/magnetostriction machinesFixed capacitor electrodesCeramic capacitorElectronic component

Owner:MURATA MFG CO LTD

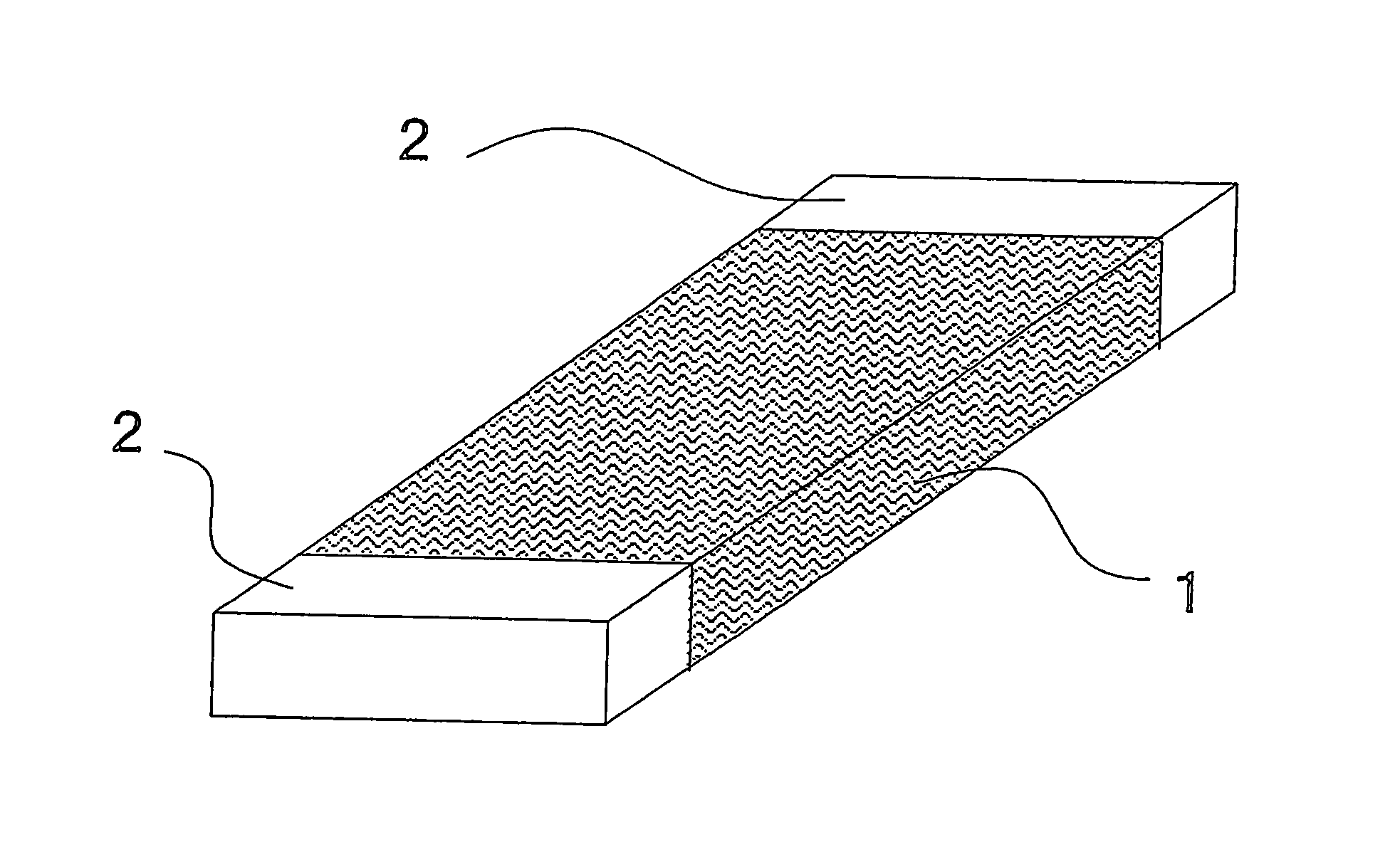

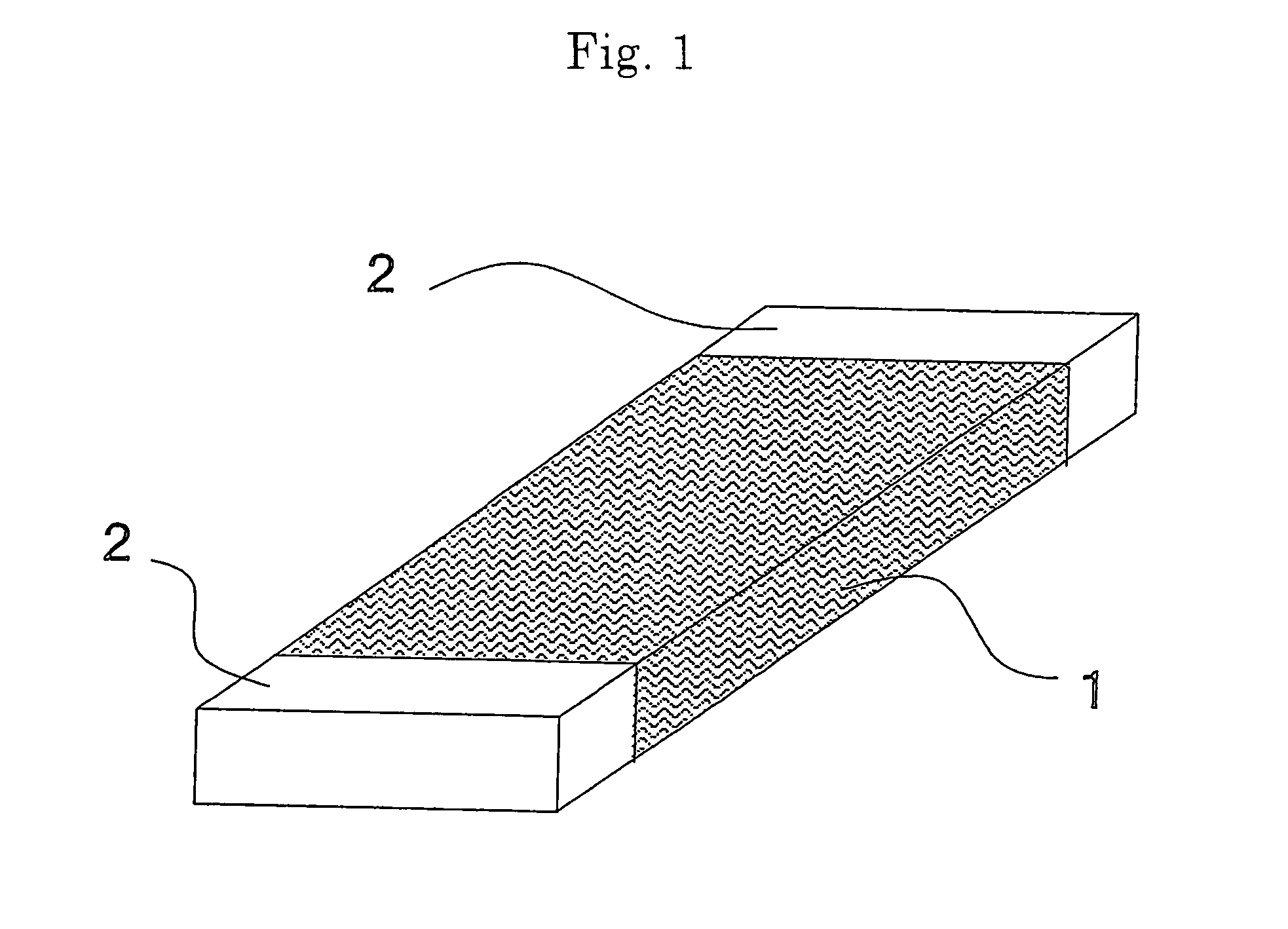

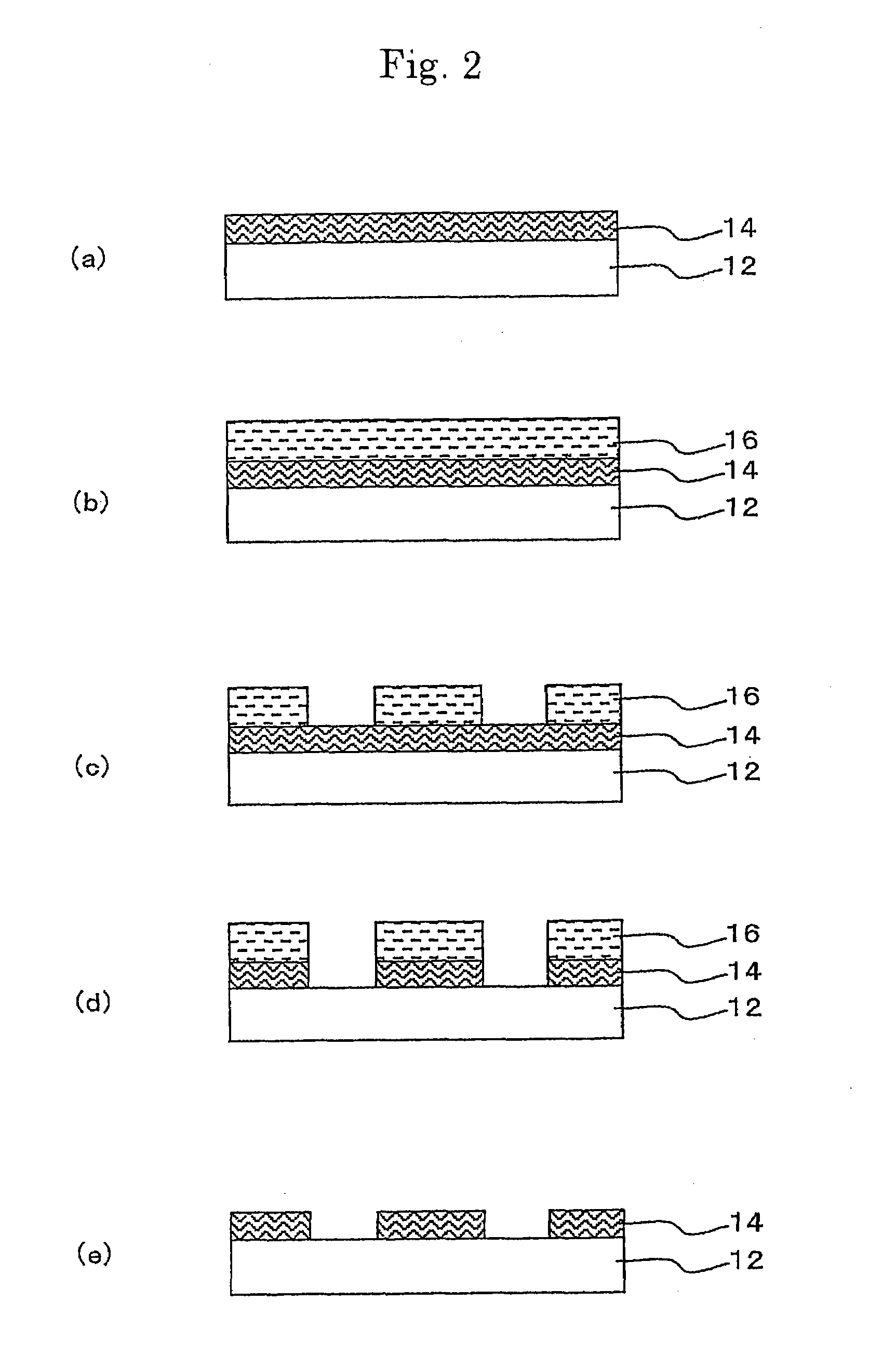

Resistance element, method of manufacturing the same, and thermistor

InactiveUS7217374B2Good duplicability and stabilityEasy and stable coatingMaterial nanotechnologyCurrent responsive resistorsCross-linkCarbon nanotube

To provide a resistance element having an electric resistance body with excellent stability and a method of manufacturing the same. The resistance element includes an electric resistance body, on a base body surface, consisting of a carbon nanotube structure layer 14, which configures a mesh structure in which at least plural carbon nanotubes are cross-linked to one another. The method of manufacturing the resistance element includes: an applying step of applying the base body surface 12 with a liquid solution containing carbon nanotubes having functional groups; and a cross-linking step of forming the carbon nanotube structure layer 14, used as an electric resistance body, that configures a mesh structure in which the plural carbon nanotubes are cross-linked to one another through curing of the liquid solution after application.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Electronic component and method for manufacturing the same

ActiveUS20150084481A1Piezoelectric/electrostriction/magnetostriction machinesPrinted circuit manufactureInsulation layerOptoelectronics

In an electronic component, an outer electrode includes a sintered layer containing a sintered metal, an insulation layer containing an electric insulation material, and a Sn-containing layer containing Sn. The sintered layer extends from each of end surfaces of an element assembly onto at least one main surface thereof so as to cover each of the end surfaces of the element assembly. The insulation layer is directly provided on the sintered layer at each of the end surfaces of the element assembly so as to extend in a direction perpendicular or substantially perpendicular to a side surface of the element assembly, and defines a portion of a surface of the outer electrode. The Sn-containing layer covers the sintered layer except for a portion of the sintered layer that is covered by the insulation layer, and constitutes another portion of the surface of the outer electrode.

Owner:MURATA MFG CO LTD

Multilayered ceramic electronic component and fabrication method thereof

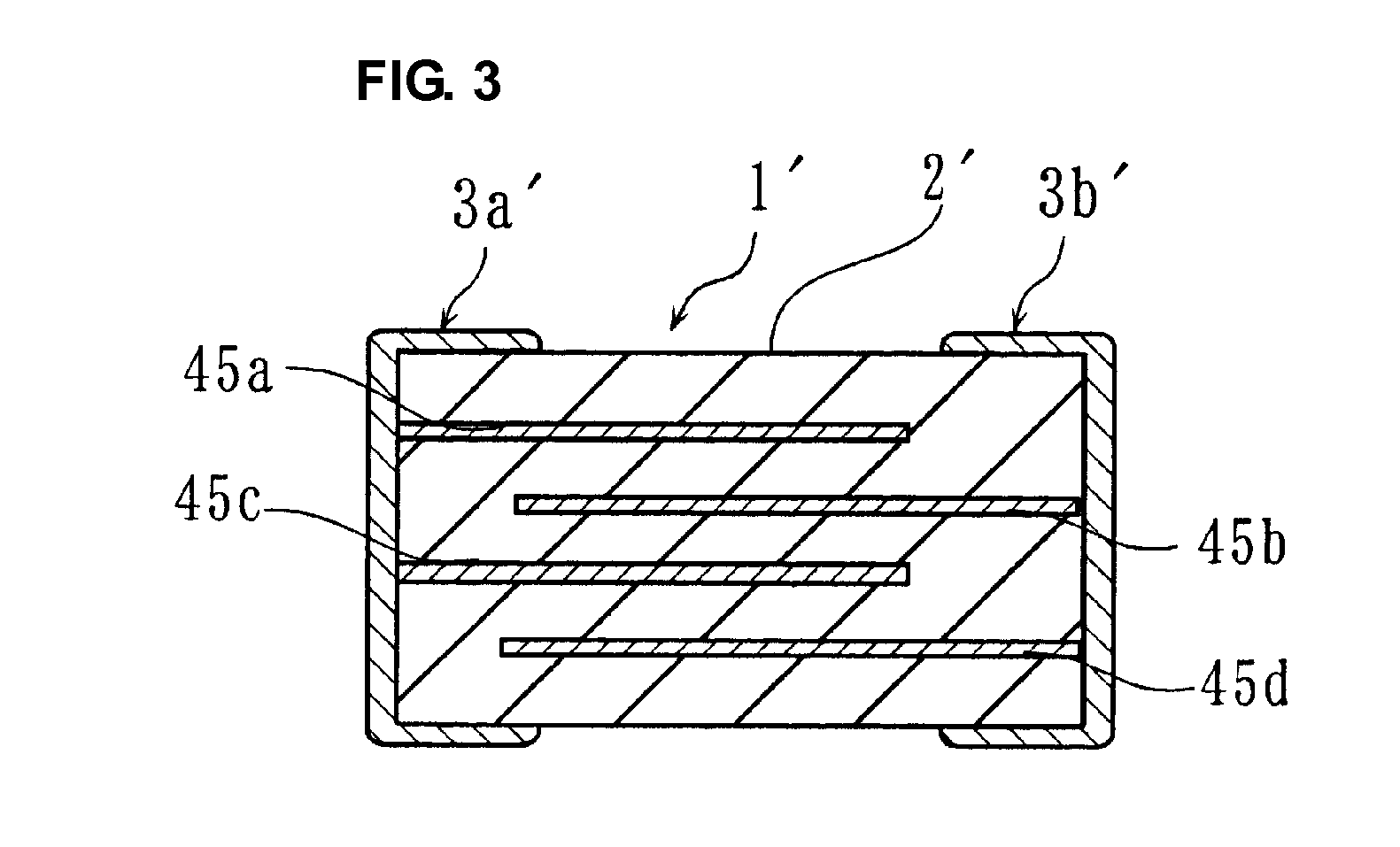

ActiveUS20130107422A1Avoid impuritiesFixed capacitor electrodesPiezoelectric/electrostriction/magnetostriction machinesMetallurgyElectronic component

A multilayered ceramic electronic component includes: a ceramic element having a plurality of dielectric layers laminated therein; first inner electrodes formed on the dielectric layers disposed in upper and lower portions in the ceramic element, the width of a portion of each of the first inner electrodes exposed from one end face of the ceramic element being less than that of a portion thereof disposed within the ceramic element; and second inner electrodes formed on the dielectric layers disposed in the middle portion in the ceramic element, the width of a portion of each of the second inner electrodes exposed from one end face of the ceramic element being equal to that of a portion thereof disposed within the ceramic element.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Thin film thermosensitive resistor and tis resistance valve regulating method

InactiveCN1409329APrevent compositional changesWith characteristicsResistor trimmingThermistorsHeat sensitiveOptoelectronics

In a thin film thermistor with a cutting portion of a metallic pattern for resistance adjustment, initially, the resistance is roughly adjusted by adjusting the film thickness of a second heat-sensitive film, and secondly finely adjusted by trimming the cutting portion by laser irradiation. Thus, the thin film thermistor with a resistance adjusted accurately can be produced.

Owner:ISHIZUKI ELECTRONICS

Temperature sensor with leads

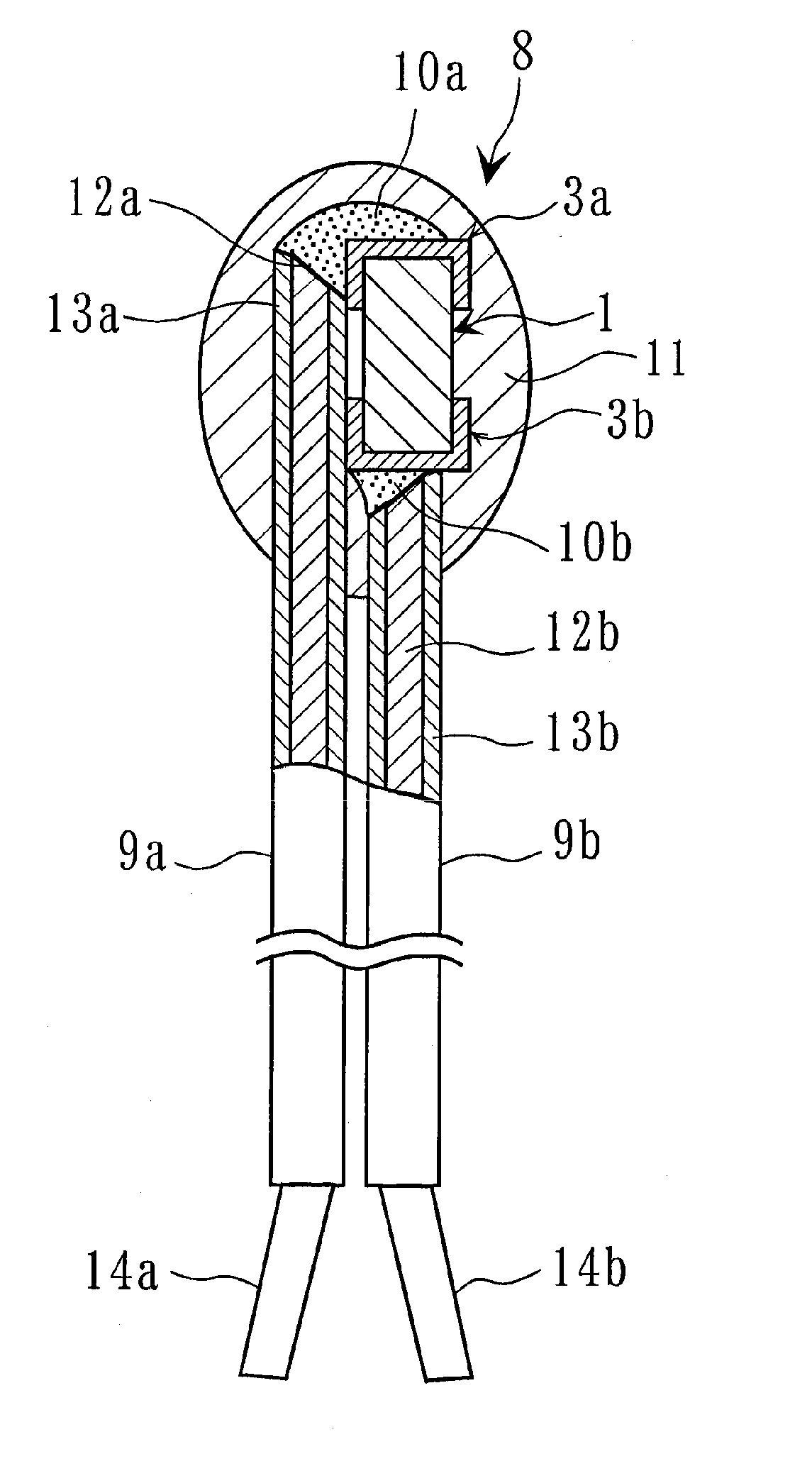

ActiveUS20090316752A1High detection sensitivityImprove reliabilityThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceElectricity

Owner:MURATA MFG CO LTD

Thermistor Device

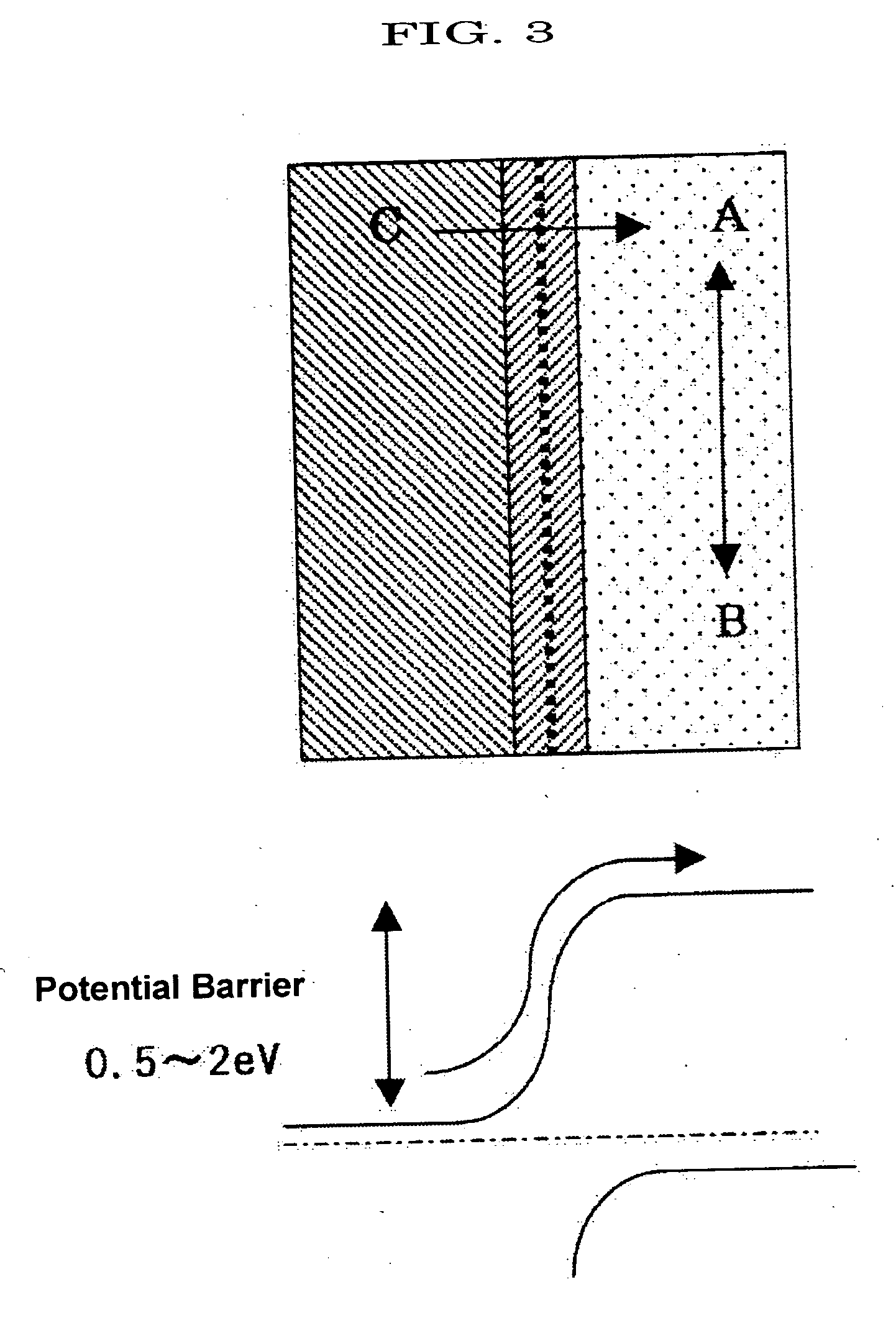

InactiveUS20070262408A1TemperatureHigh on-off ratioPhotovoltaicsNegative temperature coefficient thermistorsElectrical resistance and conductanceEngineering

A thermistor device having a high-speed response to temperature and a large ON / OFF ratio at the operating temperature. The thermistor device comprises a first layer of a first material having a positive temperature coefficient of resistance and a second layer of a second material having a semiconductivity and formed directly on the first layer. As the first material changes from conductive to a semiconductive or an insulative at or near the transition temperature TM-I, the interface between the first and second layer changes to a pn junction.

Owner:NEC SCHOTT COMPONENTS CORP +1

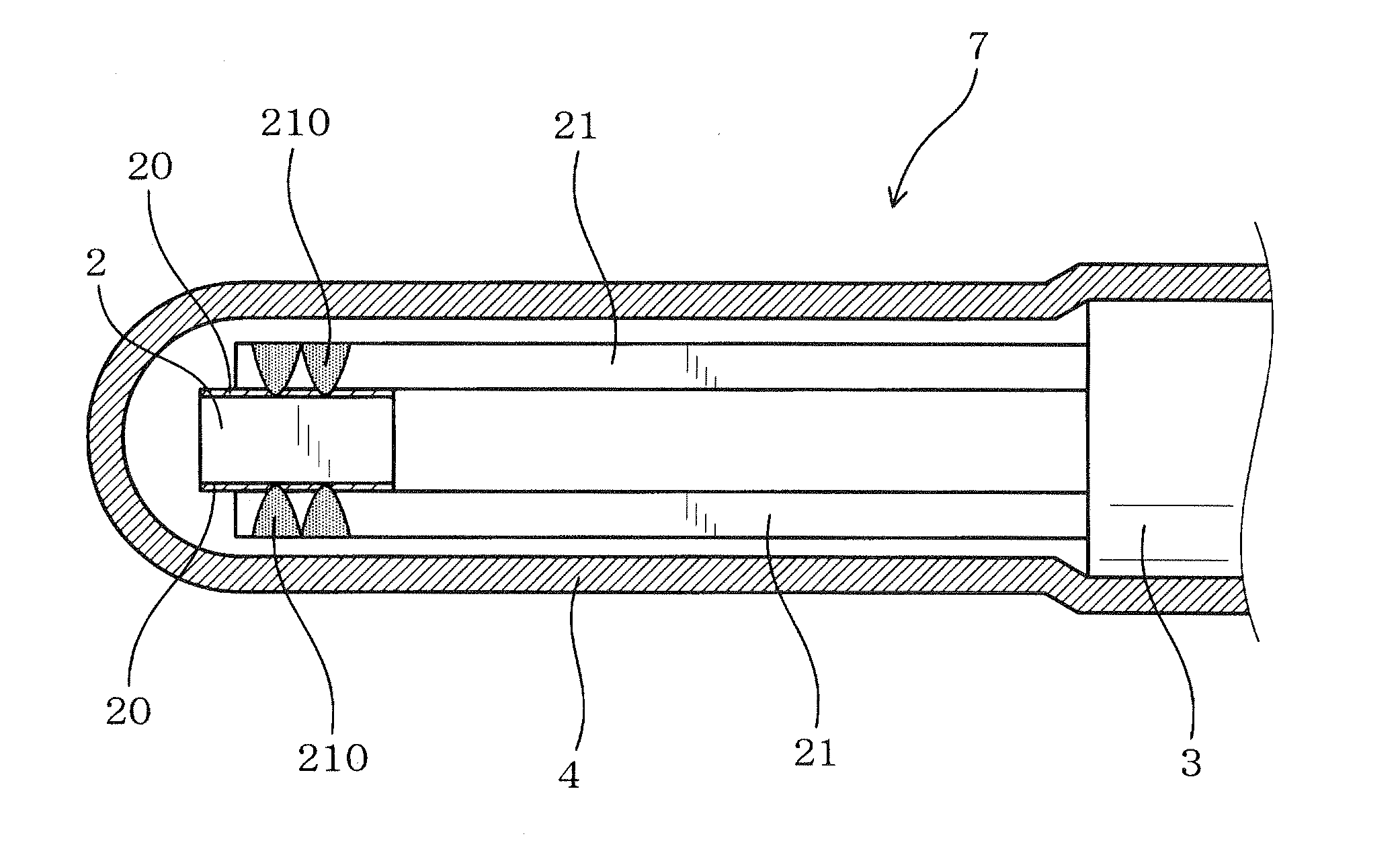

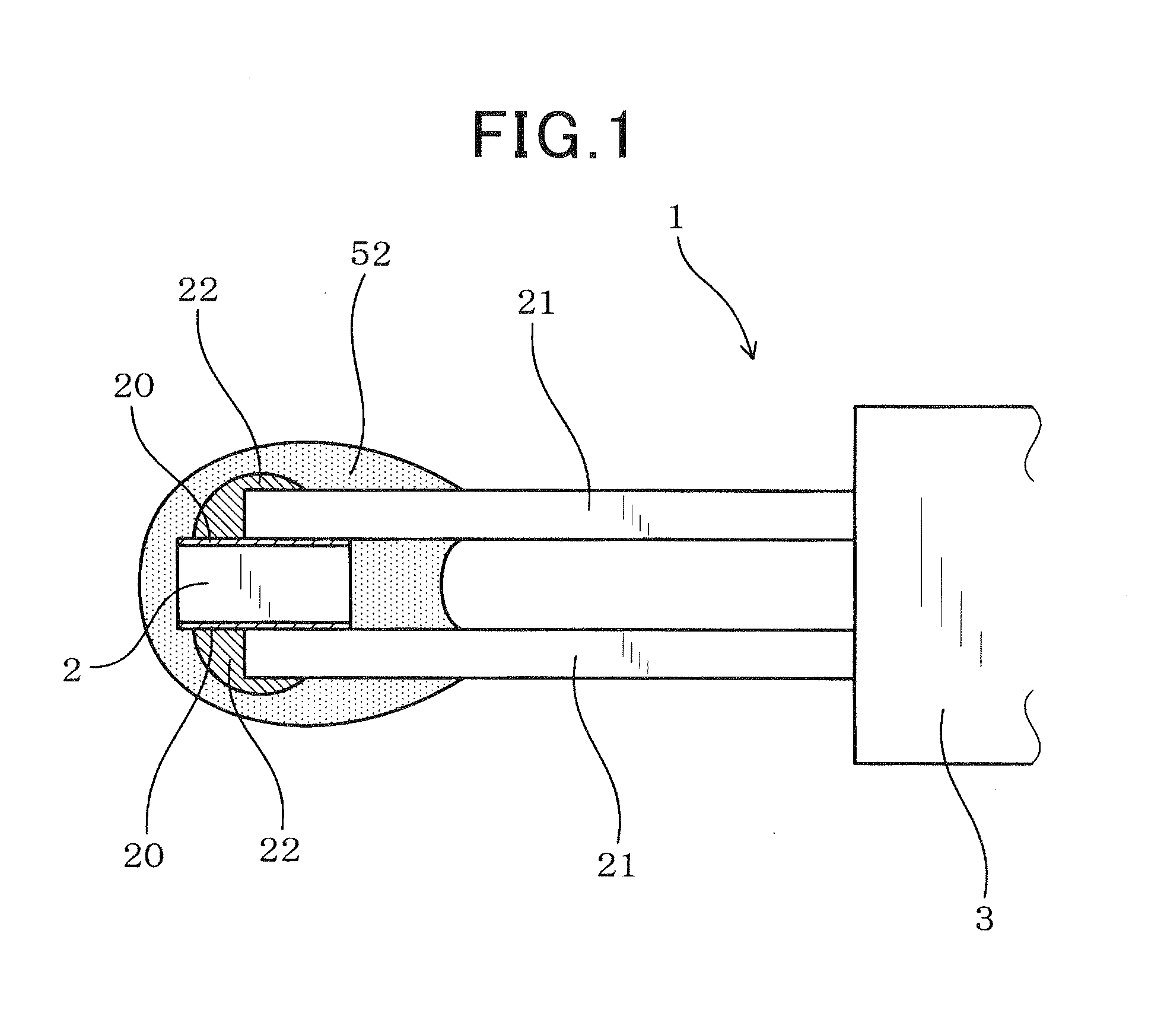

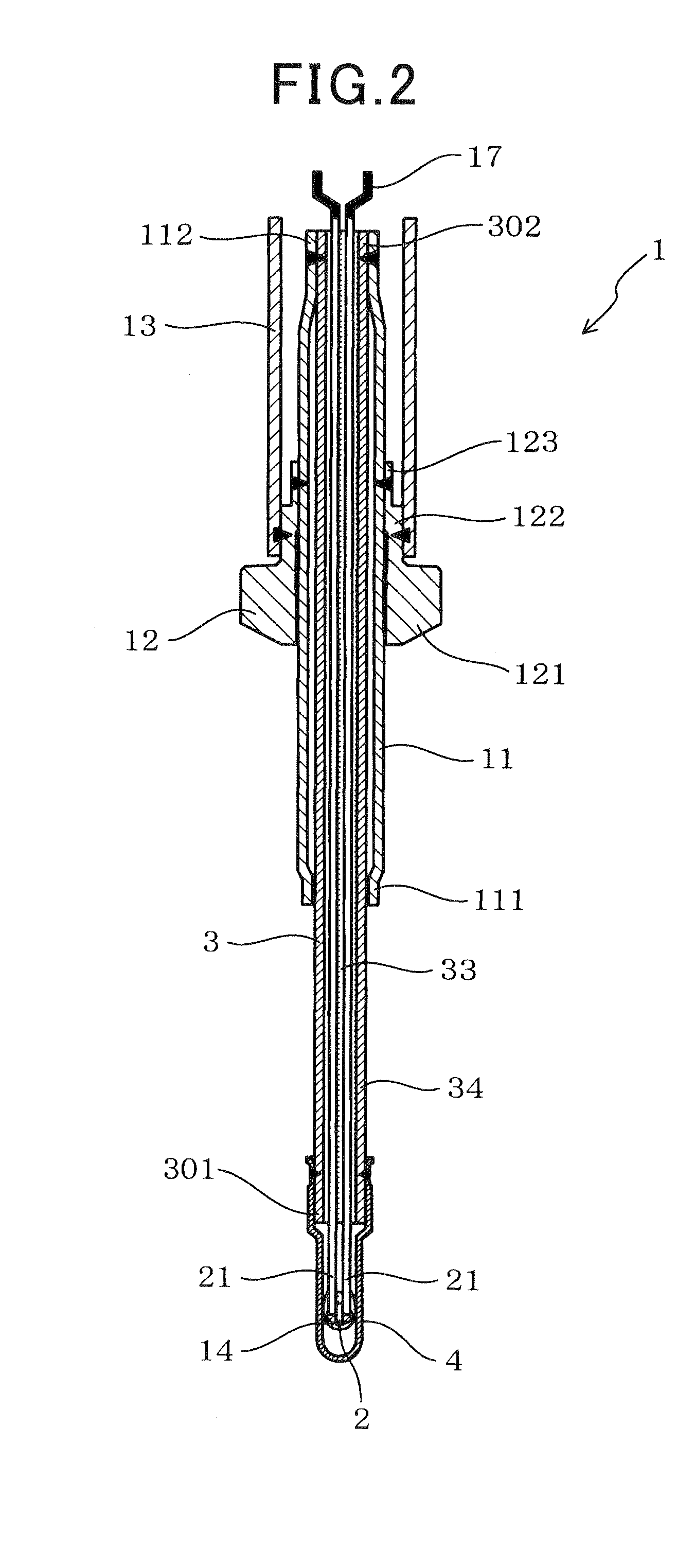

Temperature sensor including thermosensitive element

ActiveUS20130223479A1Improve reliabilityReduce thermal stressThermometer detailsThermometers using electric/magnetic elementsThermal expansionCeramic

A temperature sensor 1 includes: a thermosensitive element 2 composed of a low-thermal expansion ceramics having a coefficient of linear expansion of 3×10−6 / ° C. to 5×10−6 / ° C. and of which electrical s characteristics change depending on temperature; a pair of electrode films 20 provided on the surfaces of the thermosensitive element 2; and a pair of lead wires having a coefficient of linear expansion of 15×10−6 / ° C. or less and bonded to the electrode films 20. When the coefficients of linear expansion of the thermosensitive element 2, the electrode film 20, and the lead wire 21 are respectively Ta( / ° C.), Tb( / ° C.), and Td( / ° C.), the temperature sensor 1 satisfies a relationship Ta≦Tb≦Td.

Owner:DENSO CORP

Distributed thermoelectric string and insulating panel

ActiveUS8969703B2Reduce energy consumptionDissipate heating and coolingOther resistor networksThermoelectric device with peltier/seeback effectElectricityCold side

Inexpensive, lightweight, flexible heating and cooling panels with highly distributed thermoelectric elements are provided. A thermoelectric “string” is described that may be woven or assembled into a variety of insulating panels such as seat cushions, mattresses, pillows, blankets, ceiling tiles, office partitions, under-desk panels, electronic enclosures, building walls, refrigerator walls, and heat conversion panels. The string contains spaced thermoelectric elements which are thermally and electrically connected to lengths of braided, meshed, stranded, foamed, or otherwise expandable and compressible conductor. The elements and a portion of compacted conductor are mounted within the insulating panel On the outsides of the panel, the conductor is expanded to provide a very large surface area of contact with air or other medium for heat absorption on the cold side and for heat dissipation on the hot side.

Owner:LEAR CORP

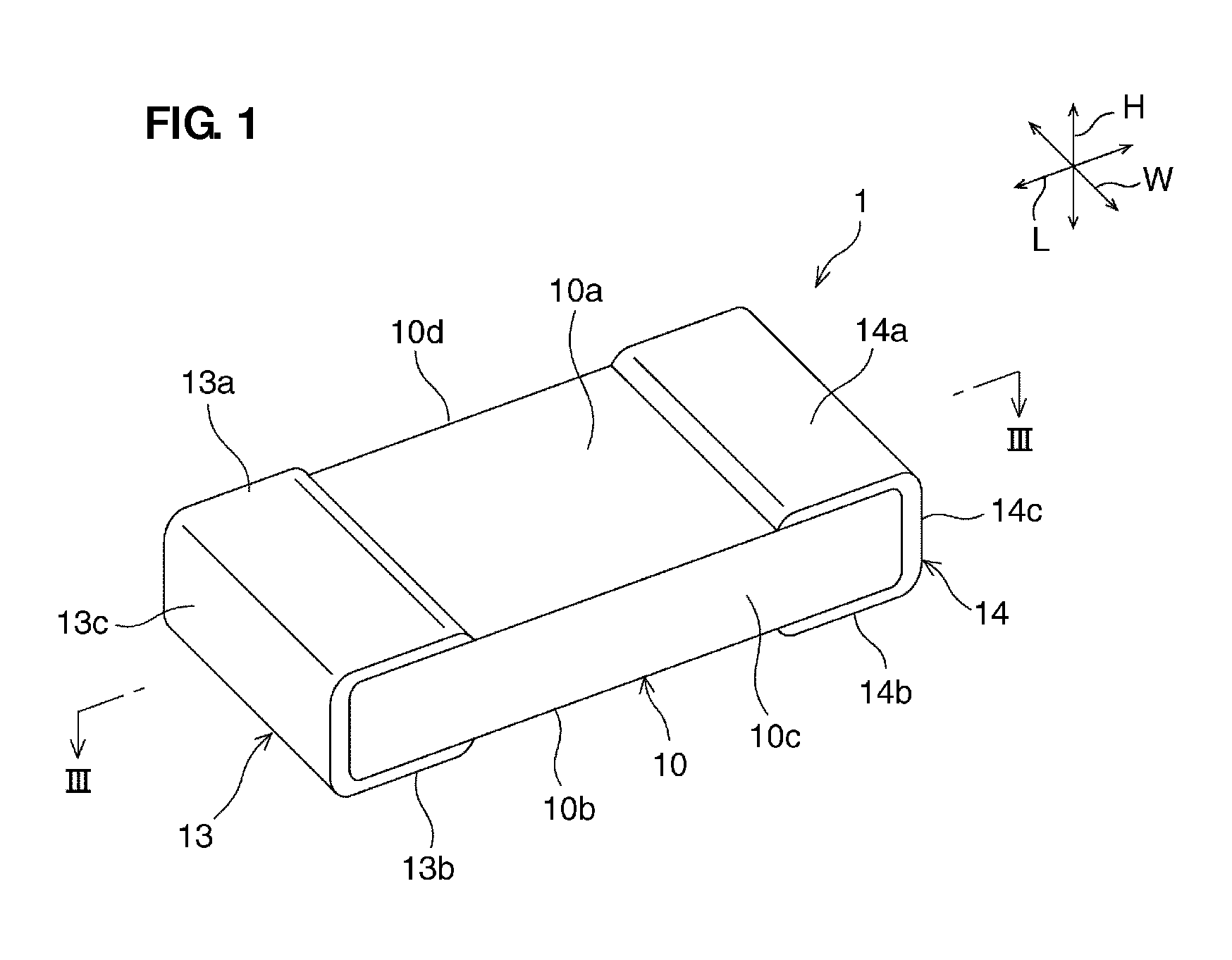

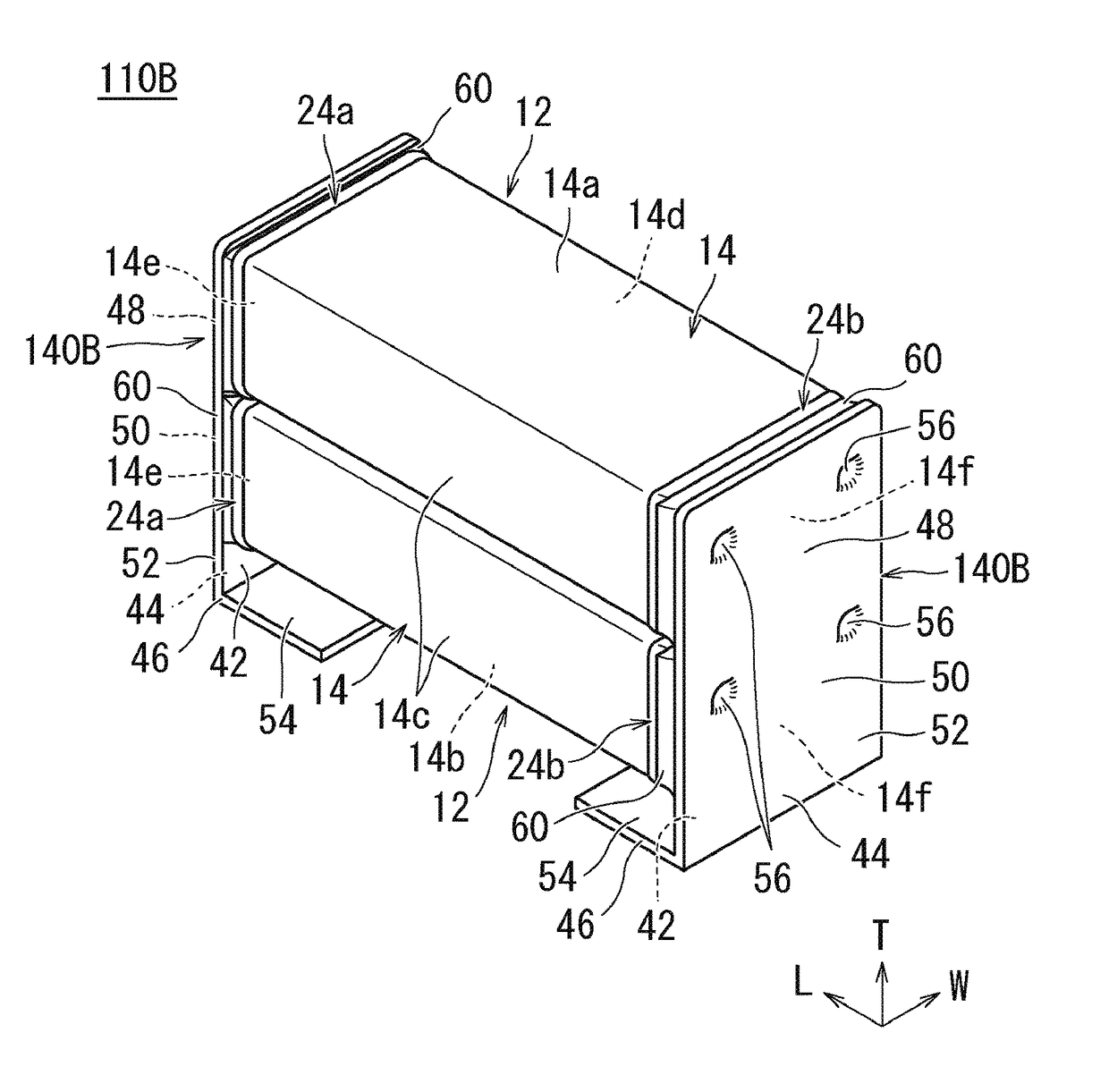

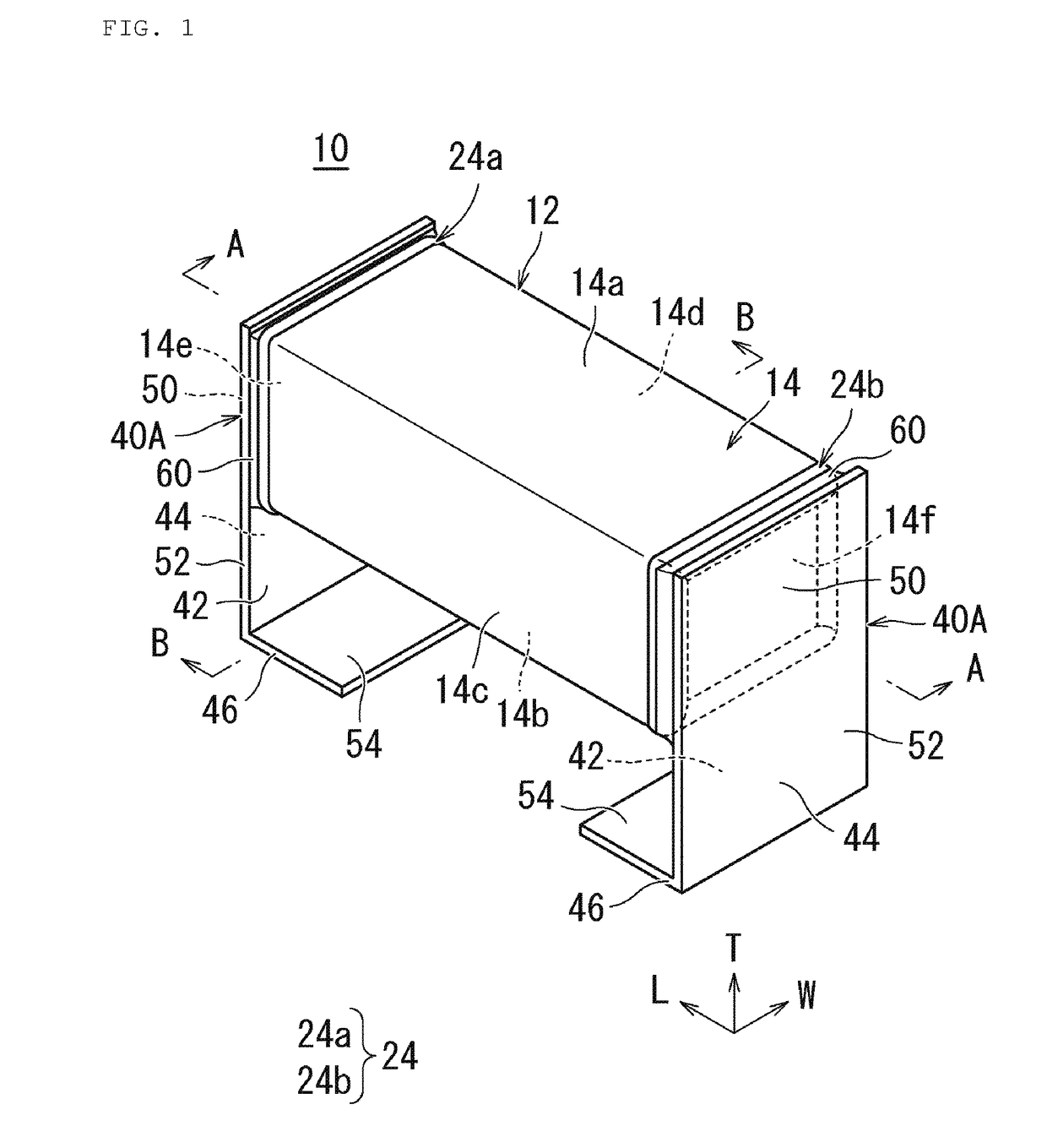

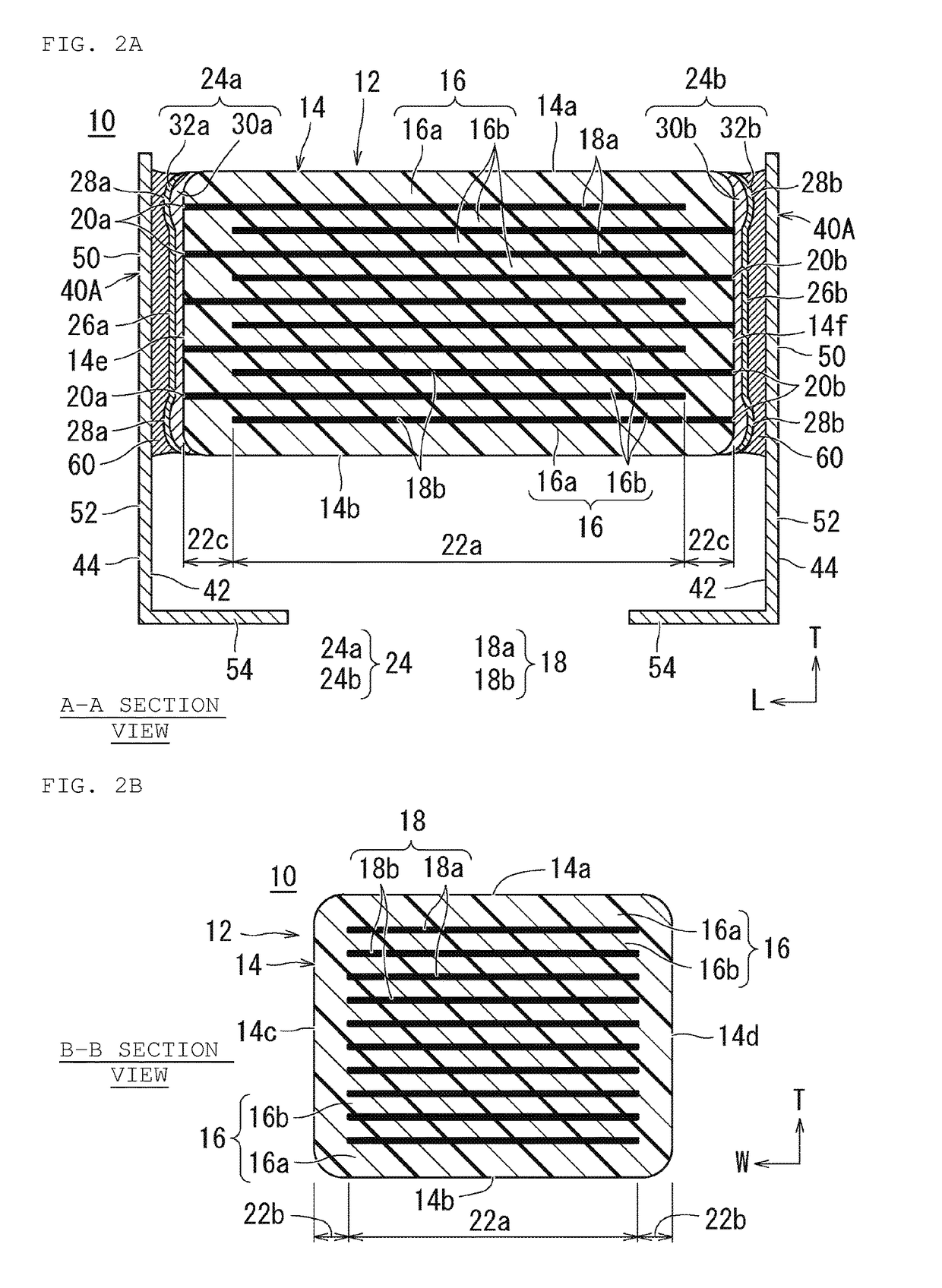

Multilayer ceramic electronic component

ActiveUS20180033556A1Reduce tensile stressAvoid it happening againFixed capacitor electrodesFixed capacitor dielectricElectronic componentMaterials science

A multilayer ceramic electronic component includes an electronic component body including a laminate and an external electrode, and a pair of metal terminals that are joined by a joining material. The pair of metal terminals includes a terminal joint portion, an extended portion and a mounting portion. The external electrode is provided only on both end surfaces of the laminate, and includes first and second external electrodes. The first external electrode and the second external electrode each include a saddle portion with a thickness larger than the thickness of a center portion of each end surface in the periphery of the first end surface and the second end surface of the laminate, respectively.

Owner:MURATA MFG CO LTD

Electronic component and electronic component-mounted structure

ActiveUS20160212850A1Good effectPiezoelectric/electrostriction/magnetostriction machinesResistor terminals/electrodesElectronic componentComposite material

An electronic component includes an electronic component body and an external electrode. The external electrode is disposed on the electronic component body. The external electrode includes a Pd plating layer and a Ni plating layer. The Pd plating layer defines an outermost layer. The Ni plating layer is disposed inside the Pd plating layer. The Ni plating layer is partly exposed from the Pd plating layer.

Owner:MURATA MFG CO LTD

Ceramic electronic component

ActiveUS20120019099A1Reduce thicknessImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesFixed capacitor electrodesElectronic componentMaterials science

A ceramic electronic component includes a ceramic base, first and second internal electrodes, and first and second external electrodes. The first external electrode is disposed at a first end portion of a first major surface in the longitudinal direction. The second external electrode is disposed at a second end portion of the first major surface in the longitudinal direction. A portion of each of the first and second external electrodes is opposed in the thickness direction to a region where the first and second internal electrodes are opposed to each other in the thickness direction. A condition ( 1 / 10)t0≦t1≦(⅖)t0 is satisfied, where t0 is the thickness of each of the first and second external electrodes and t1 is the thickness of a portion in which each of the first and second external electrodes is embedded in the first major surface.

Owner:MURATA MFG CO LTD

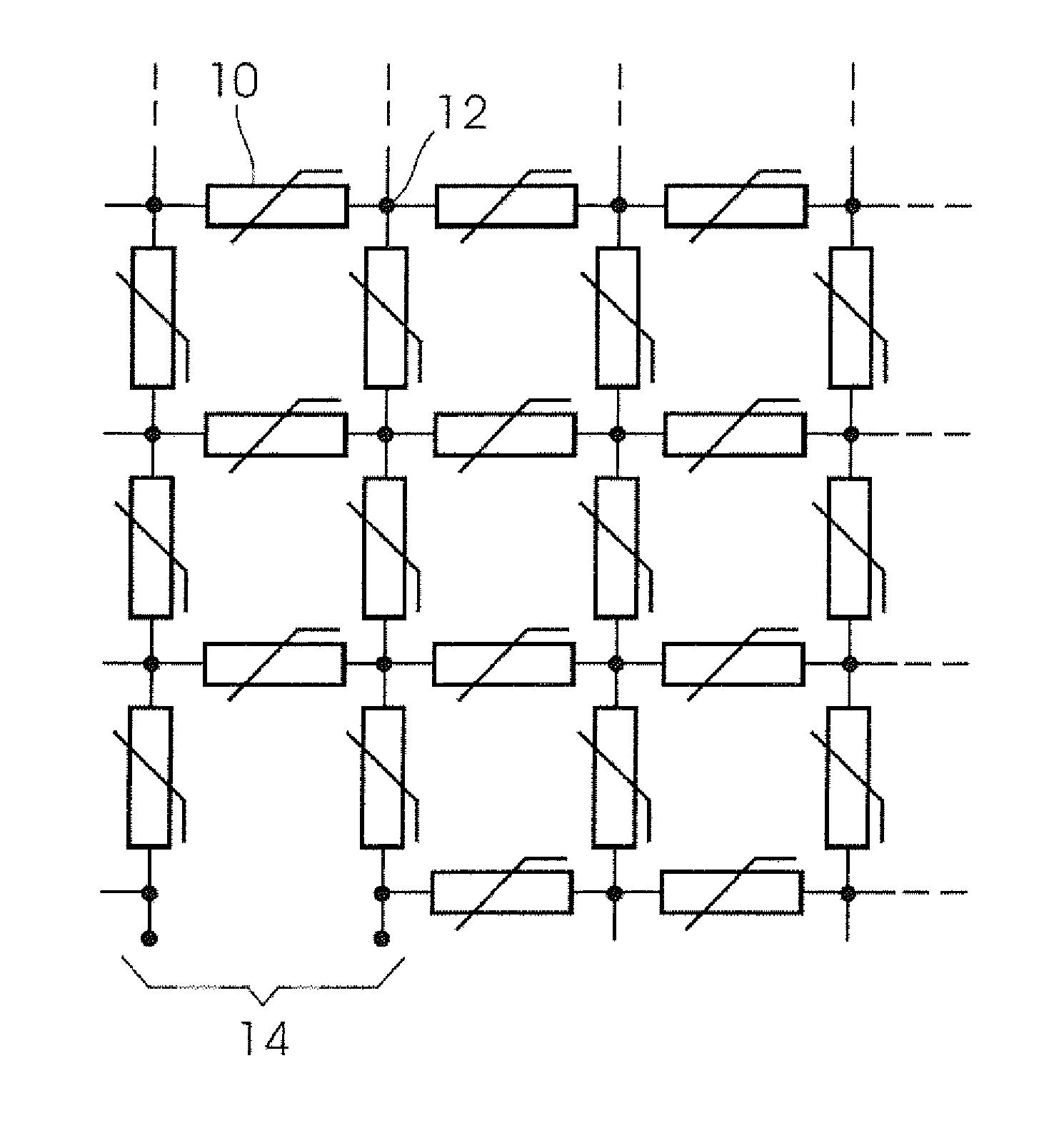

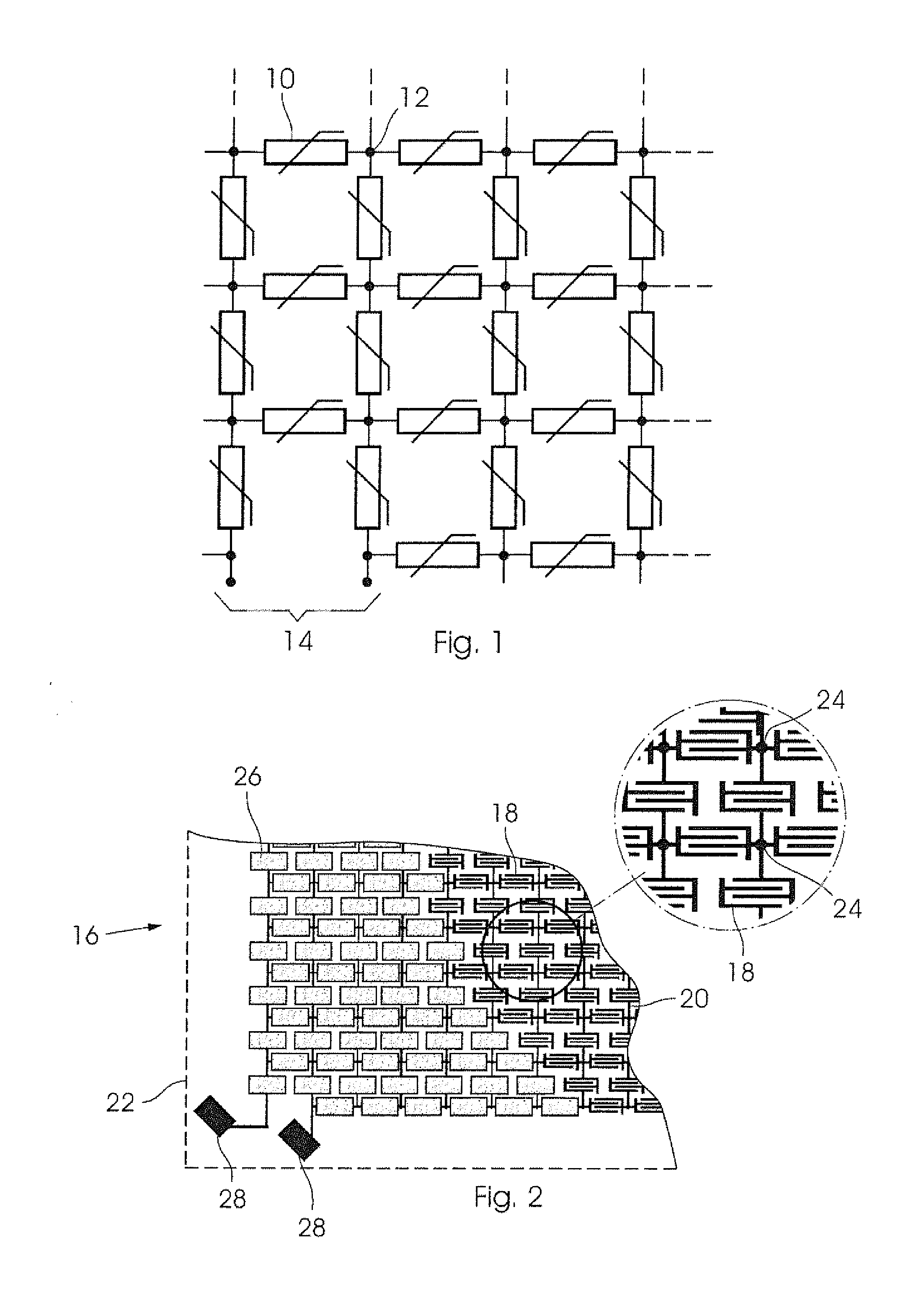

Large Area Temperature Sensor

InactiveUS20150023393A1Thermometer detailsOther resistor networksElectrical resistance and conductanceEngineering

A sensing device is made up of a network of nominally identical temperature dependent resistors which is topologically equivalent to a square resistor network. The device has terminals at which an average resistance value thereof can be measured. The resistors are supported on a substrate which can be reduced in size from an initial size without substantially changing the average resistance value. In preferred embodiments, a pattern of contacts and conductive tracks joining the contacts are printed on a substrate, and a material having a temperature dependent resistance is applied over the contacts to define a network of interconnected thermistors. Alternatively, the material can be applied to the substrate first and the contacts and tracks printed on it.

Owner:PST SENSORS

Ceramic electronic component

ActiveUS20150116901A1Occurrence of crack is reduced and preventedFixed capacitor electrodesFixed capacitor dielectricElectronic componentComposite material

A ceramic electronic component includes a first fired electrode layer disposed on top of a ceramic body. The first fired electrode layer includes first to fifth portions that are separate from each other. The first portion is disposed on top of a first end surface. The second portion is disposed on top of a first principal surface. The third portion is disposed on top of a second principal surface. The fourth portion is disposed on top of a first side surface. The fifth portion is disposed on top of a second side surface.

Owner:MURATA MFG CO LTD

Ceramic electronic component and method of manufacturing the same

ActiveUS20140375173A1Reduce and prevent occurrencePiezoelectric/electrostriction/magnetostriction machinesTransformers/inductances coils/windings/connectionsElectrical connectionAlloy

A ceramic electronic component includes a rectangular or substantially rectangular parallelepiped shaped laminate in which a ceramic layer and an internal electrode are alternately laminated and an external electrode provided on a portion of a surface of the laminate and electrically connected to the internal electrode. The external electrode includes an inner external electrode covering a portion of the surface of the laminate and including a mixture of a resin component and a metal component and an outer external electrode covering the inner external electrode and including a metal component. The inner external electrode includes, as a metal component, a first metal component of which a portion forms an alloy with the internal electrode so as to connect the internal electrode and the inner external electrode to each other, and a second metal component higher in melting point than the first metal component, of which a portion forms an alloy with the first metal component so as to connect the inner external electrode and the outer external electrode to each other. A concentration of a metal in a surface layer of the inner external electrode is not lower than about 17%.

Owner:MURATA MFG CO LTD

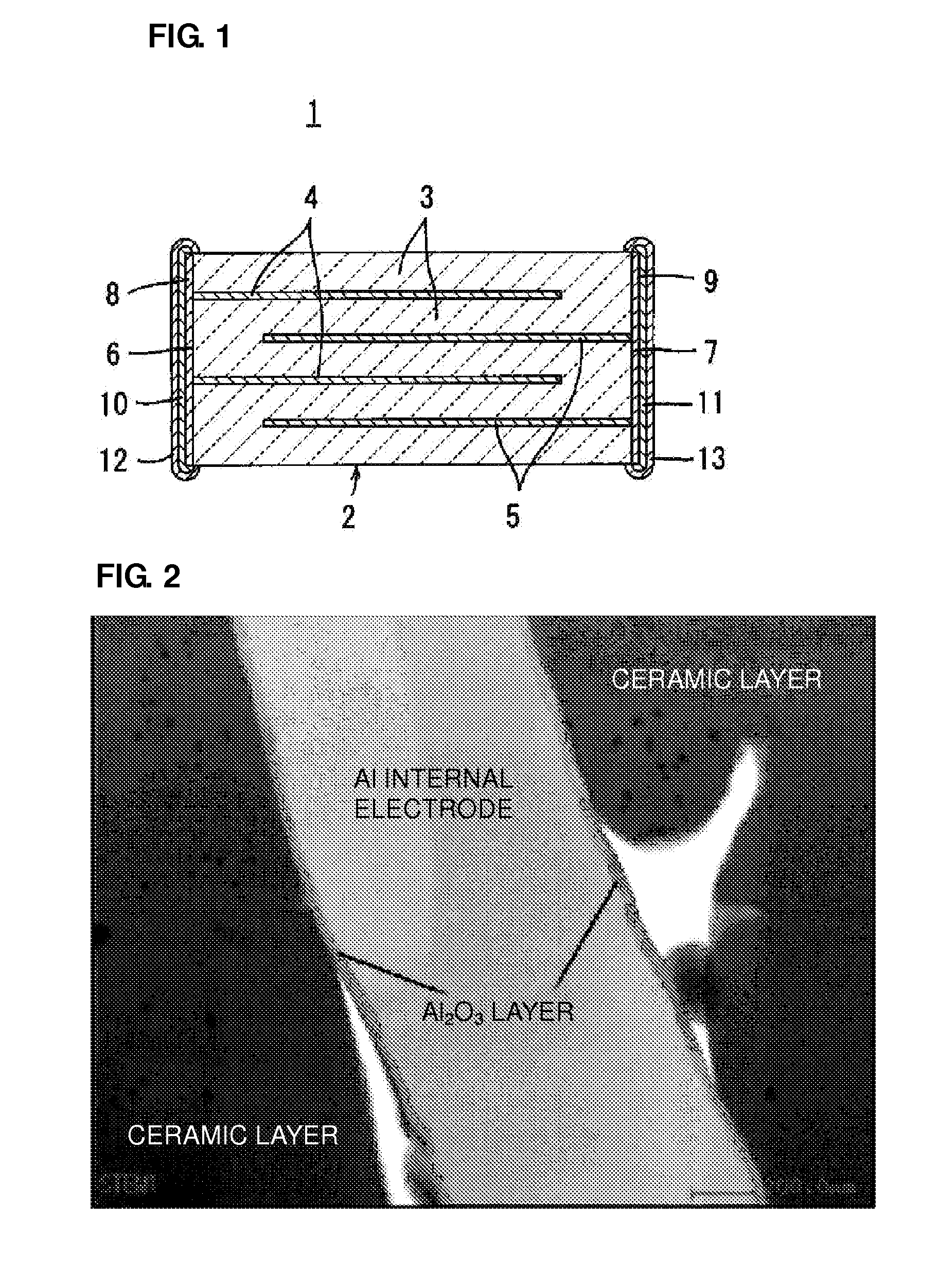

Laminated ceramic electronic component and method for producing laminated ceramic electronic component

ActiveUS20110075318A1Improve mechanical propertiesGood electrical propertiesFixed capacitor electrodesFixed capacitor dielectricElectrical performanceElectronic component

A laminated ceramic electronic component has a variety of superior mechanical properties and electrical properties, including a high degree of freedom in the design for ceramic materials, and can be manufactured at low cost and with a low percentage of defective products. The laminated ceramic electronic component includes a laminate including a plurality of stacked ceramic layers and a plurality of internal electrodes containing Al as a main constituent, the internal electrodes being arranged along specific interfaces between the ceramic layers, and external electrodes located on an outer surface of the laminate, wherein surface layer sections of the internal electrodes include an Al2O3 layer.

Owner:MURATA MFG CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com