Thin film thermosensitive resistor and tis resistance valve regulating method

A thin-film thermistor and heat-sensitive technology, applied in the thermistor, resistor, resistor manufacturing and other directions, can solve the problems of reduced contact strength, difficulty in producing small-tolerance products, and unstable electrical characteristics of thermal films. , to prevent component changes, improve reliability, and achieve the effect of small deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

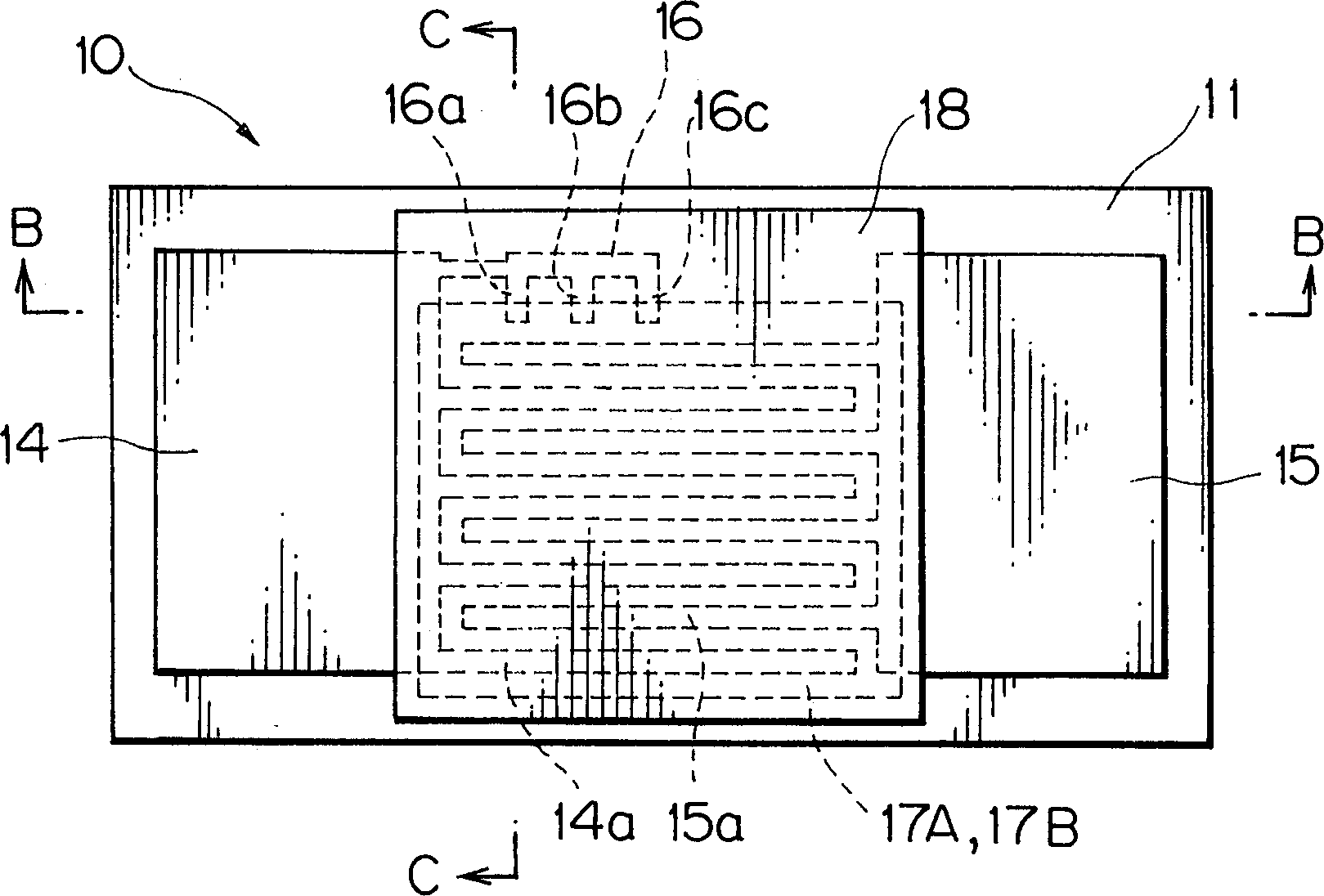

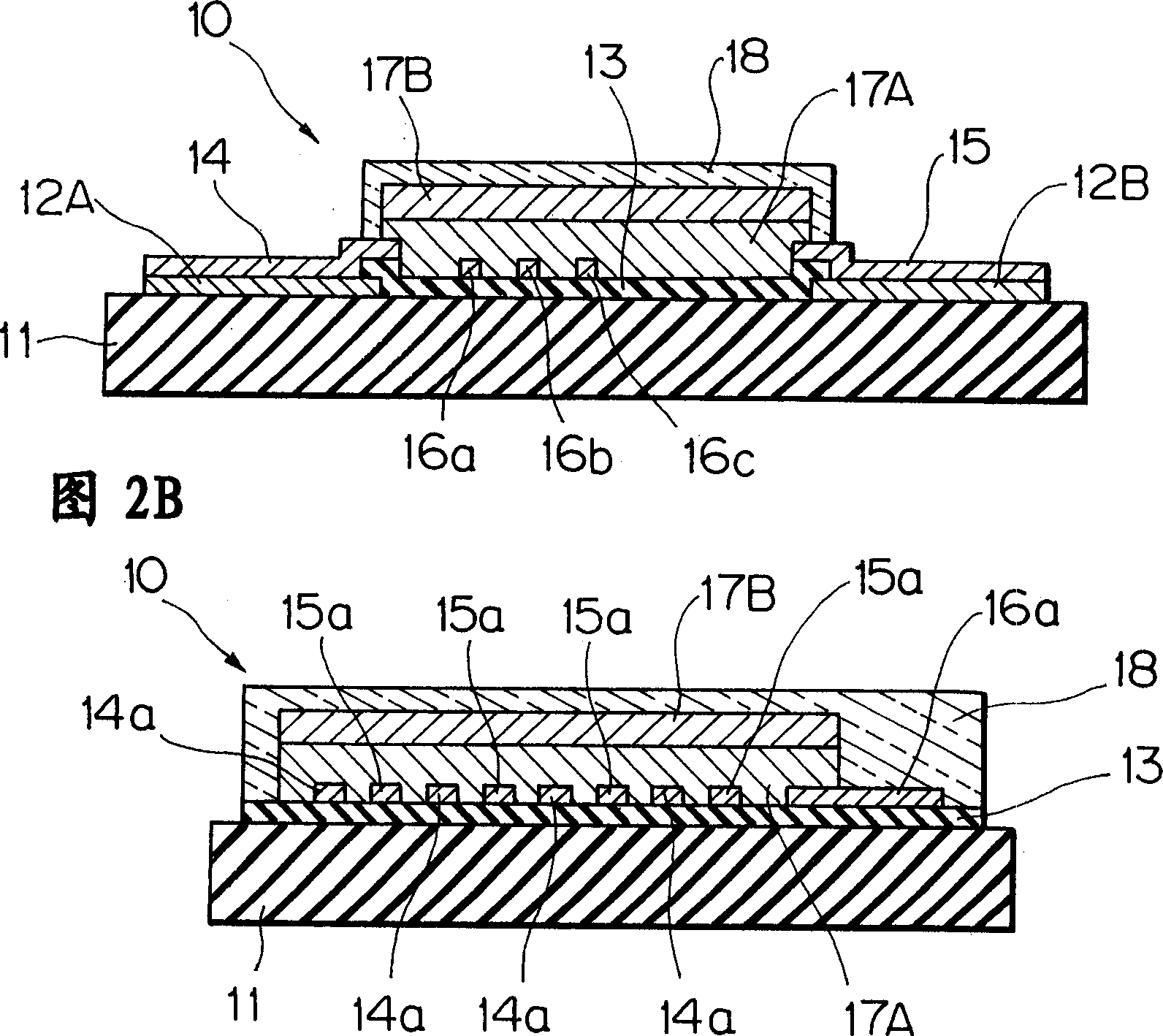

[0064] Explanations will now be given of various embodiments of the thin film thermistor according to the present invention with reference to the drawings.

[0065] exist figure 1 and 2, reference numeral 10 denotes a thin film thermistor. The thin film thermistor 10 includes: an insulating substrate 11; a pair of opposite lower electrodes 12A and 12B formed on the insulating substrate 11; an insulating coating 13 formed between the lower electrodes 12A and 12B; lead electrodes 14 and 15 ; The comb electrodes 14a and 15a extending from the extraction electrodes 14 and 15 to the insulating coating 13; the metallic pattern 16 for resistance adjustment electrically connected with the extraction electrodes 14, which has a cutting portion 16a for cutting , 16b and 16c; a first thermosensitive film 17A formed over the comb electrodes 14a and 15a; a second thermosensitive film 17B formed over the first thermosensitive film 17A; and a protective film 18.

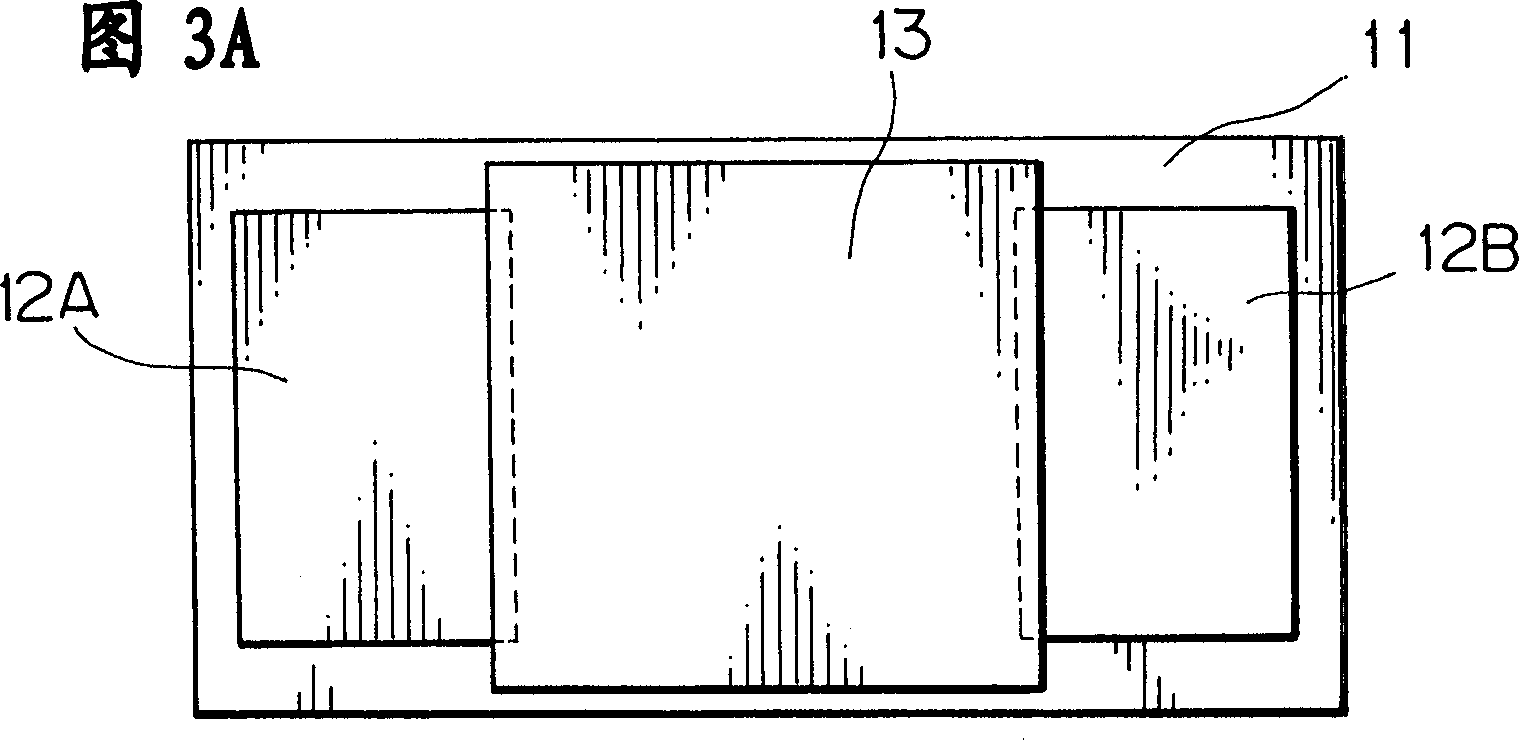

[0066] Referring to FIG. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com