Device for pre-lithiation of negative electrode and method for pre-lithiation of negative electrode

A pre-lithiation and negative electrode technology, applied in the direction of negative electrodes, lithium batteries, battery electrodes, etc., can solve the problems of pre-lithiation electrode deviation, uneven electrode pre-lithiation, hindering large-scale production, etc., and achieve the goal of preventing composition changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120]

[0121] 85.1 wt % of graphite and 9.5 wt % of SiO as negative electrode active materials, 1.3 wt % of Denka black as a conductive material, 3.0 wt % of SBR as a binder, and 1.1 wt % of a thickener CMC was added to water to prepare negative electrode slurry.

[0122]The negative electrode slurry was coated on both surfaces of a copper current collector (thickness: 8 μm), and then rolled and dried in a vacuum oven at 130° C. A negative electrode active material layer is formed on each surface, thereby manufacturing a negative electrode.

[0123] The negative electrode was wound on a negative electrode roll made of stainless steel and having a diameter of 3 inches.

[0124]

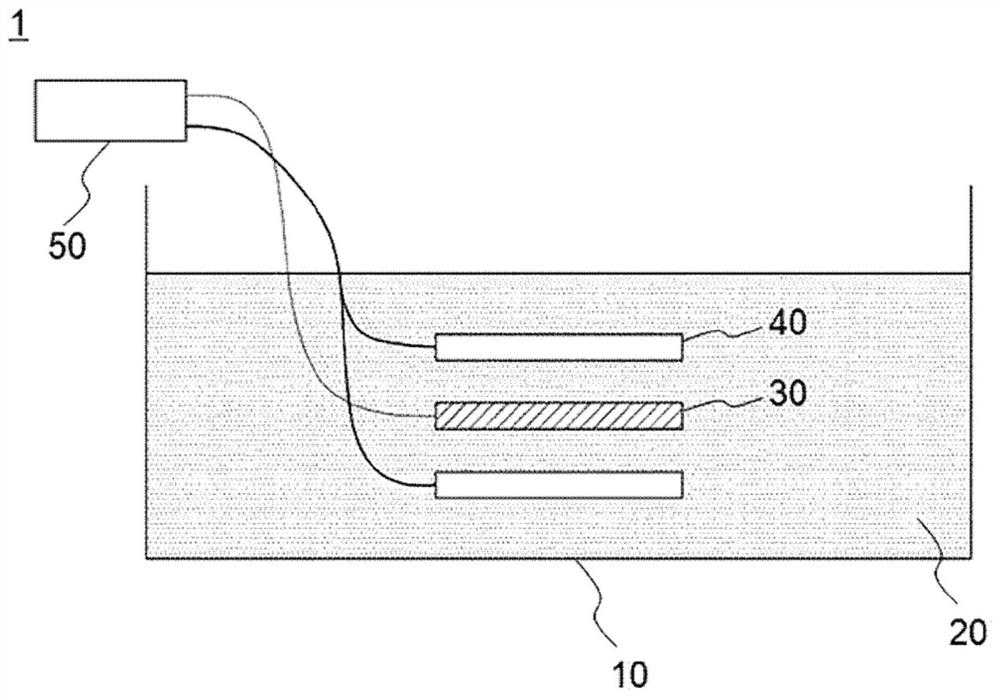

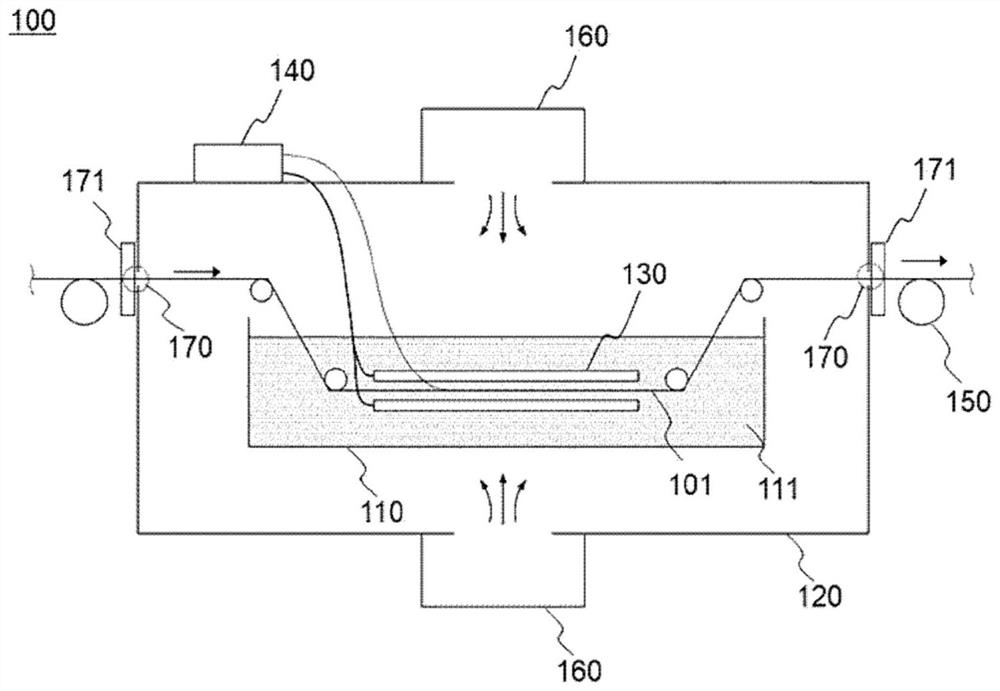

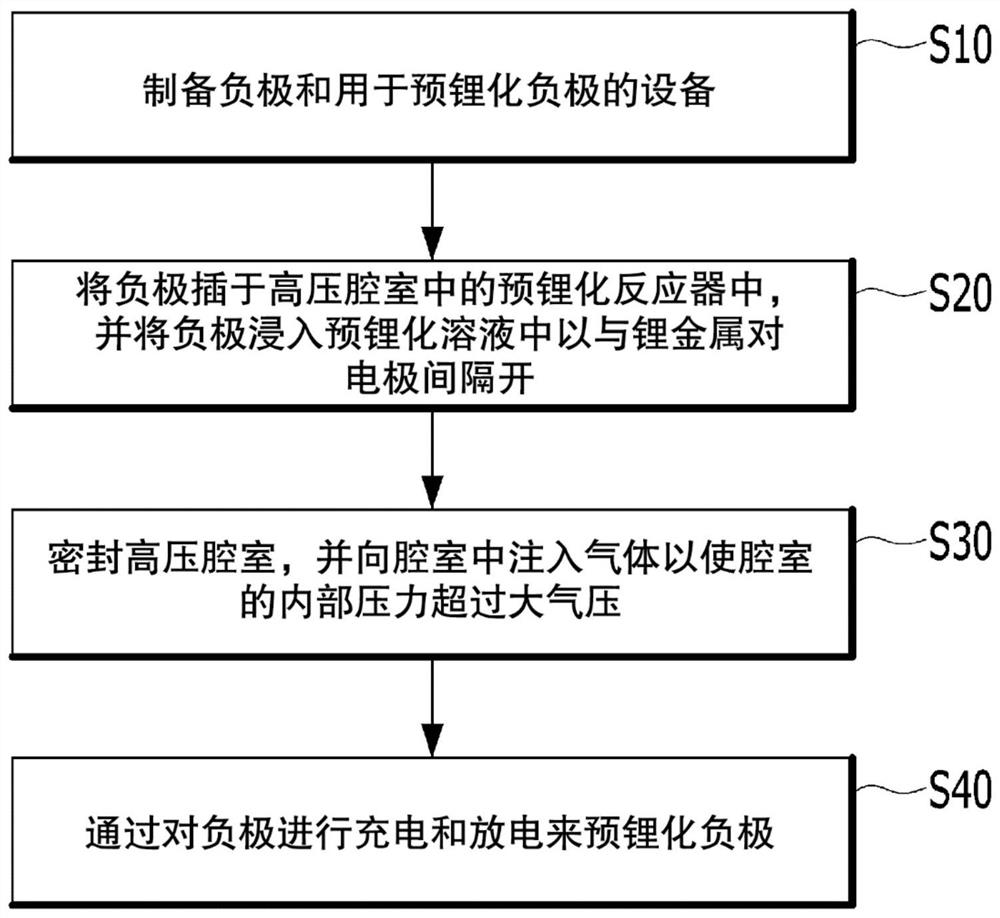

[0125] prepared as figure 2 Pre-lithiation device shown. Specifically, a pre-lithiation reactor made of stainless steel was prepared and housed in a high pressure chamber. The prelithiation solution was injected into the prelithiation reactor. The temperature of the prelithiation reactor wa...

Embodiment 2

[0131] The pre-lithiation process was repeated 10 times using the pre-lithiation solution and the pre-lithiation apparatus of Example 1 . After that, by newly inserting the negative electrode into the pre-lithiation reactor of the pre-lithiation apparatus of Example 1, a pre-lithiated negative electrode was obtained by performing pre-lithiation in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com