ZnO-based sputtering target and photovoltaic cell having passivation layer deposited using the same

A photovoltaic cell and sputtering target technology, which is applied in photovoltaic power generation, sputtering coating, coating, etc., can solve the problems of photovoltaic cell efficiency reduction, achieve the effects of improving uniformity, reducing interface diffusion, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

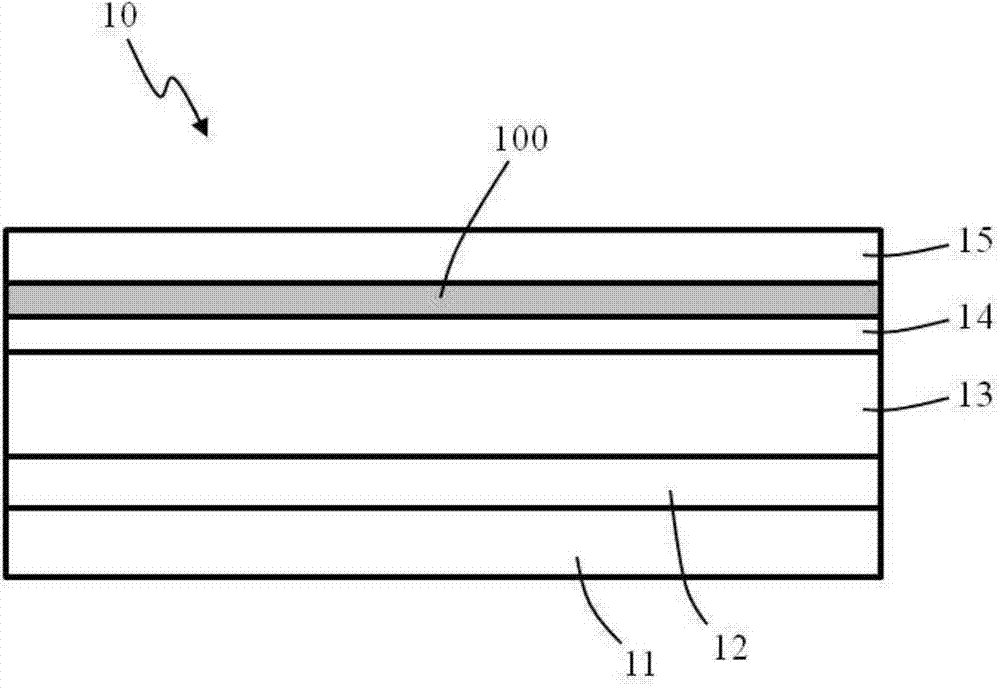

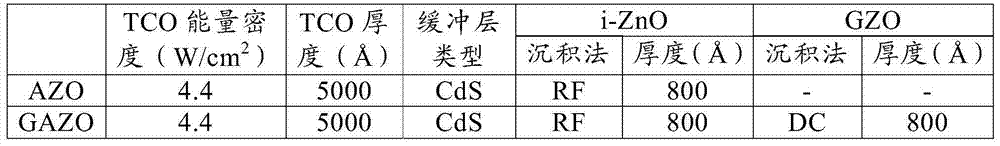

[0045] A buffer layer is formed by depositing cadmium sulfide (CdS) on a light absorbing layer made of copper indium gallium selenide (CIGS) compound. A passivation layer was formed on the buffer layer by direct current (DC) sputtering using a gallium oxide doped zinc oxide (GZO) target. A transparent electrode (TCO) was formed on the passivation layer by DC sputtering using a Ga-Al-Zn-O (GAZO) target. Then, the properties of the resulting structures were analyzed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com