High-strength cermet for cutting non-ferrous metal sheet and preparation method thereof

A non-ferrous metal sheet and cermet technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high cost and low service life, and achieve the effect of low cost, reduced production cost and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

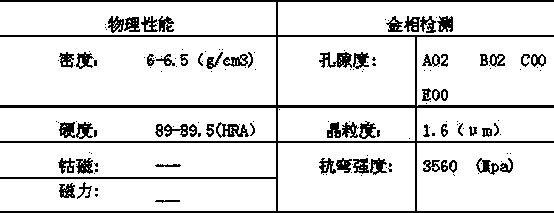

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

[0026] According to one aspect of the present invention, there is provided a preparation method of high-strength cermet for cutting non-ferrous metal sheets, wherein the preparation method includes the following steps:

[0027] a. Take virgin TiC (titanium carbide) powder, virgin Mo (molybdenum) powder, virgin Ni (nickel) powder and NbC (niobium carbide) powder through ball milling media for 48h-64h to obtain slurry. The average value of virgin TiC powder The Fibonacci particle size ≤1.0μm, the mass percentage is 44%-46% (for example, 45%), the average Fibonacci particle size of the primary Mo powder is ≤1.0μm, and the mass percentage is 14%-16% (for example 15%). The averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com