Continuous annealing method of pure titanium roll

An annealing and titanium coil technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of large temperature range for titanium strip heating, long annealing time, and large total annealing time range, so as to ensure the smooth operation of production and improve Grain uniformity, the effect of ensuring annealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example is used to illustrate the continuous annealing method of the pure titanium coil of the present invention.

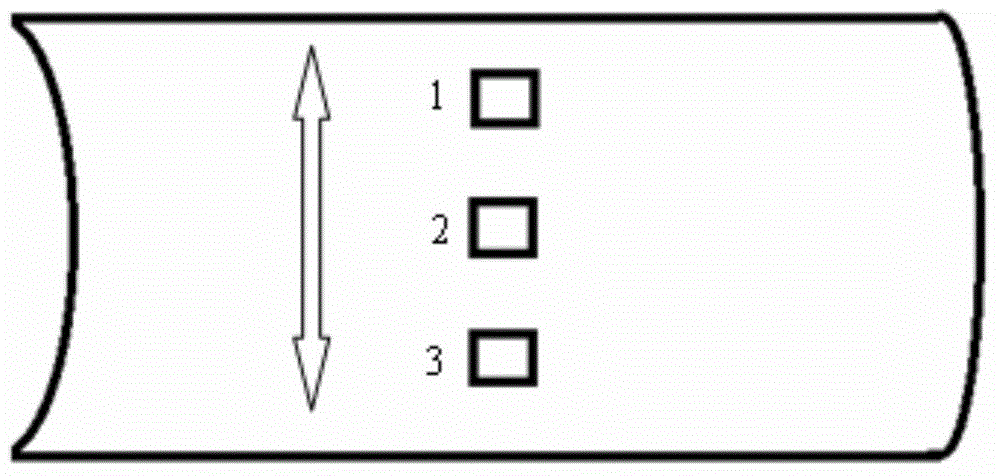

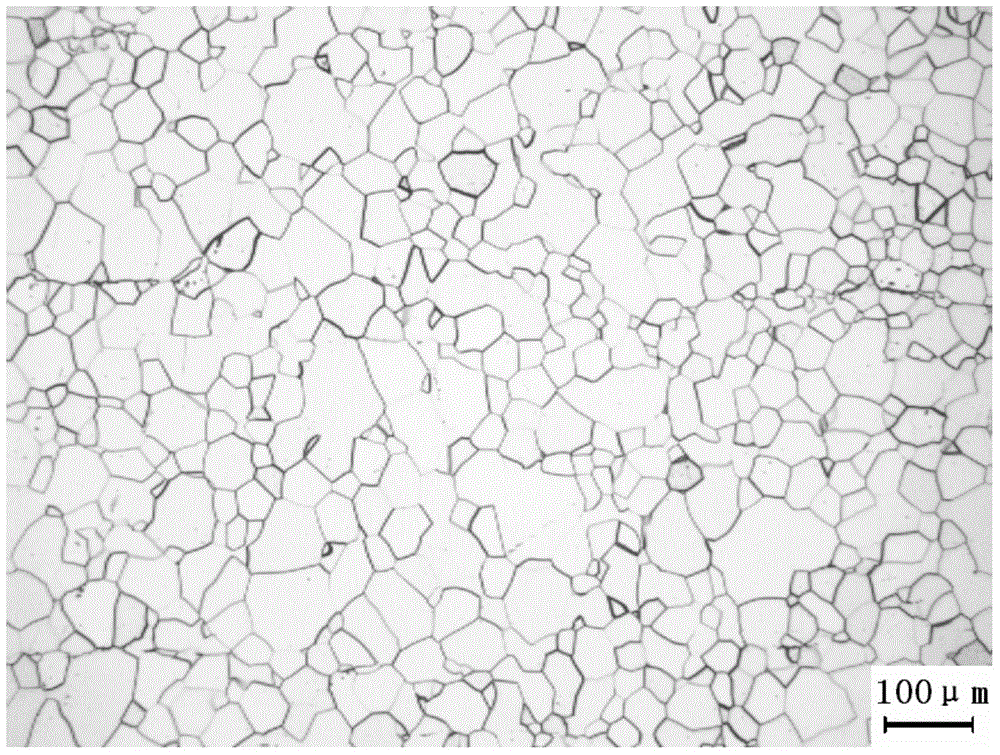

[0034]The pure titanium coil to be annealed is uncoiled on the uncoiler, and the head of the last titanium coil unrolled on the uncoiler is welded to the tail of the previous titanium coil, and each titanium coil is repeated in this way; the titanium strip is applied by a tension roller. The tension of 500kg makes the titanium belt pass through the preheating section, heating section and soaking section of the annealing furnace continuously at a speed of 3m / min. Pass between the flames of the upper and lower rows of burners; and by adjusting the gas flow, combustion-supporting air flow and burner opening, the titanium belt is preheated to 320°C in the preheating section, and the titanium belt passes through at a constant temperature of 720°C Heating section, and make the titanium strip pass through the soaking section at a constant temperature of 720°...

Embodiment 2

[0037] This example is used to illustrate the continuous annealing method of the pure titanium coil of the present invention.

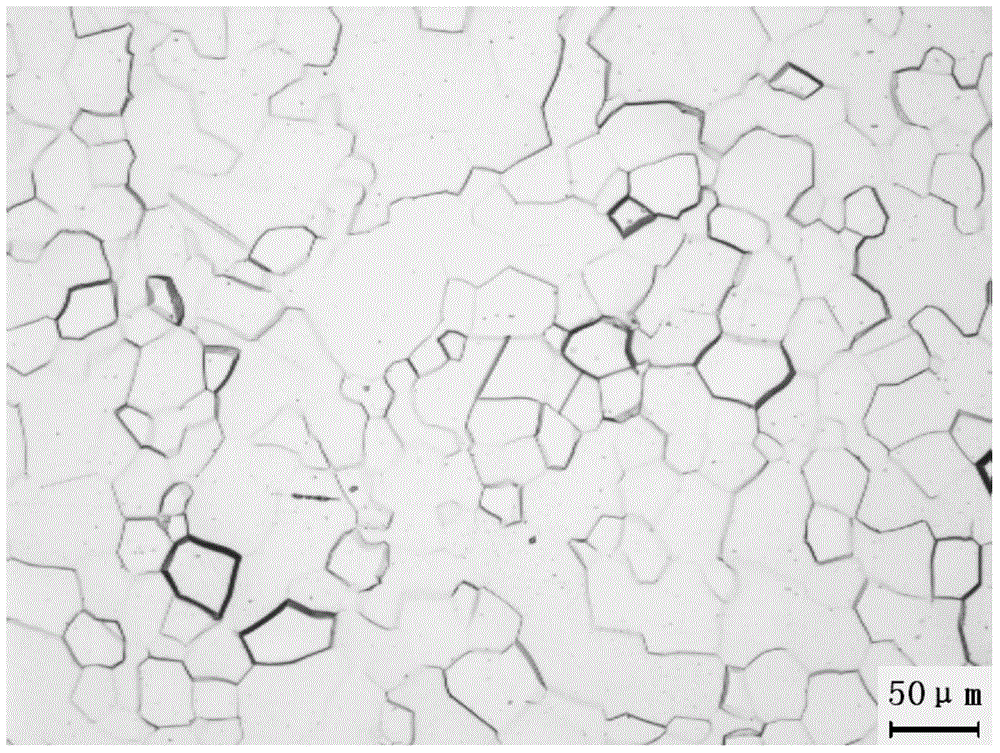

[0038] The pure titanium coil to be annealed is uncoiled on the uncoiler, and the head of the last titanium coil unrolled on the uncoiler is welded to the tail of the previous titanium coil, and each titanium coil is repeated in this way; the titanium strip is applied by a tension roller. The tension of 800kg makes the titanium belt pass through the preheating section, heating section and soaking section of the annealing furnace continuously at a speed of 2m / min. Pass between the flames of the upper and lower rows of burners; and by adjusting the gas flow, combustion-supporting air flow and burner opening, the titanium belt is preheated to 250°C in the preheating section, and the titanium belt passes through at a constant temperature of 700°C Heating section, and make the titanium strip pass through the soaking section at a constant temperature of 700...

Embodiment 3

[0041] This example is used to illustrate the continuous annealing method of the pure titanium coil of the present invention.

[0042] The pure titanium coil to be annealed is uncoiled on the uncoiler, and the head of the last titanium coil unrolled on the uncoiler is welded to the tail of the previous titanium coil, and each titanium coil is repeated in this way; the titanium strip is applied by a tension roller. With a tension of 200kg, the titanium strip continuously passes through the preheating section, heating section and soaking section of the annealing furnace at a speed of 5m / min. Pass between the flames of the upper and lower rows of burners; and by adjusting the gas flow, combustion-supporting air flow and burner opening, the titanium belt is preheated to 350°C in the preheating section, and the titanium belt passes through at a constant temperature of 750°C Heating section, and make the titanium strip pass through the soaking section at a constant temperature of 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com