Energy-saving and environment-friendly annealing furnace

An energy saving, environmental protection, annealing furnace technology, applied in the field of photovoltaics, can solve the problems of inability to adjust semiconductor wafers, fixed shape and size, energy waste, etc., and achieve the effects of good popularization practicability, energy saving, and simple modification methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

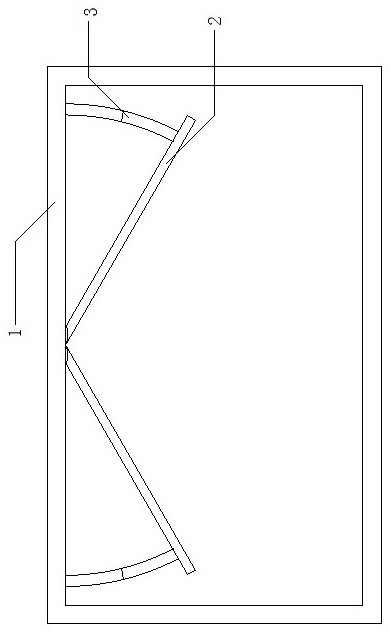

[0023] Such as figure 1 Shown is a schematic structural diagram of the present invention, which is an energy-saving and environment-friendly annealing furnace, comprising an annealing furnace body 1 and an adjustable inner wall cover plate 2 installed inside the annealing furnace body 1 .

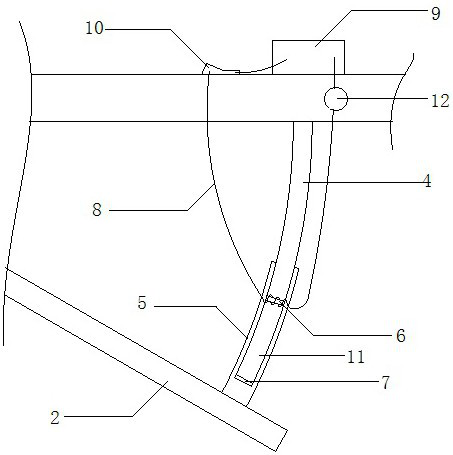

[0024] The number of inner wall cover plates 2 is two, and the ends of the two inner wall cover plates 2 that are close to each other are installed on the top of the furnace body wall along the depth direction of the annealing furnace body 1, and the ends that are far away from each other are installed on the annealing furnace through the adjustment piece 3 On the furnace inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com