A temperature control system and method for silicon carbide crystal resistance annealing

A temperature control system, silicon carbide technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as no annealing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

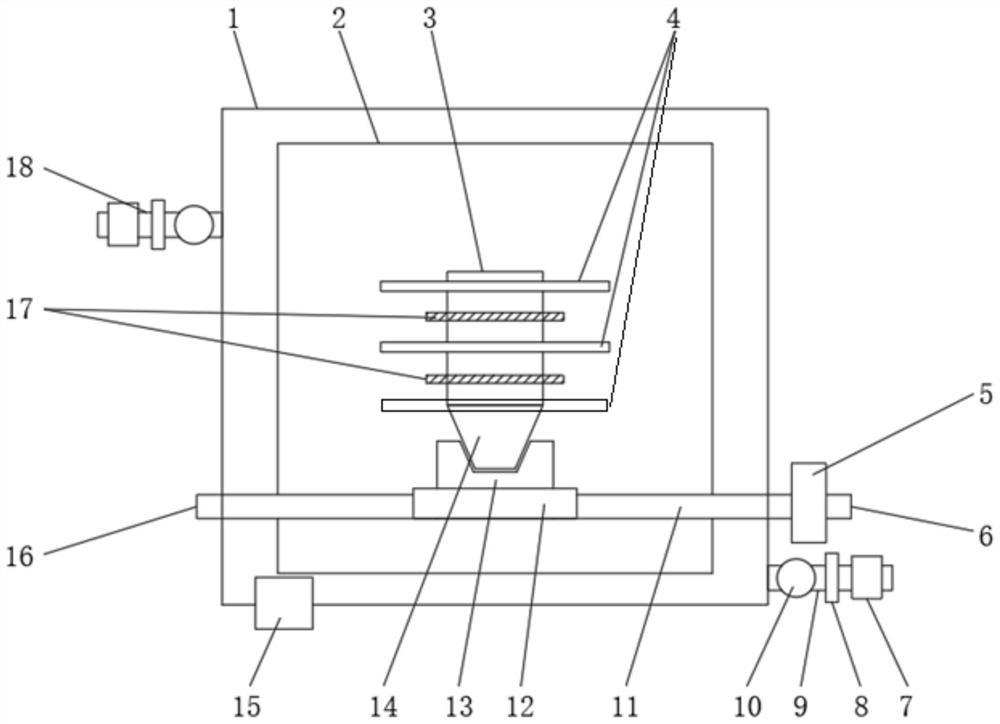

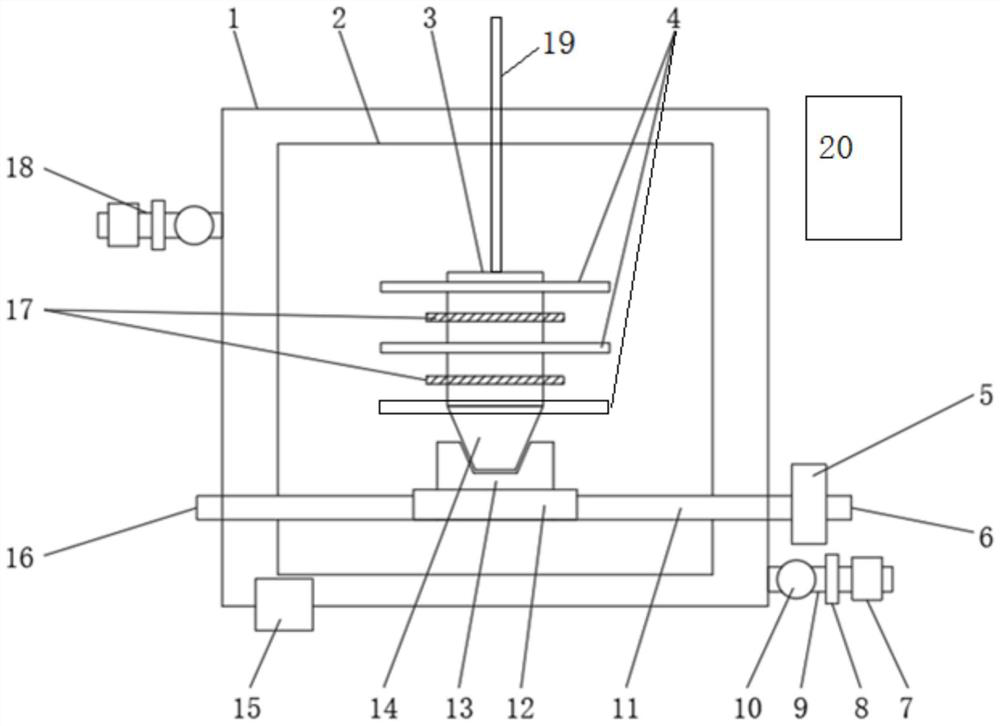

[0017] by figure 1 Shown as an example, specifically implemented in the following manner: a temperature control system for silicon carbide crystal resistance annealing, comprising a growth furnace body 1, a heat preservation cover 2, a crucible 3, and a heating device 4, characterized in that: the resistance annealing The temperature control system also includes a flow controller 5, a water inlet 6, a flow control device 7, a thermometer 8, an air outlet pipe 9, a barometer 10, a heat transfer rod 11, a base 12, a crucible holder 13, a seed crystal tank 14, and a vacuum system 15. Water outlet 16, shelf-type temperature measuring thermocouple group 17 and air intake pipe 18, heat transfer rod 11 passes through the inside of the growth furnace body 1 transversely, and the left end of heat transfer rod 11 is provided with water outlet 16, the The water outlet 16 is arranged on the outside of the growth furnace body 1, the right end of the heat transfer rod 11 is provided with a ...

Embodiment 2

[0022] A temperature control method for silicon carbide crystal resistance method annealing, which utilizes a temperature control system for silicon carbide crystal resistance method annealing as described above to implement, it is characterized in that it includes the following steps: 1) annealing temperature step setting step : Set the annealing temperature step, set the initial temperature to 1900°C, and set N-level cooling intervals, each level of annealing temperature step is 50°C, and the final cooling temperature of the Nth level is TPn (n=1,2,3...) , and set the time required for each level of cooling, set the time required for cooling down from 1900 ° C to the Nth level as Tn minutes (n = 1, 2, 3...), the final temperature of annealing is 50 ° C, a total of 37 annealing temperature steps, the above settings are input in the control platform and stored in the control PC, and can be called at any time when controlling the annealing temperature steps; 2) steps for determi...

Embodiment 3

[0024] A temperature control method for silicon carbide crystal resistance method annealing, which utilizes a temperature control system for silicon carbide crystal resistance method annealing as described above to implement, it is characterized in that it includes the following steps: 1) annealing temperature step setting step : Set the annealing temperature step, set the initial temperature to 1900°C, and set N-level cooling intervals, each level of annealing temperature step is 60°C, and the final cooling temperature of the Nth level is TPn (n=1,2,3...) , and set the time required for each level of cooling, set the time required for cooling down from 1900 ° C to the Nth level as Tn minutes (n = 1, 2, 3...), the final temperature of annealing is 40 ° C, a total of 31 annealing temperature steps, the above settings are input in the control platform and stored in the control PC, and can be called at any time when controlling the annealing temperature steps; 2) steps for determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com