Manufacturing method of wolfram-contained austenite stainless steel seamless tube

A manufacturing method and tungsten austenite technology, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve problems such as poor product quality, and achieve the effects of avoiding hot processing, good room temperature performance, and improving grain uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

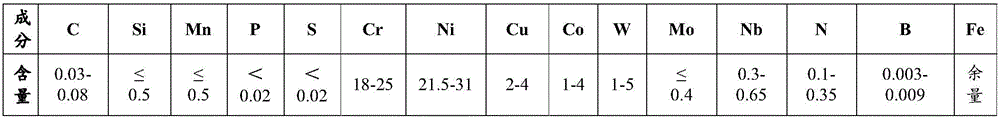

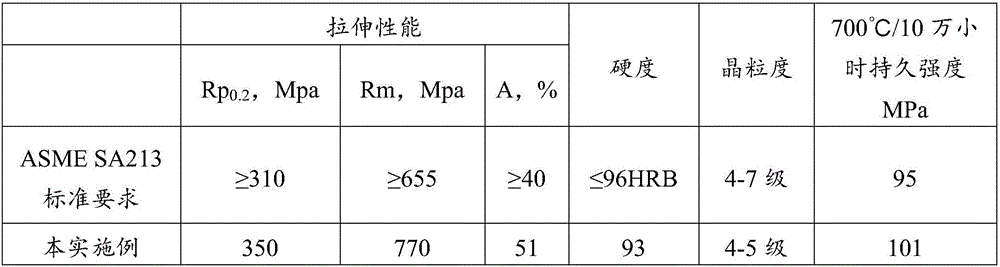

[0057] The finished product specification of the seamless pipe in this embodiment is Ф45×10mm, and the specific components are as follows (mass fraction%), and the balance in the following table is Fe:

[0058] C Si MnPSCr NiWCu Nb BN 0.050.190.500.0140.00221.8024.803.602.820.420.00250.18

[0059] Taking the tube blank of Φ219 / 50mm as an example, the main process specification design is:

[0060] Φ219 / 50mm→(extrusion) Ф108×18mm→(first cold rolling) Ф76×13mm→(second cold rolling) Ф57×10mm.

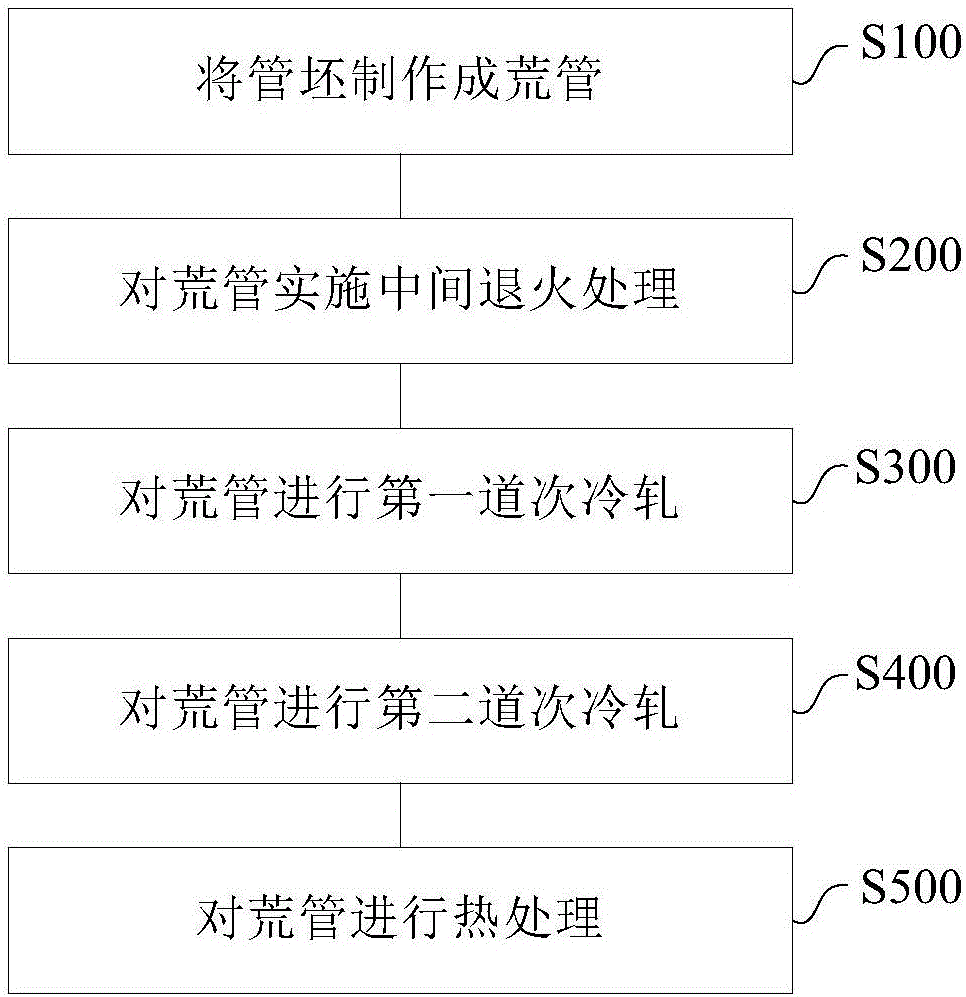

[0061] Specific steps are as follows:

[0062] Step 1: Make the tube blank into a waste tube.

[0063] Sub-step B1, preparation of tube blank.

[0064] Using Φ219mm tube blank, deep hole drill drills a Φ50mm through hole in the center, one end face is chamfered and processed into a 40° bell mouth, and the tube blank is surface treated.

[0065] Substep B2, preheating of the ring furnace.

[0066] Put the tube blank into the ring furnace for preheating, the furnace temperature is 550°C, the total heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com