Patents

Literature

68results about How to "Improve room temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength cast Mg alloy containing rare-earth and preparing process thereof

A high-strength cast RE-contained Mg-alloy contains Nd (2.5-3.6 Wt%), Zr (0.35-0.8), Zn (0-0.4), Ca (0-0.5), impurities (0-0.02) and Mg (rest). It is prepared through smelting Mg, adding Nd, Zr and Ca in Mg-Nd, Mg-Zr and Mg-Ca alloy mode, adding Zn, solution treating at 525-540 deg.C for 4-12 hr, quenching in water and ageing at 200 deg.C for 12-20 hr. It has high strength, hardness and high-temp creep performance.

Owner:SHANGHAI JIAO TONG UNIV

Cast aluminum-silicon alloy for engine cylinder head and heat treatment process

InactiveCN102071341AImprove room temperature performanceHigh tensile strengthChemical compositionSilicon alloy

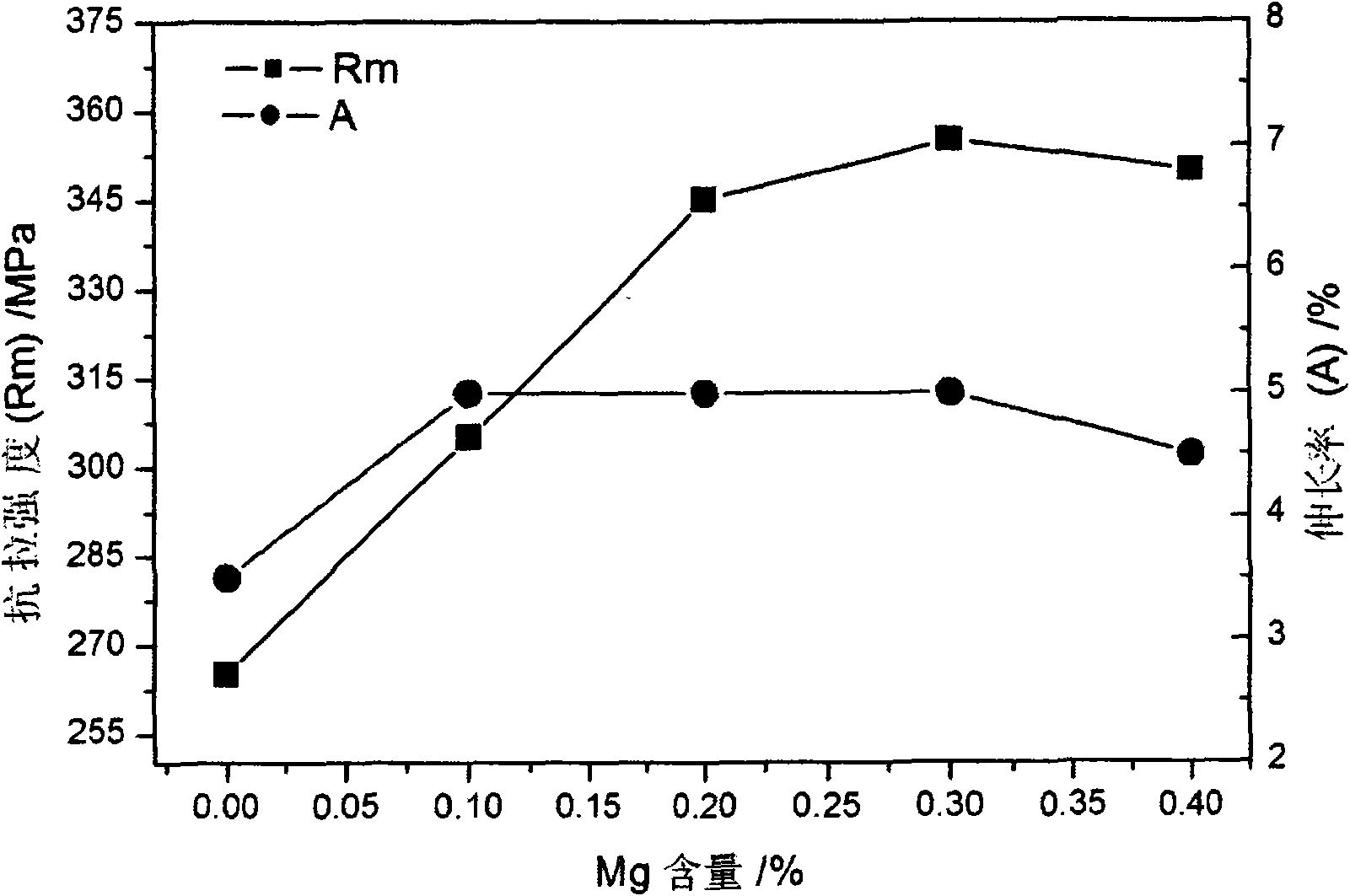

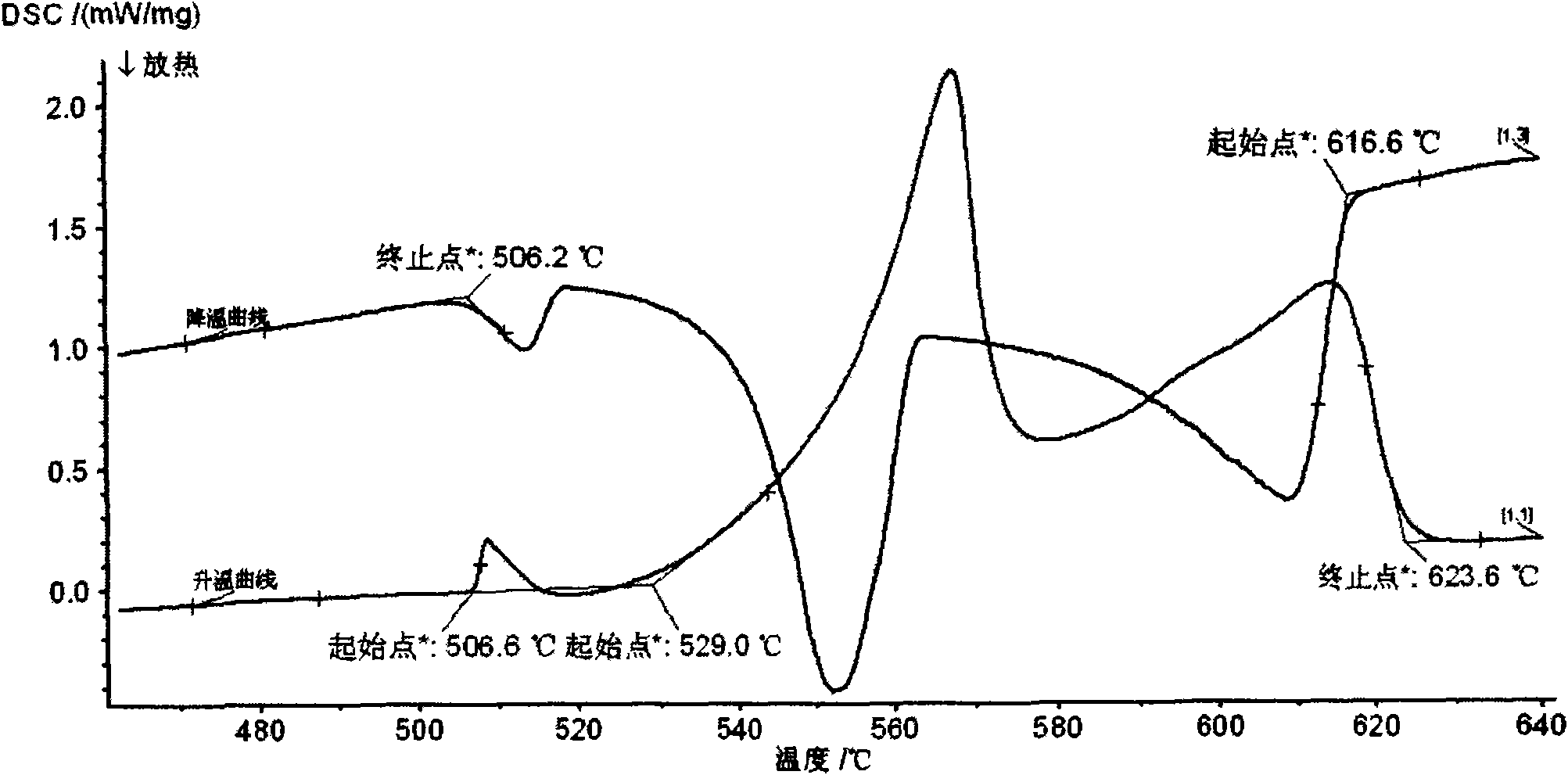

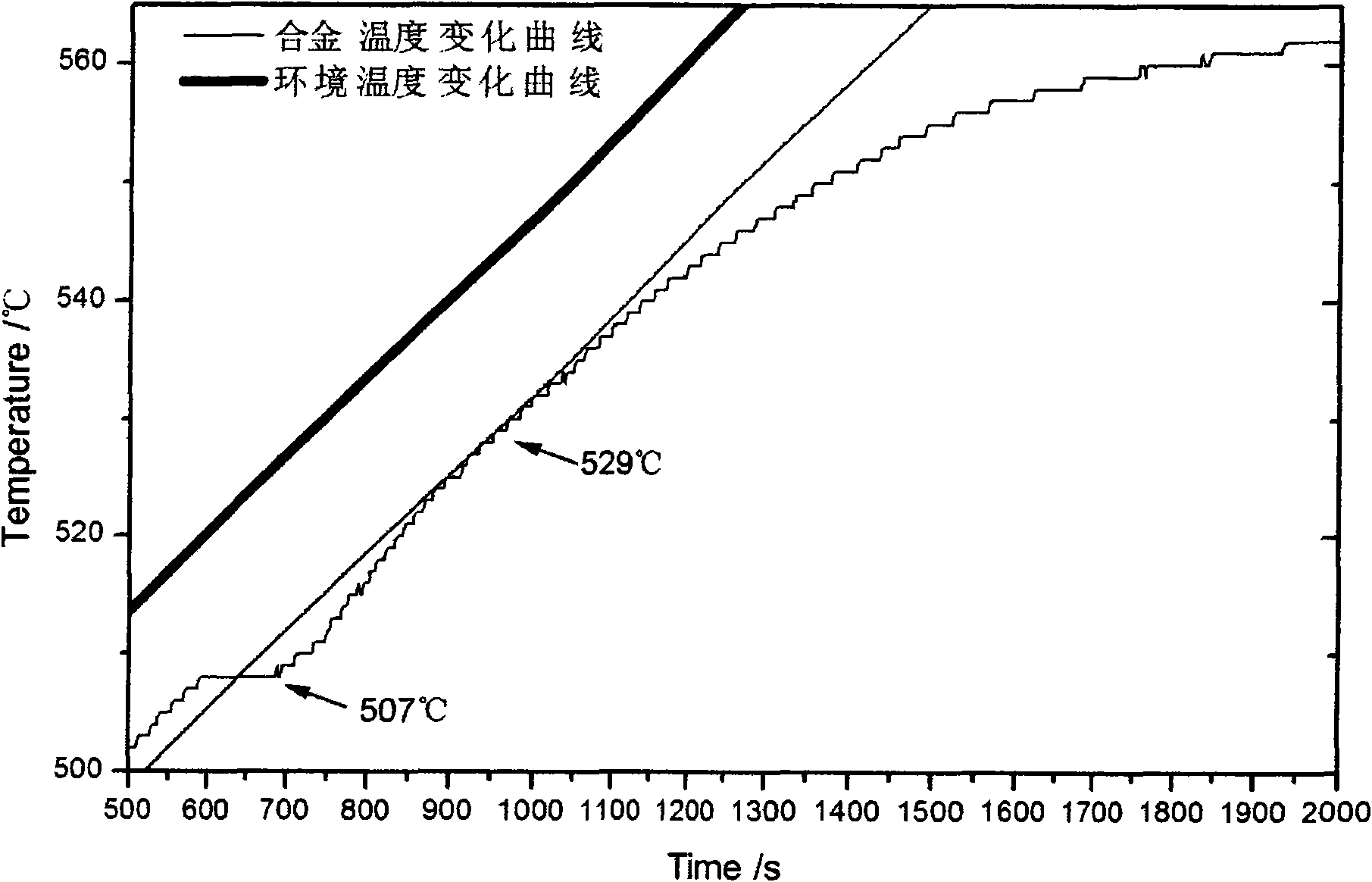

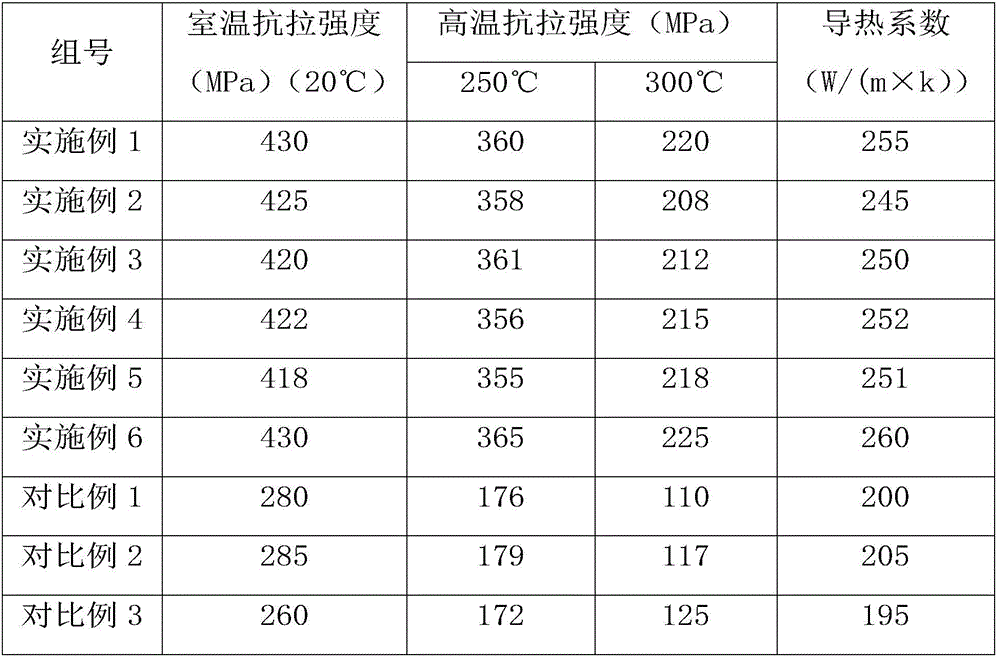

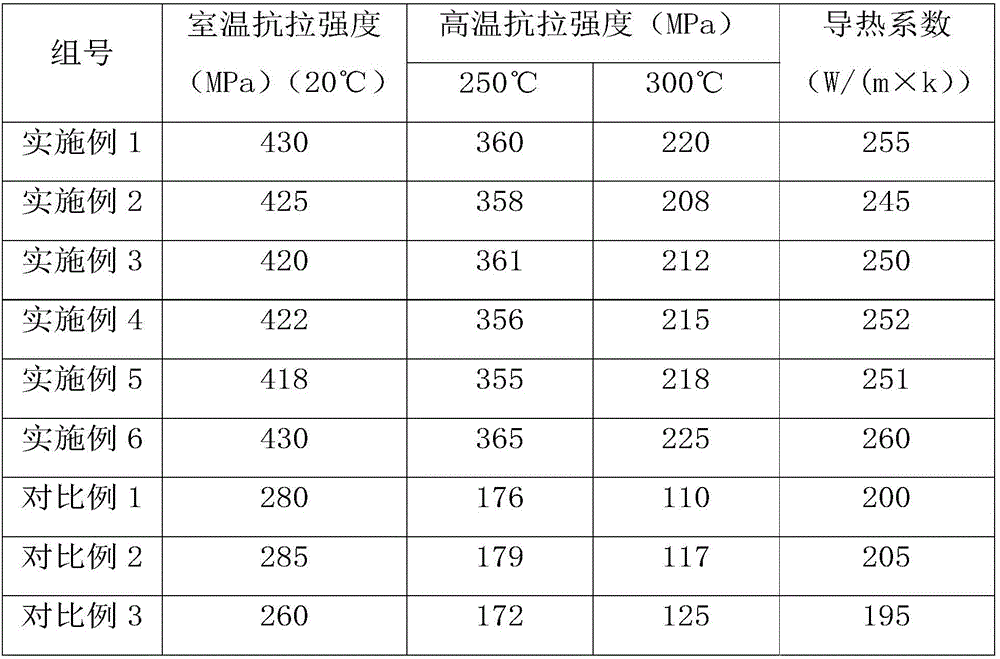

The invention relates to a cast aluminum-silicon alloy for an engine cylinder head and a heat treatment process. The alloy comprises the following chemical ingredients in percentage by weight: 5.0 to 7.0 percent of Si, 3.0 to 4.0 percent of Cu, 0.2 to 0.4 percent of Mg, 0.1 to 0.3 percent of Mn, 0.10 to 0.20 percent of Zr, 0.15 to 0.25 percent of Ti, 0.01 to 0.05 percent of B, 0.02 to 0.09 percent of Sr, 0.1 to 0.3 percent of rare earth (RE), less then 0.3 percent of Fe and the balance Al, wherein the rare earth (RE) adopts mixed rare earth. The heat treatment process comprises the following steps: carrying out primary solution at a temperature between 490 DEG C and 505 DEG C, and carrying out heat insulation for 4 to 6h; carrying out secondary solution at a temperature between 510 DEG C and 525 DEG C, carrying out heat insulation for 6 to 10h, and carrying out quenching by hot water of 60 to 80 DEG C; and carrying out aging treatment with parameters of the aging temperature being 155to 165 DEG C and the heat insulation time being 5 to 9h, and carrying out cooling in the air. All alloy elements of the cast aluminum-silicon alloy provided by the invention are reasonably matched, good mechanical performance is realized, at a normal temperature, the tensile strength reaches 325 to 355MPa, the tensile stretch is 2.5 to 5.5 percent, at a high temperature of 250 DEG C, the tensile strength reaches 240 to 270MPa, and the tensile stretch is 3.0 to 5.5 percent, after the heating processing technology, the heat resistance performance of the alloy is improved, and the casting defect is reduced.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

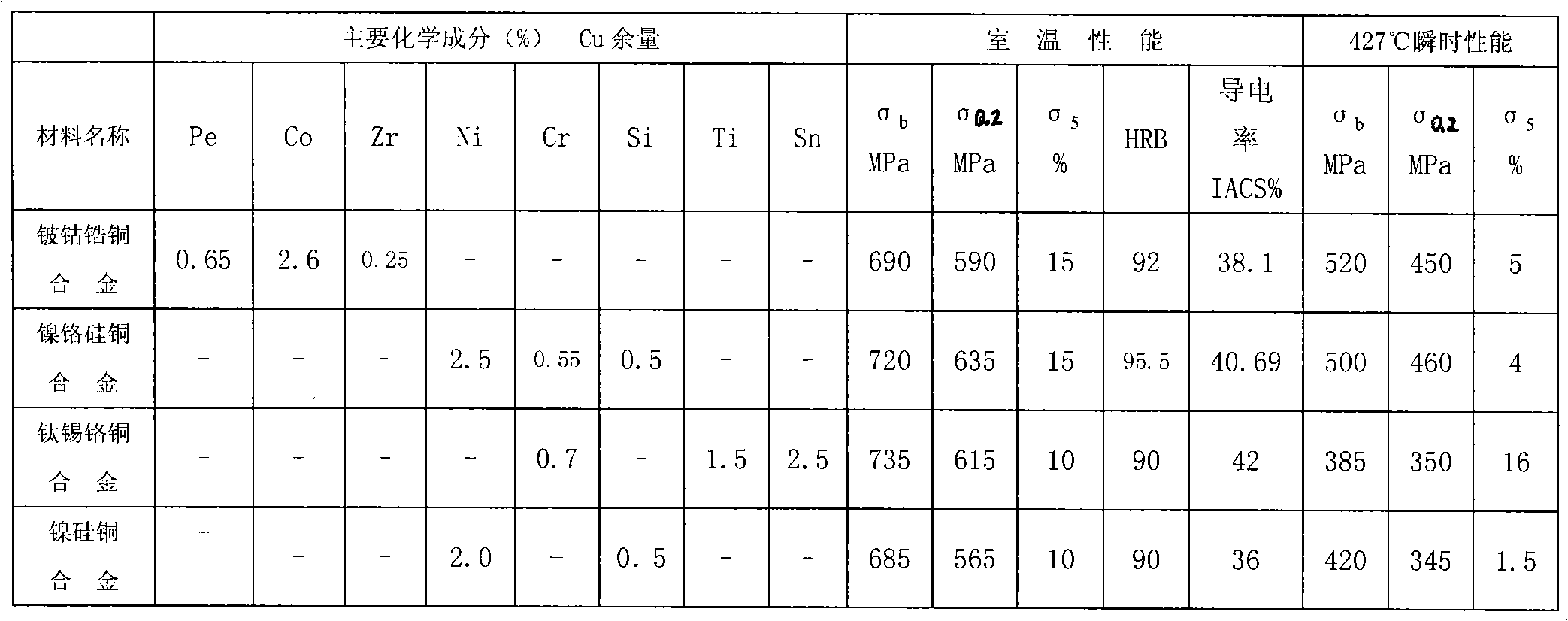

High-strength nickel-chromium-silicon-copper alloy material and processing technology thereof

The invention relates to a copper alloy material and a processing technology thereof, in particular to a high-strength nickel-chromium-silicon-copper alloy material and a processing technology thereof. The alloy material has low toxicity and low cost. The alloy material comprises the following components by mass: 2.1-2.9% of Ni, 0.4-0.7% of Cr, 0.3-0.7% of Si, not more than 0.3% of total impurities and the balance of Cu. The processing technology comprises the steps of casting, press processing, high-temperature solution hardening and heat treatment, cold press processing, aging heat treatment and mechanical processing.

Owner:SHENYANG XINGGONG COPPER IND

Light-weight and high-strength cast aluminum lithium alloy and preparation method thereof

The invention discloses a light-weight and high-strength cast aluminum lithium alloy and a preparation method thereof. The alloy consists of Li, Cu, Mg, Zn, Zr, Ti, Mn, Ce and impurity elements in specific percentages by weight as well as the balance of Al. During preparation, an aluminum alloy is obtained by smelting Al-Li, Al-Cu, Al-Zr, Al-Ti-B, Al-Mn, Al-Ce intermediate alloy, pure aluminum, pure Zn and Pure Mg, and then is subjected to two-stage solid solution heat treatment of 400-450 DEG C / 8-10h and 510-540 DEG C / 20-28h, and one-stage aging treatment of (120-190) DEG C* (30-48) h is carried out after hardening treatment to obtain the light-weight and high-strength cast aluminum lithium alloy. The mechanical properties such as room temperature strength, hardness, rigidity and breaking tenacity of the prepared aluminum lithium alloy are superior to those of a traditional business aluminum alloy, and the aluminum lithium alloy is also low in cost.

Owner:SHANGHAI JIAO TONG UNIV

Laser synthesis preparation method of intermetallic compound and granule reinforced composite material

InactiveCN1546694AThe ingredients are designed to be simpleReduce manufacturing costHigh power lasersChemical compound

The invention relates to a laser synthesis preparation method of intermetallic compound and granule reinforced composite material which includes, using the powder stock containing the same elements with the intermetallic compound to be prepared, adding additionally elements during the process of sedimentation and mixing, forming local molten pool on the base material surface through high power laser irradiation, feeding the mixed powder into molten pool, stacking up to obtain large area coating, block material or formed parts, adjusting powder components or laser technique to obtain intermetallic compound or particle reinforcement intermetallic composite material with dissimilar compositions, structure and property.

Owner:TSINGHUA UNIV

Aluminum based composite material for piston and preparation thereof

The invention belongs to the metallic material field, relating to aluminium base composite materials used in a piston and a preparation method thereof. The composite materials comprise a matrix alloy and a wild phase. The matrix alloy comprises silicon, copper, nickel, magnesium, phosphorus, titanium and aluminium and is characterized in that the matrix alloy comprises the components according to the mass percent: 10.0-25.0% of silicon, 0.5-2.5% of copper, 0.5-4.0% of nickel, 0.2-1.5 of magnesium, 0.2-3.0 % of phosphorus, 0.01-1.0% of titanium and the rest is magnesium. The wild phase is AIP particles generated by reaction in situ. The preparation method comprises the following steps: the raw materials are weighted according to the mass percent; flash set argon pulverization treatment is carried out on Si-P interalloy; the commercially pure aluminium, silicon, copper, nickel, magnetism and titanium are melted into multielement aluminium alloy in a smelter hearth in the temperature of 760 DEG C to 850 DEG C, and is added with flash set Si-P interalloy particles after refining; the metal mold gravity casting or the extrusion casting are used for pouring piston rough; T6 heat treatment is carried out on the casting rough. In the invention, the production can be carried out by using a common aluminium alloy smelting unit in atmosphere condition. The invention has simple technique and low production cost.

Owner:SHANDONG UNIV +1

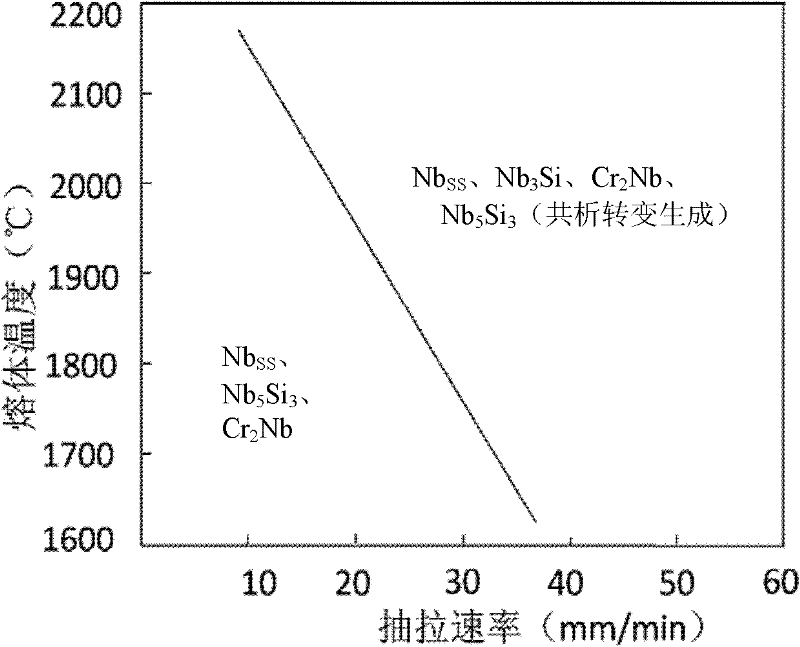

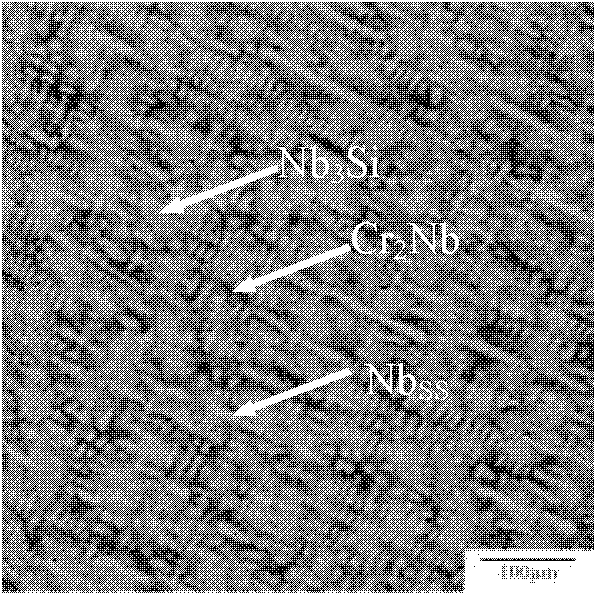

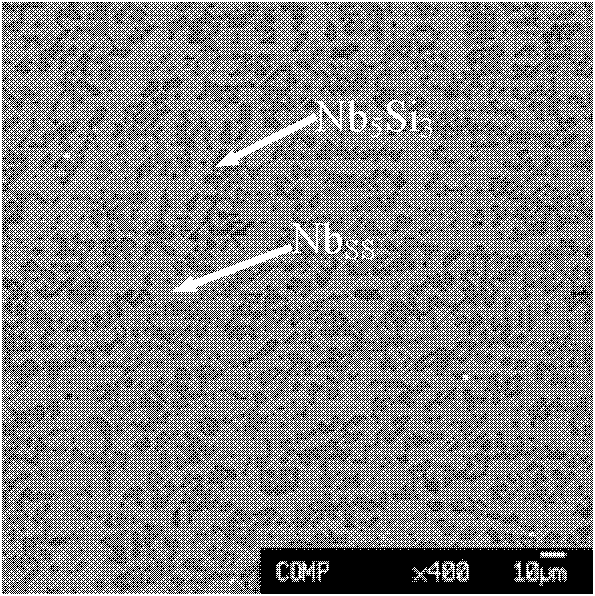

Structure controlled preparation method for Nb-Si-based complex alloy

InactiveCN102418025AImproved room temperature performanceShort preparation cycleOxidation resistantDuctility

The invention discloses a structure controlled preparation method for an Nb-Si-based complex alloy. According to the method, the structure of the Nb-Si-based complex alloy is controlled by adopting a combined process of unbalanced quick directional solidification and heat treatment; and the faceted growth property of silicide in the alloy is weakened, dimensions of a reinforcing phase Nb5Si3 and an anti-oxidation phase Cr2Nb in the alloy are remarkably reduced, a Nbss phase is used as the matrix in the steady-state structure of the Nb-Si-based complex alloy, the reinforcing phase Nb5Si3 is uniformly distributed on the matrix in a wormlike shape, and the anti-oxidation phase Cr2Nb is uniformly distributed or fixedly dissolved in the matrix in a granular shape, wherein the average length of the wormlike Nb5Si3 phase is less than 20 microns, the width of the Nb5Si3 phase is 5 microns, the size of the granular Cr2Nb phase is less than 10 microns, and the content of the two phases is not less than 35 percent. By structure control, the alloy contains enough Nb5Si3 and Cr2Nb phases, so that the alloy has good room temperature toughness and ductility on the premise of achieving excellent high-temperature mechanical property and oxidation resistance.

Owner:BEIHANG UNIV

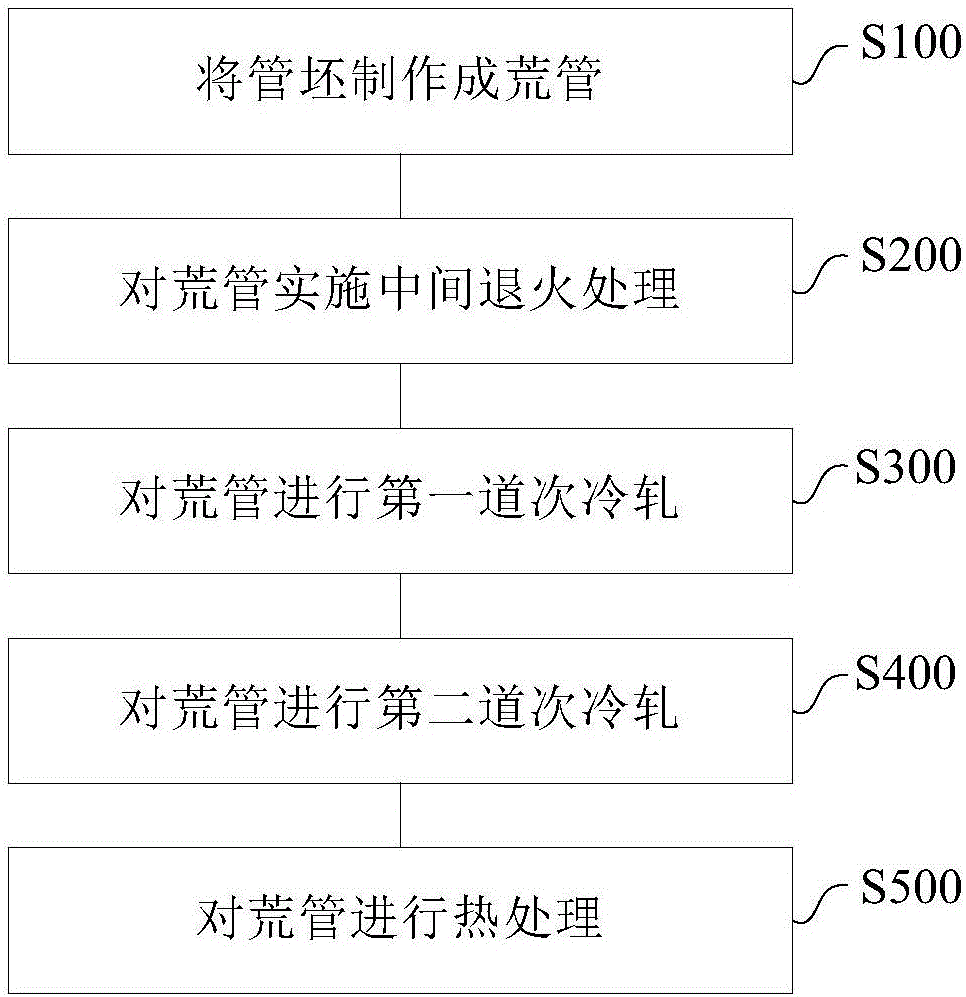

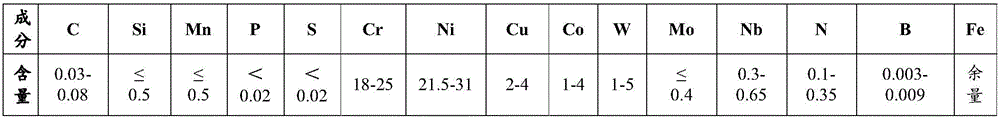

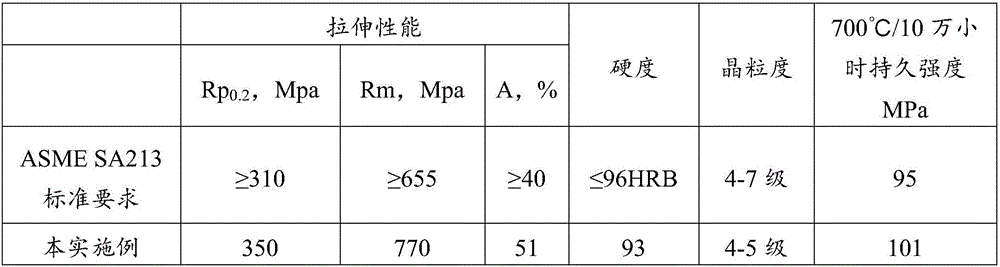

Manufacturing method of wolfram-contained austenite stainless steel seamless tube

InactiveCN106702259AImprove grain uniformityImprove room temperature performanceFurnace typesMetal rolling arrangementsHeat treatedAustenitic stainless steel

The invention discloses a manufacturing method of a wolfram-contained austenite stainless steel seamless tube. The method comprises following steps: 11, a tube blank is manufactured into a pierced billet, in the process of manufacturing the pierced billet, the extrusion ratio of extrusion to the pierced billet ranges from 6 to 12, and the extrusion speed ranges from 130 to 180mm / s; 12, the pierced billet is subject to first-pass cold rolling, and the pass deformation amount of the first-pass cold rolling ranges from 40% to 60%; 13, intermediate annealing treatment is applied to the pierced billet subject to first-pass cold rolling, the annealing temperature ranges from 1120 DEG C to 1200 DEG C, and heat preservation is carried out for 30 min to 60 min; 14, second-pass cold rolling is applied to the pierced billet subject to intermediate annealing treatment, and the pass deformation amount of the second-pass cold rolling is controlled to range from 35% to 50%; 15, the pierced billet subject to second-pass cold rolling is subject to heat treatment, temperature of heat treatment ranges from 1150 DEG C to 1250 DEG C, and heat preservation is carried out for 30 min to 60 min. The manufacturing method solves the problem that the product quality of a wolfram-contained austenite stainless steel seamless tube manufactured at present is poor.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

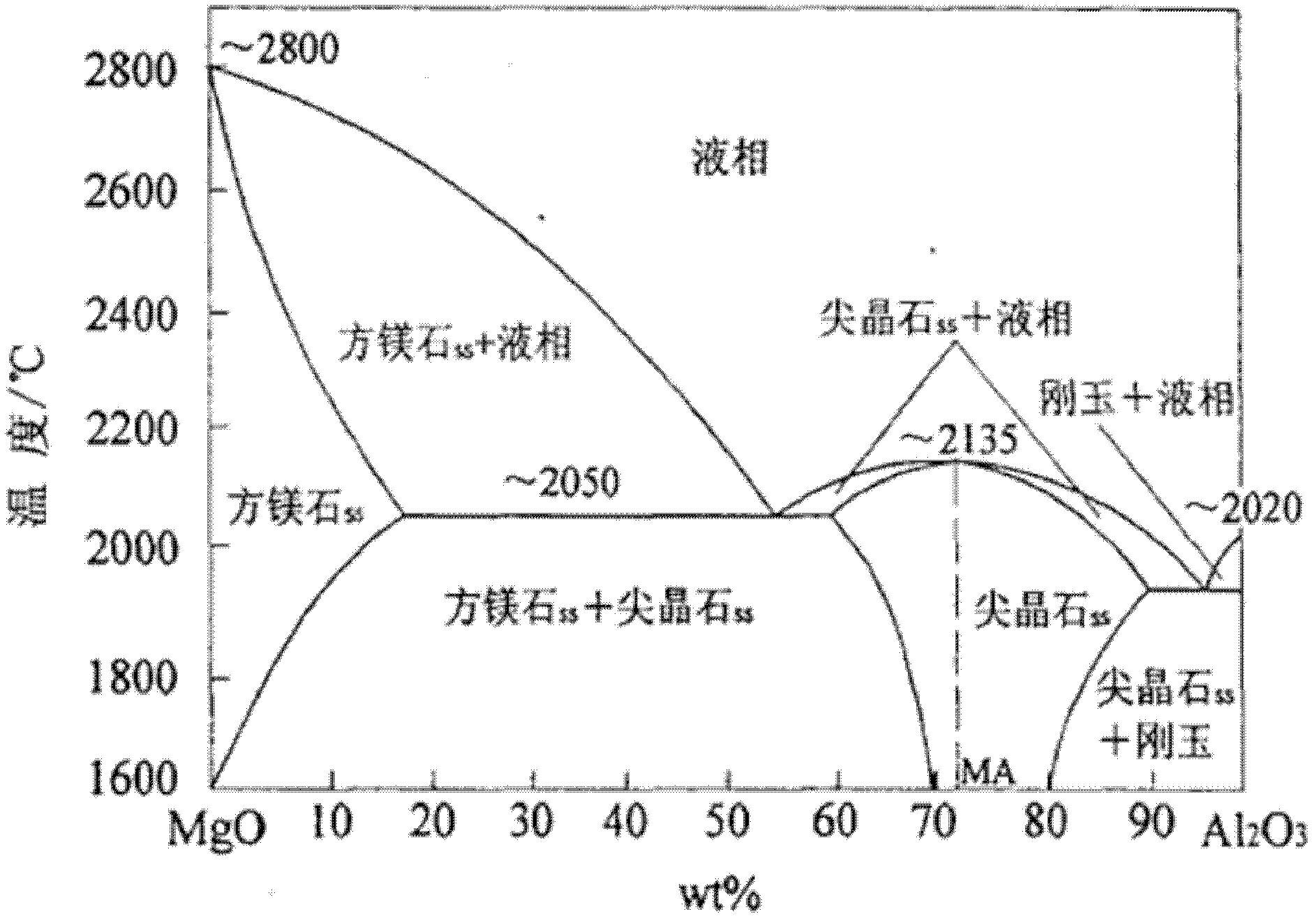

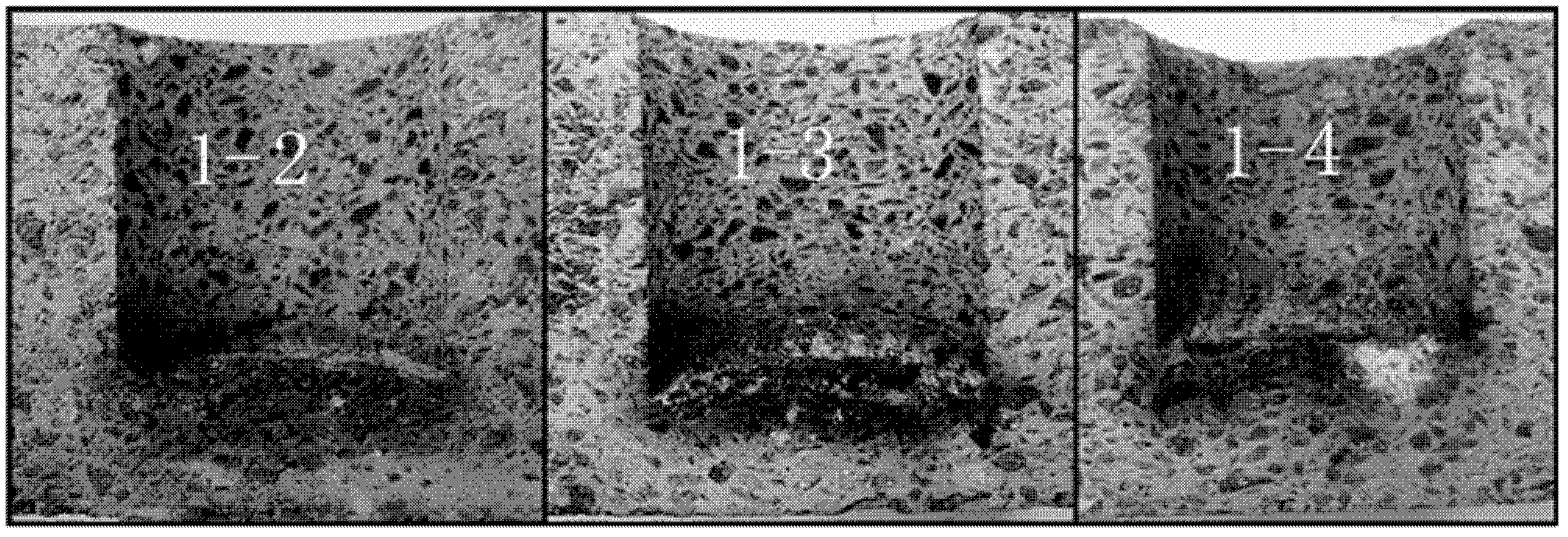

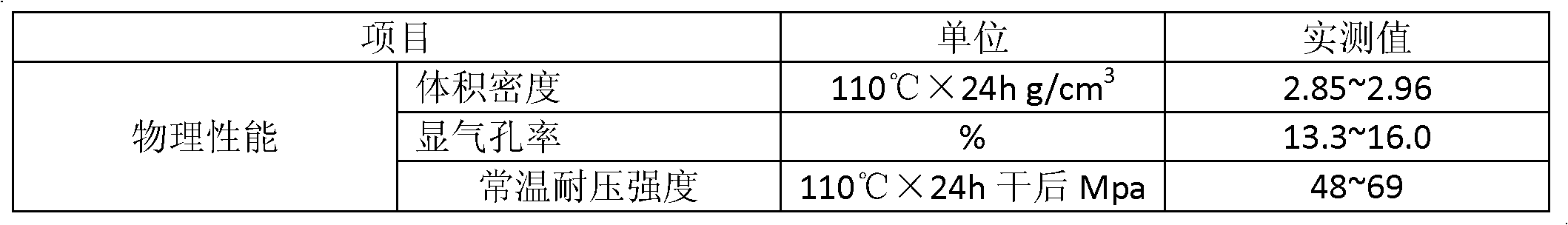

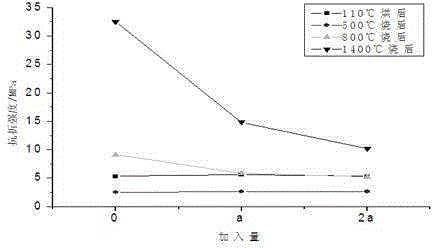

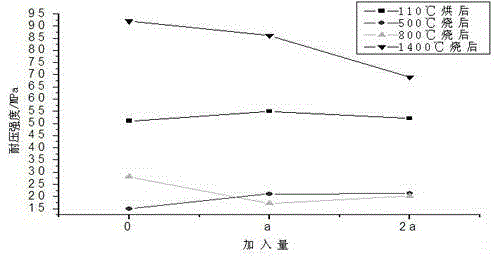

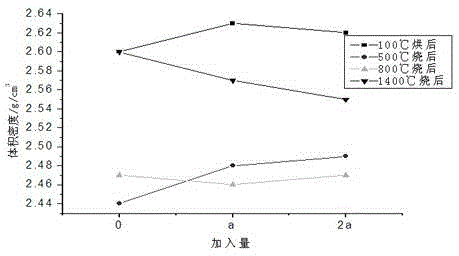

Aluminum-spinel-magnesia composite refractory as well as preparation method and application thereof

The invention belongs to the field of refractory, and discloses an aluminum-spinel-magnesia composite refractory as well as a preparation method and an application thereof. The aluminum-spinel-magnesia composite refractory comprises a raw material and an additional inorganic binding agent, wherein the raw material comprises the following components by weight: 60-94% of magnesia, 5-30% of magnesium-rich spinel or magnesium-aluminum spinel and 1-15% of metal aluminum powder, and the inorganic binding agent is 1-5% of the raw material. The aluminum-spinel-magnesia composite refractory is mainly used for substituting for magnesite-chrome bricks in an RH refining surface. The refractory can be thermally prepared at low temperature, so that energy consumption in the preparation process is lowered and the environmental pollution is reduced; and in the using process, part of the added aluminum powder is oxidized and forms a CA2 protective layer together with the calcium oxide in the slag so that the anti-slag permeability is improved.

Owner:江苏诺明高温材料股份有限公司

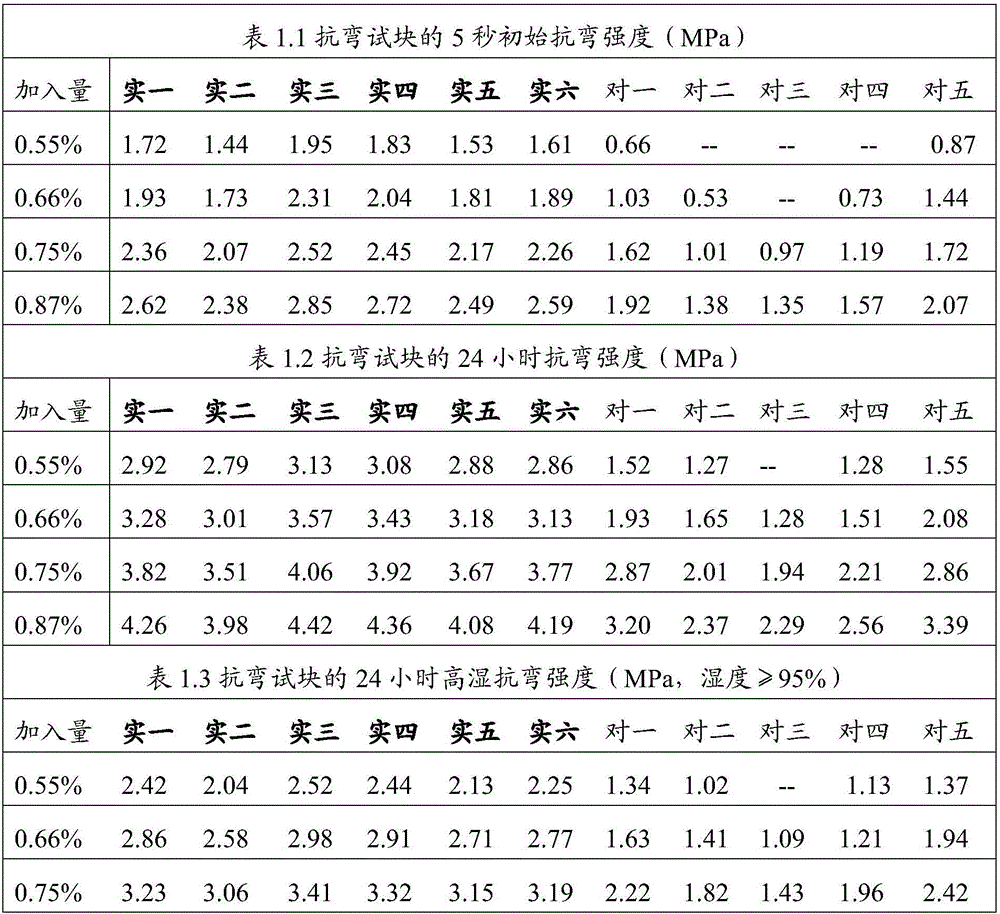

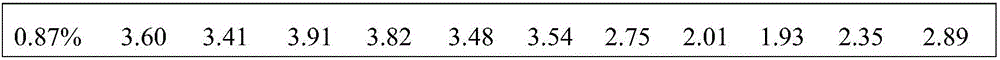

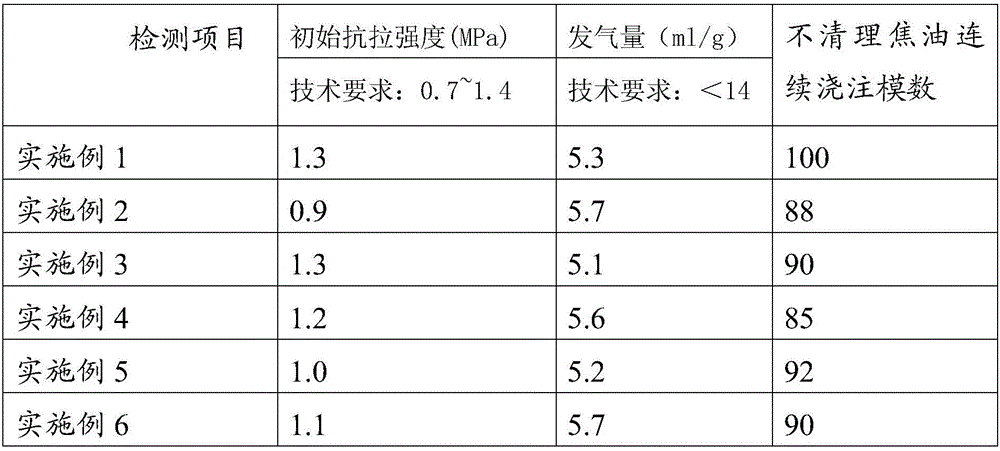

Cold core box binder and casting molding body

ActiveCN106040966AImprove room temperature performanceImprove room temperature strengthFoundry mouldsFoundry coresTarHydrocarbon solvents

The invention discloses a cold core box binder and a casting molding body and belongs to the technical field of binders. The cold core box binder comprises a first component. The first component is composed of, by weight, 40-80 parts of benzyl ether phenolic resin, 1-50 parts of high-boiling-point ester and / or hydrocarbon solvents and 0.1-10 parts of tackifying auxiliaries, wherein the content of hydroxymethyl of the benzyl ether phenolic resin is 32%-50%. According to the cold core box binder, the resin using amount is decreased to 0.55%-0.75% under the condition that the strength of a resin sand mold core is ensured; compared with the prior art, the resin using amount is greatly decreased, and the collapsibility of the resin sand mold core is greatly improved; and meanwhile, the residual quantity of tar on a metal mold is decreased, and the production efficiency is improved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

High-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy and casting method thereof

InactiveCN105908024AImprove room temperature performanceImprove mechanical propertiesPressure castingGasoline

The invention relates to a high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy and a casting method thereof. The high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy is composed of the following components including, by weight, 9%-13% of Si, 0.2%-3% of Mg, 1%-6% of Cu, 1%-4% of Ni, 0.6%-1.0% of Fe, 0.6%-1.0% of Mn, 0.05%-1.2% of Zr, 0.05%-1.2% of V, 1%-25% of TiB2 particles, and the balance Al. After the high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy is subjected to pressure casting, the tensile strength is larger than or equal to 235 MPa at the temperature of 300 DEG C, the tensile strength is larger than or equal to 150 MPa at the temperature of 350 DEG C, and the coefficient of linear expansion within the temperature interval of 300 DEG C to 400 DEG C is (14-21)*10<-6> / DEG C; the casting property of the alloy is improved, the high-temperature (300 DEG C and 350 DEG C) tensile strength of the alloy is improved substantially, the coefficient of linear expansion of the alloy is reduced, and the application range of traditional cocrystallized Al-Si alloys is widened; and the high-temperature-resistant nano ceramic particle reinforced cocrystallized Al-Si alloy is particularly applicable to parts such as pistons of gasoline engines and diesel engines with quite high requirements for high temperature mechanical properties and for dimensional stability in the high-temperature working range.

Owner:SHANGHAI JIAO TONG UNIV

High-strength castable for prolonging service life of desulfuration spray gun and preparation method thereof

The invention discloses a high-strength castable for prolonging the service life of a desulfuration spray gun and a preparation method thereof. The castable is composed of following raw materials, by mass, 8-20% of andalusite, 15-25% of mullite, 20-35% of flint clay, 10-25% of spinel, 4-8% of SiC, 10-20% of a binding agent, and a water reducing agent accounting for 0.04-0.12% of the total weight the raw materials hereinabove. In the invention, the flint clay and the mullite are used as the main raw materials of the castable, the andalusite is used as an expansion agent and the spinel and fine powder of SiC are used as a composite additive in the castable. In addition, a multi-stage blending process is employed with the low-cement combination technology being applied, wherein the characters of ultra-micro powder are fully considered, so that the castable is excellent in normal temperature performances and is high in medium and high temperature strength.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

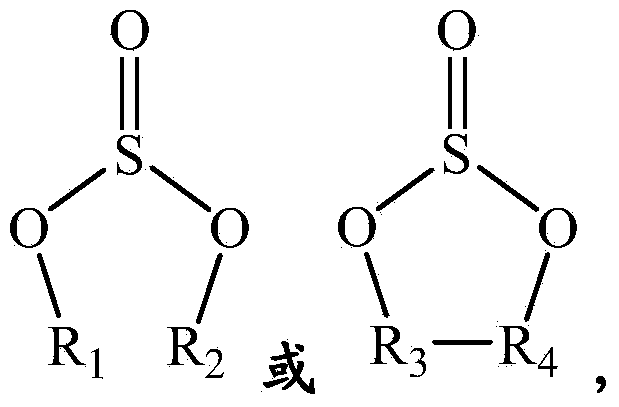

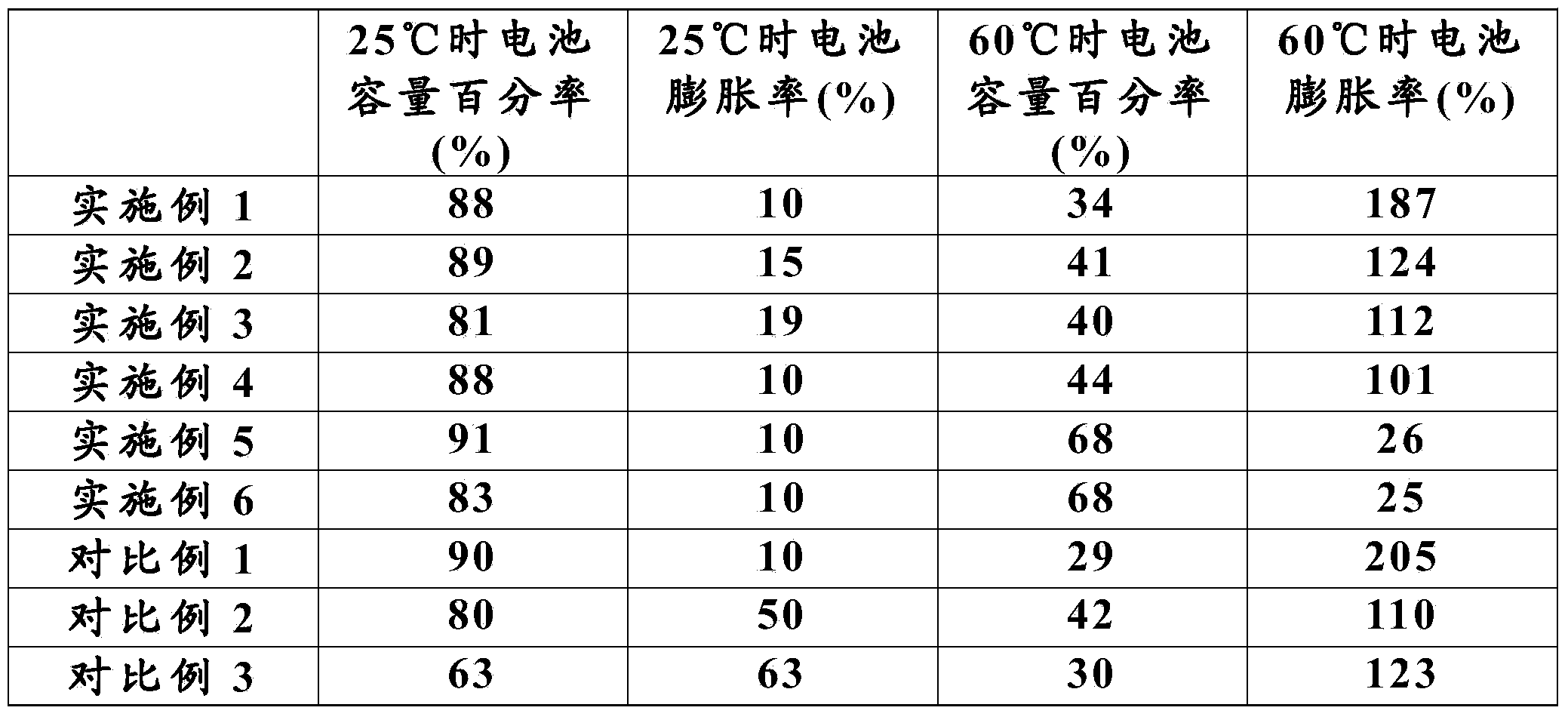

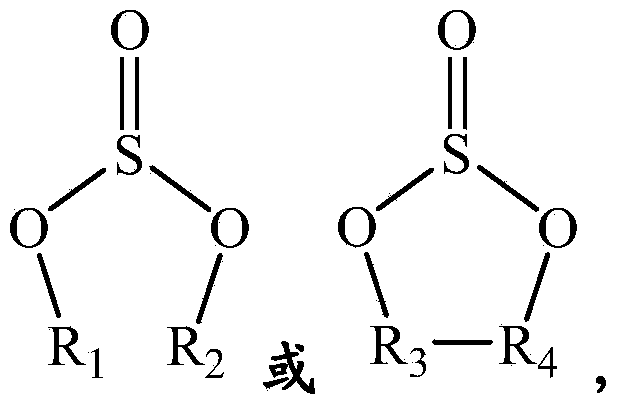

Silicon-anode lithium battery electrolyte and silicon-anode lithium battery

InactiveCN104241684AImprove charge and discharge performanceReduce flatulenceSecondary cellsOrganic electrolytesOrganic solventPhysical chemistry

The invention relates to silicon-anode lithium battery electrolyte. The silicon-anode lithium battery electrolyte consists of an organic solvent, a lithium salt and additives, wherein the concentration of the lithium salt is 0.001-2 mol / L; the additives consist of an additive A and fluorinated ethylene carbonate; the mass of the additive A accounts for 0.1-20% of the mass of the electrolyte; the mass of the fluorinated ethylene carbonate accounts for 0.1-10% of the mass of the electrolyte; the additive A is a sulfite compound. In a silicon-anode lithium ion battery, in non-aqueous electrolyte, the sulfite compound and the FEC (fluorinated ethylene carbonate) are used, and in EC (ethylene carbonate)-based electrolyte, electrochemical improvement effect on a silicon anode is good, and a formed SEI (solid electrolyte interface) film is thicker, so that the defect that the silicon anode has large volume expansion change in the cycle is made up, the charge and discharge performance of the silicon-anode lithium ion battery can be improved more effectively, side reactions can be reduced, thereby reducing battery expansion and improving the cycle life of the battery, and thus the room temperature performance and the high temperature performance of the battery are very good.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

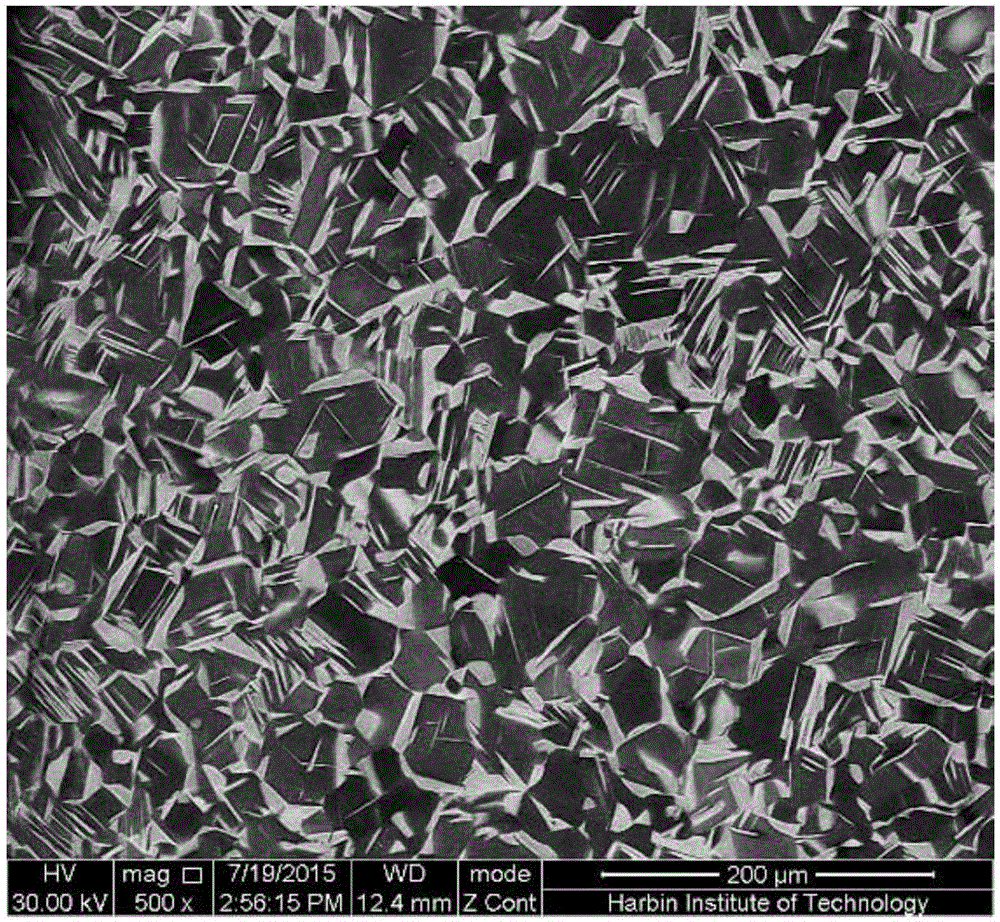

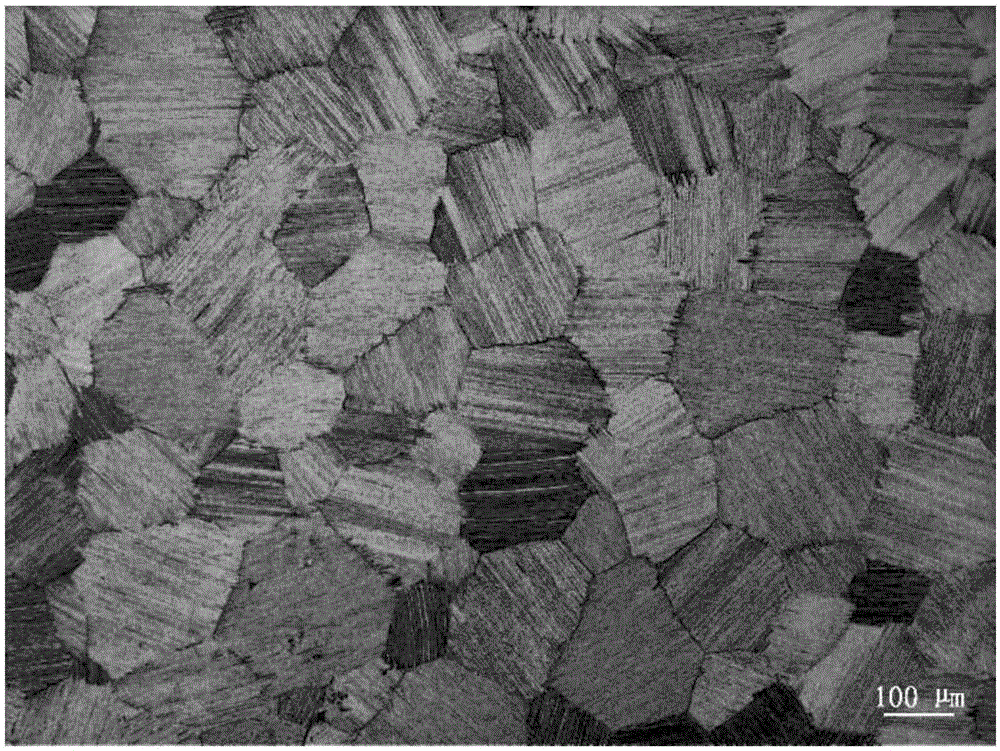

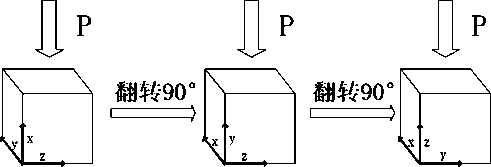

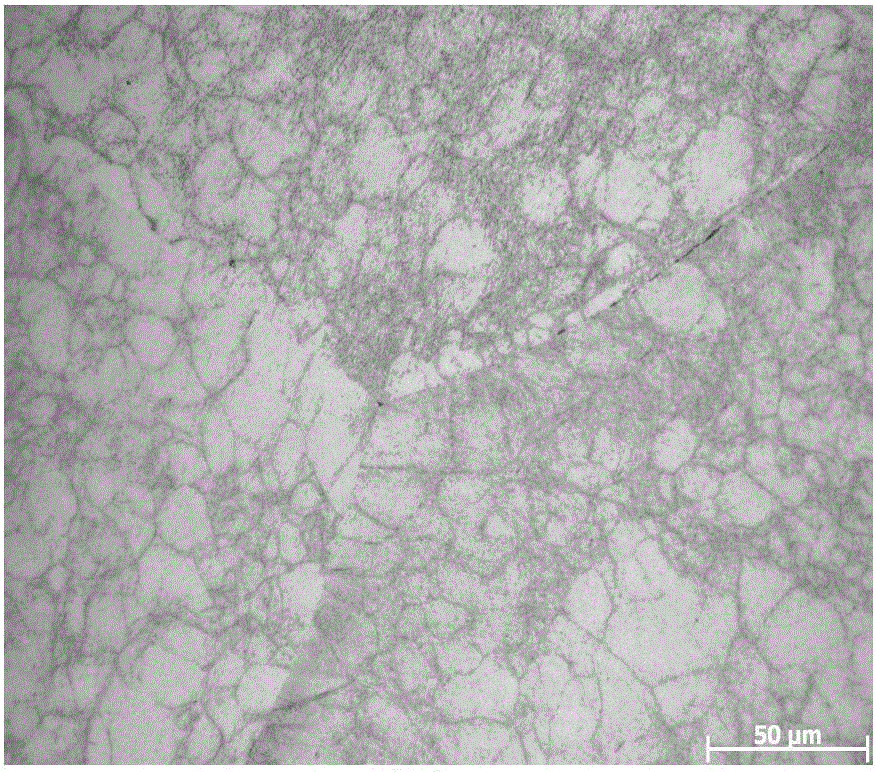

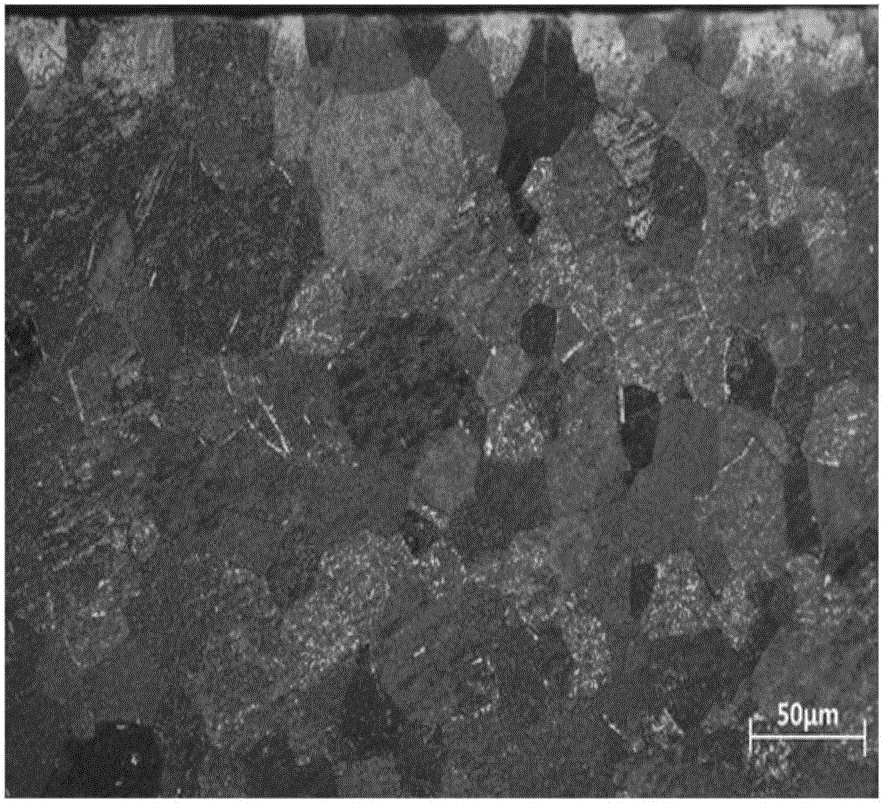

Multi-step circulation heat treatment method for improving mechanical performance of traditional cast gamma-TiAl alloy

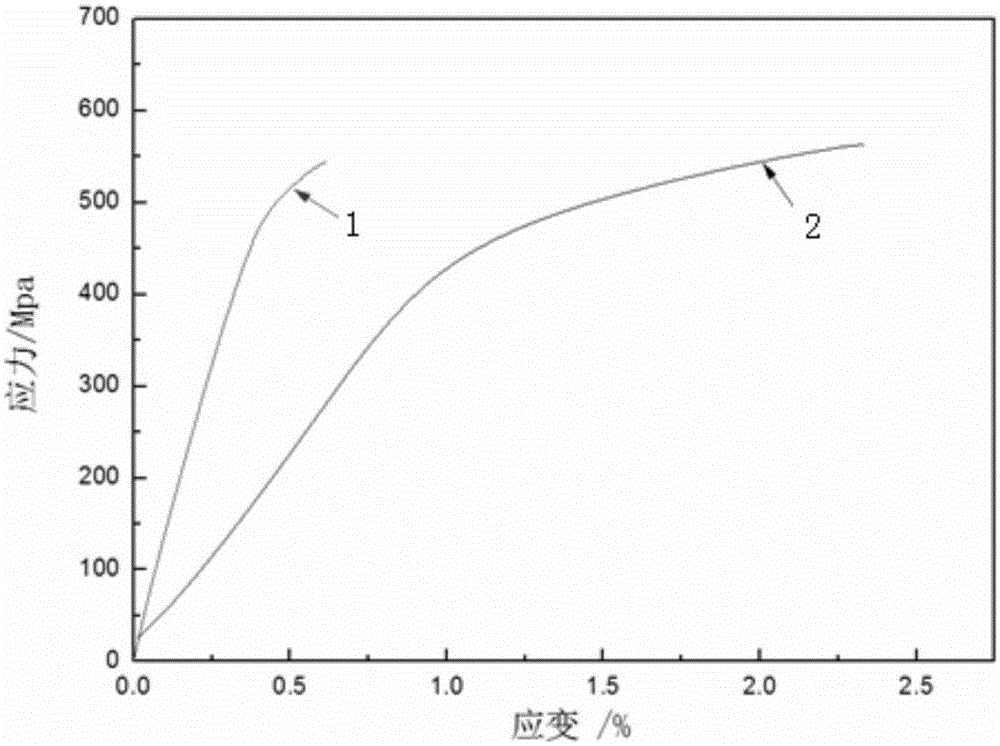

ActiveCN105220096AImprove room temperature performanceMeets specifications for aerospace applicationsBreaking strengthRoom temperature

The invention relates to a multi-step circulation heat treatment method for improving the mechanical performance of traditional cast gamma-TiAl alloy in order to solve the problems of a rough room temperature structure and poor plasticity of the cast gamma-TiAl alloy. The multi-step circulation heat treatment method comprises the steps of preparation of alloy, hot isostatic pressing treatment, homogenizing treatment, alpha2 / gamma phase spheroidizing cycle heat treatment, equiaxed heat treatment and near-lamellar / full-lamellar heat treatment. According to the multi-step circulation heat treatment method, the structure development process is well controlled, a rough lamellar structure is converted into a fine equiaxed structure, and the room temperature performance of the gamma-TiAl alloy is effectively improved. According to the alloy treated through the method, the ductility is 1.9-2.3%, the yield strength is 430-450 Mpa, the breaking strength is 540-570 Mpa, and the aerospace application standards of the TiAl alloy are completely met.

Owner:HARBIN INST OF TECH

High-temperature wear-resistance high-strength aluminum alloy composite material for piston and preparation method thereof

InactiveCN106756302AStrengthen the matrixImprove wettabilityMachines/enginesPistonsLow speedAlloy composite

The invention belongs to the field of metal materials and relates to a high-temperature wear-resistance high-strength aluminum alloy composite material for a piston and a preparation method thereof. According to the high-temperature wear-resistance high-strength aluminum alloy composite material for the piston and the preparation method thereof, the problem that a piston head is easy to crack due to the fact that the strength is insufficient under a high-temperature working condition. The material composed of a substrate and reinforcing phases; the substrate alloy comprises, by weight, 11.0-16.0% of silicon, 3.0-5.0% of nikel, 2.0-4.0% of cooper, 0.5-2.0% of magnesium, 0.5-1.5% titanium and the balance aluminum; and the reinforcing phases are Al2O3 particles generated through an in-situ reaction. The preparation method of the high-temperature wear-resistance high-strength aluminum alloy composite material for the piston comprises the following steps that raw materials are weighed by mass percentage; industry pure aluminum, crystalline-silicon, copper, nickel, magnesium and titanium are smelted at the temperature of 750-900 DEG C; the materials are cooled down to 540-600 DEG C at the speed of 20 DEG C / min, and (Al and B2O3) powder with the temperature being 200 DEG C is slowly added, ball-milled and preheated ; a piston blank is formed through high-pressure low-speed metal mold casting or squeezing casting; and the poured blank is subjected to T6 heat treatment. According to the high-temperature wear-resistance high-strength aluminum alloy composite material for the piston and the preparation method thereof, at the normal temperature and under normal pressure, production can be conducted through common aluminum alloy smelting equipment.

Owner:镇江创智特种合金科技发展有限公司

Preparation method for TiAl-Ni alloy plate with high strength and toughness and high stability

ActiveCN110643853AEasy to handleImprove thermal deformation abilityMetal rolling arrangementsIngotUltimate tensile strength

The invention relates to the field of preparation of alloy materials, in particular to a preparation method for a TiAl-Ni alloy plate with high strength and toughness and high stability. The preparation method aims to solve the problems of uneven structure and poor mechanical properties caused by excessive grain growth and process heredity of a TiAl alloy plate material prepared through existing ingot metallurgy and powder metallurgy methods, especially the problems of low strength and plasticity. The preparation method comprises the following steps of 1, weighing raw materials; 2, smelting acast ingot; 3, carrying out primary pretreatment on a blank; 4, carrying out secondary pretreatment on the blank; 5, carrying out jacketing and hot rolling; 6, carrying out stabilizing treatment; and7, removing a jacket so as to obtain the TiAl alloy plate. The plate obtained through the preparation method has the advantages of being good in surface quality, fine and uniform in structure, good inmechanical property and high in repeatability.

Owner:TAIYUAN UNIV OF TECH

A superplastic titanium alloy

InactiveCN106507837BImprove room temperature performanceReduce manufacturing costRoom temperatureBeta titanium alloy

A superplastic titanium alloy relates to a β-rich α+β titanium alloy, which is suitable for preparing structural parts with complex shapes. The weight percent composition of the alloy is: Al: 3.5% to 5.5%, V: 2.2% to 3.7%, Mo: 0.5% to 3.5%, Fe: 0.5% to 3.5%, Zr: 0.5% to 3.5%, and the balance Ti and inevitable impurity elements. The alloy is forged into a blank at a temperature of 1050°C-1150°C, the deformation of the fire is 60%-78%, the forging temperature of the finished bar is controlled at 930°C-980°C, and the final forging or final rolling temperature is 780 ℃-830℃, the plate rolling temperature is controlled at 600℃-650℃, and the finished plate is used in a cold-rolled state. Compared with existing titanium alloys, under the premise of maintaining good comprehensive properties at room temperature, the superplastic temperature of this alloy can be greatly reduced, and it is easy to form parts with complex shapes at lower temperatures, and the production cost is greatly reduced. meet the needs of industrial production.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Low-alloyed high-performance superplastic magnesium alloy and preparation method thereof

The invention provides a low-alloyed high-performance superplastic magnesium alloy and a preparation method thereof. The chemical components of the low-alloyed high-performance superplastic magnesiumalloy comprises, by mass, 0.5-2.5% of zinc, 0.05-1.0% of argentum, 0.05-1.0% of calcium, 0.05-1.0% of zirconium and the balance magnesium. The gross of mass percent of the chemical components of alloyelements except magnesium is less than 3%. The preparation method for the low-alloyed high-performance superplastic magnesium alloy comprises four steps of gradient-temperature smelting, accurate andrapid solidifying, rolling technology and recrystallization treatment. According to the low-alloyed high-performance superplastic magnesium alloy and the preparation method thereof, a traditional superplastic magnesium alloy design principle is broken through; through combination of a multi-element small-amount alloy component design principle, an accurate and rapid solidifying method and the rolling technology, the superplastic magnesium alloy which is characterized by having low-alloyed high performance and being short in process and low in cost and the preparation method thereof are acquired; the tensile strength of larger than 300 MPa can be acquired by the alloy with components optimized; the elongation rate is larger than 15%; room-temperature performance is outstanding; and in addition, the alloy with components optimized has superplasticity, the elongation rate at the temperature of 300 DEG C is 300%, and the elongation rate at the temperature of 250 DEG C is 250%.

Owner:JILIN UNIV

Aluminum alloy bar and production method thereof

The invention discloses an aluminum alloy bar. The aluminum alloy bar is prepared from, by mass, 3.8-4.0% of Cu, 0.6-0.7% of Mg, 0.55-0.6% of Mn, 0.5-0.55% of Si, 0.25-0.3% of Fe, 0.012-0.02% of Ti, 0-0.1% of Cr, 0-0.1% of Zn and the balance Al. The invention further discloses a production method of the aluminum alloy bar. The method includes the flowing steps that an extruded and formed bar semi-finished product is placed for one day and subjected to cold-drawing deformation twice, then kerosene cleaning is performed, and then the aluminum alloy bar is obtained through quenching treatment of heating in a furnace. The produced aluminum alloy bar can have high room temperature mechanical property and cutting property, the bar has no coarse-grain ring, and therefore various properties can reach a standard requirement, and industrial batch production of the aluminum alloy bar is achieved.

Owner:ZHONGSHAN LING YINGHUI METAL TECH CO LTD

High-strength cast Mg alloy containing rare-earth and preparing process thereof

InactiveCN100335666COptimizing componentsImprove room temperature performanceRare earthHigh intensity

A high-strength cast RE-contained Mg-alloy contains Nd (2.5-3.6 Wt%), Zr (0.35-0.8), Zn (0-0.4), Ca (0-0.5), impurities (0-0.02) and Mg (rest). It is prepared through smelting Mg, adding Nd, Zr and Ca in Mg-Nd, Mg-Zr and Mg-Ca alloy mode, adding Zn, solution treating at 525-540 deg.C for 4-12 hr, quenching in water and ageing at 200 deg.C for 12-20 hr. It has high strength, hardness and high-temp creep performance.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of TA7 titanium alloy cake

ActiveCN102994922AGood low temperature toughness and room temperature performanceSimple processWork in processChemical composition

The invention provides a preparation method of a TA7 titanium alloy cake. The method includes the following steps of firstly, cutting and removing a dead head and an ingot bottom of a TA7 titanium alloy ingot, and removing surface defects of the TA7 titanium alloy ingot; subjecting the TA7 titanium alloy ingot to blooming forging to obtain a primary forging stock; subjecting the primary forging stock to intermediate forging to obtain a semi-finished forging stock; and sawing the semi-finished forging stock, and then performing forming forging to obtain the TA7 titanium alloy cake. According to physical characteristics of TA7 titanium alloy materials, by means of proportioning design of chemical components and comprehensive control of technological parameters of initial forging temperatures, final forging temperatures, total forging ratios and the like, uniform control of microstructural dimensions of the primary forging stock, the semi-finished forging stock and the TA7 titanium alloy cake is achieved; and the micro-structure of the TA7 titanium alloy cake is uniform, low temperature mechanical performances and room temperature mechanical performances are excellent, and the preparation method is suitable for large-scale industrial production.

Owner:WESTERN TITANIUM TECH

Tung oil modified triethylamine cold-box resin component I and production method thereof

InactiveCN107083015AImprove technical indicatorsImprove moisture resistanceFoundry mouldsFoundry coresAromatic solventsParaformaldehyde

In allusion to problems existing in the prior art, the invention provides a production method of a tung oil modified triethylamine cold-box resin component I. The production method of the tung oil modified triethylamine cold-box resin component I includes the following raw materials (by weight): 25-40% of phenol, 2-8% of tung oil, 0.01-0.04% of a catalyst 1, 11-19% of paraformaldehyde, 0.04-0.1% of a catalyst 2, 1-2% of a regulator, 12-24% of dibasic acid ester, 14-25% of high-boiling-point aromatic solvent oil, 2.5-5% of a high-boiling-point plasticizer, 2-6% of ethyl silicate and 0.5-1% of a reinforcing agent. According to the invention, tung oil and phenol are subjected to a cationic alkylation reaction under an acidic condition, and then modified phenol and formaldehyde react to generate tung oil modified phenolic resin. Then, the triethylamine cold-box resin component I which has high molding-sand strength, good high-temperature property and good wet resistance, has long service time and excellent environment protection property and can satisfy batch core production is obtained.

Owner:GANSU KOCEL CHEM

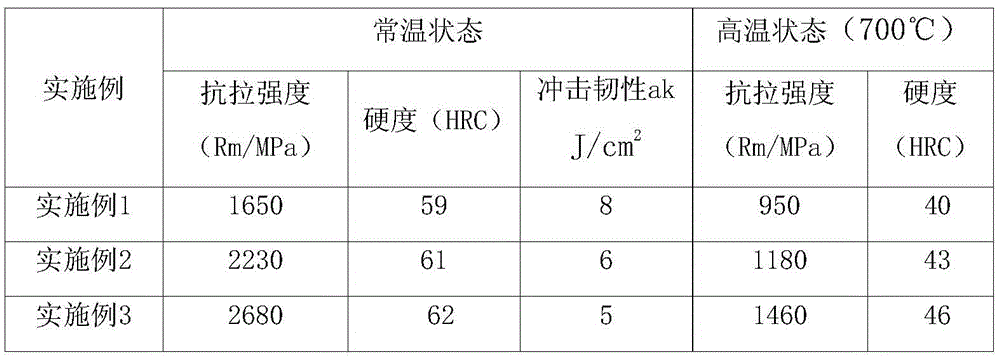

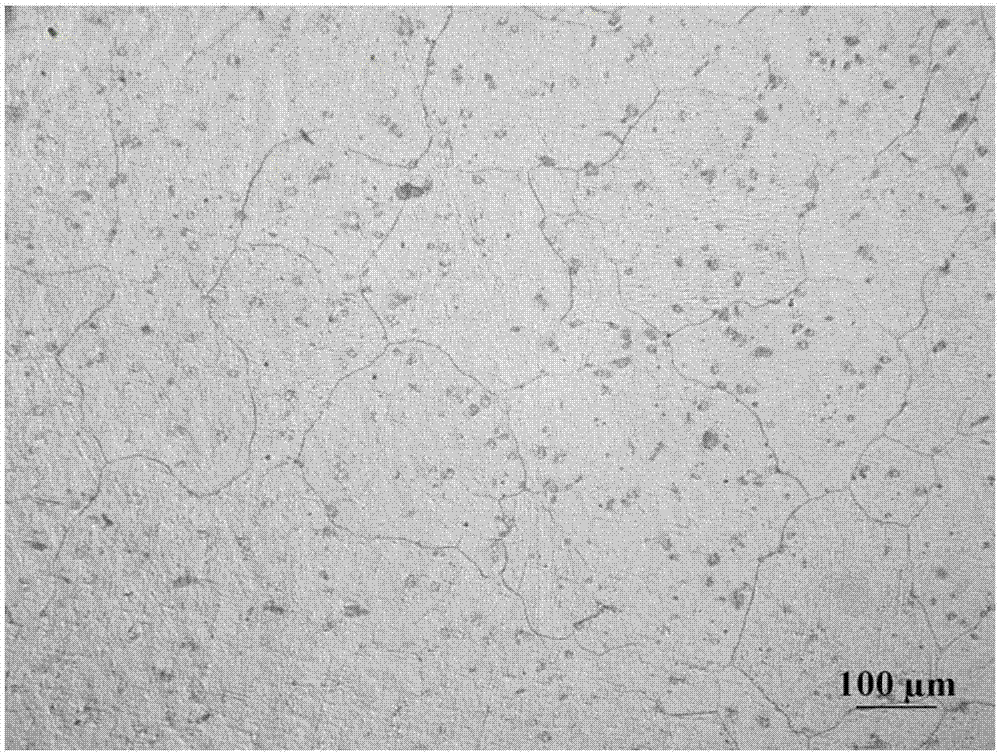

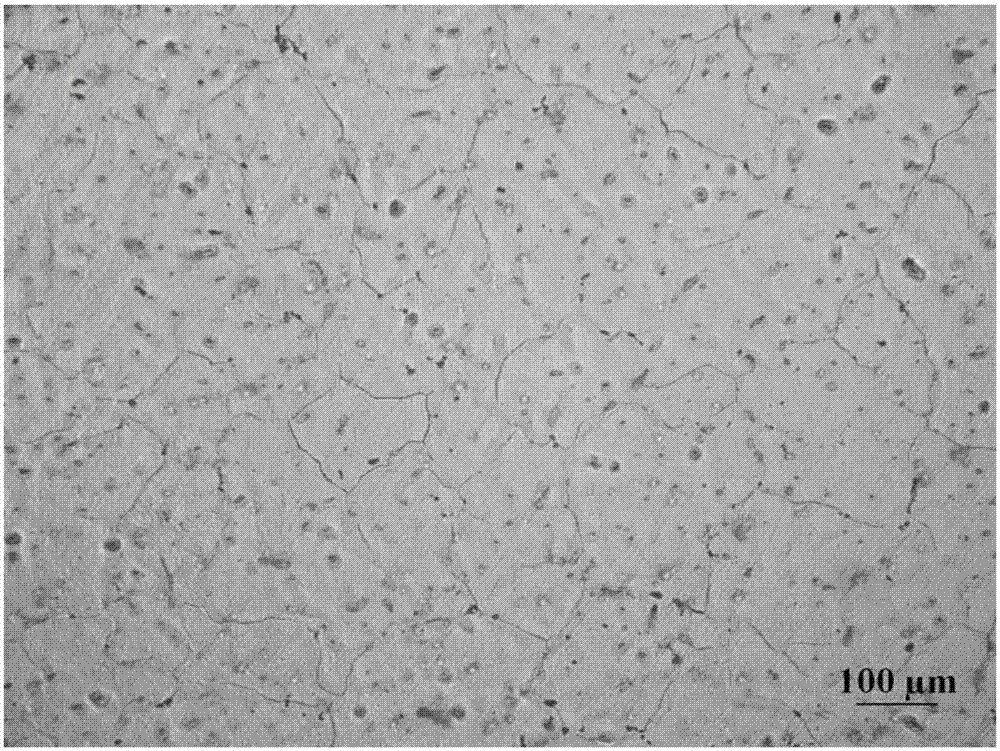

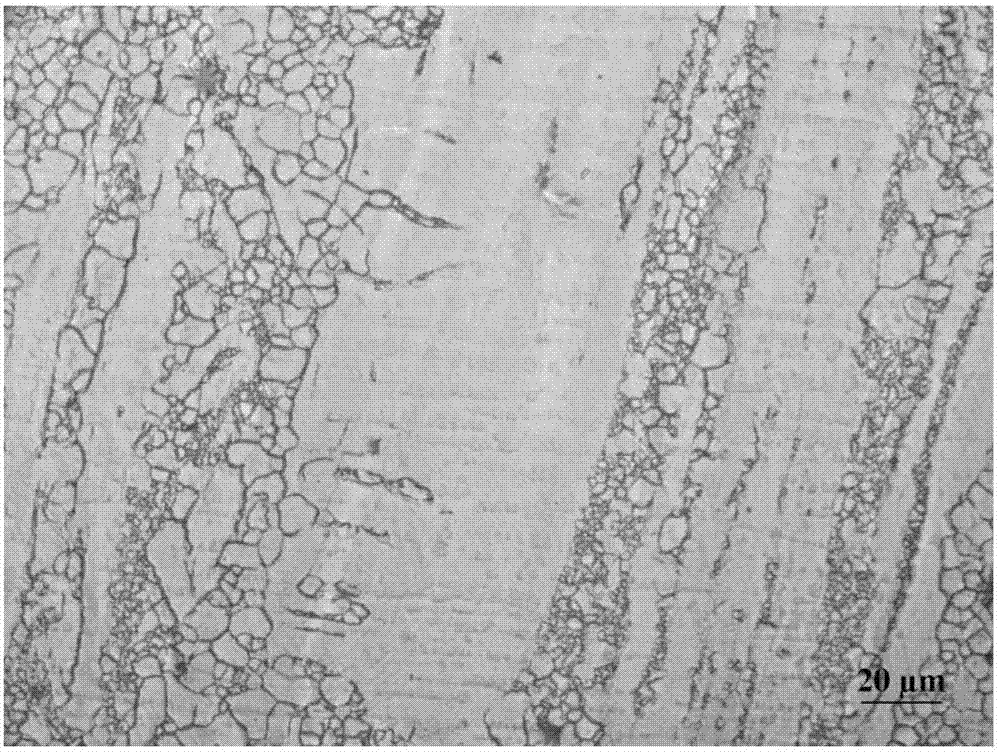

Steel for liner plate forging die, liner plate forging die and preparation method thereof

ActiveCN105463333AImprove room temperature performanceImprove high temperature performanceForging/hammering/pressing machinesUltimate tensile strengthToughness

The invention discloses steel for a liner plate forging die. The steel for the liner plate forging die is prepared from, by weight, C 0.5%-0.6%, Si 0.2%-0.6%, Mn 0.4%-0.8%, W 2%-5%, Cr 3%-5%, Mo 1%-3%, Co 1%-5%, Nb 0.001%-0.005%, V 2%-4%, Ti 0.02%-0.1% and the balance Fe and inevitable impurities. The requirements for normal-temperature performance and high-temperature performance of the forging die are met, the steel has higher strength, hardness, toughness and abrasion resistance in a normal-temperature state and a high-temperature state and is a material used for the forging die and meeting the technical requirements of usage and cost requirements. The invention further provides the liner plate forging die made of the steel for the liner plate forging die and a preparation method of the liner plate forging die.

Owner:SHANDONG HUAMIN STEEL BALL

High strength AZ31-CaO magnesium alloy and preparing method thereof

The invention belongs to the technical field of metal materials, and relates to a high strength AZ31-CaO magnesium alloy and a preparing method thereof. According to the allot, a certain mass of CaO is added into an AZ31 magnesium alloy, refining, casting, homogenization treatment and plastic deformation are carried out, and the AZ31-CaO magnesium alloy is obtained. By means of the alloy, casting state crystalline grains are refined, the strengthening phase with the high temperature stability is formed, the strengthening effect is achieved, the newly-generated high temperature stabilization strengthening phase during plastic deformation promotes recrystallization, and therefore the AZ31-CaO alloy has the excellent mechanical property, and the strength of extension is greatly improved under the condition that the ductility is basically kept unchanged.

Owner:JIANGSU UNIV OF TECH

Aluminum alloy used for preparing gearbox shell and preparation method thereof

The invention relates to an aluminum alloy used for preparing a gearbox shell and a preparation method thereof and belongs to the field of aluminum alloys. Raw materials of the aluminum alloy comprise 9.5-12.5% of Silicon, 2.5-3.5% of copper, 0.5-0.75% of nickel, 3.5-4.5% of magnesium, 7.5-8.5% of zinc, 2.5-3.5% of manganese, 0.9-1.1% of titanium, 1.5-2.5% of chrome, 0.01-0.015% of lanthanum, 0.002-0.004% of yttrium, 0.01-0.015% of samarium and the balance aluminum. The raw materials are heated till the temperature is 775-785 DEG C and then are melted; helium pre-heated for 2-3 min is pumped into the raw materials in a molten condition from the bottom of a container, clinker and dross are removed, then the raw materials in the molten condition are poured into a mould after standing is conducted for 20-30 min, and a primary manufactured shell is obtained; and quenching treatment is conducted at the temperature of 510-515 DEG C, and aging treatment is conducted at the temperature of 160-220 DEG C. The aluminum alloy used for preparing the gearbox shell is good in high-temperature mechanical property and airtightness, and the service life of a gearbox is prolonged.

Owner:重庆顺博铝合金股份有限公司

Negative pole piece for solid-state battery as well as preparation method and application of negative pole piece

PendingCN112670450AInhibit growthInhibit interface reactionElectrode rolling/calenderingSolid electrolytesAll solid stateLithium metal

The invention provides a negative pole piece for a solid-state battery as well as a preparation method and application of the negative pole piece. The negative pole piece comprises a copper foil, a lithium metal layer, a lithium nitride layer and an organic-inorganic composite layer which are sequentially stacked. Ultrathin uniformly-electroplated lithium metal is used as a base material, and surface modification is carried out on the surface of the base material through nitrogen, so that the lithium metal is uniformly deposited, short circuit is prevented, and loss of a lithium source in the circulation process is reduced; and then the organic-inorganic composite coating layer is compounded on the surface of the treated lithium metal, so that the charged and deposited lithium metal is deposited more uniformly and compactly, the short circuit is effectively inhibited, and the interface reaction promotion cycle generated by direct contact between the lithium metal and an electrolyte is inhibited, so that the technical problem that the lithium metal is difficult to apply to an all-solid-state battery is solved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Aluminum alloy for preparing engine cylinder body and preparation method thereof

The invention relates to an aluminum alloy for preparing an engine cylinder body and a preparation method thereof and belongs to the field of aluminum alloys. Raw materials are prepared according to a formula which comprises 8.5-11.5% of silicon, 2-5% of copper, 0.7-0.9% of iron, 0.55-0.65% of magnesium, 0.15-0.35% of manganese, 0.6-0.65% of zinc, 0.04-0.06% of nickel, 0.1-0.15% of titanium, 0.1-0.25% of zirconium, 0.01-0.015% of erbium, 0.002-0.004% of thulium, 0.01-0.015% of lutecium and the balance aluminum. The temperature is raised to be 705-720 DEG C to conduct melting, helium which is pre-heated for 2-3 min enters molten raw materials from the bottom of a container, molten slag and floating slag are removed, and after still standing is conducted for 20-30 min, the molten raw materials are casted into a mold, and thus a primarily-prepared cylinder body is obtained; and quenching treatment and aging treatment are conducted under the temperature of 410-430 DEG C and the temperature of 180-200 DEG C correspondingly. The aluminum alloy is good in heat dispersion property, and the service life of an engine is prolonged.

Owner:重庆顺博铝合金股份有限公司

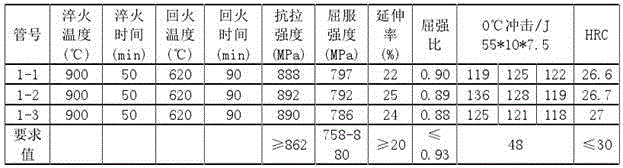

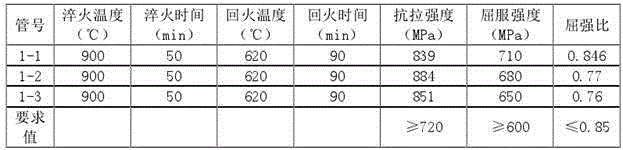

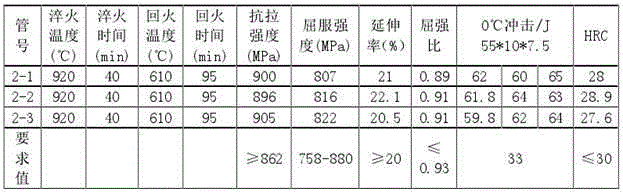

Heat resistant steel tube and manufacturing process thereof

The invention discloses a heat resistant steel tube and a manufacturing process thereof. The heat resistant steel tube is prepared from the following components in percentage by mass: 0.25-0.32 percent of C, 0.20-0.37 percent of Si, 0.9-1.1 percent of Mn, no larger than 0.017 percent of P, no larger than 0.008 percent of S, 0.02-0.1 percent of Ni, 0.9-1.2 percent of Cr, no larger than 0.04 percent of Nb, no larger than 0.25 percent of Cu, 0.02-0.06 percent of Al, 0.02-0.07 percent of Ti, 0.1-0.2 percent of Mo, no larger than 0.04 percent of V and the balance of Fe and inevitable impurities and is prepared by the following steps: melting by an electric furnace, refining outsides the furnace, vacuum degassing, continuous casting, steel billet heating, steel tube rolling, quenching and tempering treatment, straightening and the like. According to the manufacturing process disclosed by the invention, with adoption of the melting mode, steel purity is ensured; the manufactured steel tube is excellent in room temperature performance, is good in matching of strength and toughness and has the characteristics of high high-temperature strength and good heat stability, thus ensuring safety of oil extraction in an oil well; the heat resistant steel tube is suitable for the field of thermal recovery of high-density oil and has wide application prospect.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

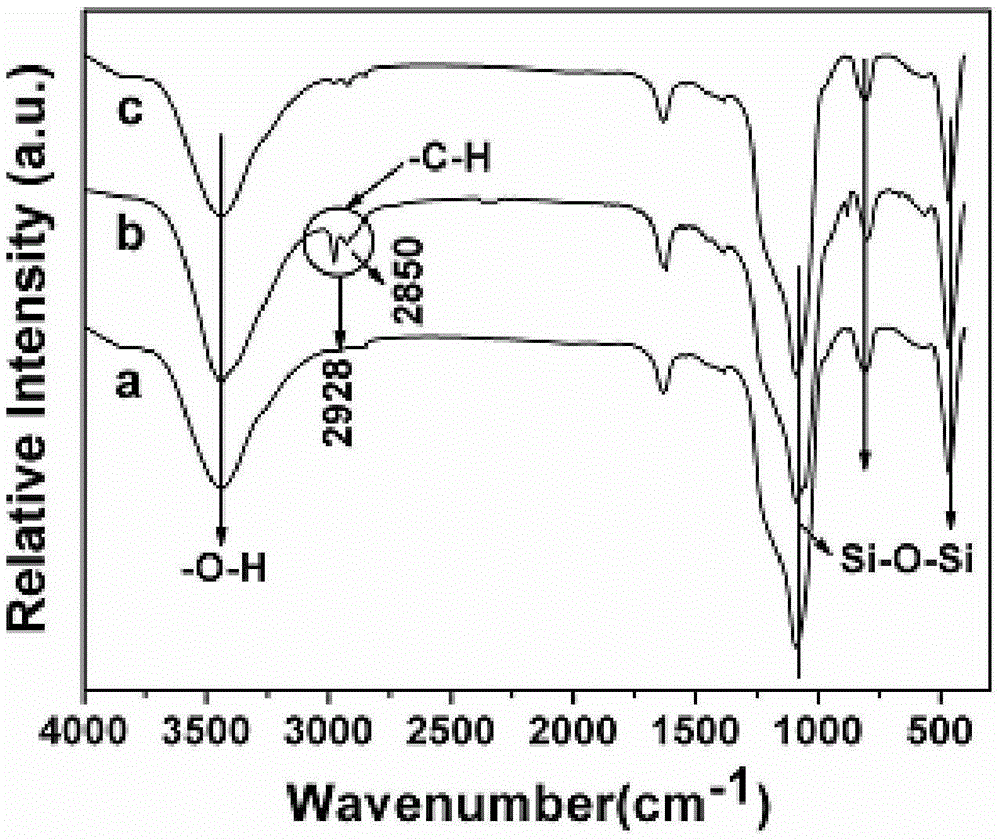

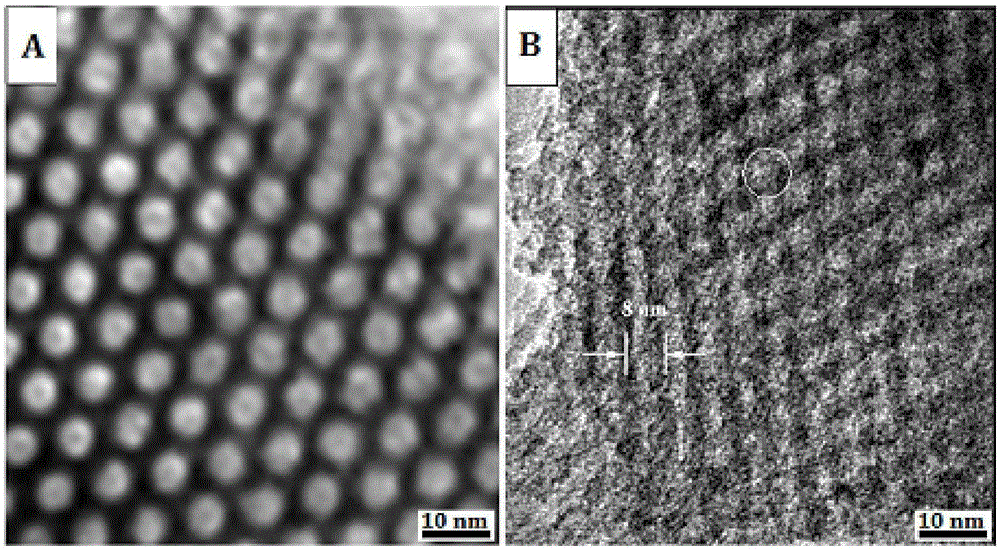

Absorption material suitable for sea water desalination, and preparation method of absorption material suitable for sea water desalination

ActiveCN105289517AModified rate is adjustableLarge specific surface areaOther chemical processesSeawater treatmentWater desalinationAbsorption capacity

The invention relates to an absorption material suitable for sea water desalination, and a preparation method of the absorption material suitable for the sea water desalination. The absorption material is obtained by performing surface finishing on a mesoporous or large-pore material for multiple times by a siloxane reagent, and then performing hydrolysis in an acidic condition. The method is easy and liable to operate, and the prepared hybrid micro-pore and mesoporous absorption material is low in cost. When the hybrid micro-pore and mesoporous absorption material is used for absorbing a NaCl solution, a fact that the absorption effect of the material is excellent, the absorption capacity is up to 517.5mg / g, and the material can absorb various ions and can absorb anion and cations simultaneously is found.

Owner:BEIJING UNIV OF CHEM TECH

Low-cost titanium alloy panel applied to titanium dinner plates and preparation method of low-cost titanium alloy panel

The invention provides a low-cost titanium alloy panel applied to titanium dinner plates and a preparation method of the low-cost titanium alloy panel. The titanium alloy panel is made of, by mass percentage, 0.5-1.5% of Al, 0.5-1.5% of Fe, 0.10-0.20% of O, less than 0.02% of C, less than 0.008% of N, less than 0.0015% of H and the balance Ti. The titanium alloy panel has the beneficial effects of being non-poisonous and harmless to the human body and is quite suitable for manufacturing the dinner plates; a certain proportion of Fe and Al are added, and thus a low-cost titanium alloy material is obtained; and by means of the panel obtained by rolling the titanium alloy material, material cost can be lowered, and in addition, the low-cost titanium alloy panel is non-poisonous and harmless to the human body and quite suitable for manufacturing the dinner plates.

Owner:沈阳泰恒通用技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com