Negative pole piece for solid-state battery as well as preparation method and application of negative pole piece

A technology of negative pole piece and solid-state battery, applied in electrode manufacturing, battery electrode, lithium battery, etc., can solve the problems of lithium negative electrode, battery short-circuit failure, reaction passivation, etc., which is beneficial to normal temperature performance and uniform thickness control, the effect of uniform and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

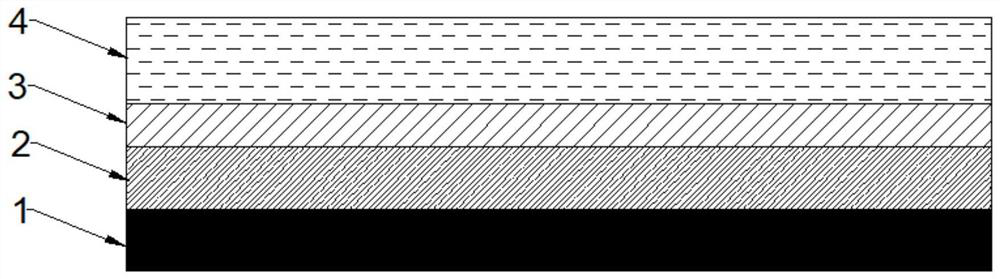

[0058] This embodiment provides a negative electrode sheet for a solid-state battery, such as figure 1 As shown, the negative electrode sheet includes a 5 μm thick copper foil 1 , a 5 μm thick lithium metal layer 2 , a 0.5 μm thick lithium nitride layer 3 and a 50 μm thick organic-inorganic composite layer 4 which are sequentially stacked.

[0059] The preparation method of the negative electrode sheet is as follows:

[0060] (1) Electroplate lithium metal with a thickness of 5 μm on the surface of copper foil 1 as the base material of the lithium-copper composite strip, place the above-mentioned lithium-copper composite strip on a flat vacuum panel and fix it, and use a continuous gas heating spraying device connected to a nitrogen pipe at 150 ° C. Under the conditions of spraying pressure of 0.5Mpa and spraying speed of 0.03m / S, a layer of lithium nitride (Li 3 N) layer to obtain a lithium-copper composite substrate after surface treatment.

[0061] (2) 30 parts of PMMA po...

Embodiment 2

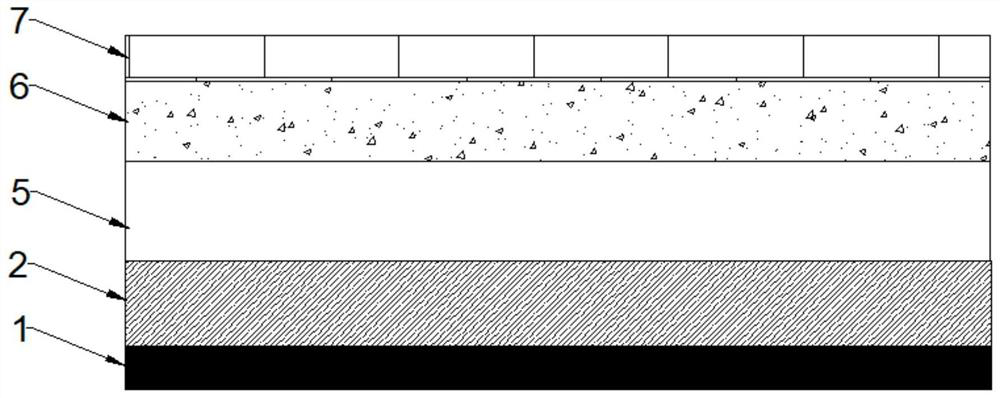

[0064] This embodiment provides a negative electrode sheet for a solid-state battery. The negative electrode sheet includes a 5 μm thick copper foil, a 1 μm thick lithium metal layer, a 100 nm thick lithium nitride layer, and an 80 μm thick organic-inorganic composite layer that are sequentially stacked. layer.

[0065] The preparation method of the negative pole piece is as follows: (1) Electroplate lithium metal with a thickness of 5 μm on the surface of copper foil 1 as a lithium-copper composite strip substrate, place the above-mentioned lithium-copper composite strip on a flat vacuum panel to fix it, and use a nitrogen gas connection to The continuous gas heating injection equipment of the tube sprays the surface of lithium metal at 150°C with a spray pressure of 0.5Mpa and a spray speed of 0.03m / S to generate a layer of lithium nitride (LiN) in situ. 3 N) layer to obtain a lithium-copper composite substrate after surface treatment.

[0066] (2) 30 parts of PMMA polymer ...

Embodiment 3

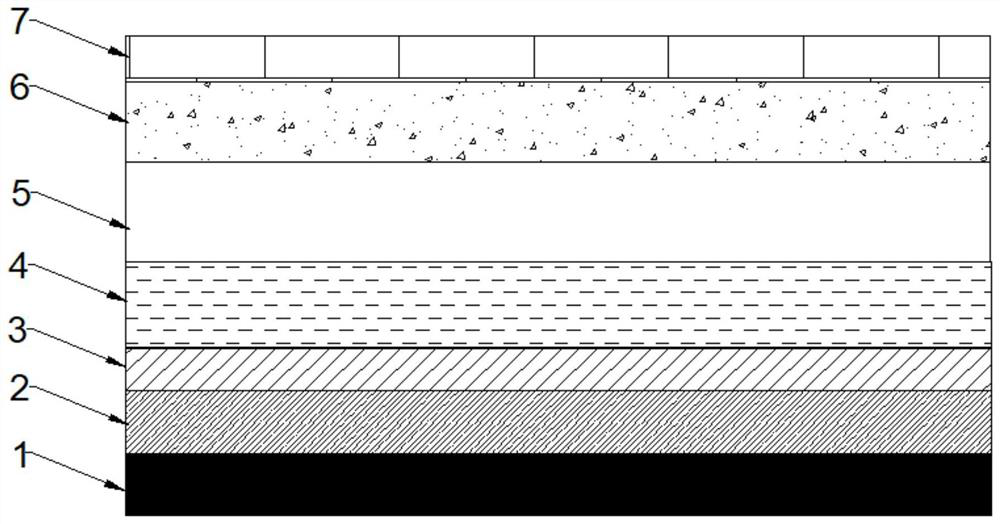

[0068] This embodiment provides a negative electrode sheet for a solid-state battery. The negative electrode sheet includes a 5 μm thick copper foil, a 10 μm thick lithium metal layer, a 1 μm thick lithium nitride layer, and a 50 μm thick organic-inorganic composite layer that are sequentially stacked. layer.

[0069] The preparation method of the negative electrode sheet is as follows:

[0070] (1) Electroplate lithium metal with a thickness of 5 μm on the surface of copper foil 1 as the base material of the lithium-copper composite strip, place the above-mentioned lithium-copper composite strip on a flat vacuum panel and fix it, and use a continuous gas heating spraying device connected to a nitrogen pipe at 150 ° C. Under the conditions of spraying pressure of 1Mpa and spraying speed of 0.01m / S, the surface of lithium metal is sprayed to form a layer of lithium nitride (LiN) in situ. 3 N) layer to obtain a lithium-copper composite substrate after surface treatment.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com