Silicon-anode lithium battery electrolyte and silicon-anode lithium battery

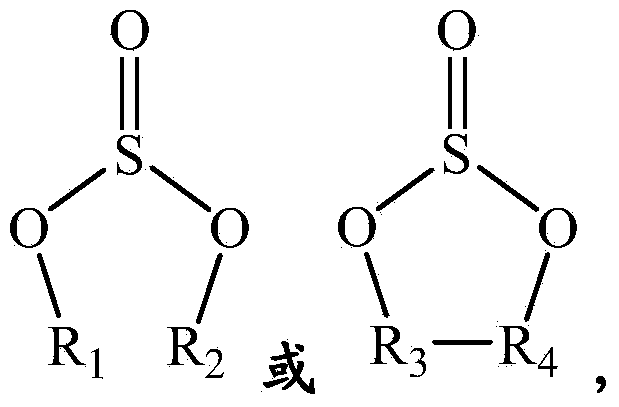

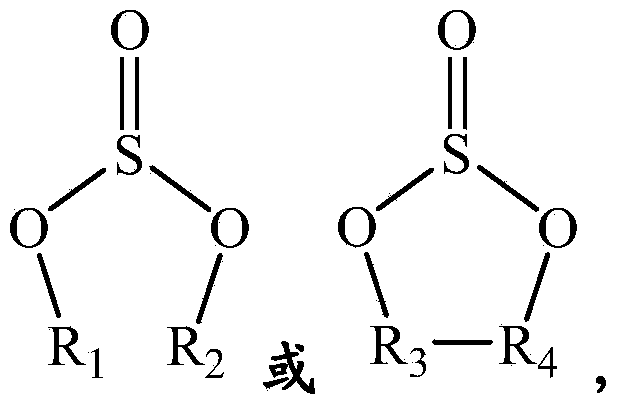

An electrolyte and lithium battery technology, applied in the field of electrochemistry, can solve the problems of large battery expansion and poor battery cycle performance, and achieve the effects of reducing battery flatulence, good electrochemical improvement effect, and improving charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

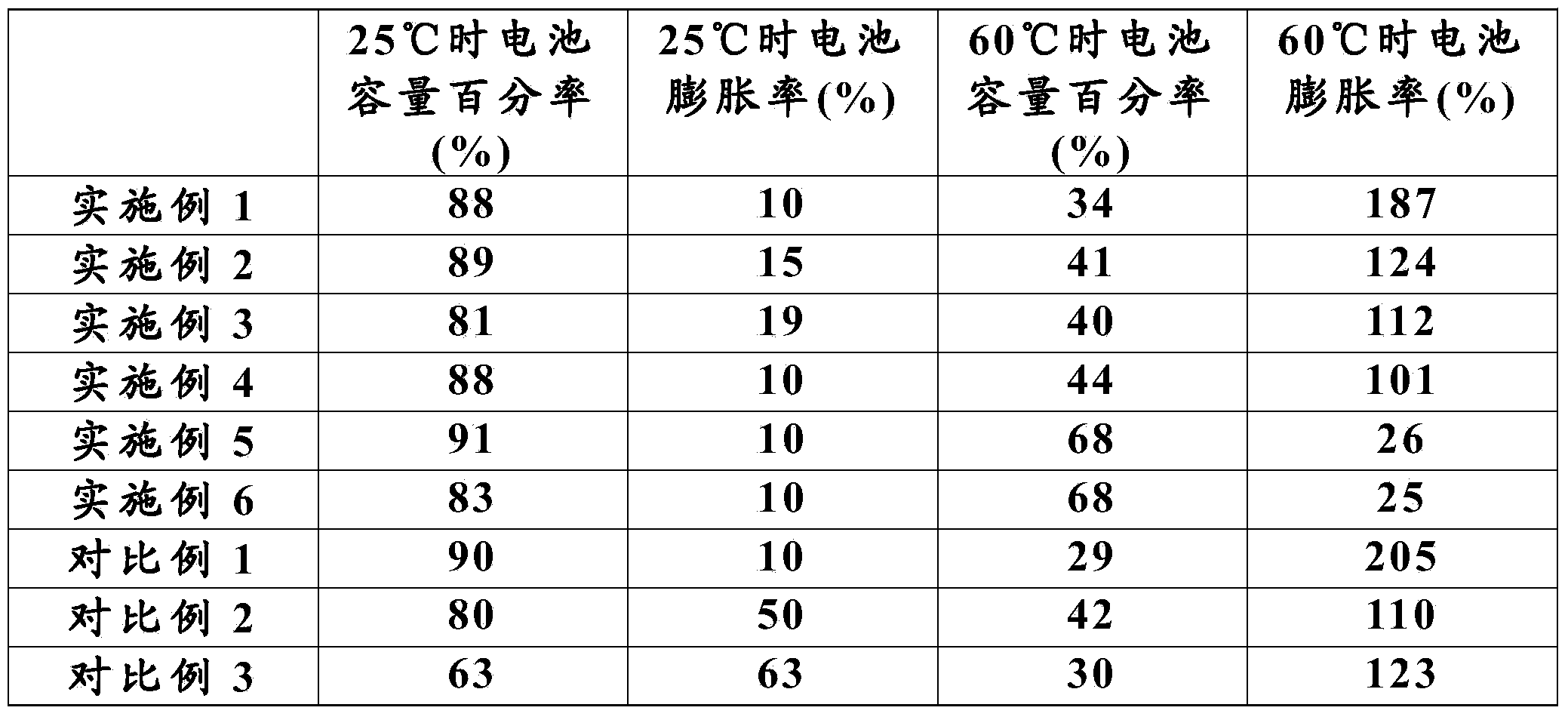

[0028] In an argon glove box with a water content of less than 10ppm, prepare lithium-ion battery electrolyte: lithium salt LiPF 6 Soluble in a mixed solvent of EC / DMC / EMC (mass ratio 1:1:1), in which LiPF 6 The final concentration is 1mol / L; then add 2% vinyl sulfite and FEC accounting for 10% of the total mass of the electrolyte to the electrolyte, and then use the electrolyte to prepare a silicon negative lithium ion battery. The specific test method of the battery: the silicon negative electrode lithium battery is charged to a voltage of 4.2V at a constant current / constant voltage and discharged to a voltage of 2.5V at a constant current, and the charge and discharge cycle is repeated 100 times. The discharge capacity of the lithium battery cell was measured at each cycle and the thickness before and after the cycle was measured. The tests were performed at 25°C and 60°C, respectively. The capacity retention (%) was obtained as a percentage calculated by dividing the dis...

Embodiment 2

[0030] In an argon glove box with a water content of less than 10ppm, prepare lithium-ion battery electrolyte: lithium salt LiPF 6 Soluble in a mixed solvent of EC / DMC / EMC (mass ratio 1:1:1), in which LiPF 6 The final concentration is 1mol / L; then add 5% vinyl sulfite and FEC accounting for 10% of the total mass of the electrolyte to the above electrolytic solution, and then use the electrolytic solution to prepare a silicon negative electrode lithium-ion battery. The test method is the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0032] In an argon glove box with a water content of less than 10ppm, prepare lithium-ion battery electrolyte: lithium salt LiPF 6 Soluble in a mixed solvent of EC / DMC / EMC (mass ratio 1:1:1), in which LiPF 6 The final concentration is 1mol / L; then add vinyl sulfite and FEC accounting for 10% of the total mass of the electrolyte to the above electrolyte, and then use the electrolyte to prepare a silicon negative lithium-ion battery. The test method is the same as in Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com