Carbon anode material for lithium ion battery and preparation method for carbon anode material

A technology of carbon negative electrode materials and lithium-ion batteries, which is applied in the field of materials science, can solve the problems of poor high-current charge and discharge performance, material pulverization, difficult core-shell structure, etc., and achieve low irreversible specific capacity and good charge and discharge performance. Good, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

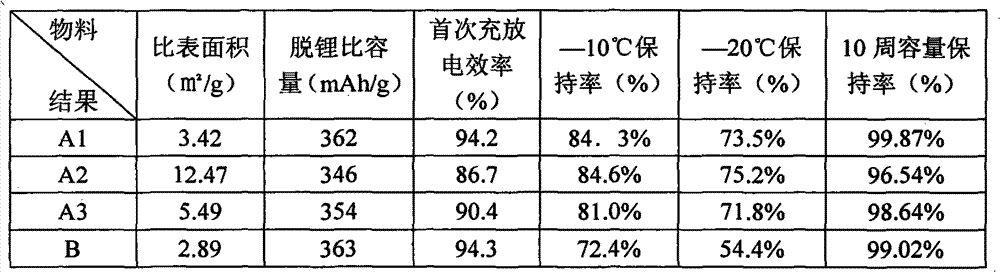

Embodiment 1

[0016] The raw material formula is as follows:

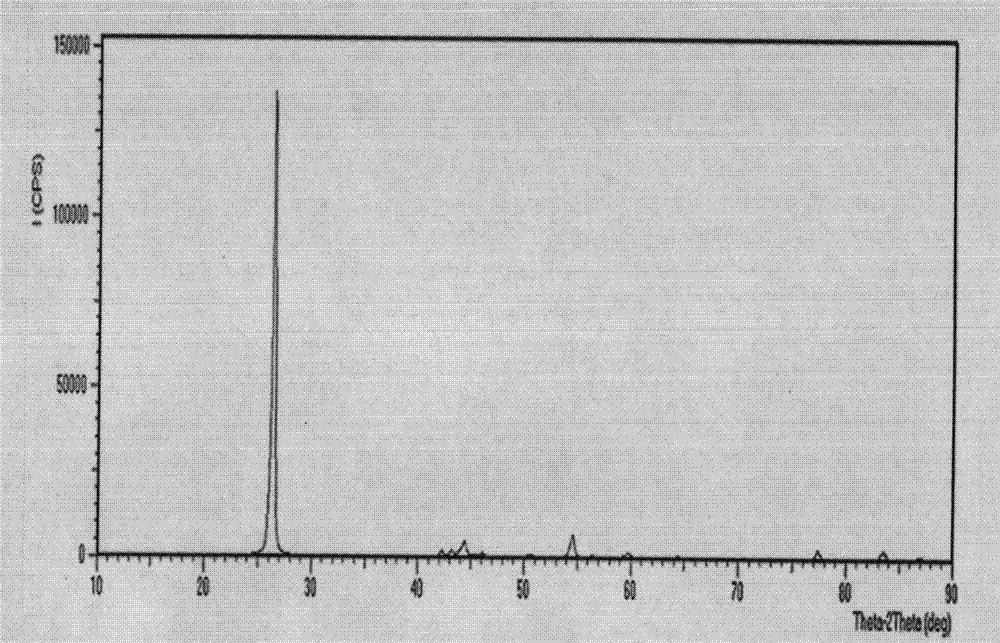

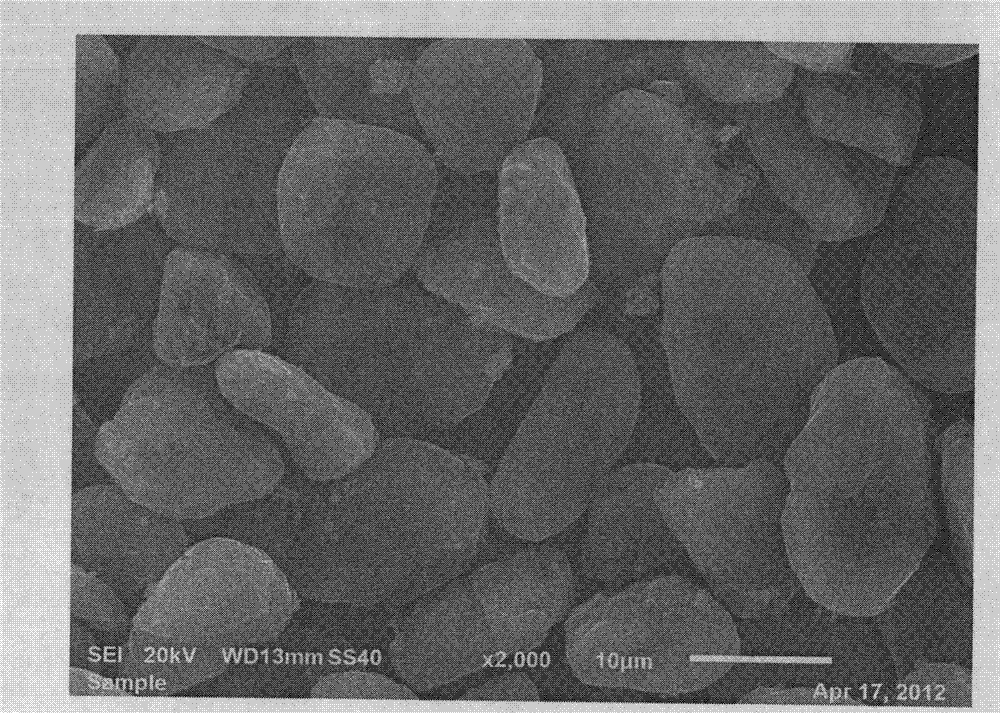

[0017] Natural graphite: 100.0g (spherical graphite, battery grade), the average particle size is 6-30μm, and the interlayer distance is d 002 0.3353~0.3354nm; organic pyrolytic carbon raw material: 4.0g petroleum pitch with a softening point of 110°C, high purity;

[0018] Solvent: 90.0g industrial grade naphthalene; carbon nanotube: 5g (battery grade, slurry, oil system 20% concentration), average diameter is 30-100nm, average length is 80-400nm,

[0019] The preparation method is as follows:

[0020] (1) Take naphthalene crystals, put them into a special sealed stainless steel beaker, heat and stir in a heat-conducting silicone oil bath at 140°C, and after it dissolves, add petroleum pitch with a high softening point, stir at 300r / min to disperse and dissolve for 5min, and then add carbon nano tube, stir and disperse for 5 minutes;

[0021] (2) Add natural graphite powder, stir and disperse for 2h;

[0022] (3) Warming up...

Embodiment 2

[0026] The difference from Example 1 is: "10.0 g of petroleum pitch with a softening point of 110° C." is used instead of "4.0 g of petroleum pitch with a softening point of 110° C.".

[0027] Other steps are with embodiment 1. The carbon negative electrode material obtained at last is denoted as A2.

Embodiment 3

[0029] The difference from Example 1 is: the first two steps of heating process in step (4) are raised from room temperature to 400°C at 5°C / min, and kept at 2h; then at 2°C / min to 600°C, kept 2h; then increase the temperature at 2°C / min to 850°C and hold the temperature for 3h" to "3°C / min heating rate from room temperature to 800°C, and keep at 800°C for 5h".

[0030] Other steps are with embodiment 1. The final carbon negative electrode material is denoted as A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com