Method for producing electrode of sodium polysulfide/bromine novel energy storage cell

A technology of sodium polysulfide and energy storage battery, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of slow electrochemical reaction rate, and achieve the effects of high practical value, high activity, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First weigh 4.955g of Ni(NO 3 ) 2 ·6H 2 O, made into an aqueous solution, weighed 1g of XC-72 carbon, and Ni(NO 3 ) 2 Mix the aqueous solution, bake at 80°C for 2 hours, transfer the obtained block into a quartz tube, and pass through H 2 Heating, the heating rate is 2°C / min to 160°C, then the heating rate is 1°C / min to 400°C, at 400°C for 30 minutes, and then pass H 2 The temperature was lowered to obtain Ni / C with a weight fraction of 50% in the form of black powder. Weigh 0.2g of Ni / C with a weight fraction of 50%, add 5ml of ethanol, mix evenly, add 4.0g of a 5% perfluorosulfonic acid resin solution (U.S. Du Pont Company), mix, and prepare a slurry like liquid. Cut a piece of carbon felt with a thickness of 2mm, a length of 25mm, and a width of 20mm, boil it with 1mol / l NaOH solution at 80°C for 30min to remove impurities, wash it with deionized water three times to remove NaOH, and dry it. Apply the Ni / C slurry liquid to the carbon felt several times. Bake ...

Embodiment 2

[0042] The slurry Ni / C liquid used for the negative electrode is the same as in Example 1; cut a piece of graphite-type carbon paper with a thickness of 0.4 mm, a length of 25 mm, and a width of 20 mm, and apply the Ni / C slurry liquid to the carbon paper several times. Bake at 80°C for 2h, then heat treat at 140°C for 30min. Then impregnate in a sodium tetrasulfide solution at a temperature of 80°C for 12 hours. The prepared negative electrode was stored for future use.

[0043] The slurry Pt / C liquid used for the positive electrode is the same as in Example 1; a piece of graphite-type carbon paper with a thickness of 0.4 mm, a length of 25 mm, and a width of 20 mm is also cut, and the Pt / C slurry liquid is applied to the carbon paper several times. . Bake at 80°C for 2 hours, boil in water until the electrode is completely hydrophilic.

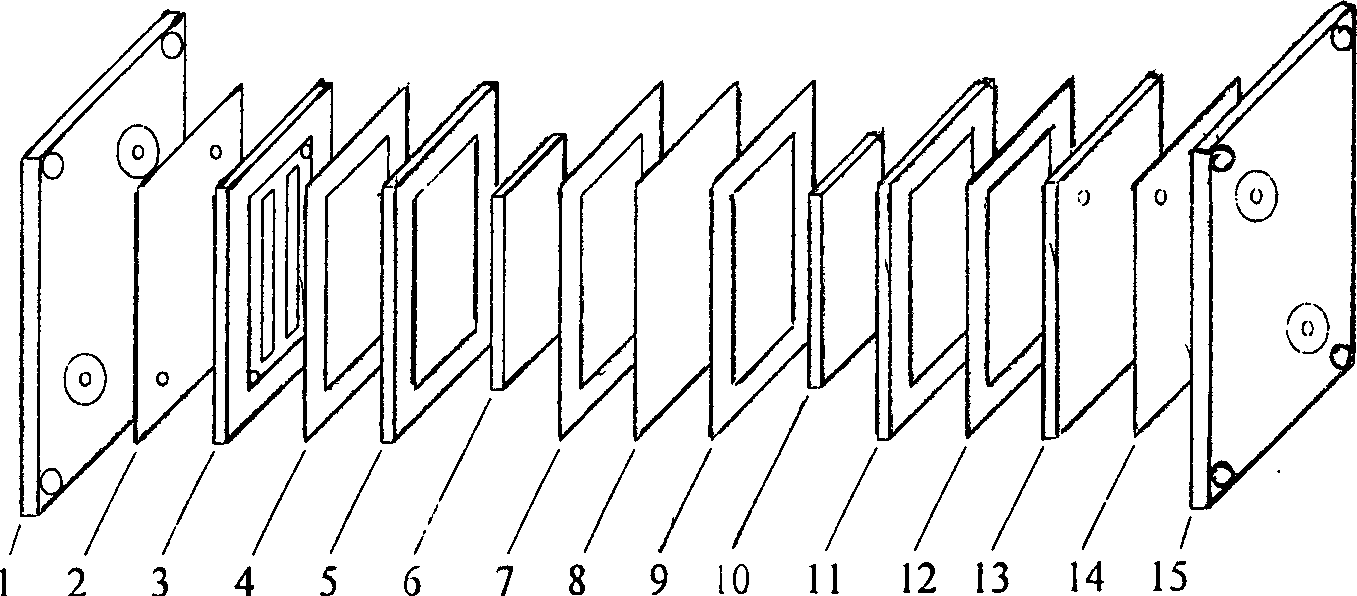

[0044] Place the prepared negative pole and positive pole on both sides of the Nafion-115 membrane, press the attached figure 1 Assemble...

Embodiment 3

[0047] The slurry Ni / C liquid used for the negative electrode is the same as in Example 1. Weigh 0.1g of Ni / C with a weight fraction of 50%, add 5ml of ethanol, mix evenly, add 2.0g of a 5% perfluorosulfonic acid resin solution (U.S. Du Pont Company), mix, and prepare a slurry like liquid. Spread the Ni / C slurry liquid on the carbon felt (thickness 2mm, length 25mm, width 20mm carbon felt) several times, dry, then heat treatment at 140°C for 30min, and then in the sodium tetrasulfide solution at the temperature of 80°C For impregnation, the impregnation time is 12h.

[0048] Weigh 0.015g of Pt / C with a weight fraction of 10%, add 5ml of ethanol, vibrate in ultrasonic for 30min, add 0.3g of perfluorosulfonic acid resin solution with a weight fraction of 5%, vibrate in ultrasonic for 10min, and prepare Slurry liquid, apply Pt / C slurry liquid on carbon felt (2mm thick, 25mm long, 20mm wide carbon felt) in several times, and dry at 80°C.

[0049] Place the prepared negative pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com