Heat resistant steel tube and manufacturing process thereof

A production process and technology for steel pipes, applied in the field of heat-resistant steel pipes and their production processes, can solve problems such as yield strength and tensile strength decline, inability to expand and contract freely, and easy damage to casings, so as to achieve good strength and toughness coordination, The effect of ensuring safety and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

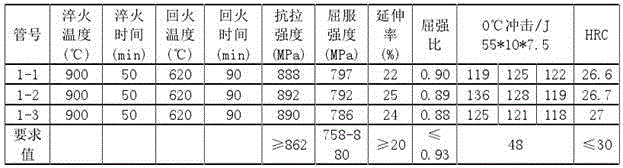

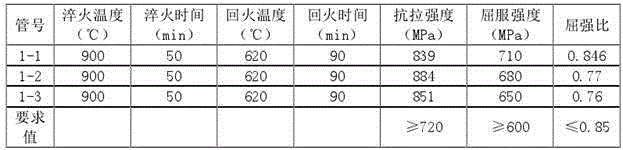

Embodiment 1

[0018] In the embodiment of the present invention, a heat-resistant steel pipe with a specification of φ177.8×9.19, the composition according to mass percentage includes: C0.28%, Si0.30%, Mn1.0%, P0.012% , S0.005%, Ni0.08%, Cr1.2%, Nb0.01%, Cu0.032%, Al0.05%, Ti0.03%, Mo0.15%, V0.01%, the rest are Fe and Unavoidable impurities.

[0019] The unavoidable impurities of the heat-resistant steel pipe with a specification of φ177.8×9.19 include: Sb, Bi, Pb, AS, Sn, O, H, N, of which: Sb0.004%, Bi0.006%, Pb0.010, AS0.008%, Sn0.005%, As+Sn+Pb+Sb+Bi0.033%, O25PPm, H1.5PPm, N80PPm.

[0020] The manufacturing process of the heat-resistant steel pipe with a specification of φ177.8×9.19 includes the following steps:

[0021] (1) Billet smelting: molten steel is smelted in an electric furnace first, sent to an LF refining furnace for refining, and fed with Al wire. The amount of Al wire added is 3.0Kg / T steel. The temperature is 55Pa, add SiCa block before vacuum, the addition amount of ...

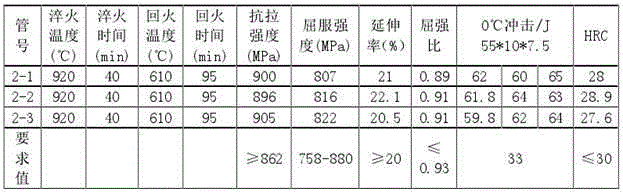

Embodiment 2

[0031] In the embodiment of the present invention, a heat-resistant steel pipe with a specification of φ101.6×6.65 heat-resistant steel pipe, the components according to mass percentages include: C0.30%, Si0.24%, Mn0.9%, P0.010%, S0.003%, Ni0.06%, Cr1.1%, Nb0.008%, Cu0.041%, Al0.04%, Ti0.05%, Mo0.16%, V0.005%, the rest is Fe and not Avoid impurities.

[0032] The unavoidable impurities of the heat-resistant steel pipe with a specification of φ101.6×6.65, according to the mass percentage, include: Sb, Bi, Pb, AS, Sn, O, H, N, of which: Sb0.002%, Bi0.004%, Pb0.008, AS0.005%, Sn0.003%, As+Sn+Pb+Sb+Bi: 0.022%, O20PPm, H1.2PPm, N60PPm.

[0033] The manufacturing process of the heat-resistant steel pipe with a specification of φ101.6×6.65 includes the following steps:

[0034] (1) Billet smelting: molten steel is first smelted in an electric furnace, sent to an LF refining furnace for refining, and fed with Al wire. The amount of Al wire added is 2.5Kg / T steel. The temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com