Absorption material suitable for sea water desalination, and preparation method of absorption material suitable for sea water desalination

A technology of adsorbent and porous material, which is applied in the field of adsorption materials suitable for seawater desalination and its preparation, can solve problems such as equipment corrosion and economic loss, and achieve the effects of energy saving, increased adsorption capacity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

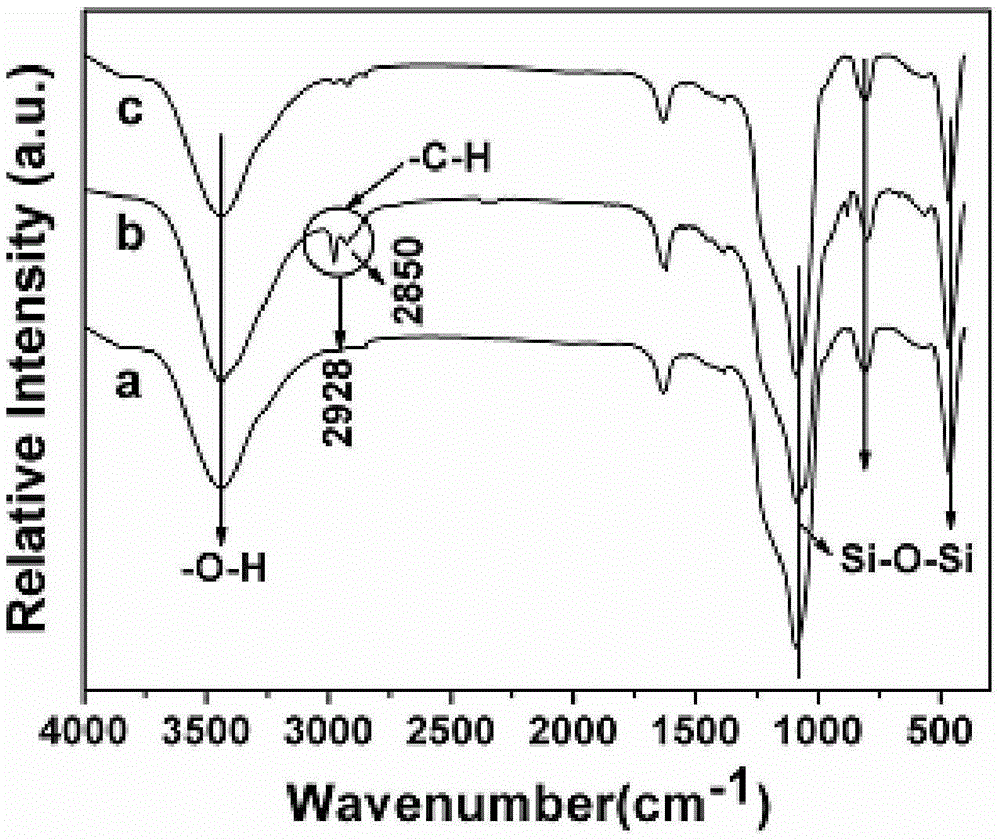

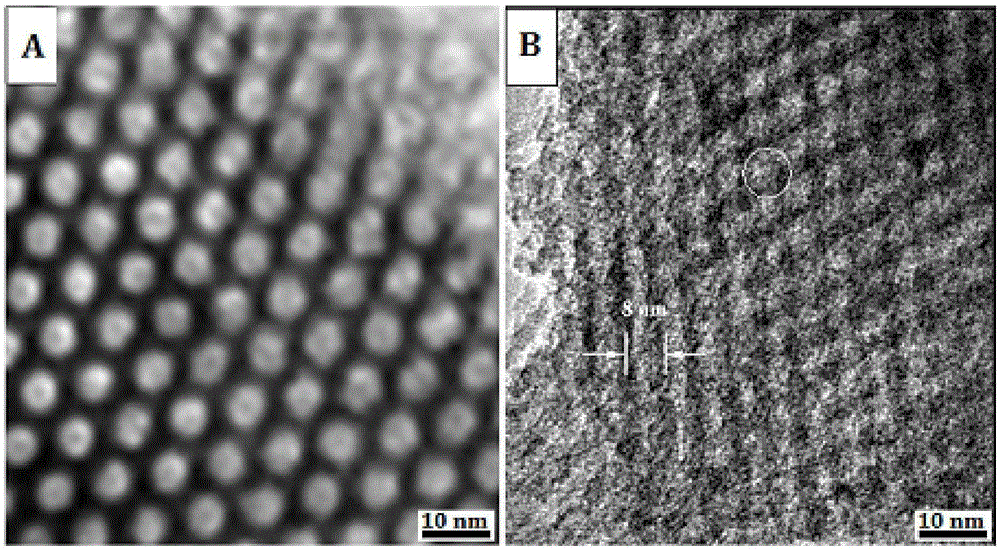

[0031]A. Accurately weigh 1.13g of SBA-15, place it in a glass bottle, and dry it in vacuum at 100°C for 12 hours. Use metal sodium to remove water and reflux the toluene until it is dark blue for collection. After the 250mL three-necked reaction flask was ventilated with nitrogen for 10 minutes, pour the dry SBA-15 into it, add a stirring bar and 20mL dry toluene and start stirring. Mix tetraethoxysilane and dry toluene at a volume ratio of 1:1 to form a 50mL solution, put it in the dropping funnel, add the mixed solution dropwise into the reaction flask, and stir at reflux at 90°C for 24h under the protection of nitrogen.

[0032] B. After the solid obtained by centrifugation was washed with ethanol, the solid was added to 150 mL of 10% (mass percentage concentration) HCl solution, and stirred at room temperature for 12 h. After the reaction was completed and the centrifuged solid was washed several times with deionized water, it was placed in a blast drying oven at 80°C and...

Embodiment 2

[0035] A. Accurately weigh 2.08g of SBA-15 and place it in a glass bottle, dry it in vacuum at 100°C for 16 hours, use metal sodium to remove water and reflux the toluene until it is dark blue for collection. After the 250mL three-necked reaction flask was ventilated with nitrogen for 10 minutes, pour the dry SBA-15 into it, add a stirring bar and 20mL dry toluene and start stirring. Mix tetraethoxysilane and dry toluene at a volume ratio of 1:1 to form a 50mL solution, put it in the dropping funnel, add the mixed solution drop by drop into the reaction flask, and stir at reflux at 80°C for 20h under the protection of nitrogen. .

[0036] B. After the solid obtained by centrifugation was washed with ethanol, the solid was added to 150 mL of 10% (mass percentage concentration) HCl solution, and stirred at room temperature for 8 h. After the reaction was completed and the centrifuged solid was washed several times with deionized water, it was placed in a blast drying oven at 80...

Embodiment 3

[0039] A. Accurately weigh 4.56g of SBA-15 and place it in a glass bottle, dry it in vacuum at 100°C for 20 hours, use metal sodium to remove water and reflux the toluene until it is dark blue for collection. After the 500mL three-necked reaction flask was ventilated with nitrogen for 15 minutes, pour the dry SBA-15 into it, add a stirring bar and 50mL dry toluene and start stirring. Mix tetraethoxysilane (TEOS) and dry toluene at a volume ratio of 1:1 to form a 100mL solution, put it in the dropping funnel, add the mixed solution drop by drop into the reaction flask, and stir under constant temperature at reflux at 90°C under nitrogen protection 36h.

[0040] B. After the solid obtained by centrifugation was washed several times with ethanol, the solid was added to 300 mL of 10% HCl (mass percentage concentration) solution, and stirred at room temperature for 24 h. After the reaction was completed and the centrifuged solid was washed several times with deionized water, it wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com