Low-cost titanium alloy panel applied to titanium dinner plates and preparation method of low-cost titanium alloy panel

A titanium alloy, low-cost technology, applied in the field of low-cost titanium alloy plate and its preparation, can solve the problems of hexavalent chromium, toxicity, etc., and achieve the effect of uniform structure, good room temperature performance, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

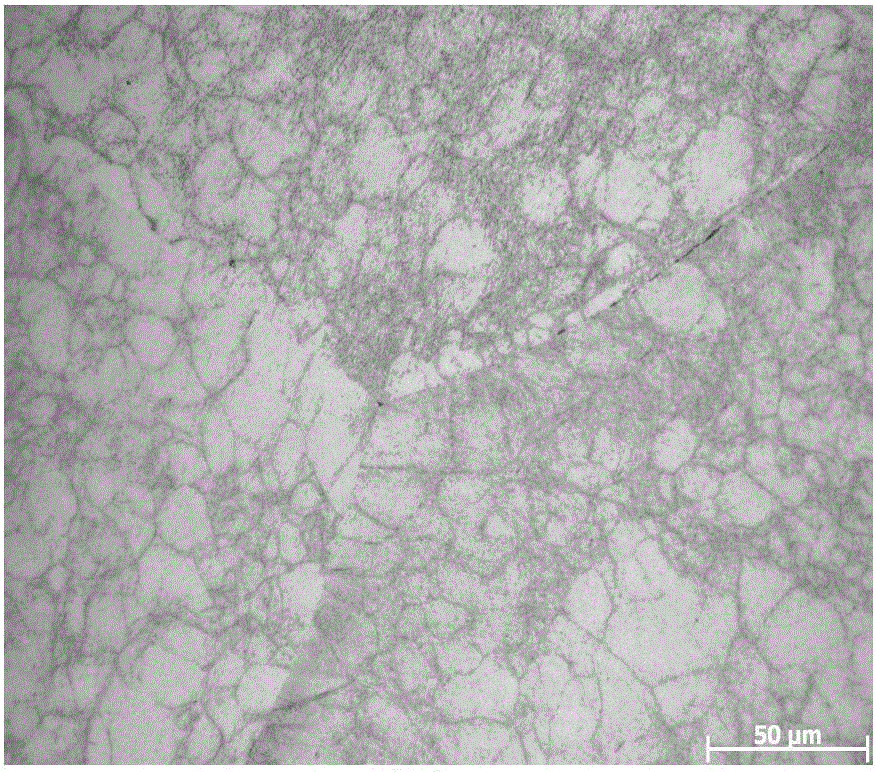

Embodiment 1

[0024] The preparation method of the present embodiment Ti-1.0Al-1.0Fe titanium alloy plate comprises the following steps:

[0025] Step 1: Melting Ti-1.0Al-1.0Fe titanium ingot in a 1.0t vacuum consumable electric arc furnace; the cross section of the Ti-1.0Al-1.0Fe titanium alloy ingot has a diameter of 380 mm; the Ti-1.0Al -1.0Fe titanium alloy ingots are produced by smelting twice in a vacuum consumable electric arc furnace. The smelting current for the first time is 4500A, the smelting voltage is controlled at 37.5V, and the vacuum degree is controlled at 0.1-1.2MPa. The secondary melting current is 6500A, the melting voltage is controlled at 37.5V, and the vacuum degree is controlled at 0.1-1.0MPa; the mass percentage of Al in the Ti-1.0Al-1.0Fe titanium alloy ingot is 0.5%, and the mass percentage of Fe is 0.5%. Min content is 0.5%. Content of other impurities, the mass percentage of O is 0.10%, C<0.02, N<0.008, H<0.0015;

[0026] Step 2: use a 3t electro-hydraulic ha...

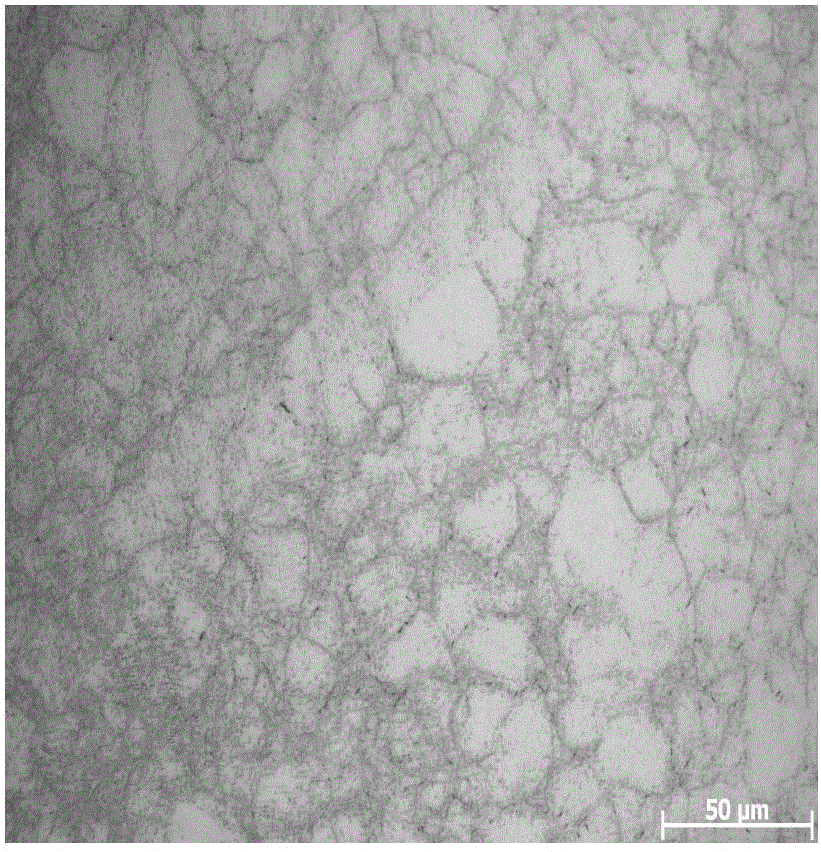

Embodiment 2

[0036] The preparation method of the present embodiment Ti-1.0Al-1.0Fe titanium alloy plate comprises the following steps:

[0037] Step 1: Melting Ti-1.0Al-1.0Fe titanium ingot in a 1.0t vacuum consumable electric arc furnace; the cross section of the Ti-1.0Al-1.0Fe titanium alloy ingot has a diameter of 380 mm; the Ti-1.0Al -1.0Fe titanium alloy ingots are produced by smelting twice in a vacuum consumable electric arc furnace. The current of the first smelting is controlled at 5000A, the smelting voltage is controlled at 37.5V, and the vacuum degree is controlled at 0.1-1.2MPa. The secondary melting current is controlled at 7000A, the melting voltage is controlled at 37.5V, and the vacuum degree is controlled at 0.1-1.0MPa; the mass percentage of Al in the Ti-1.0Al-1.0Fe titanium alloy ingot is 1.0%, Fe The mass percentage is 1.0%. Content of other impurities, the mass percentage of O is 0.15%, C<0.02, N<0.008, H<0.0015;

[0038] Step 2: use a 3t electro-hydraulic hammer t...

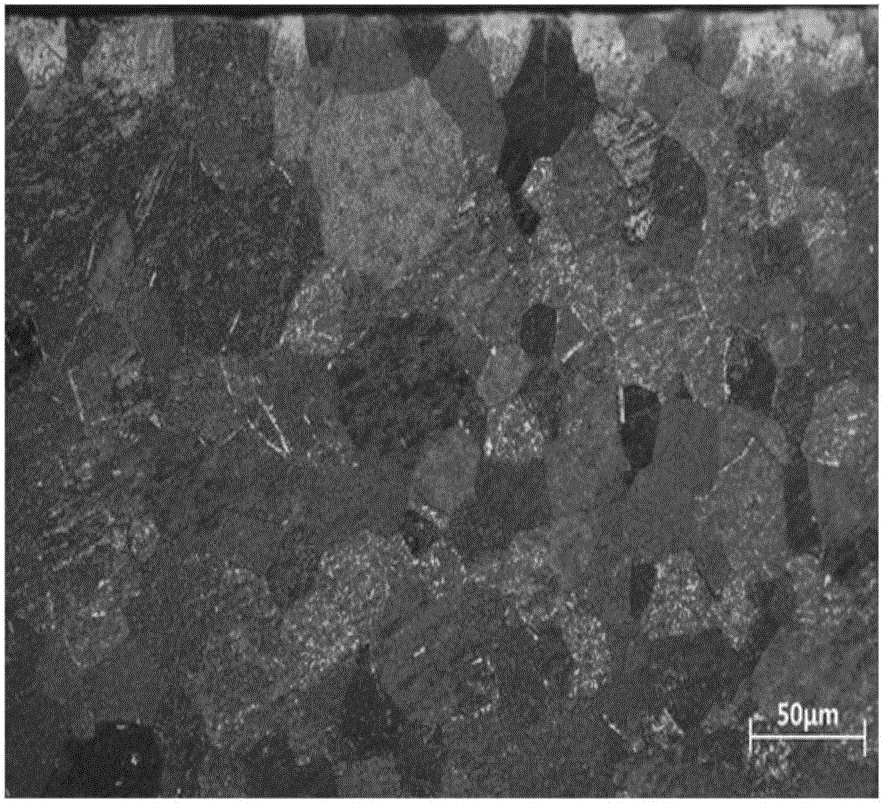

Embodiment 3

[0048] The preparation method of the present embodiment Ti-1.0Al-1.0Fe titanium alloy plate comprises the following steps:

[0049] Step 1: Melting Ti-1.0Al-1.0Fe titanium ingot in a 1.0t vacuum consumable electric arc furnace; the cross section of the Ti-1.0Al-1.0Fe titanium alloy ingot has a diameter of 380 mm; the Ti-1.0Al -1.0Fe titanium alloy ingots are produced by smelting twice in a vacuum consumable electric arc furnace. The smelting current is controlled at 5500A, the smelting voltage is controlled at 37.5V, and the vacuum degree is controlled at 0.1-1.2MPa. The 2nd smelting current is controlled at 7500A, the smelting voltage is controlled at 37.5V, and the vacuum degree is controlled at 0.1-1.0MPa; the mass percentage of Al in the Ti-1.0Al-1.0Fe titanium alloy ingot is 1.5%, Fe The mass percentage content is 1.5%. Content of other impurities, the mass percentage of O is 0.20%, C<0.02, N<0.008, H<0.0015;

[0050] Step 2: use a 3t electro-hydraulic hammer to carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com