Steel for liner plate forging die, liner plate forging die and preparation method thereof

A technology of steel for molds and liners, which is applied in the field of steel for forging molds for liners, forging molds for liners and their preparation fields, and can solve the problems of normal temperature performance and high temperature performance that cannot meet the requirements of forging production liners, coarse grains, and environmental pollution, etc. problems, to meet the use of technical requirements and cost requirements, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

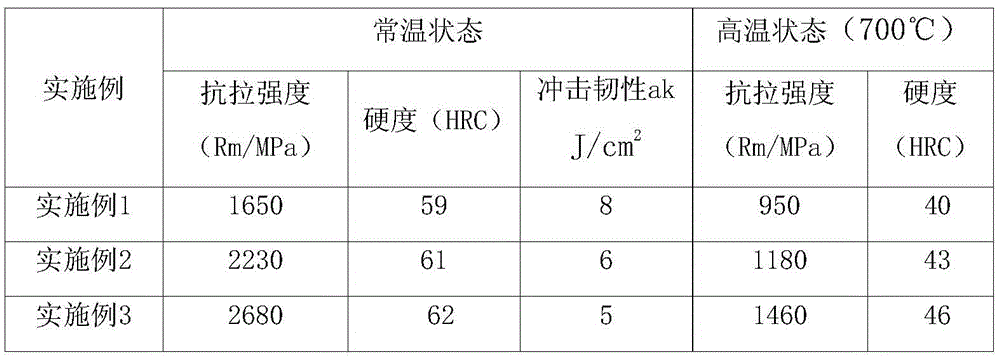

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the above-mentioned liner forging die, comprising the following steps:

[0037] 1) Steelmaking: molten steel is obtained through steelmaking, and the end point components of the molten steel include the following components in weight percentage: 0.5% to 0.6% of C; 0.2% to 0.6% of Si; 0.4% to 0.8% of Mn; 2 %~5% W; 3%~5% Cr; 1%~3% Mo; 1%~5% Co; 0.001%~0.005% Nb; 2%~4% V; 0.02%~ 0.1% Ti, the rest is Fe and unavoidable impurities;

[0038] 2) casting: casting the molten steel obtained in step 1) to obtain steel ingots or billets for forging;

[0039] 3) forging: forging the steel ingot or billet obtained after casting in step 2) into a forging close to the shape of the lining plate forging die;

[0040] 4) Finishing: process the forging obtained after step 3) into the design size of the forging liner die through machine tools;

[0041] 5) Quenching: heat the finished forging in step 4) to 1150°C-1200°C in a vacuu...

Embodiment 1

[0048] A method for preparing a liner forged liner, comprising the following steps:

[0049] 1) Steelmaking: molten steel is obtained through steelmaking, and the end point composition of the molten steel includes the following components in weight percentage: 0.5% of C; 0.6% of Si; 0.4% of Mn; 5% of W; 3% of Cr; 3% Mo; 1% Co; 0.005% Nb; 2% V; 0.1% Ti, the rest is Fe and unavoidable impurities;

[0050] 2) casting: casting the molten steel obtained in step 1) to obtain steel ingots for forging;

[0051] 3) forging: forging the steel ingot obtained after step 2) into a forging close to the shape of the liner plate forging die;

[0052] 4) Finishing: process the forging obtained after step 3) into the design size of the forging liner die through machine tools;

[0053] 5) Quenching: heat the finished forging in step 4) to 1150°C in a vacuum furnace, and perform oil quenching treatment, and the oil quenching time is 4 minutes;

Embodiment 2

[0057] 1) Steelmaking: molten steel is obtained through steelmaking, and the end point composition of the molten steel includes the following components in weight percentage: 0.53% C; 0.4% Si; 0.5% Mn; 3.5% W; 4.5% Cr; 1.5% Mo; 3.5% Co; 0.003% Nb; 2.5% V; 0.06% Ti, the rest is Fe and unavoidable impurities;

[0058] 2) casting: casting the molten steel obtained in step 1) to obtain steel ingots for forging;

[0059] 3) forging: forging the steel ingot obtained after step 2) into a forging close to the shape of the liner plate forging die;

[0060] 4) Finishing: process the forging obtained after step 3) into the design size of the forging liner die through machine tools;

[0061] 5) Quenching: heat the finished forging in step 4) to 1180°C in a vacuum furnace, and perform oil quenching treatment, and the oil quenching time is 4 minutes;

[0062] 6) Tempering: Tempering the forging obtained after the oil quenching in step 5), the tempering temperature is 570° C., and the hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com