Preparation method for TiAl-Ni alloy plate with high strength and toughness and high stability

A high-stability technology for alloy plates, which is applied in the direction of metal rolling, can solve problems such as rough and uneven structure of rolled billets, poor stability of plate structure and performance, and unstable rolling process, and achieve fine alloy microscopic Microstructure, improvement of high temperature deformation ability, effect of improvement of high temperature deformation ability and room temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

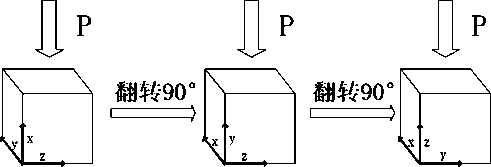

Method used

Image

Examples

Embodiment 1

[0045] Test one:

[0046] The preparation method of Ti-43Al-4Mo-2V-0.2Ni-(B, Y) alloy plate is as follows:

[0047] Step 1, weighing raw materials:

[0048] According to the atomic percentage of each component, the alloy composition is 43% Al, 4% Mo, 2% V, 0.2% Ni and 0.1% X (X is a 1:1 combination of B and Y elements), and the balance Ti and inevitable impurity elements. Weigh high-purity titanium sponge, high-purity aluminum, aluminum-molybdenum alloy (57.43% Mo content), aluminum-vanadium alloy (53.25% V content), aluminum-yttrium alloy (87.3% Y content), high-purity nickel powder (99.9% ), a total of 20Kg of boron powder as raw materials.

[0049] Step 2. Ingot melting and casting:

[0050] The high-purity titanium sponge, high-purity aluminum, aluminum-molybdenum alloy, aluminum-vanadium alloy, aluminum-yttrium alloy, high-purity nickel powder, and boron powder weighed in step 1 are added to a 20kg water-cooled copper crucible for melting in a vacuum induction shell m...

Embodiment 2

[0077] The preparation method of Ti-47Al-2Nb-2Cr-2V-2Ni-(B, C) alloy plate is as follows:

[0078] Step 1, weighing raw materials:

[0079] According to the atomic percentage of each component, the alloy composition is 47% Al, 2% Nb, 2% Cr, 2% V, 2% Ni and 0.5% X (X is a 1:1 combination of B and C elements ), the balance is Ti and unavoidable impurity elements. Weigh high-purity titanium sponge, high-purity aluminum, aluminum-niobium alloy (Nb content is 54.56%), high-purity chromium (Cr content is 99.99%), aluminum-vanadium alloy (V content is 53.25%), high-purity nickel powder (99.9% ), boron powder and carbon powder total 20Kg as raw materials.

[0080] Step 2, ingot melting and casting: same as embodiment 1.

[0081] Step three, billet pretreatment one:

[0082] a. Remove the riser of the TiAl alloy ingot and perform hot isostatic pressing treatment. The treatment process is 1280 ° C, 150 MPa, protected by argon atmosphere, kept for 4 hours, and cooled with the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com