Aluminum-spinel-magnesia composite refractory as well as preparation method and application thereof

A refractory material, a technology of magnesia-aluminum spinel, is applied in the field of aluminum-spinel-magnesia composite refractory material and its preparation, and can solve the problems of replacing magnesia-chromium refractory material, high use cost, poor slag resistance and the like, Achieve the effect of improving slag resistance, reducing pollution and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh the required raw materials according to the ratio in Table 1, first stir the raw materials with a particle size > 0.088mm at 50r / min for 5min, add half of the inorganic binder at 50r / min and stir for 5min, and mix the raw material fine powder with a particle size of ≤0.088mm at 50r / min Min and stir for 5 minutes, add the remaining inorganic binder and continue to stir at 50r / min for 10min, stop stirring to fully trap the stirred mixture, then press the trapped mixture on a press with a pressure of 150MPa to become a standard size brick, and finally put The molded refractory material is obtained by heat treatment between 300°C and 600°C.

[0030] Table 1 Sample ratio (w)

[0031]

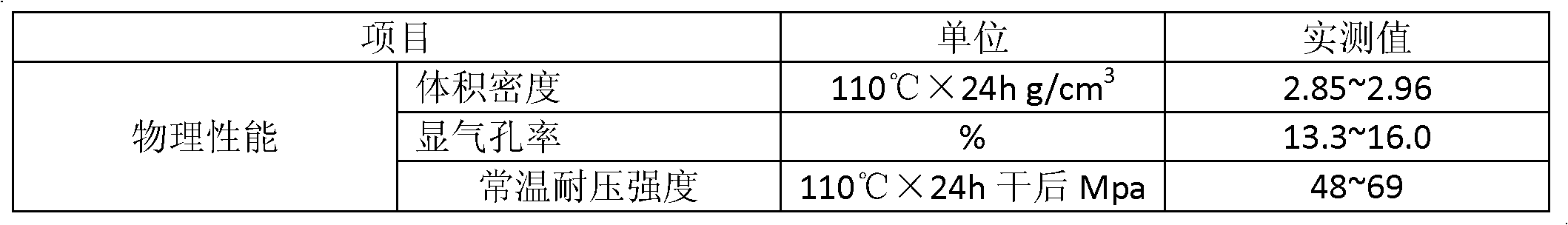

[0032] The heat-treated samples were tested for conventional physical and chemical properties such as apparent porosity (GB / T2997-2000), bulk density (GB / T2997-2000), and room temperature compressive strength (GB / T3997.2-1998). The test results are shown in Table 2.

[0033] Table 2...

Embodiment 2

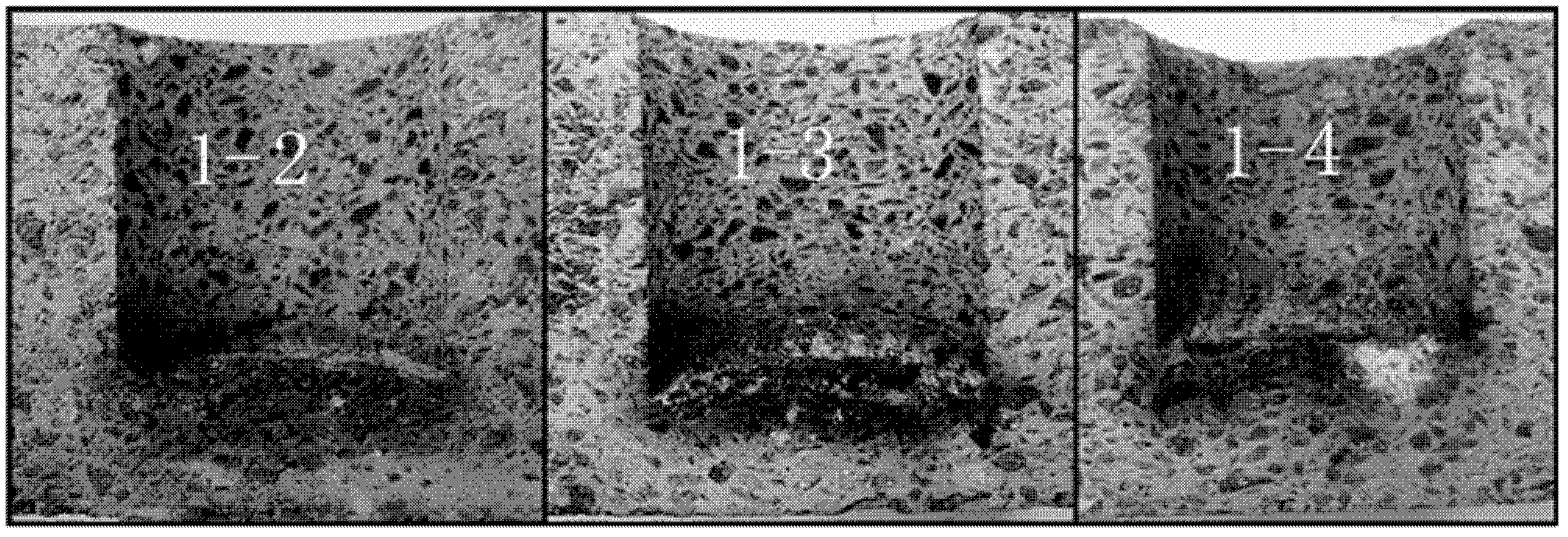

[0036] Make a cylindrical crucible with a diameter of 50mm and a depth of 50mm in the center of the samples 1-2, 1-3, and 1-4 of Example 1, put 10g of steel slag in it, put it in a tunnel kiln at 1700°C for 3 hours, and cool it naturally to room temperature . The steel slag of the sample is the steel slag refined by RH, and the chemical composition of the steel slag is (W): Al 2 o 3 42.2%, CaO 37.6%, MgO 7.35%, SiO 2 5.67%, Fe 2 o 3 1.53%, Na 2 0 0.13%, K 2 O0.14%, TiO 2 0.14%; m(CaO) / m(SiO 2 )≈7.5. Slices of the samples after the test are shown in figure 2 As shown, the three crucibles all maintain good shape, the erosion and penetration of slag are not serious, and the slag resistance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com