Structure controlled preparation method for Nb-Si-based complex alloy

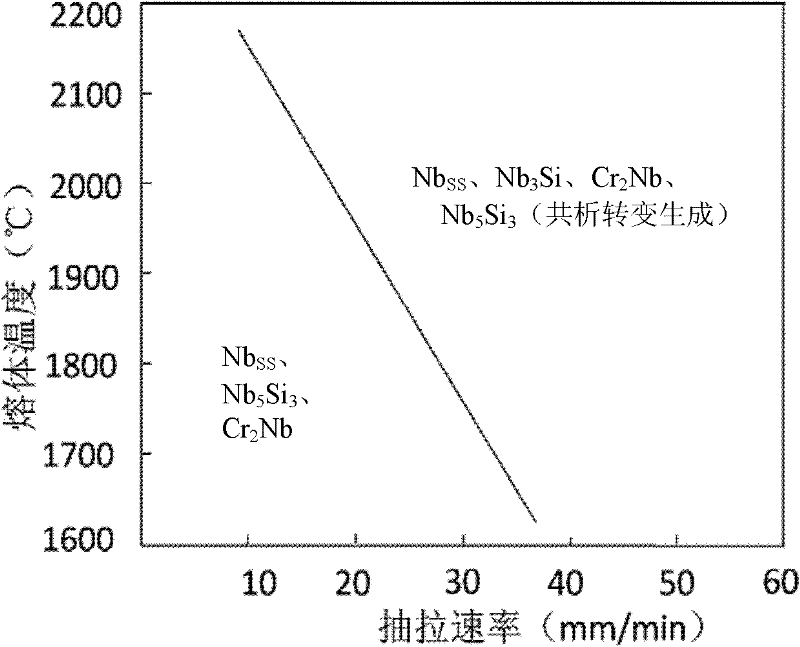

A technology of base alloy and structure, applied in the field of changing the structure of Nb-Si base multi-alloy, can solve the problems of reducing the plasticity and ductility at room temperature, smaller size, coarse structure, etc., to improve room temperature performance, reduce processing cost, Avoid performance degradation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

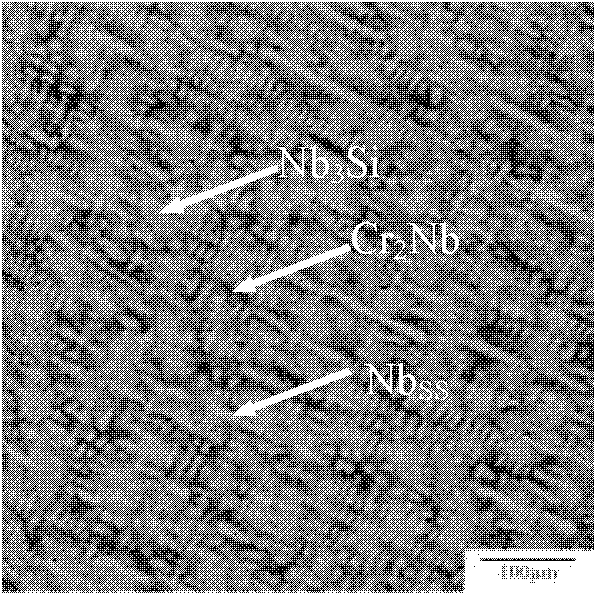

Embodiment 1

[0028] The nominal composition of embodiment 1 is Nb 50 Si 12 Ti 24 al 2 Cr 10 f 2

[0029] Step 1: Prepare master alloy ingot

[0030] 99.8wt% niobium (Nb), 99.9wt.% silicon (Si), 99.8wt.% titanium (Ti), 99.9wt.% aluminum (Al), 99.9wt.% chromium (Cr), 99.8wt.% hafnium (Hf) according to the nominal composition ratio;

[0031] Vacuum non-consumable electric arc furnace is used for melting, and the vacuum degree of the vacuum chamber of non-consumable electric arc furnace is 3×10 -3 Pa, then fill with high-purity argon (mass percentage purity 99.99%) to make the vacuum of the vacuum chamber to 0.5 × 10 5 Pa; the alloy ingot was repeatedly smelted four times to ensure uniform composition, and the current during the smelting process was 1300A to prepare a 1.5kg master alloy ingot;

[0032] Step 2: Cut the test rod from the master alloy ingot by wire cutting method, the diameter of the test rod is about 14mm; then use sandpaper to clean the scale on the surface of the test...

Embodiment 2

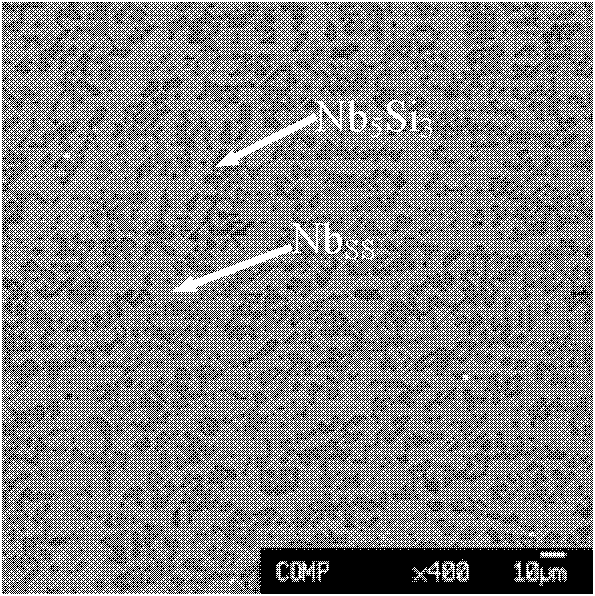

[0039] Embodiment 2 Nominal composition is Nb 48 Si 12 Ti 22 al 2 Cr 14 f 2

[0040] Step 1: Prepare master alloy ingot

[0041] 99.8wt% niobium (Nb), 99.9wt.% silicon (Si), 99.8wt.% titanium (Ti), 99.9wt.% aluminum (Al), 99.9wt.% chromium (Cr), 99.8wt.% Hafnium (Hf) according to the nominal composition ratio; the vacuum degree of the vacuum chamber of the vacuum non-consumable electric arc furnace is 4×10 -3 Pa, then fill with high-purity argon (mass percentage purity 99.99%) to make the vacuum of the vacuum chamber to 0.8 × 10 5 Pa; the alloy ingot was repeatedly smelted four times to ensure uniform composition, and the current during the smelting process was 800A to prepare a 1.5kg master alloy ingot;

[0042] Step 2: Cut the test rod from the master alloy ingot by wire cutting method, the diameter of the test rod is about 14mm; then use sandpaper to clean the scale on the surface of the test rod, wash it with acetone, and dry it at a drying temperature of 100 °C d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com