Needle, flake-shaped nano single crystal mg-al hydrotalcite Mg8Al2(OH)16CO3 4H2O preparation method

A technology of 16CO3·4H2O and magnesium aluminum hydrotalcite, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of increasing the complexity of the preparation process and preparation cost, long cycle time, and high baseline, and achieves favorable Protection of the environment and human health, avoidance of autoclave requirements, effect of uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

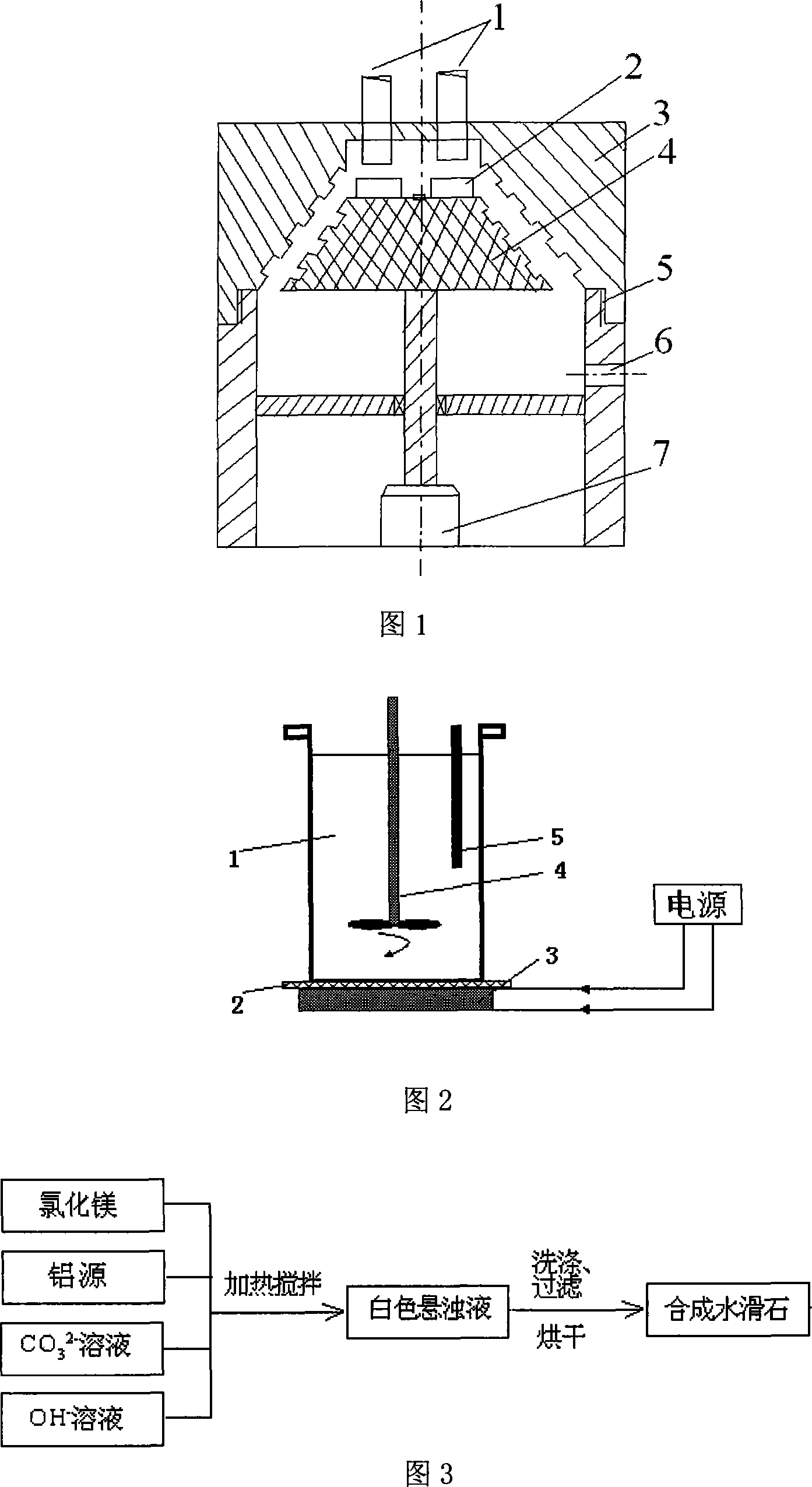

[0098] According to the typical process flow of the liquid phase co-precipitation method for preparing magnesium aluminum hydrotalcite shown in Figure 3, the steps for preparing magnesium aluminum hydrotalcite are:

[0099] In the first step, according to the moles of each component, the moles of crystalline magnesium chloride and sodium hydroxide are dissolved in deionized water, and heated in reactor 1 for 2 to 5 minutes while stirring; the amount of deionized water added is based on the prepared The amount of magnesium aluminum hydrotalcite depends on the requirements, generally greater than 500mL; if the reaction aqueous solution is too small, the distance between the "stirrer 4" in the stirring while heating in Figure 2 is too close to the bottom of the reaction vessel, and it is easy to rub against the bottom of the stainless steel vessel. Reaction temperature: 100°C;

[0100] In the second step, while heating while stirring, aluminum salt and sodium carbonate are added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com