Preparation method of in-situ grown graphene reinforced metal-based composite material

A metal composite material and composite material technology, applied in the field of metal matrix composite material preparation, can solve the problems of dangerous process, low strength, and many defects, and achieve the effects of easy industrialized mass production, high degree of crystallization, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

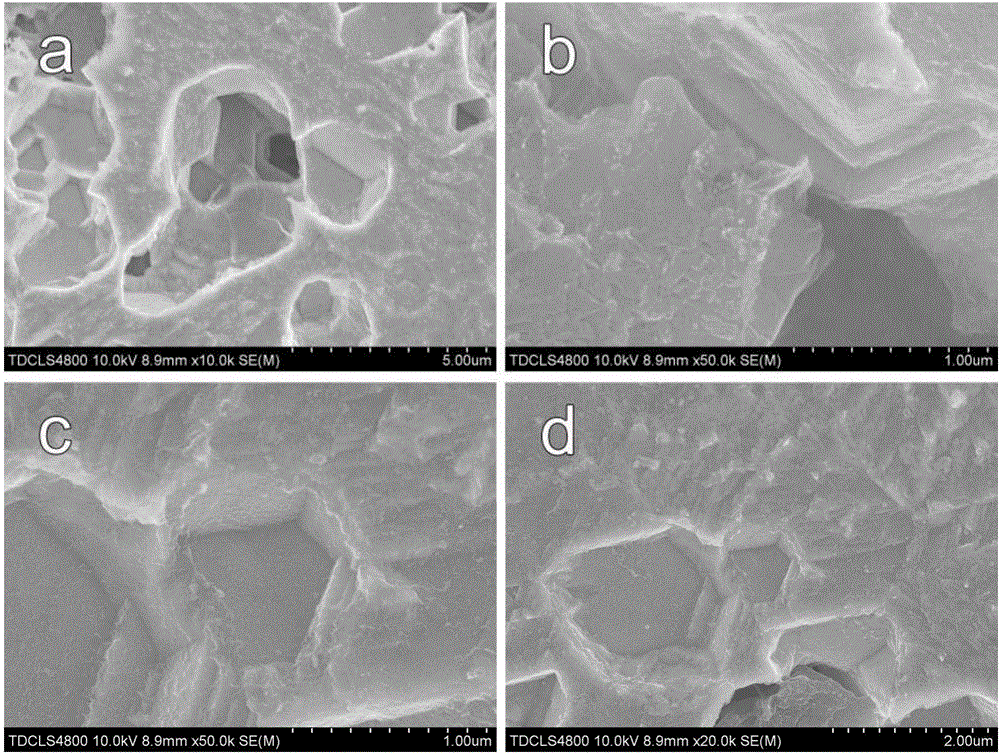

[0022] 0.6g of sucrose and 18g of nickel powder (the mass ratio of sucrose in the composite powder is 3.23%) were uniformly mixed in 200mL of water (which can completely dissolve sucrose), stirred mechanically, and evaporated to dryness by heating at 70°C. After 24 hours of vacuum drying (10torr) and grinding, the nickel powder / sucrose prefabricated powder was obtained. Put the prefabricated powder in a hot press, under the protection of argon (500mL / min) atmosphere, raise the temperature from room temperature to 1000°C at a rate of 10°C / min, keep it warm for 30min, load the pressure at 1000MPa, and cool down with the furnace, one-step method Obtain graphene-enhanced nickel-based composites, materials such as figure 1 Shown is a graphene-reinforced Ni-based composite block with a diameter of 30 mm and a thickness of approximately 3 mm. The prepared material was corroded by a 1mol / L ferric chloride solution, and observed by a scanning electron microscope (SEM). Such as figu...

example 2

[0024] 0.3 g of glucose and 30 g of copper-nickel alloy powder were evenly mixed in 200 mL of water (glucose accounted for 0.99%), stirred mechanically, and evaporated to dryness by heating at 70°C. After 24 hours of vacuum drying (10torr) and grinding, the copper-nickel / glucose prefabricated powder was obtained. Put the prefabricated powder in a hot press, under the protection of argon (100mL / min) atmosphere, raise the temperature from room temperature to 1300°C at a rate of 10°C / min, keep it warm for 48h, load the pressure at 2000MPa, and cool down with the furnace, one step Graphene-reinforced copper-nickel alloy matrix composites were obtained by this method. Higher temperature will increase the graphitization degree of graphene to a certain extent.

example 3

[0026] 0.3 g of glucose and 30 g of nickel powder were uniformly mixed in 200 mL of water (glucose accounted for 0.99%), stirred mechanically, and evaporated to dryness by heating at 70°C. After 24 hours of vacuum drying (10torr) and grinding, nickel / glucose prefabricated powder was obtained. Put the prefabricated powder in a hot press, under the protection of argon (300mL / min) atmosphere, raise the temperature from room temperature to 500°C at a rate of 10°C / min, keep it warm for 24h, load the pressure at 10MPa, and cool down with the furnace, one step Graphene-reinforced nickel-based composites were obtained by this method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com