Method for replicating metal relic with high fidelity

A copying method and technology of cultural relics, applied in the direction of metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve problems such as error, less texture and charm, damage to original cultural relics, etc., to achieve short manufacturing cycle, advanced technology, and precise craftsmanship Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

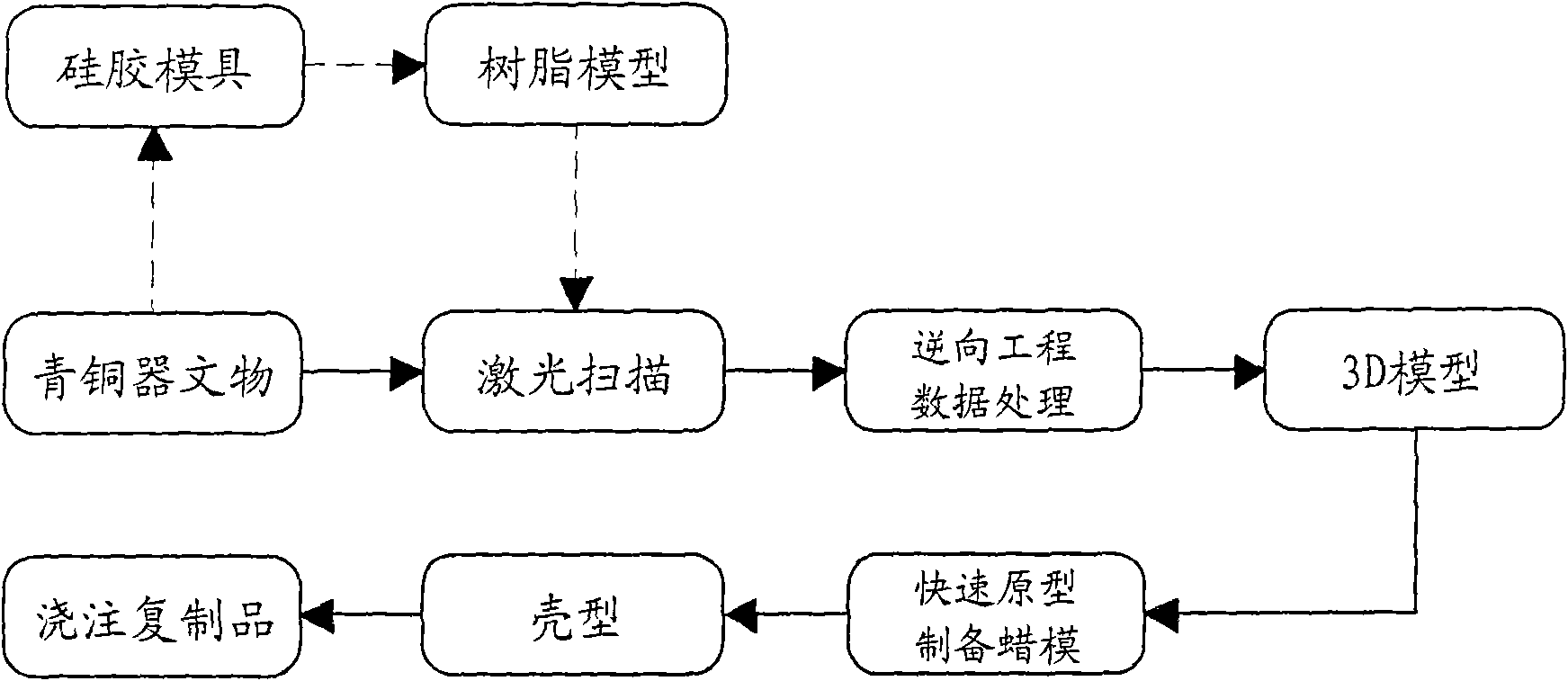

[0033] What the present invention discloses is a kind of metal cultural relic duplication method, such as figure 1 Shown, is the schematic diagram of the present invention, and it comprises following four steps:

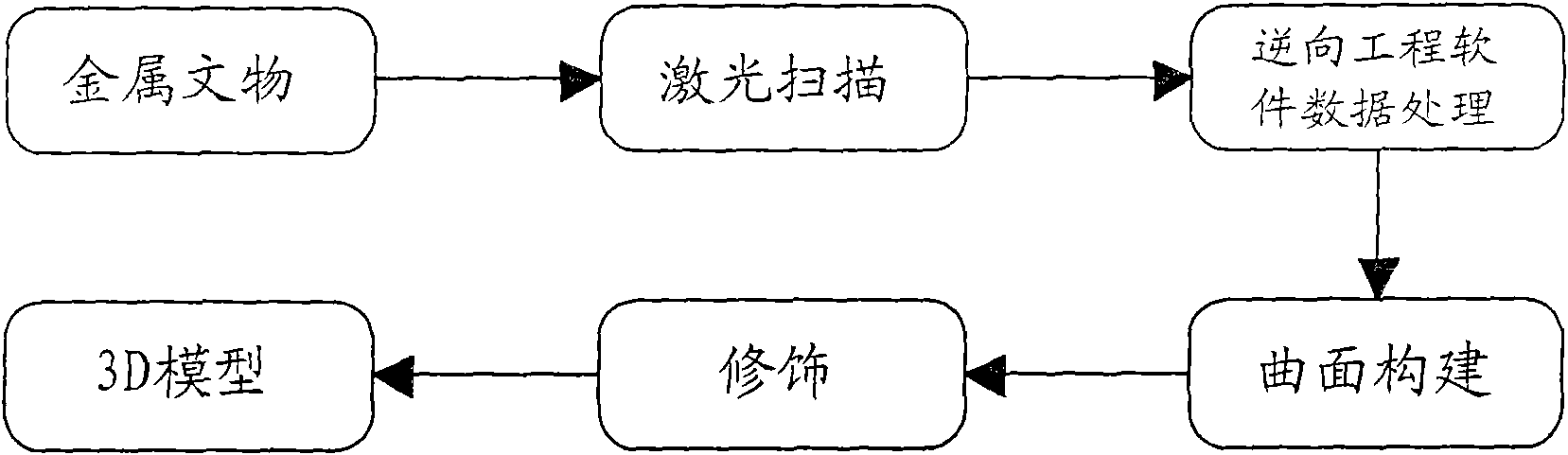

[0034] ① Reversely seek the 3D model of the original metal cultural relic: directly use the laser scanner to scan the original metal cultural relic and obtain the 3D model of the original cultural relic through reverse reverse technology, or first obtain the resin model of the original cultural relic through a silicone mold, and then process the resin The model is scanned by laser and the 3D model of the bronze prototype is obtained through reverse reverse technology;

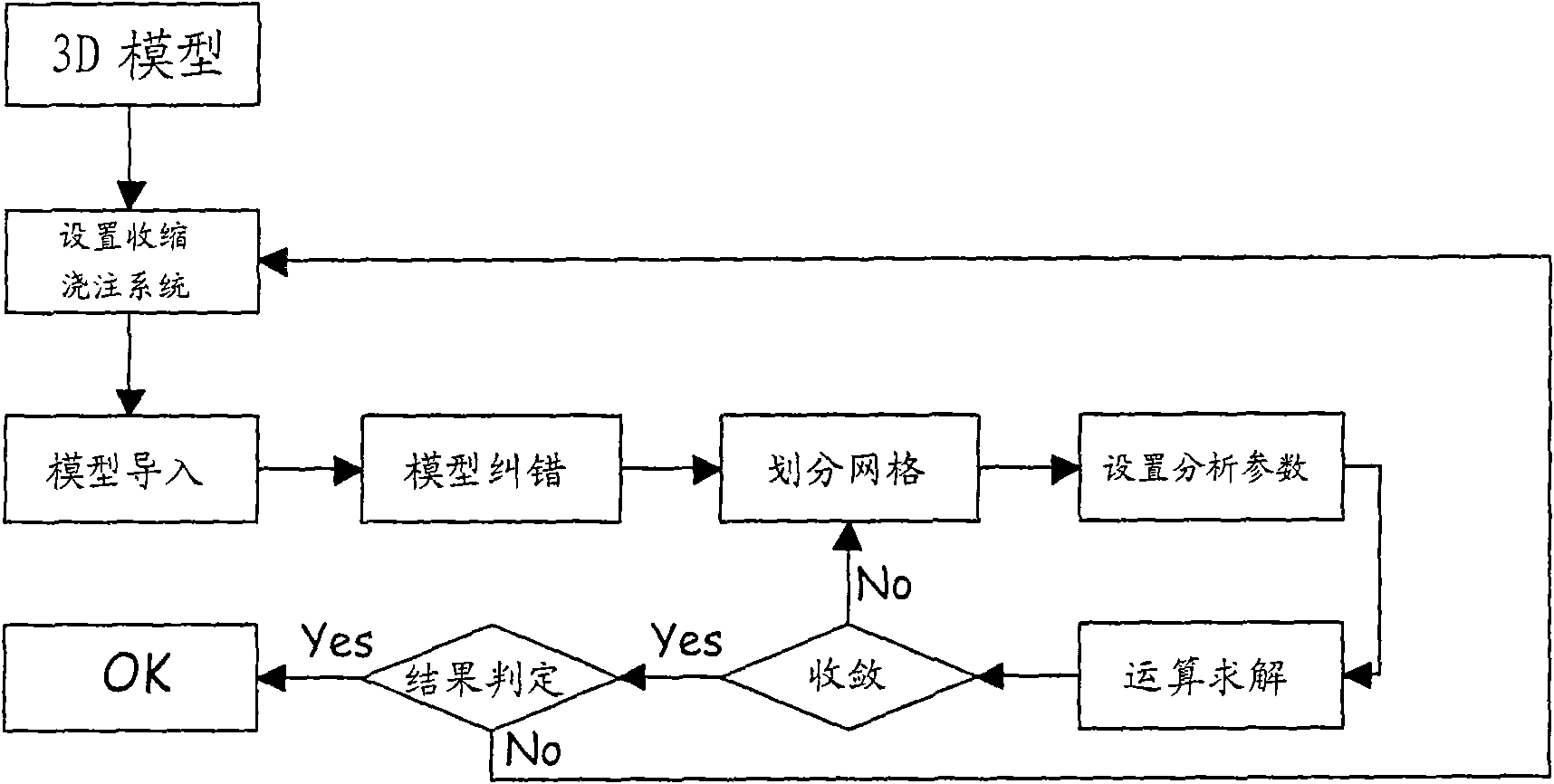

[0035] ②Casting simulation correction 3D model: Use finite element method to simulate the actual process of actual investment shell casting, and correct the 3D model according to the simulation results (such as shrinkage);

[0036] ③Preparation of wax molds by rapid prototyping: according to the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com