High-strength nickel-chromium-silicon-copper alloy material and processing technology thereof

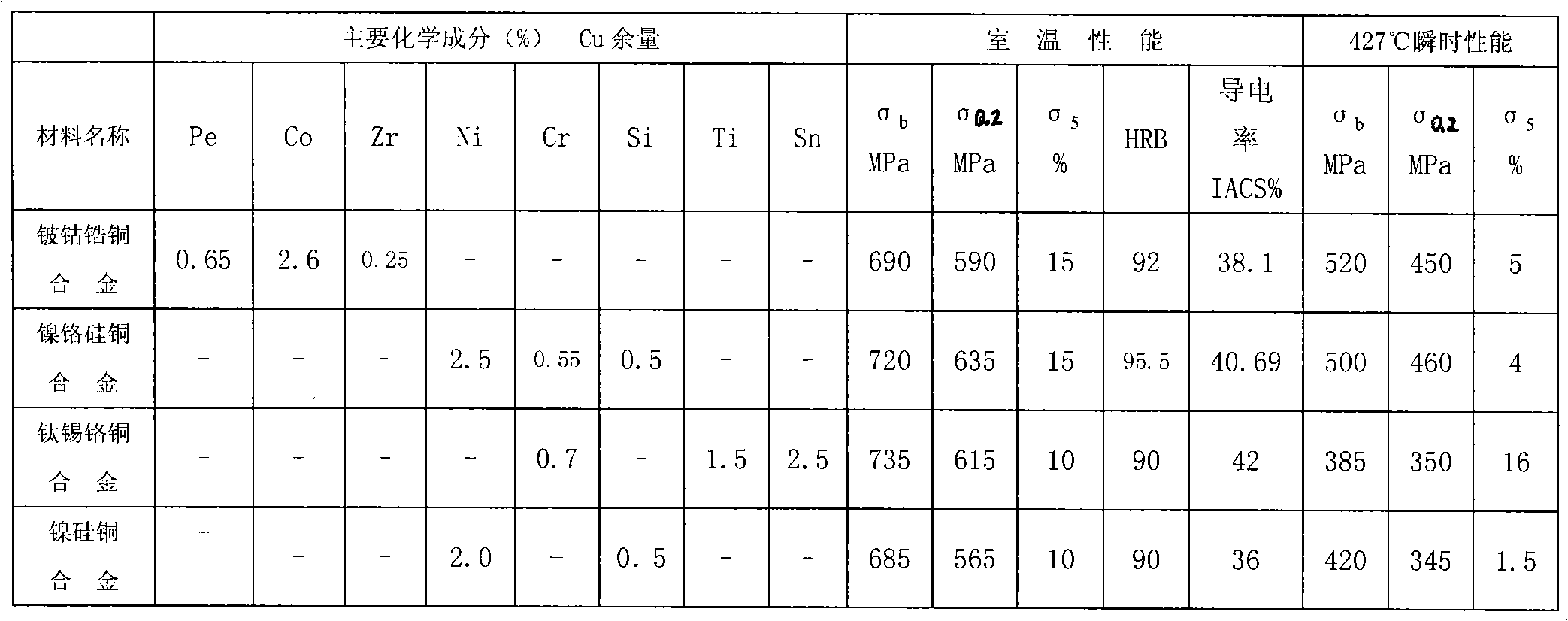

A technology of silicon-copper alloy and processing technology, applied in the field of high-strength nickel-chromium-silicon-copper alloy material and its processing technology, can solve the problems of high cost of beryllium-cobalt-zirconium-copper alloy material, high price of cobalt metal, high toxicity, etc., and achieve mechanical High performance, environmental protection and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Ni: 2.9%, Cr: 0.55%, Si: 0.7%, the total amount of impurities ≤ 0.3%, and the balance of Cu.

Embodiment 2

[0028] Example 2: Ni: 2.5%, Cr: 0.5%, Si: 0.5%, the total amount of impurities ≤ 0.3%, and the balance of Cu.

Embodiment 3

[0029] Embodiment 3: Ni: 2.1%, Cr: 0.7%, Si: 0.3%, the total amount of impurities ≤ 0.3%, and the balance of Cu.

[0030] Nickel can improve the mechanical properties and corrosion resistance of copper alloy materials, and has good electrical conductivity. Nickel and silicon can form a compound Ni 2 Si is soluble in copper; chromium, similar to nickel, can form chromium silicide, a compound soluble in solid copper with silicon, to strengthen the body; chromium is not easy to reduce the conductivity of copper, and can improve the mechanical properties of the material by precipitation hardening.

[0031] The embodiment of processing technique of the present invention is as follows:

[0032] Embodiment 1 (forged bar, specification 45*60*L):

[0033] 1. Casting

[0034] It adopts the semi-continuous casting method of industrial frequency electric furnace melting. Cu and Ni can be directly added into the furnace during melting and casting. Cr is pre-loaded into the copper tube in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com