Laser synthesis preparation method of intermetallic compound and granule reinforced composite material

A technology of intermetallic compound and laser synthesis, which is applied in the field of synthesis and manufacturing of intermetallic compound, to achieve the effect of satisfying performance, low production cost, and good comprehensive mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

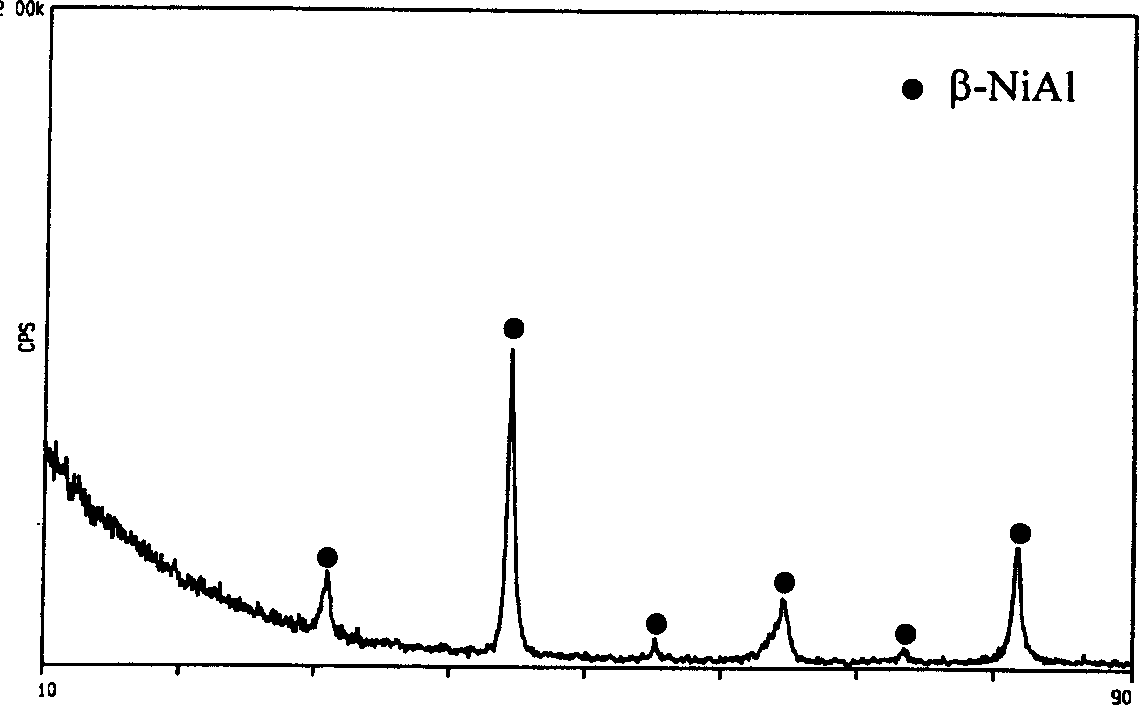

[0032] Preparation of Ni20Al30Fe Intermetallic Compounds by Laser Synthesis

[0033] Ordinary binary NiAl intermetallic compounds have high melting point, good thermal conductivity, and high temperature oxidation resistance, but their brittleness is relatively large, so it is difficult to be applied in engineering practice. By adding Fe as an alloying element, its plasticity at room temperature can be significantly improved and its performance improved. The present invention is implemented in laser synthesis and prepares Ni20Al30Fe intermetallic compound, and its method is:

[0034] (1) Using Ni-packed Al powder, pure Al, and pure Fe powder as raw materials, according to the atomic percentage of Ni20Al30Fe, an additional 10wt% of pure Al powder is added to compensate for the Al content burned in the composite material, and the powder particle size is - 150 mesh to +200 mesh, the above powder is mixed by mechanical stirring, and kept in an oven at 100°C for 1 hour to remove mo...

Embodiment 2

[0040] Preparation of TiC Particle Reinforced Ni-Al-Fe Intermetallic Compound Matrix Composites by Laser Synthesis

[0041] Ni20Al30Fe (at.%) is obtained by adding Fe as an alloying element to NiAl intermetallic compound, which has high room temperature plasticity and toughness. On this basis, adding 20% TiC (wt.%) to prepare a particle reinforced intermetallic compound matrix composite The material can ensure the high temperature strength of the alloy, so as to obtain good comprehensive mechanical properties. The present invention is implemented in the preparation of TiC particle reinforced Ni20Al30Fe intermetallic compound-based composite material by laser synthesis, and the method is as follows:

[0042] (1) Use Ni-packed Al powder, pure Al, pure Fe powder element powder, according to the atomic percentage of Ni20Al30Fe, add an additional 30wt% of pure Al powder to compensate for the Al content burned in the composite material, add 20wt to the above powder % TiC powder, ...

Embodiment 3

[0048] The present invention is implemented in laser synthesis to prepare TiAl intermetallic compound, and its method is:

[0049] (1) adopt pure Ti, pure Al powder elemental powder as raw material, according to the atomic percentage of TiAl, additionally add the pure Al powder of 20wt% and the pure Ti powder of 15wt% to compensate the Al and Ti content of burning loss in the composite material, The particle size of the powder is -150 mesh to +200 mesh. The above powder is mixed by mechanical stirring, and kept in an oven at 100°C for 2 hours to remove moisture;

[0050] (2) Using a high-power diode laser, the laser power is 5000W, focused into a spot with a diameter of 6mm, and at a scanning speed of 2m / min, irradiating the surface of the cleaned and polished low-carbon steel to form a local molten pool;

[0051] (3) While the laser melts the base material to form a local molten pool, the mixed powder is sent into the molten pool by the side powder feeding method, and the Ti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com