Alloy reinforced titanium carbonitride-based composite material and preparation method thereof

A titanium carbonitride-based, composite material technology, applied in the field of cemented carbide materials, can solve the problems of poor grain size uniformity, slippage, and no significant improvement in material strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of an alloy-strengthened titanium carbonitride-based composite material is carried out as follows:

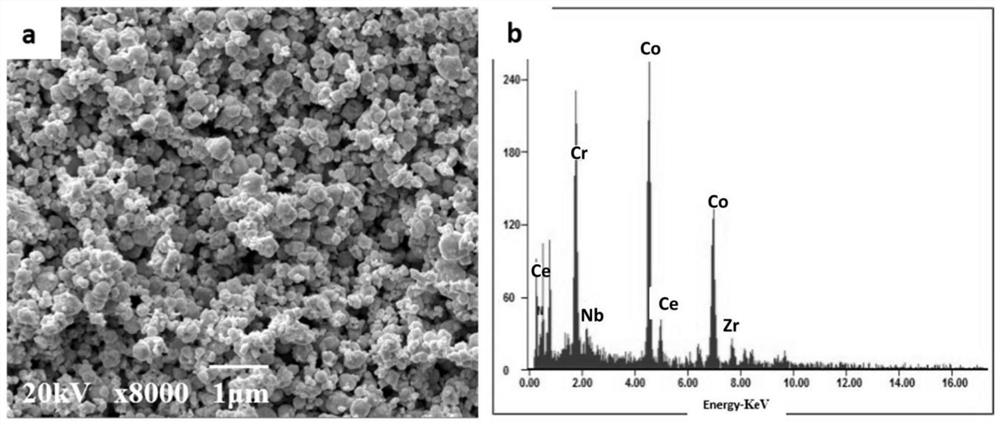

[0045] Preparation of Alloy Phase Composite Powder

[0046] (1) Weigh raw materials: Weigh the corresponding cobalt oxide powder, chromium oxide, cerium oxide, niobium oxide, Zirconium (oxide purity greater than 99%);

[0047] (2) Mechanical impact mill crushing and mixing: put the weighed oxide powder and TiCN balls into a stirring ball mill tank, add absolute ethanol in an amount of 0.05L / kg, and then carry out mechanical impact crushing and mixing to form a wet slurry. The ball-to-material ratio is 3:1, the stirring ball milling speed is 300 rpm, and the crushing and mixing time is 48 hours;

[0048] (3) High-pressure spray drying: sieve the mixed wet slurry to remove balls, atomize the slurry under a pressure of 15MPa, mix and dry the atomized slurry with hot air at 60°C to form a micro-nano alloy mixture powder;

[0049] (4) Nitrogen hydroge...

Embodiment 2

[0055] A preparation method of an alloy-strengthened titanium carbonitride-based composite material is carried out as follows:

[0056] Preparation of Alloy Phase Composite Powder

[0057] (1) Weigh raw materials: Weigh the corresponding cobalt oxide powder, chromium oxide, cerium oxide, niobium oxide, Zirconium (oxide purity greater than 99%);

[0058] (2) Mechanical impact mill crushing and mixing: Put the weighed oxide powder and TiCN balls into a stirring ball mill tank, add absolute ethanol in an amount of 0.1L / kg, and then carry out mechanical impact crushing and mixing to form a wet slurry. The ball-to-material ratio is 5:1, the stirring ball milling speed is 500 rpm, and the crushing and mixing time is 36 hours;

[0059] (3) High-pressure spray drying: sieve the mixed wet slurry to remove balls, atomize the slurry at a pressure of 2 MPa, mix and dry the atomized slurry with hot air at 80°C to form a micro-nano alloy mixture powder;

[0060] (4) Nitrogen hydrogenati...

Embodiment 3

[0066] A preparation method of an alloy-strengthened titanium carbonitride-based composite material is carried out as follows:

[0067] Preparation of Alloy Phase Composite Powder

[0068] (1) Weigh raw materials: Weigh the corresponding cobalt oxide powder, chromium oxide, cerium oxide, niobium oxide, Zirconium (oxide purity greater than 99%);

[0069] (2) Mechanical impact mill crushing and mixing: put the weighed oxide powder and TiCN balls into a stirring ball mill tank, add absolute ethanol in an amount of 0.08L / kg, and then carry out mechanical impact crushing and mixing to form a wet slurry. The ball-to-material ratio is 4:1, the stirring ball milling speed is 400 rpm, and the crushing and mixing time is 40 hours;

[0070] (3) High-pressure spray drying: sieve the mixed wet slurry to remove balls, atomize the slurry under a pressure of 10MPa, mix and dry the atomized slurry with hot air at 70°C to form a micro-nano alloy mixed powder ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com