Forging method achieving uniformity of crystal particles of GH141 abnormally-shaped annular forged piece

A homogenization and special-shaped ring technology, which is applied in the field of forging technology, can solve the problems of unsatisfactory grain size and large grain size difference, and achieve the effects of improving mixed crystal defects, optimizing heat treatment temperature, and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

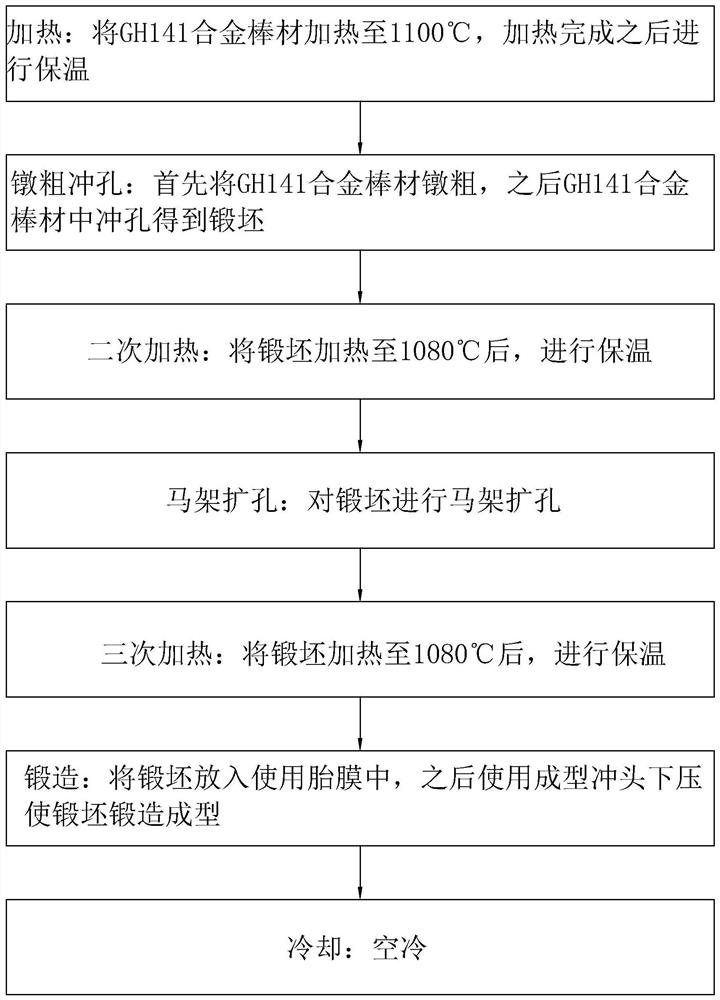

[0029] Embodiment: a kind of forging method of grain uniformity of GH141 special-shaped ring forging, such as figure 1 shown, including the following steps:

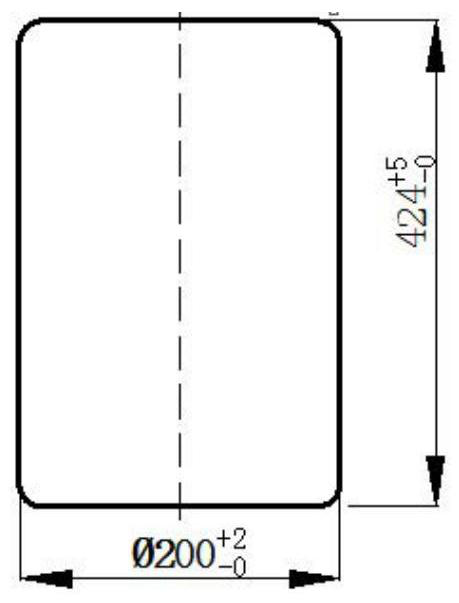

[0030] S1, heating: prepare as figure 2 The GH141 alloy bar is shown, the size of the GH141 alloy bar is φ200mm+2mm×424mm+5mm, the GH141 alloy bar is heated to 1100°C, and the heat preservation time is 160min after the heating is completed.

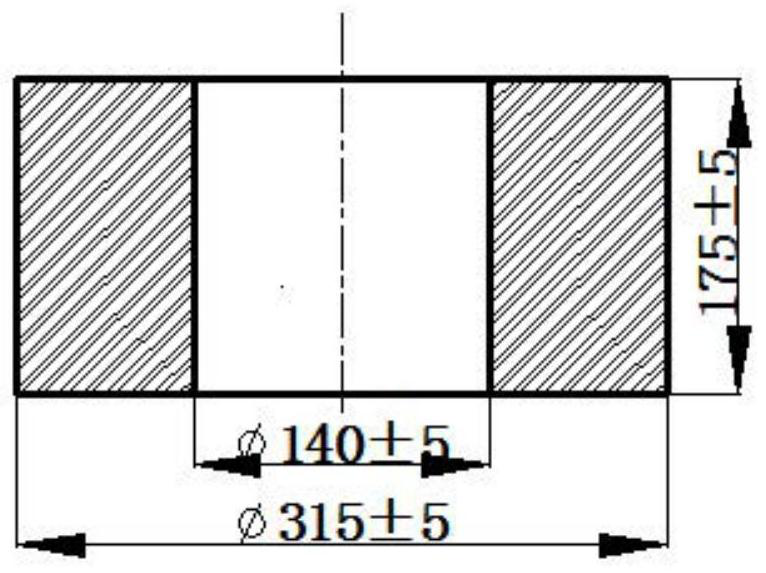

[0031] S2, upsetting and punching: first, the GH141 alloy bar is upset, and then punched in the GH141 alloy bar to obtain a forged billet (such as image 3 shown), the size is φ315mm±5mm×175mm±5mm, and the diameter of the inner hole of the forging billet is 140mm±5mm.

[0032] S3. Secondary heating: heat the forging billet to 1080° C., and then keep it warm for 105 minutes.

[0033] S4, horse frame reaming: carry out horse frame reaming to the forging billet (such as Figure 4 shown), the size of the forged blank horse frame after reaming is φ335mm±5mm×φ220mm±5mm×175mm±5mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com