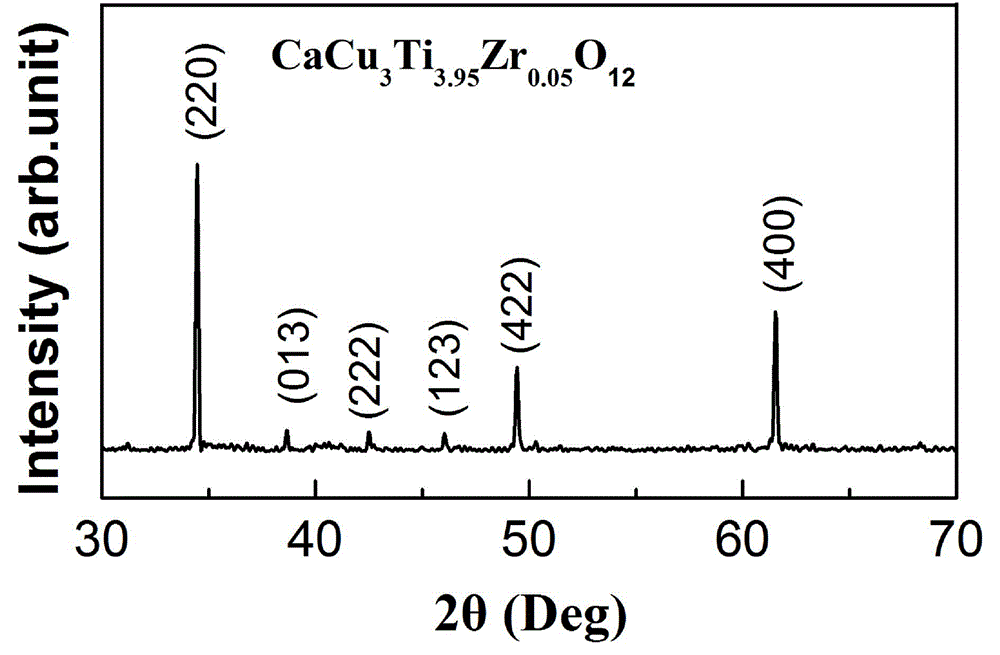

Preparation method for CaCu3Ti4-xZrxO12 ceramic with high dielectric constant and low dielectric loss

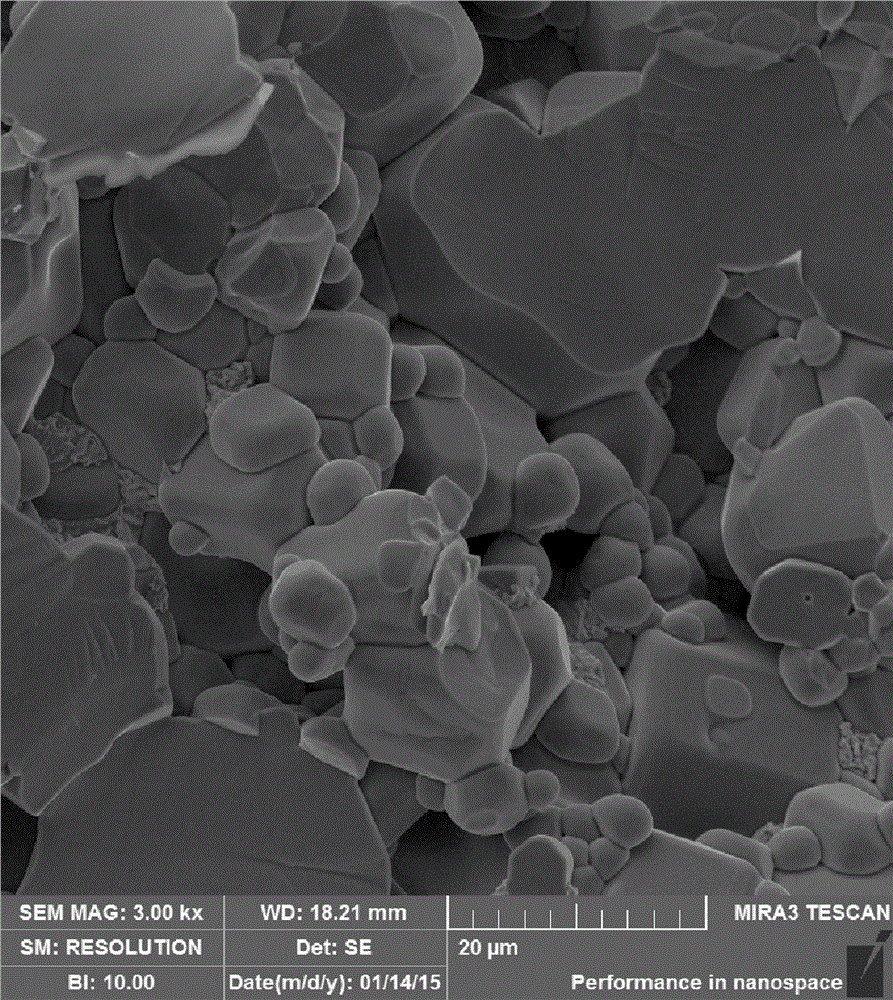

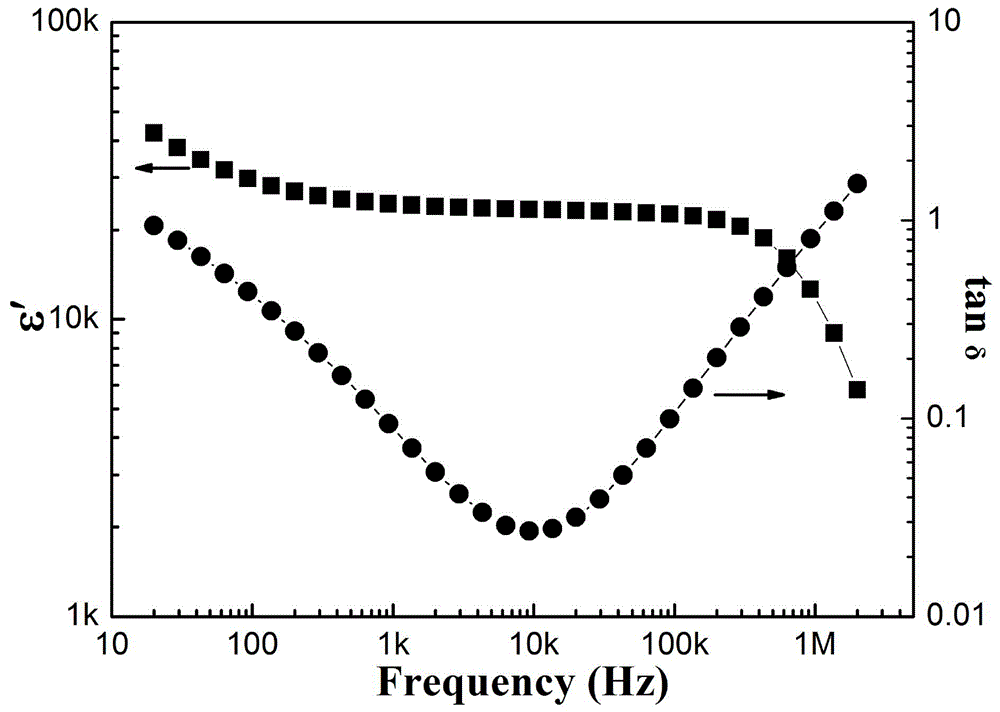

A high dielectric constant, low dielectric technology, applied in the field of dielectric ceramic synthesis, to achieve the effect of good grain uniformity, good temperature stability, and reduced dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 8.349 g of calcium nitrate, 25.624 g of copper nitrate, 0.407 g of zirconium oxynitrate and 64.876 g of citric acid, use absolute ethanol as the solvent, completely dissolve the four raw materials, and then use nitric acid to adjust the pH value to 2- 3. Finally, a blue transparent mixed solution A (x=0.05) was obtained;

[0029] (2) Measure 47.771 mL of butyl titanate, add an equal amount of absolute ethanol, stir until completely mixed, and obtain a light yellow mixed solution B;

[0030] (3) Put solution A in a magnetic stirrer and keep stirring, then slowly add solution B into solution A (to prevent hydrolysis of butyl titanate) until a transparent mixed solution is formed, then add 2 g of polyethylene glycol to promote into glue;

[0031](4) Place the mixed solution finally obtained in the above step (3) in a water bath, adjust the temperature to 80°C, and stir at 200 rpm until a blue xerogel is formed;

[0032] (5) Put the obtained blue x...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that the doping amount of Zr is different (CaCu 3 Ti 4-x Zr x o 12 , x=0.1), after the dielectric performance test, it was found that compared with Example 1, the grain size of the sample was reduced, and ε' was greatly reduced; the tanδ was higher than that of Example 1 as a whole, and the lowest tanδ was 0.039, which appeared in around 10 kHz.

Embodiment 3

[0041] The difference between this embodiment and embodiment 1 is that the doping amount of Zr is different (CaCu 3 Ti 4-x Zr x o 12 , x=0.2), after the dielectric performance test, it was found that compared with Examples 1 and 2, the grain size of the sample was further reduced, and ε' continued to decrease as a whole; tanδ was higher than that of Examples 1 and 2, and the lowest value was 0.058. Also occurs around 10 kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com