Method for preparing polycrystalline silicon thin film by laser crystallization and product and thin film transistor obtained

A polysilicon thin film, laser crystallization technology, applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of uneven color, uneven film thickness of amorphous silicon, temperature fluctuation of amorphous silicon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A method for preparing a polysilicon film by laser crystallization, the steps are:

[0027] S1, forming a thermistor layer on the glass substrate;

[0028] S2, forming an amorphous silicon layer on the thermistor layer;

[0029] S3, irradiating the amorphous silicon film layer in the crystallization step S2 with laser pulses, and at the same time heating the thermistor layer by means of electric heating or electromagnetic heating, so that the amorphous silicon layer is converted into a polysilicon layer.

[0030] The thermistor layer is a negative temperature coefficient NTC resistance layer, and its constituent materials include metal oxides and non-oxides; the metal oxides are manganese, copper, silicon, cobalt, iron, nickel, zinc at least one of; said non-oxide is at least one of silicon carbide, tin selenide and tantalum nitride. The step S3 is to heat the thermistor layer by means of electric heating or electromagnetic heating.

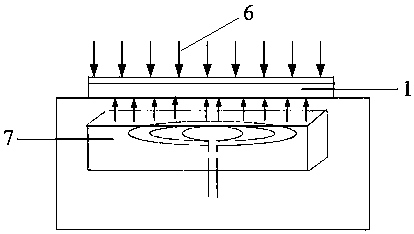

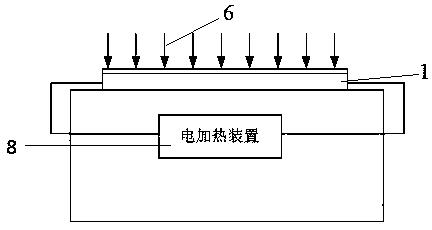

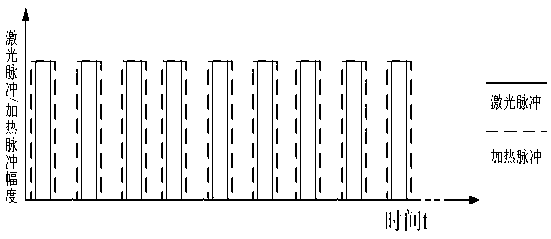

[0031] like figur...

Embodiment 2

[0035] Embodiment 2: On the basis of Embodiment 1, the process of forming an isolation layer on the glass substrate is also included before the step S1, and the isolation layer is one or both of silicon oxide and silicon nitride. Before the step S2, a buffer layer is formed on the thermistor layer, and the buffer layer is one or both of silicon oxide and nitride. The isolation layer and the buffer layer are formed by PECVD; the thermistor layer is formed by PECVD or PVD or coating and sintering.

[0036] like Figure 5 As shown: the obtained polysilicon thin film includes an isolation layer 4 , a thermistor layer 2 , a buffer layer 5 and a polysilicon layer 3 formed on a glass substrate 1 in sequence. The polysilicon thin film has the characteristics of good crystal grain uniformity, good crystal grain density consistency, good crystal grain mobility and stability.

Embodiment 3

[0037] Embodiment 3: a thin film transistor comprising the polysilicon thin film described in Embodiment 1 or Embodiment 2. The thin film transistor has the characteristics of no spot, uniform brightness and good electrical performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com