Patents

Literature

45results about How to "Not easy to plug holes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic-inorganic three-layer composite film and preparation method thereof

InactiveCN107930418AImprove bindingNot easy to leakSemi-permeable membranesPervaporationFilm material

The invention discloses an organic-inorganic three-layer composite film and a preparation method thereof, and belongs to the field of the preparation of film materials. The composite film comprises asupporting layer, a middle transition layer and a surface active layer, wherein the supporting layer adopts an inorganic film, with the surface average pore size being 10 to 800 nm; the middle transition layer adopts organic polymer, with the mass fraction being 1 to 10 percent, and the surface average pore size being 5 to 80 nm; the surface active layer adopts silicone rubber PDMS, with the filmlayer thickness being 1 to 10 micrometers. The organic-inorganic three-layer composite film takes an organic polymer film with controllable thickness and surface pore size as a middle transition layer, can optimally regulate the uniformity and thickness of the surface active layer of the composite film and the bonding strength between the dense surface active layer and the middle transition layerand between the inorganic film supporting layer and middle transition layer by controlling the viscosity of PDMS coating fluid. The composite film is large in permeation flux and high in separation factor, and the surface active layer is not easy to peel off, so that the composite film is applicable to organic solvent recovery and organic gas separation in pervaporation.

Owner:NANJING JIUSI HIGH TECH

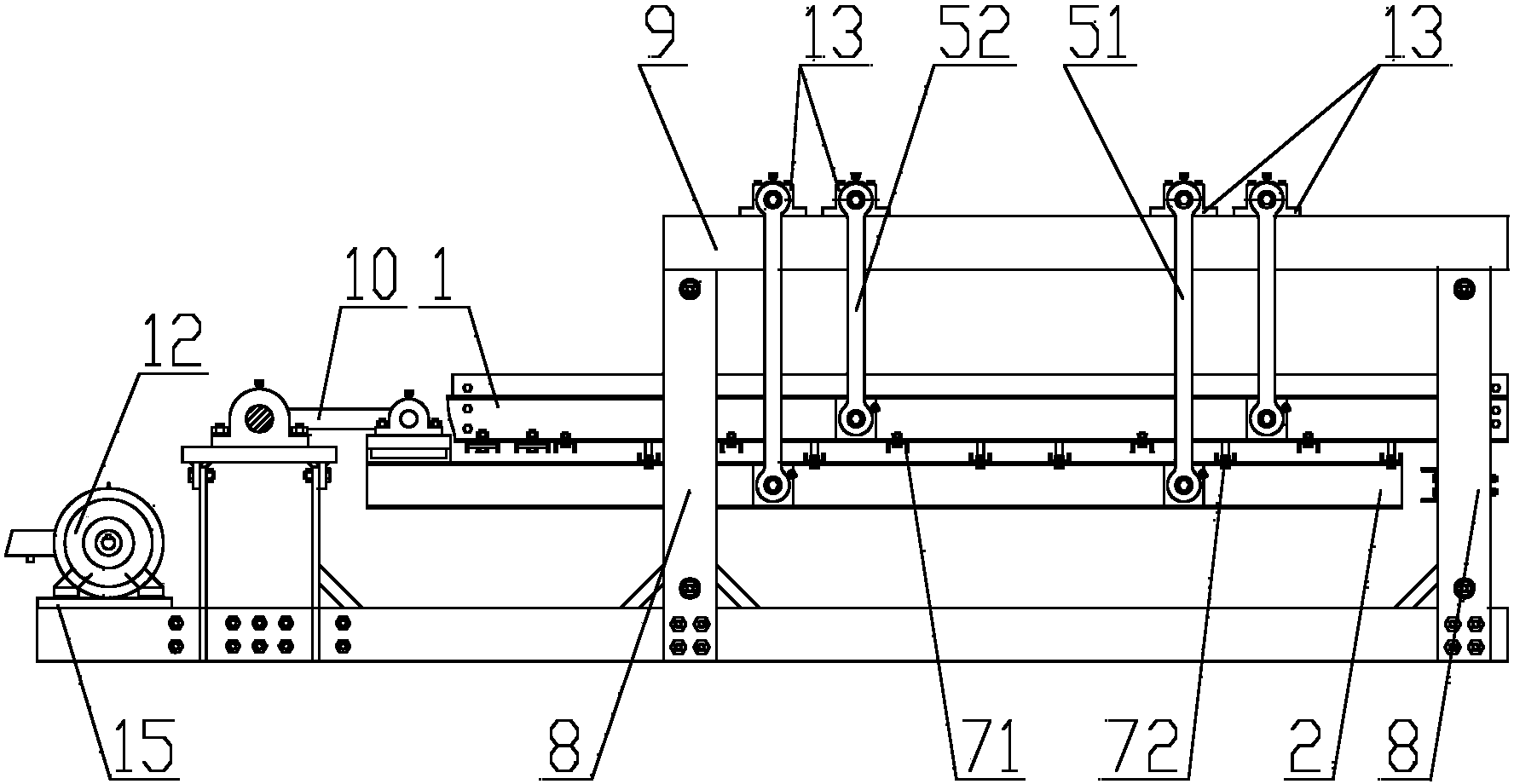

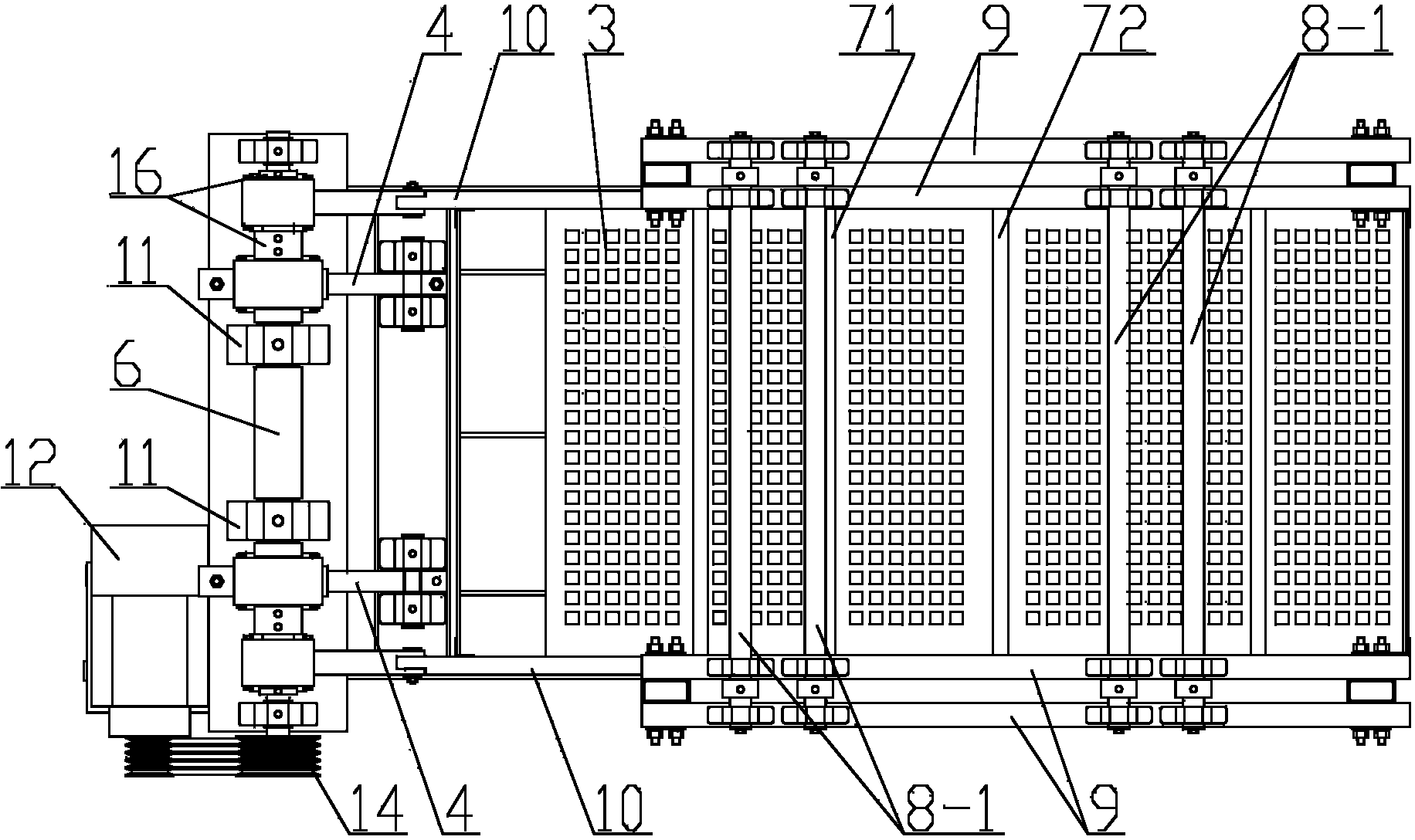

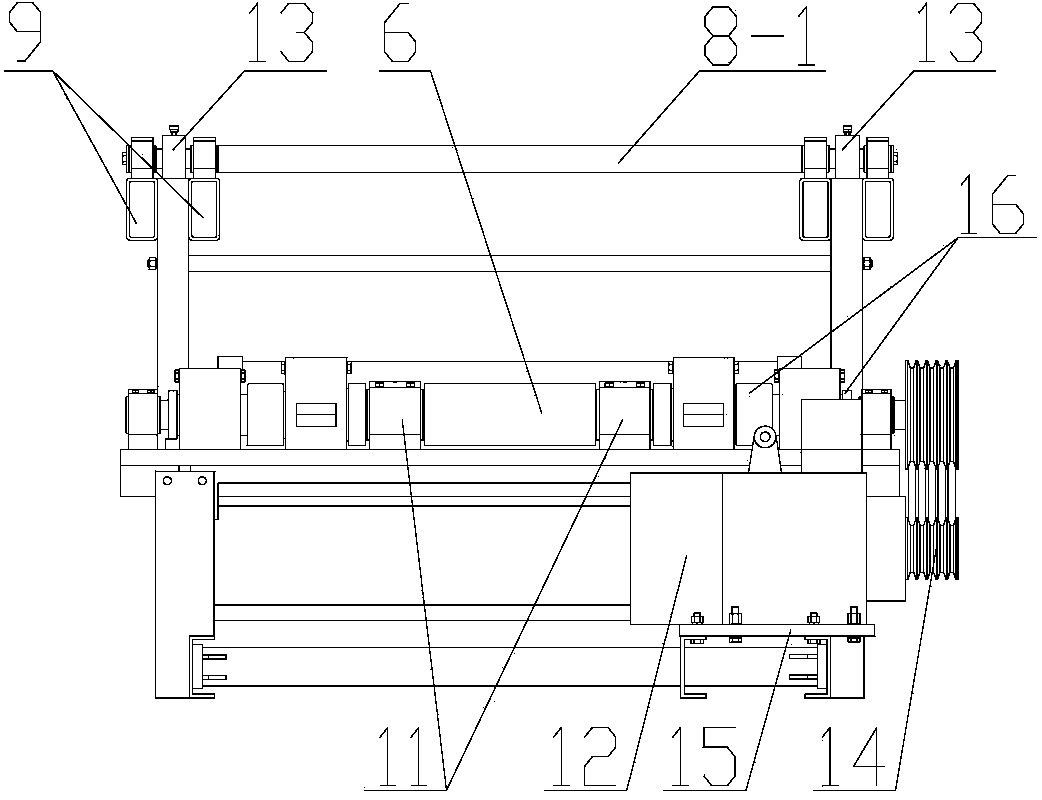

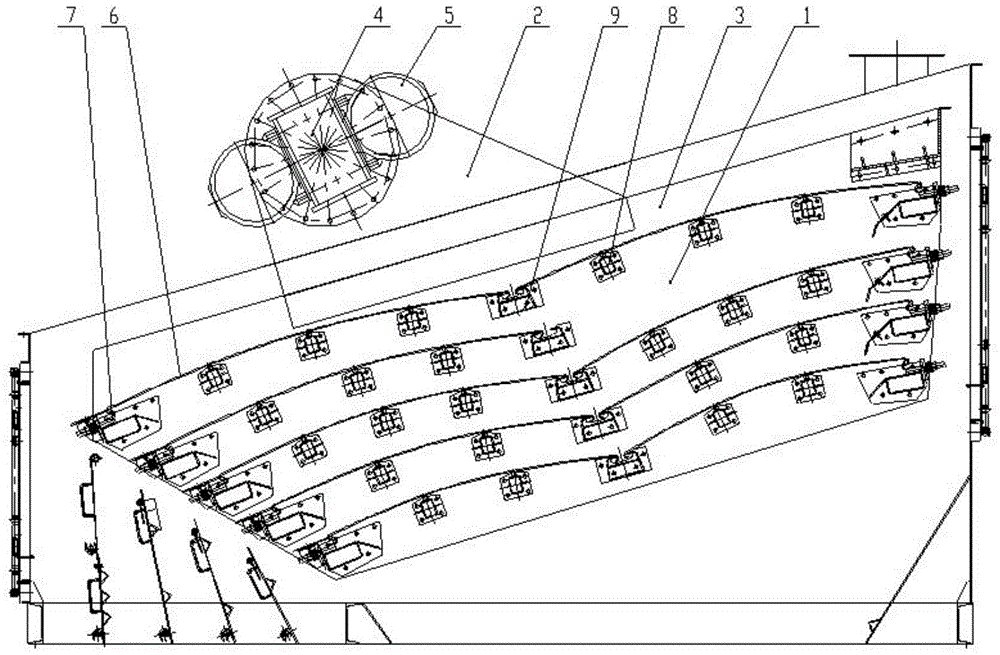

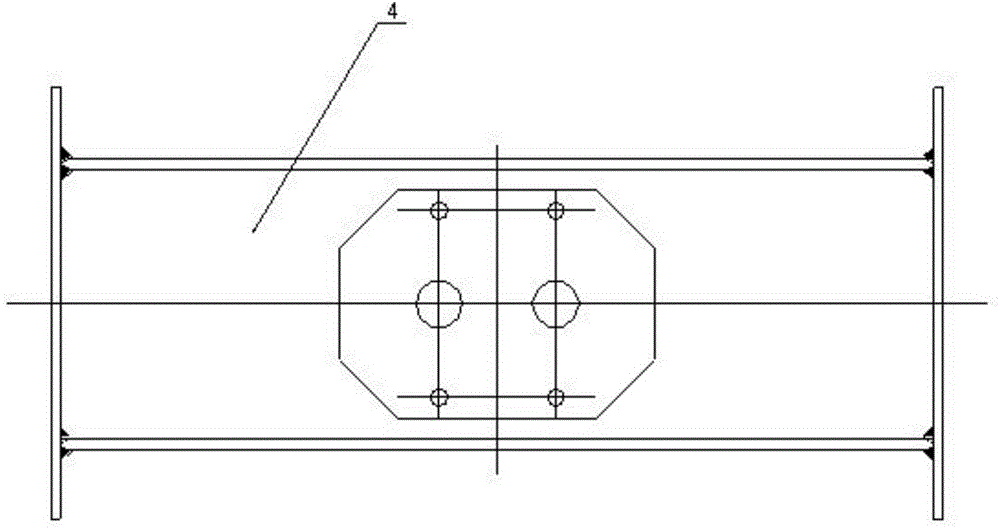

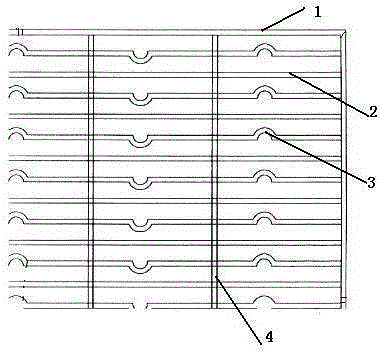

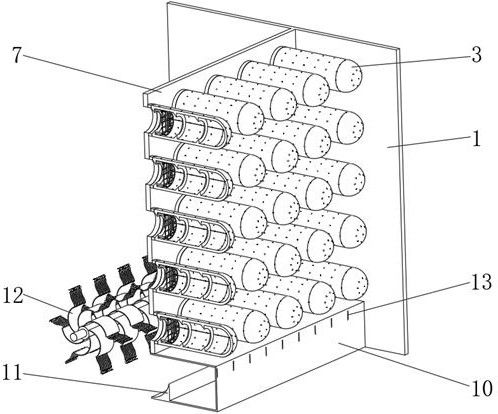

Distributed driven type rocking sieve

ActiveCN103752498AImprove screening efficiencyImprove reliability and service lifeSievingScreeningCoalEngineering

The invention discloses a distributed driven type rocking sieve comprising a base, a motor, a driving shaft, a first crank-link mechanism, a second crank-link mechanism, an inner sieve box, an outer sieve box, a first suspension rod, a second suspension rod and a rack. The two sieve boxes are suspended on two four-link mechanisms by adopting the driving shaft provided with four eccentric sections and combining the two crank-link mechanisms with the two suspension rods, an elastic sieve screen composed of multiple small rectangular sieve plates is combined, and elastic flexure movement on the elastic sieve screen is caused to realize material sieve penetration while the two sieve boxes move relatively. The distributed driven type rocking sieve is high in complete reliability, good in combination property, smooth in movement, convenient to mount and position, simple in complete structure, convenient to maintain, energy saving, low in dynamic stress of a sieving machine and applicable to the fields of coal, metallurgy, chemical engineering, environmental protection and the like.

Owner:CHINA UNIV OF MINING & TECH

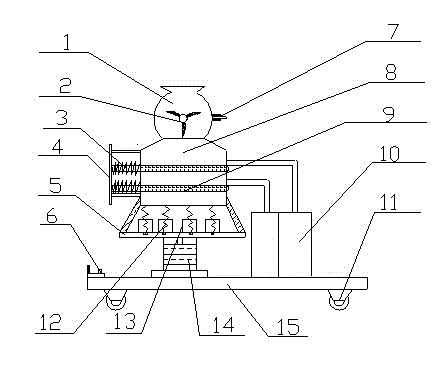

Rotary gravel vibrating screen for construction

The invention discloses a rotary gravel vibrating screen for construction. The rotary gravel vibrating screen for construction comprises a base and a screening chamber arranged on the base and further comprises a stirring chamber. A stirring impeller is arranged at the center inside the stirring chamber, the lower end of the stirring chamber is communicated with the screening chamber, two filter screens are parallelly arranged in the screening chamber, mesh holes of the filter screens are downsized from top to bottom, extending ends on one side of the filter screens are connected with compression springs, one side of the outer wall of the screening chamber is connected to a collection box arranged on the base through a collection pipe, a rotary vibrating mechanism is arranged below the screening chamber, and the base is provided with an electric control switch. The rotary gravel vibrating screen has the advantages of high screening quality, high transmission stability, reasonable structural design, convenience in use, high production efficiency, long service life and the like.

Owner:WUXI TIANYI PRINTING

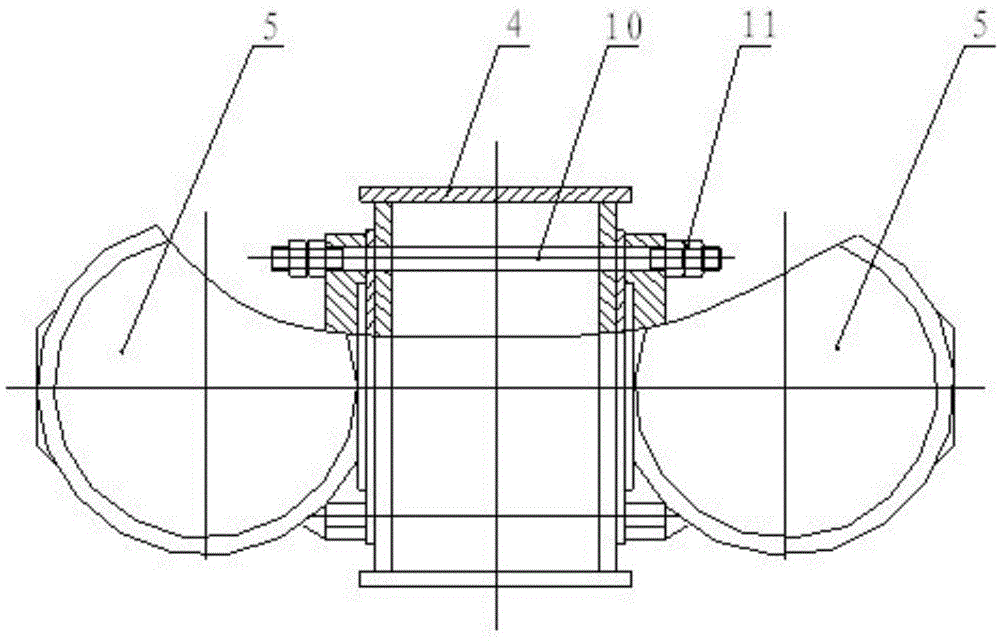

Elliptical vibrating screen for asphalt mixing plant

The invention discloses an elliptical vibrating screen for an asphalt mixing plant. The elliptical vibrating screen comprises a vibrating screen body, two supporting plates, a motor base cross beam, two vibrating motors, a screen sieve and a tensioning device. A plurality of middle supporting beams are arranged in a side plate of the vibrating screen body from top to bottom. One end of the screen sieve of the vibrating screen is connected to the middle supporting beams, and the other end of the screen sieve of the vibrating screen is connected to the screen sieve tensioning device. The two supporting plates with the size as same as the inner width of the side plate are arranged on the top of the vibrating screen body, and the motor base cross beam of a rectangular beam structure is connected between the two supporting plates. The two vibrating motors are symmetrically fixed to the motor base cross beam and have the same rotation speed and different exciting force. In the operation process of the vibrating screen, the rotation directions of the two vibrating motors are opposite. The elliptical vibrating screen integrates a linear vibrating screen and a round vibrating screen and has the advantages that the processing capacity is high, the equipment height is small, the structure is reasonable, materials are easily layered, holes will not be blocked easily and the screening efficiency is high.

Owner:XUZHOU XUGONG ROAD CONSTR MACHINERY

Large-flux enhanced PVDF unlined ultrafiltration membrane and preparation method thereof

ActiveCN110201558AReduce surface tensionOvercoming the problem of decreased hydrophilicityMembranesUltrafiltrationUltrafiltrationPolyvinylidene difluoride

The invention relates to a large-flux enhanced PVDF unlined ultrafiltration membrane. The ultrafiltration membrane is prepared from, by weight, 22-30 parts of dopamine-modified polyvinylidene fluoride, 10-20 parts of a hydrophilic agent, 50-70 parts of a polar solvent, 10-20 parts of a pore forming agent and 5-10 parts of an auxiliary agent; the hydrophilic agent contains triethanolamine. According to the large-flux enhanced PVDF unlined ultrafiltration membrane, by blending and modifying the hydrophilic agent, the auxiliary agent and the dopamine-modified polyvinylidene fluoride in the polarsolvent, the surface tension of the surface of the membrane and the inner walls of membrane pores is reduced, and the hydrophilicity of the polyvinylidene fluoride is improved; the triethanolamine inthe hydrophilic agent has hydrogen-bond interaction with polar bonds in the auxiliary agent and polar bonds in a dopamine composite layer, the hydrophilicity can be maintained for a long time accordingly, the antifouling property of the membrane is improved, and the high operating flux is kept for a long time; the small-molecule pore forming agent does not easily block the pores, the membrane forming performance is good, the pure water flux is good, the degree of entanglement with a main material is low, and the pore forming agent is easily detached from the surface of the membrane; the auxiliary agent effectively improves the melt processability, and the mechanical properties are greatly improved.

Owner:泉州碧蓝膜科技有限责任公司

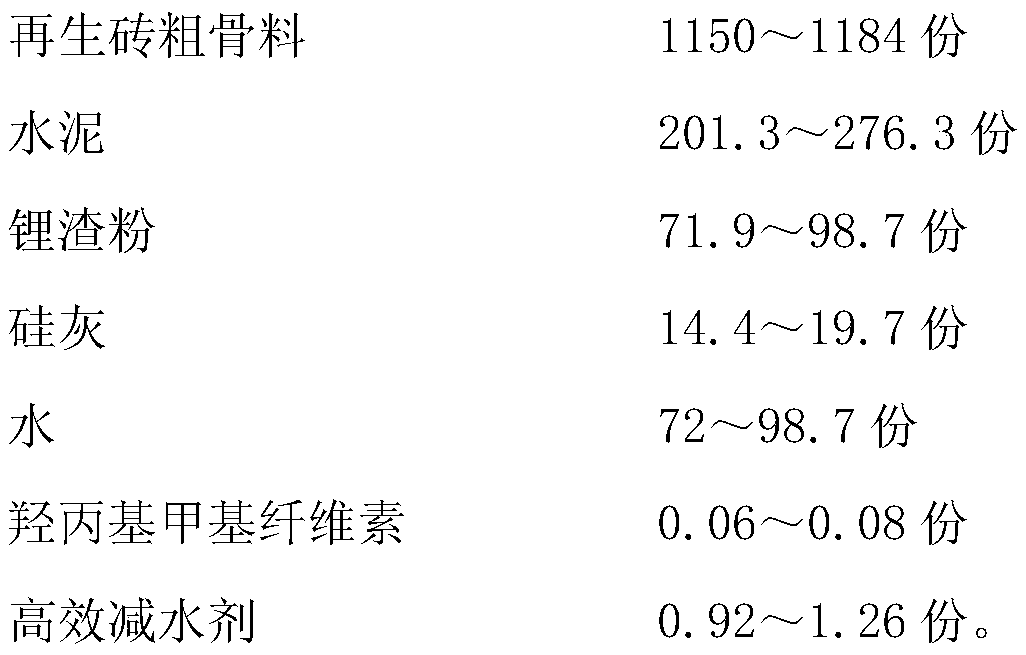

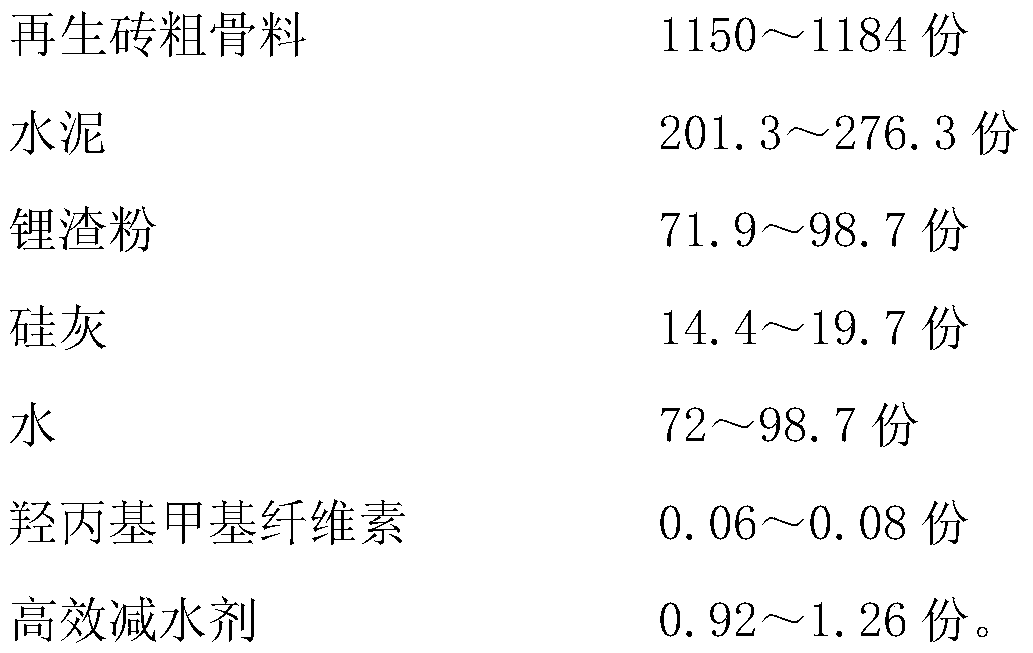

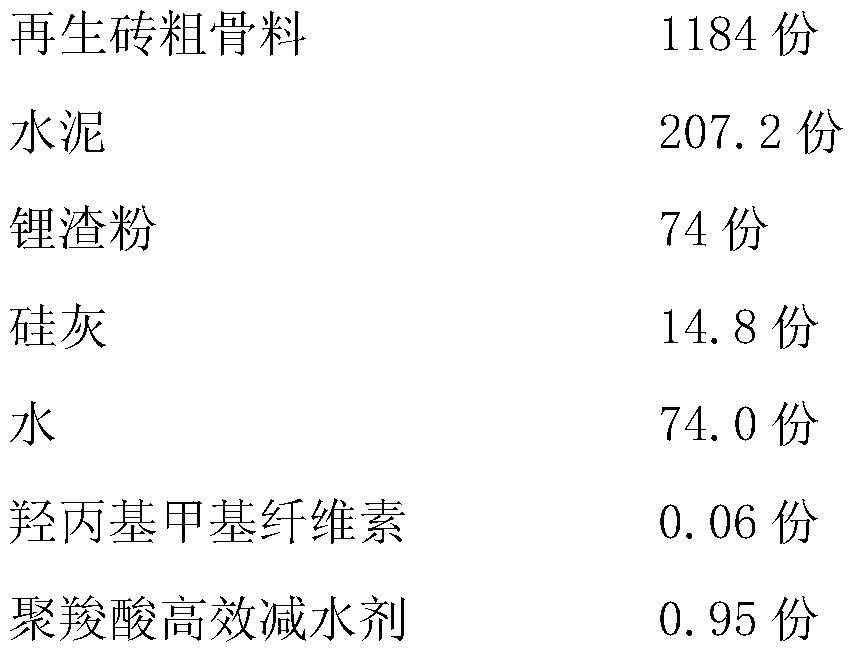

Recycled brick aggregate permeable concrete and preparation method thereof

The invention relates to recycled brick aggregate permeable concrete and a preparation method thereof. The recycled brick aggregate permeable concrete comprises the following components in parts by mass: 1150-1184 parts of a recycled brick aggregate, 201.3-276.3 parts of cement, 71.9-98.7 parts of lithium slag powder, 14.4-19.7 parts of silica fume, 72-98.7 parts of water, 0.06-0.08 part of hydroxypropyl methylcellulose and 0.92-1.26 parts of a polycarboxylate superplasticizer. The preparation method is as follows: 1) weighing the cement, the silica fume and the lithium slag powder according to proportion and mixed evenly; 2) weighing the recycled brick aggregate in proportion, adding the mixture obtained in the step 1), and stirring and mixing uniformly; (3) weighing the water, the hydroxypropyl methylcellulose and the polycarboxylate superplasticizer in proportion and adding into the mixture obtained in the step (2), and stirring and mixing evenly to obtain the recycled brick aggregate permeable concrete. The recycled brick aggregate permeable concrete has good adhesiveness, low dead weight, high water absorption, good water retention, good water purification effect, capability of adsorbing heavy metal ions and low cost, and can be widely applied to places such as river banks, slope protection, road base pavement and the like.

Owner:SOUTHEAST UNIV

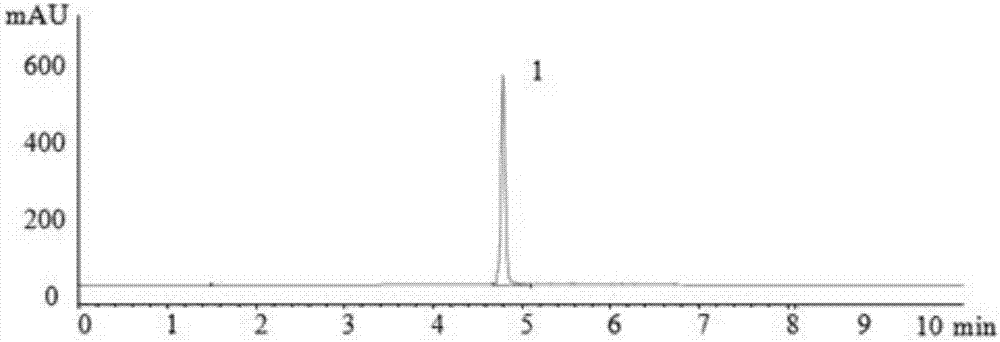

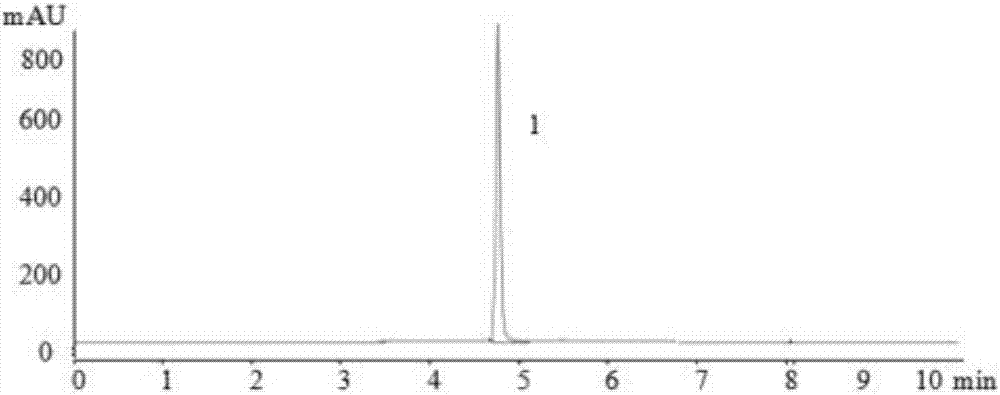

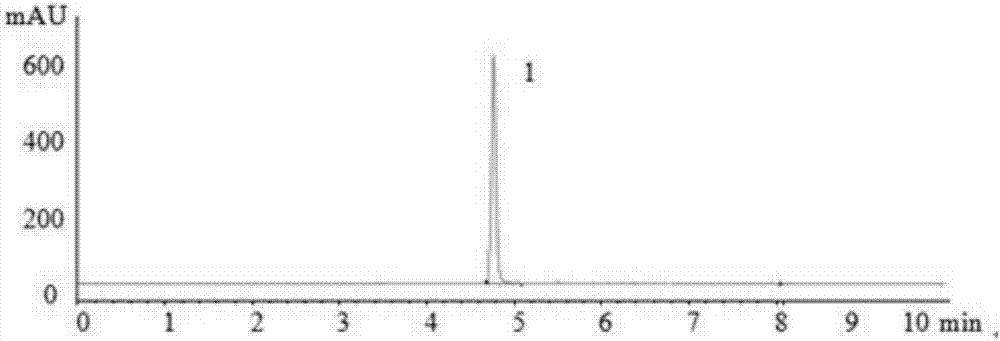

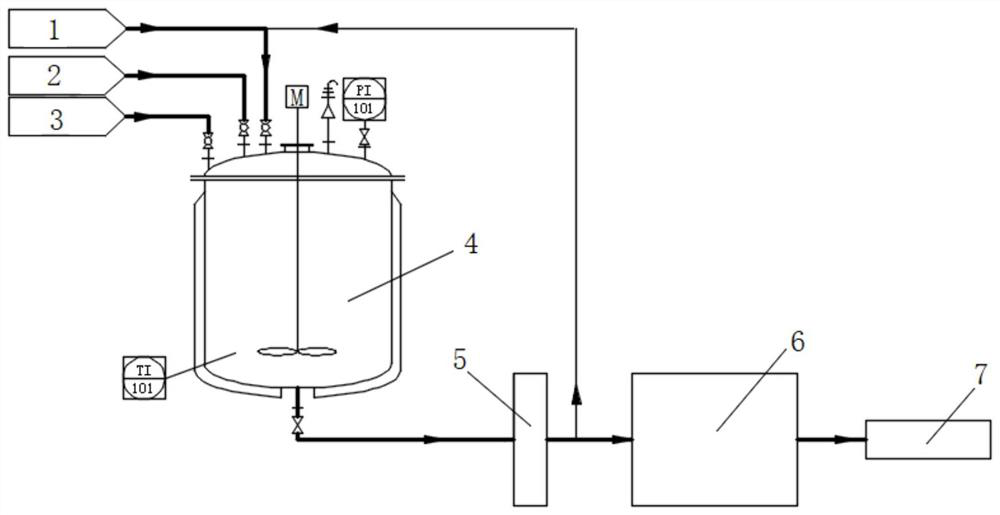

EGCG preparation method

ActiveCN106967036AReduce the use effectReduce recyclingOrganic chemistryOrganic solventFreeze-drying

The invention provides an EGCG preparation method, particularly relates to a preparation method for industrial production of high-purity EGCG and belongs to the field of separation and purification of plant monomers. For solving the problem that at present, a process for preparing the EGCG based on an organic solvent extraction method is complicated, adopts a large number of organic solvents in the production process and is not safe and environment-friendly enough, the EGCG preparation method comprises the following steps of green tea smashing, vacuum high-temperature extraction with deionized water, inorganic ceramic membrane filtration, enrichment with macroporous adsorption resin, reversed phase chromatography, vacuum concentration and freeze-drying. The method only adopts water, aqueous ethanol and other solvents in the whole preparation process of the process, the usage and recovery amount of a large amount of organic solvents is decreased, the non-toxic, safe and simple process is achieved, ceramic membrane, resin and reverse chromatographic column filler are recyclable, the cost is greatly reduced, meanwhile the purity of the EGCG is improved, and the process is more suitable for large-scale EGCG production.

Owner:盛林

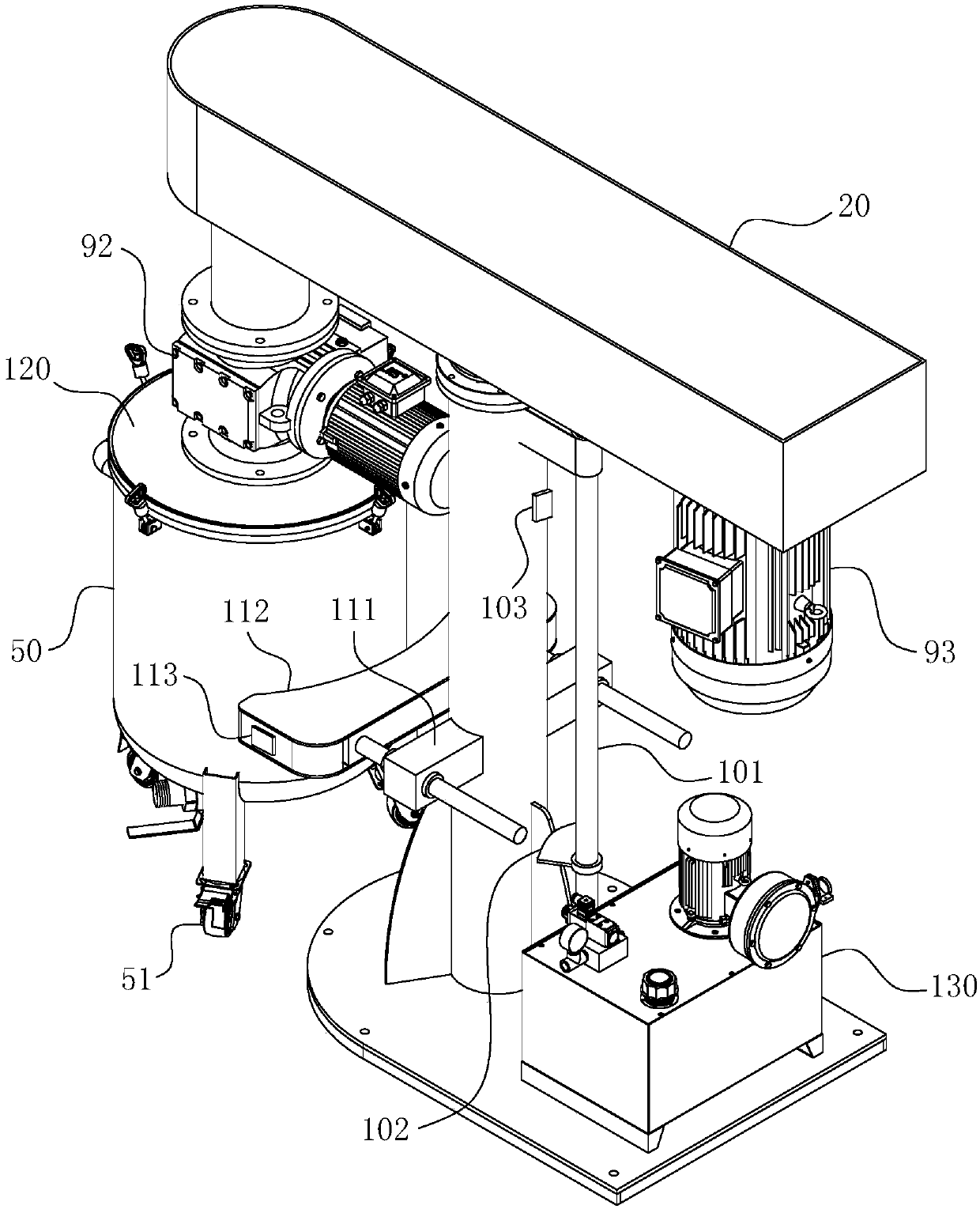

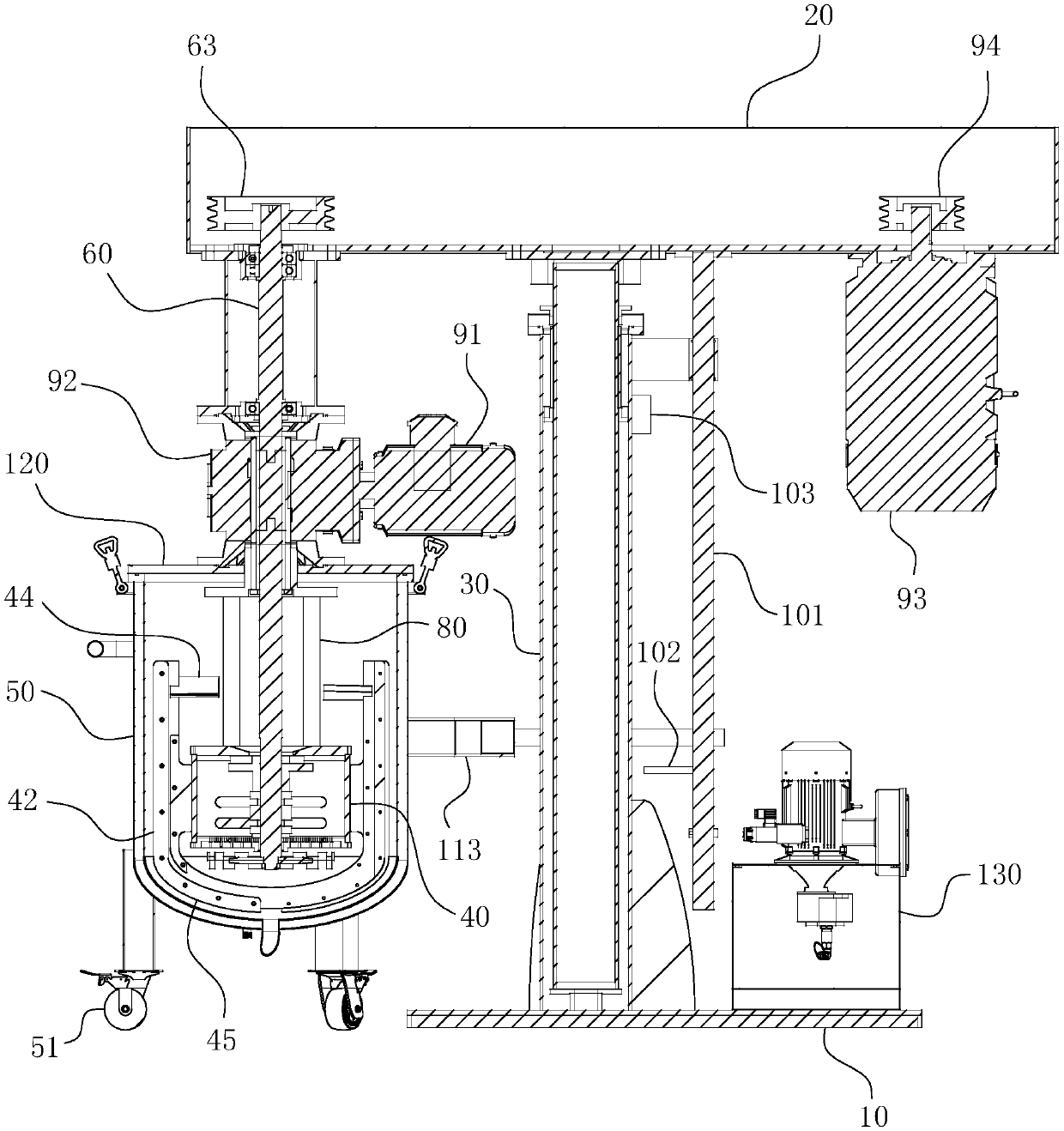

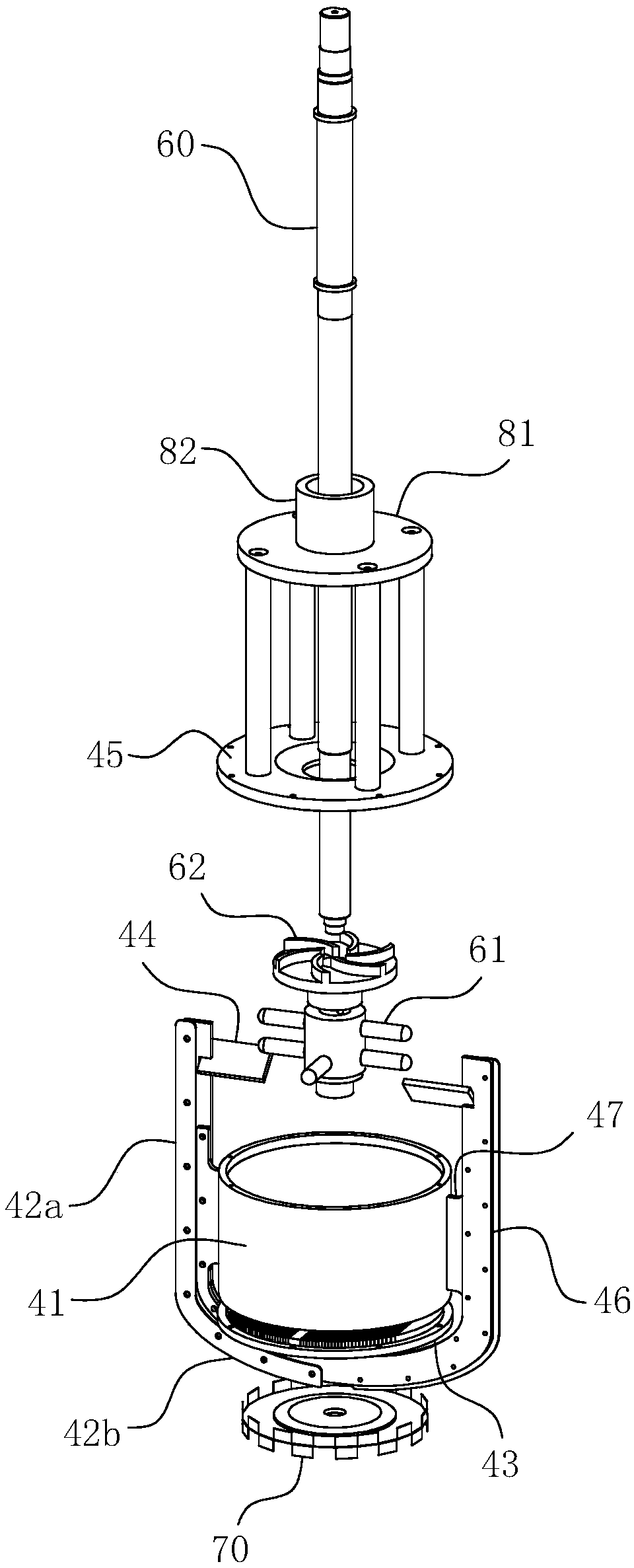

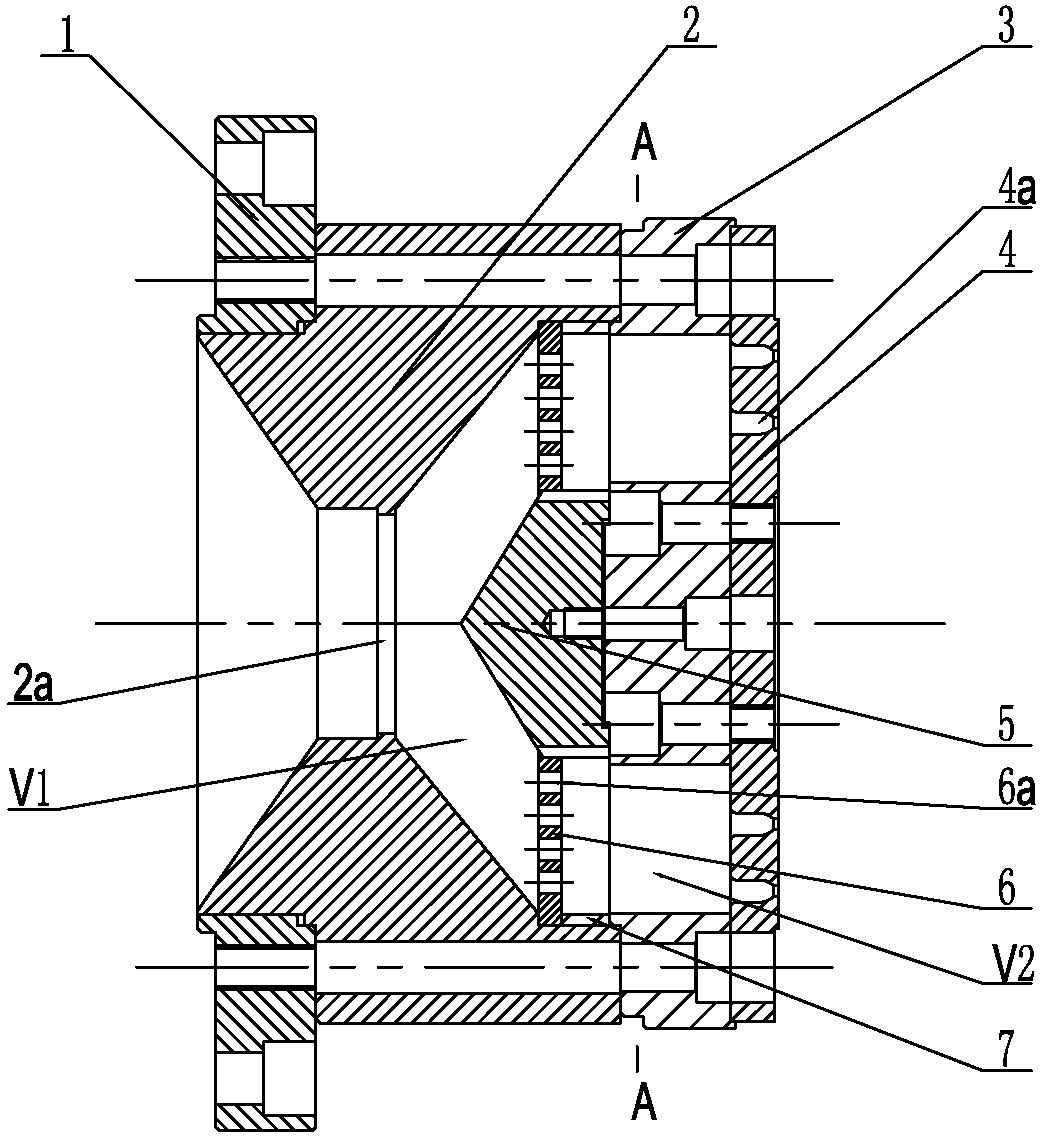

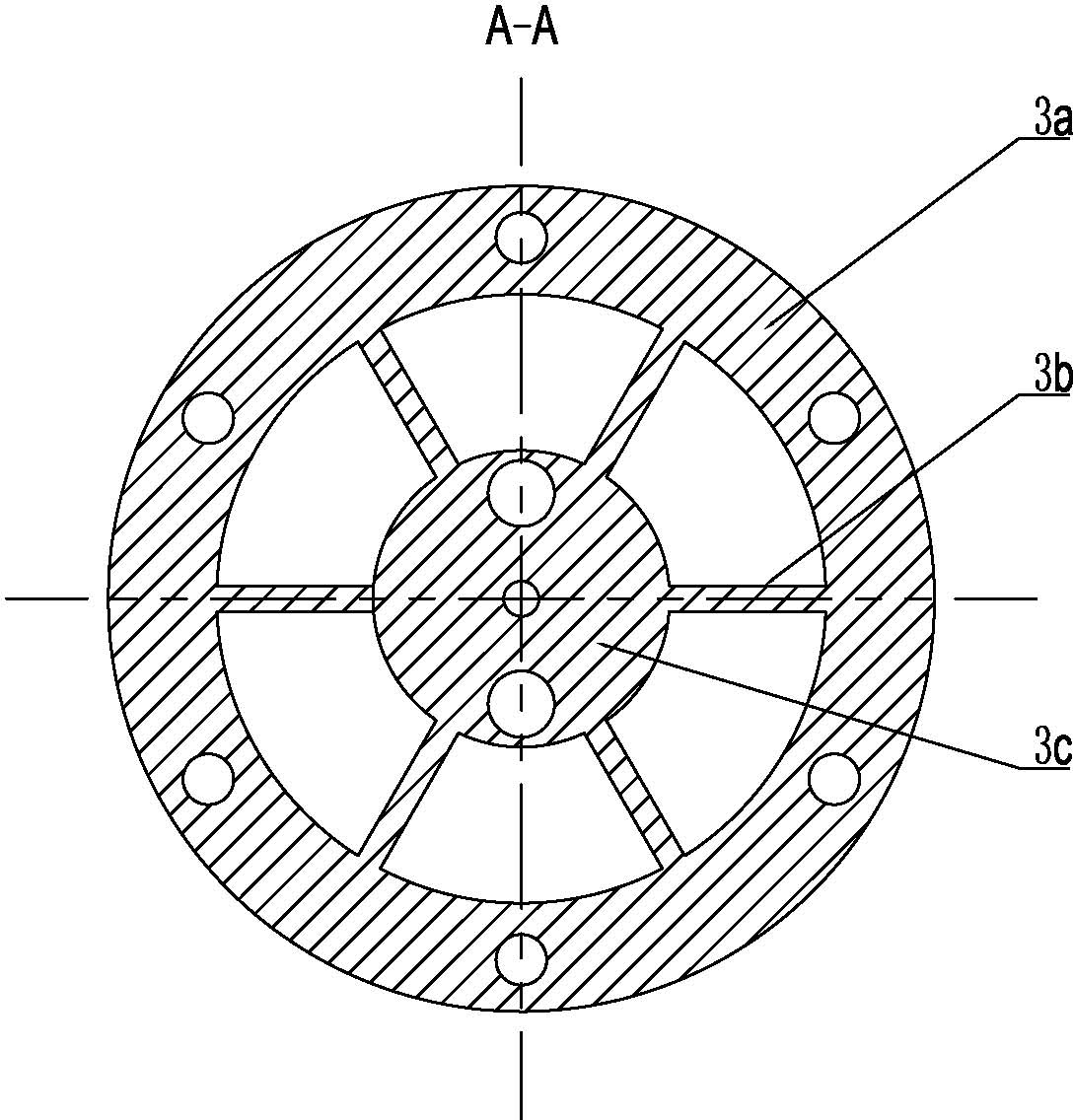

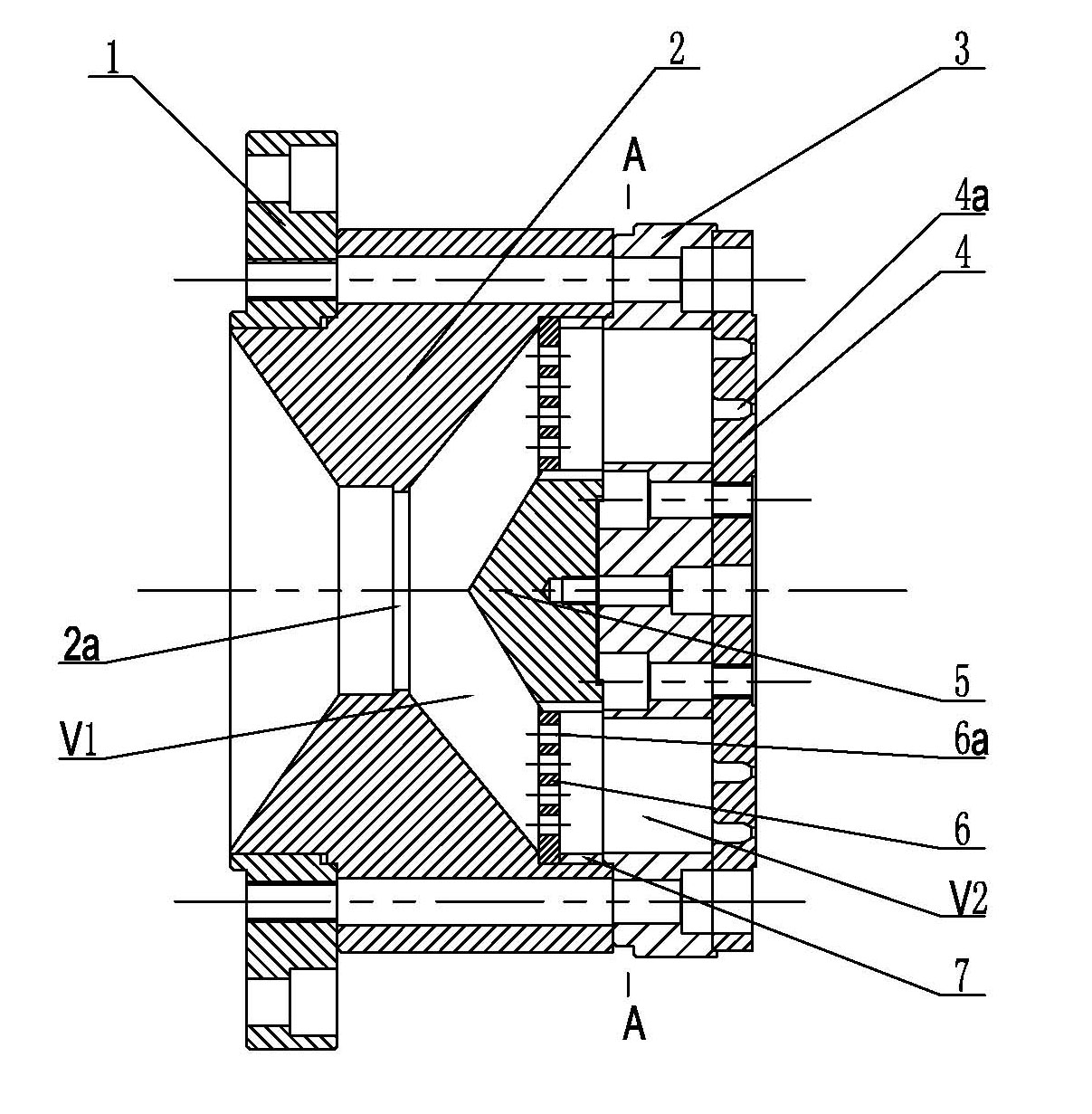

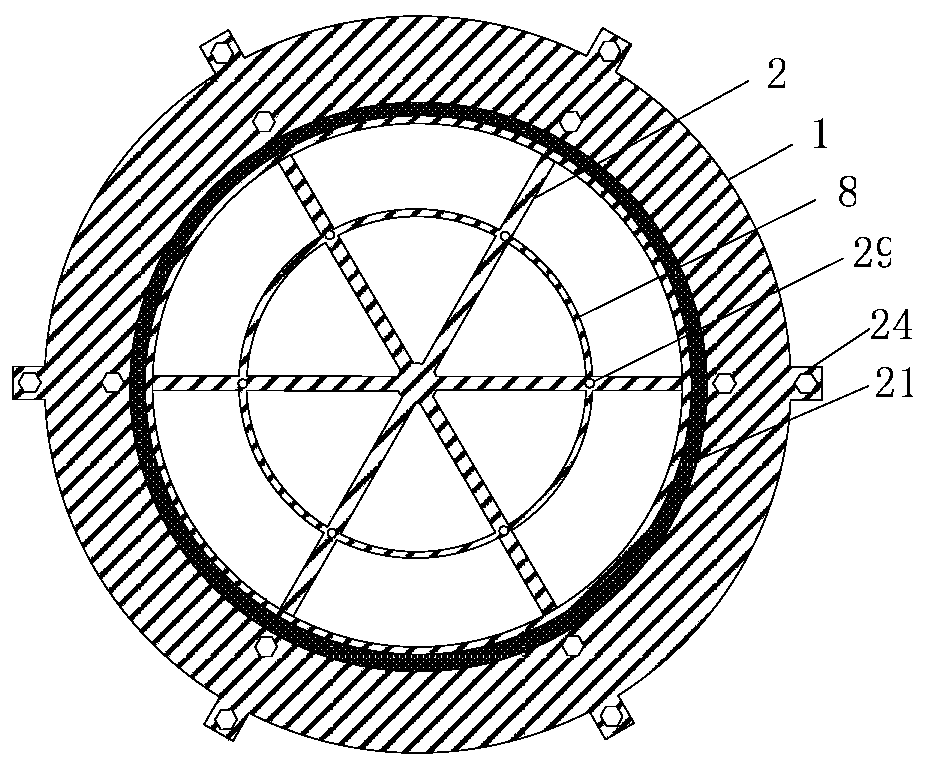

Concentric double-axis vacuum hydraulic basket grinding machine

ActiveCN109590078AEfficient mixingEfficient grindingGrain treatmentsCantileverMechanical engineering

The invention belongs to the field of grinding equipment, in particular to a concentric double-axis vacuum hydraulic basket grinding machine. The grinding machine comprises a base, a frame, a liftingassembly, a grinding basket and a cylinder. The grinding basket comprises a cylinder body, an end cap and a filter plate. The end cap and the filter plate are vertically coaxially penetrated by a stirring shaft and the stirring shaft is respectively rotatably matched with the end cap and the filter plate. A basket support is coaxially arranged with the stirring shaft but dose not interfere the stirring shaft. The top end of the basket support is matched with the output end of a second power source, and the bottom end of the basket support is coaxially fixed at the end cap for driving the grinding basket to produce a coaxial rotating action opposite to the turning direction of the stirring shaft. A cantilever extends radially outwardly at the outer wall of the grinding basket, and the extending end of the cantilever arm is fixedly connected with a scraper for scraping the attachment at the wall of a cylinder chamber. The invention has the advantages of high grinding efficiency, good stirring effect, good product fineness, convenient and reliable operation.

Owner:费曹民

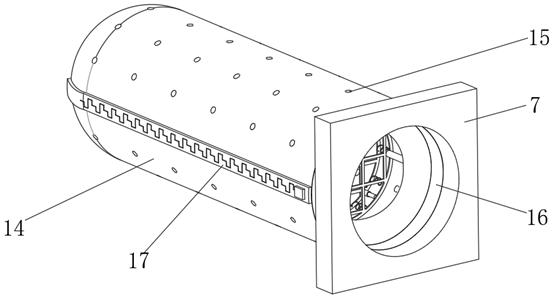

Double-template discharge device of puffing machine

InactiveCN102150938AUniform flow rateUniform final product qualityFeeding-stuffFood shapingTemplate designEngineering

The invention discloses a double-template discharge device of a puffing machine in the field of the grain machinery and the forage machinery. The double-template discharge device comprises a fixing bracket, a venturi tube, a diversion cone and a forming template, wherein the template is provided with a plurality of die holes, the fixing bracket is arranged one side in the venturi tube, a template bracket is arranged between the venturi tube and the forming template, the diversion cone is fixed at the center position on the template bracket which is faced to one side in the venturi tube, a pressure adjusting template is arranged between the venturi tube and the template bracket, the center of the pressure adjusting template is sheathed at the root of the diversion cone, the pressure adjusting template is provided with a plurality of through-flow holes, and the sum of the through-flow areas of the through-flow holes is larger than sum of the through-flow areas of the die holes. The discharge device adopts a double-template design, so that a stable space is guaranteed after the material passes through the pressure adjusting template, and the material is even in flow velocity, so that the even quality, the stability and the proper puffing degree of the final product are guaranteed; and the better puffing effect is obtained, and the yield is improved. The double-template discharge device can be applicable to the production of various puffed foods and forages.

Owner:JIANGSU MUYANG GRP CO LTD

Preparation method of polyacrylonitrile fiber

ActiveCN112831859AImprove spinnabilityNot easy to plug holesMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer scienceSpinning

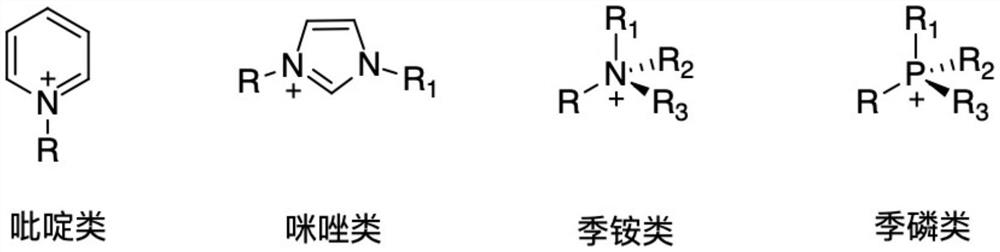

The invention discloses a preparation method of a polyacrylonitrile fiber. Polyacrylonitrile is firstly swelled and dissolved in an ionic liquid and a high-boiling-point (150-190 DEG C) solvent in a certain proportion under the conditions of high temperature and high pressure, then a volatile or low-boiling-point (30-60 DEG C) solvent is added to obtain a homogeneous spinning solution, then spinning and traction splitting are carried out to prepare the polyacrylonitrile fiber, and the polyacrylonitrile fiber has the advantages that the solvent is not prone to being wrapped in the fiber, and the fiber defect is improved; and the prepared fiber has the technical effects of denser density and thinner diameter.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

White aqueous jet ink

The invention discloses white aqueous jet ink. The formula of the ink comprises the following components in parts by weight: 10-50 parts of hollow polymer microsphere emulsion serving as a white pigment, 5-30 parts of filming emulsion and 10-70 parts of de-ionized water, wherein the hollow polymer microsphere emulsion contains one or more of hollow micro-spherical copolymer particles with acrylic acid-styrene, styrene-polyurethane or acrylic acid-polyurethane as shells; and the de-ionized water is filled in cavities of the microspheres. The white jet pink provided by the invention has the advantages of no precipitation, low probability of pore blockage, high whiteness, high covering power, good adhesion, stable performance, environmental friendliness, no pungent odor and suitability for being applied to inkjet printers, flat plate printers and ink jet printers.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Large-flux enhanced hollow fiber membrane and preparation method thereof

ActiveCN110201559AReduce surface tensionOvercoming the problem of decreased hydrophilicityMembranesSemi-permeable membranesFiberHollow fibre membrane

The invention relates to a large-flux enhanced hollow fiber membrane. A separation membrane layer is prepared from, by weight, 22-30 parts of polyvinylidene fluoride, 10-20 parts of a hydrophilic agent, 50-60 parts of a polar solvent, 10-20 parts of a pore forming agent and 5-10 parts of an auxiliary agent; the hydrophilic agent contains triethanolamine. According to the large-flux enhanced hollowfiber membrane, by blending and modifying the hydrophilic agent, the auxiliary agent and the polyvinylidene fluoride in the polar solvent, the surface tension of the surface of the membrane and the inner walls of membrane pores is reduced, and the hydrophilicity of the polyvinylidene fluoride is improved; the triethanolamine in the hydrophilic agent can have hydrogen-bond interaction with polar bonds in the auxiliary agent, the hydrophilicity can be maintained for a long time accordingly, the antifouling property of the hollow fiber membrane is improved, and the high operating flux is kept for a long time; meanwhile, the excessive triethanolamine in a membrane casting solution can be adsorbed on the surface of a hollow fiber material under hydrogen-bond acting force, the adhesion strengthbetween the separation membrane layer and hollow fibers is enhanced, and therefore the hollow fibers are added as support to prevent the membrane material from filament breakage.

Owner:泉州碧蓝膜科技有限责任公司

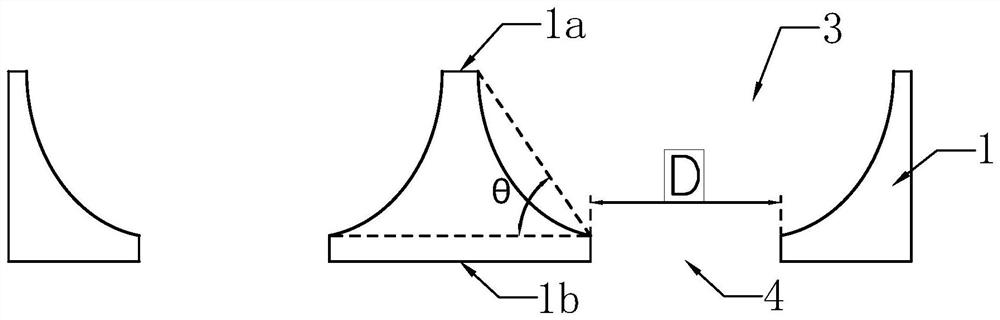

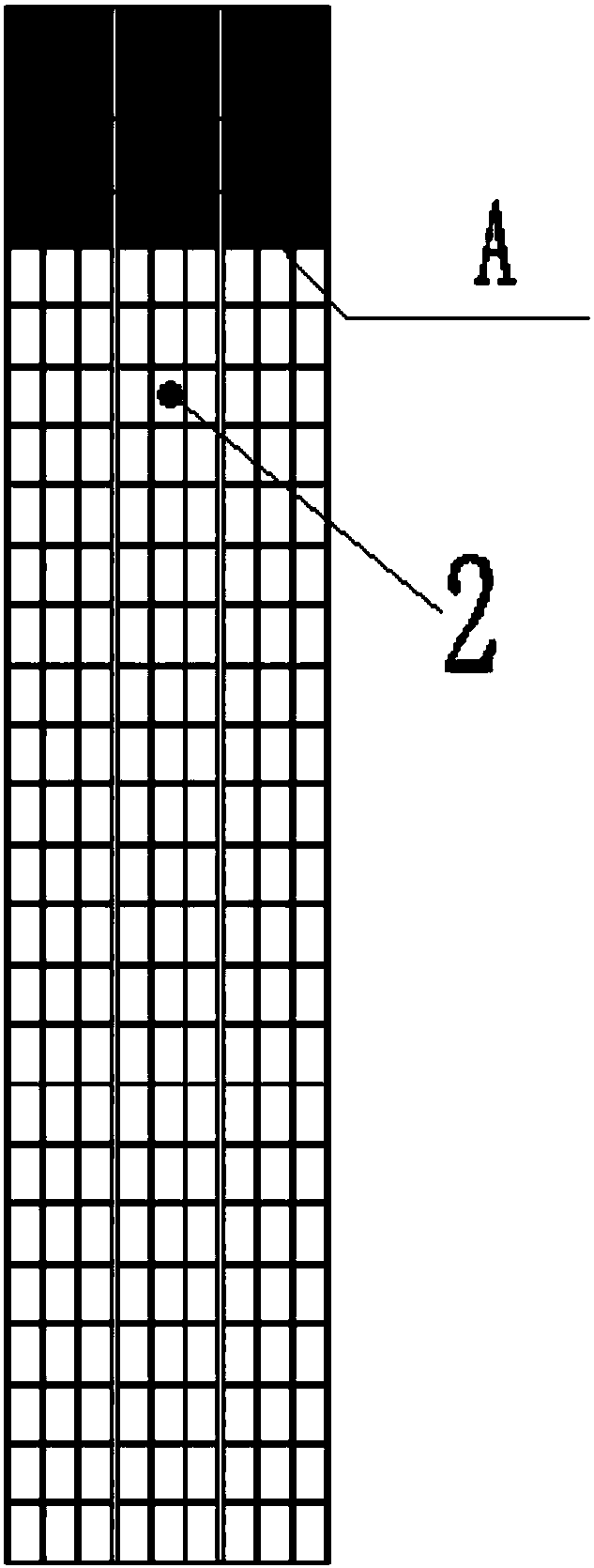

Precise metal mask and etching laser composite manufacturing method thereof

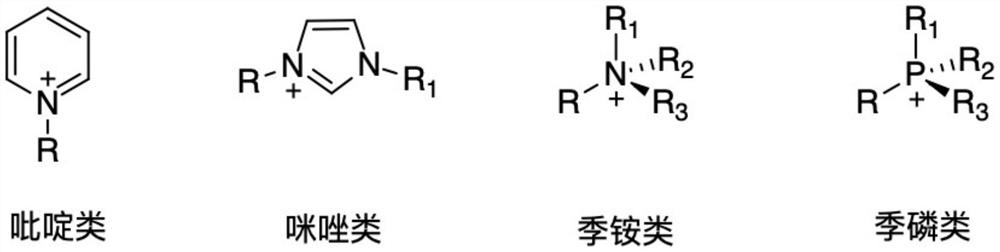

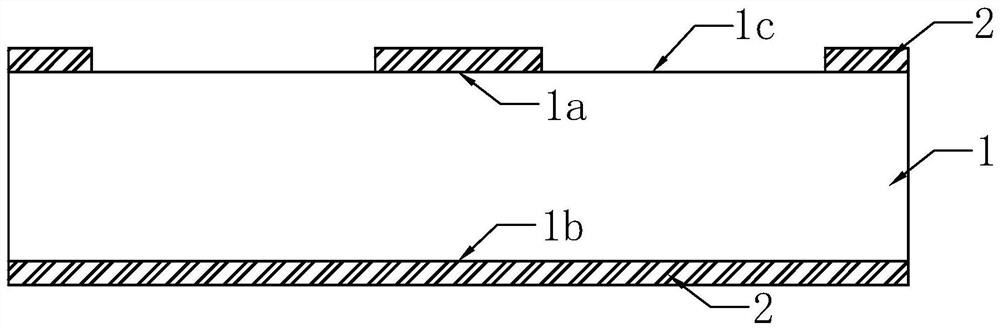

InactiveCN113373406ANot easy to plug holesLow evaporation angle requirementVacuum evaporation coatingSputtering coatingEtchingEngineering

The invention provides a precise metal mask and an etching laser composite manufacturing method thereof. The precise metal mask is characterized in that one side surface of a metal substrate is a first main surface, the other side surface of the metal substrate is a second main surface, the metal substrate is provided with a plurality of exposed holes, the exposed holes are provided with etching holes in the first main surface, the exposed holes are provided with laser holes in the second main surface, the etching holes and the laser holes of which the centers coincide communicate with each other, outer openings of the etching holes are large, inner openings of the etching holes are small, the outer openings and the inner openings are in transition connection through a concave arc hole wall, an inclined included angle of a connecting line of the outer openings and the inner openings is an evaporation angle, the laser holes are provided with vertical hole walls, and the laser holes have high-precision hole diameters. The manufacturing method comprises the following steps: completely coating a solid photoresist layer on the first main surface and the second main surface of the metal substrate; performing a single-side exposure and development process on the first main surface to manufacture a first hollowed-out area; performing a single-side etching process on the first hollowed-out area to etch a recessed area; and performing a laser process in the recessed area to bombard and engrave a through hole.

Owner:浙江众凌科技有限公司

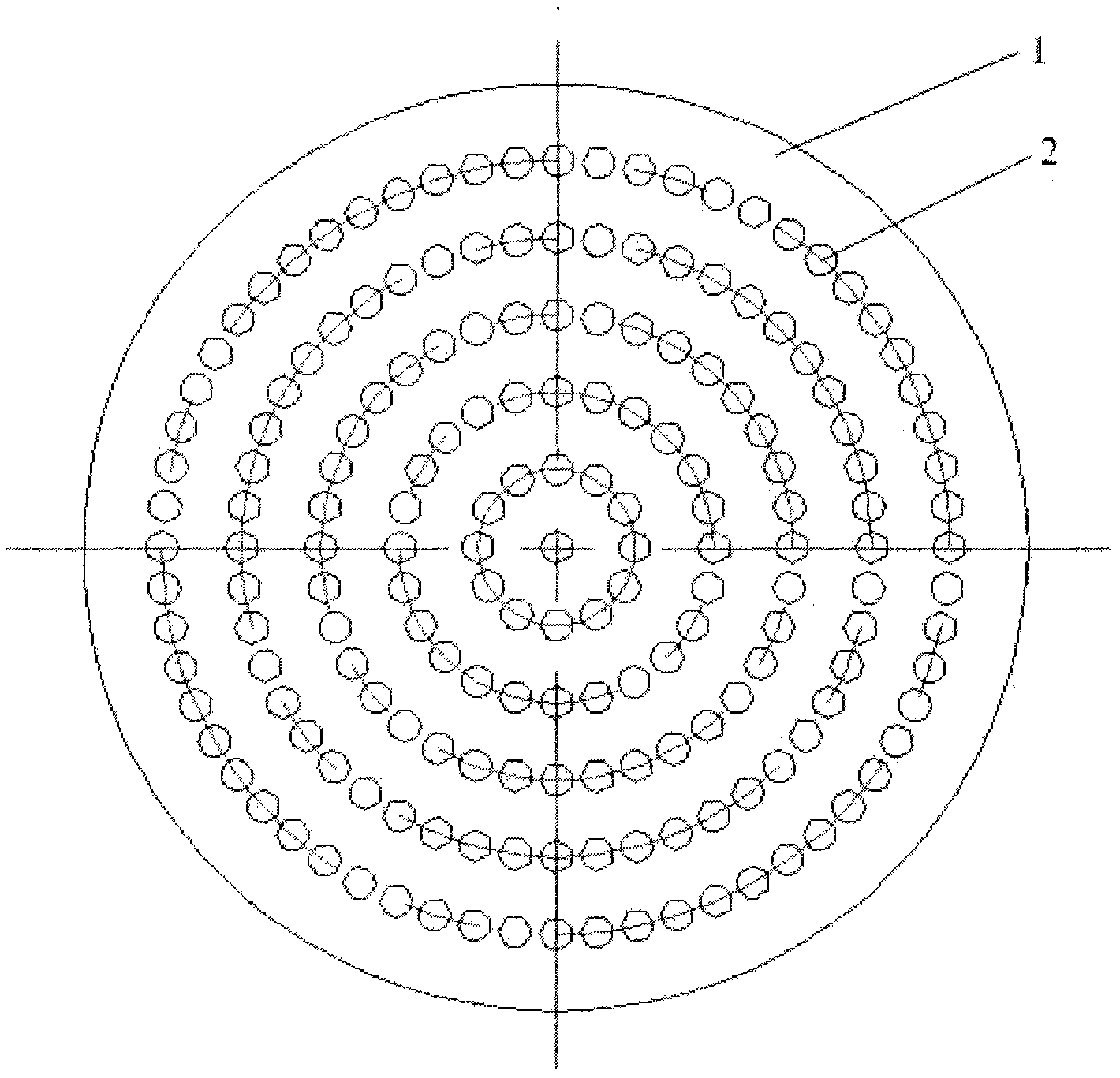

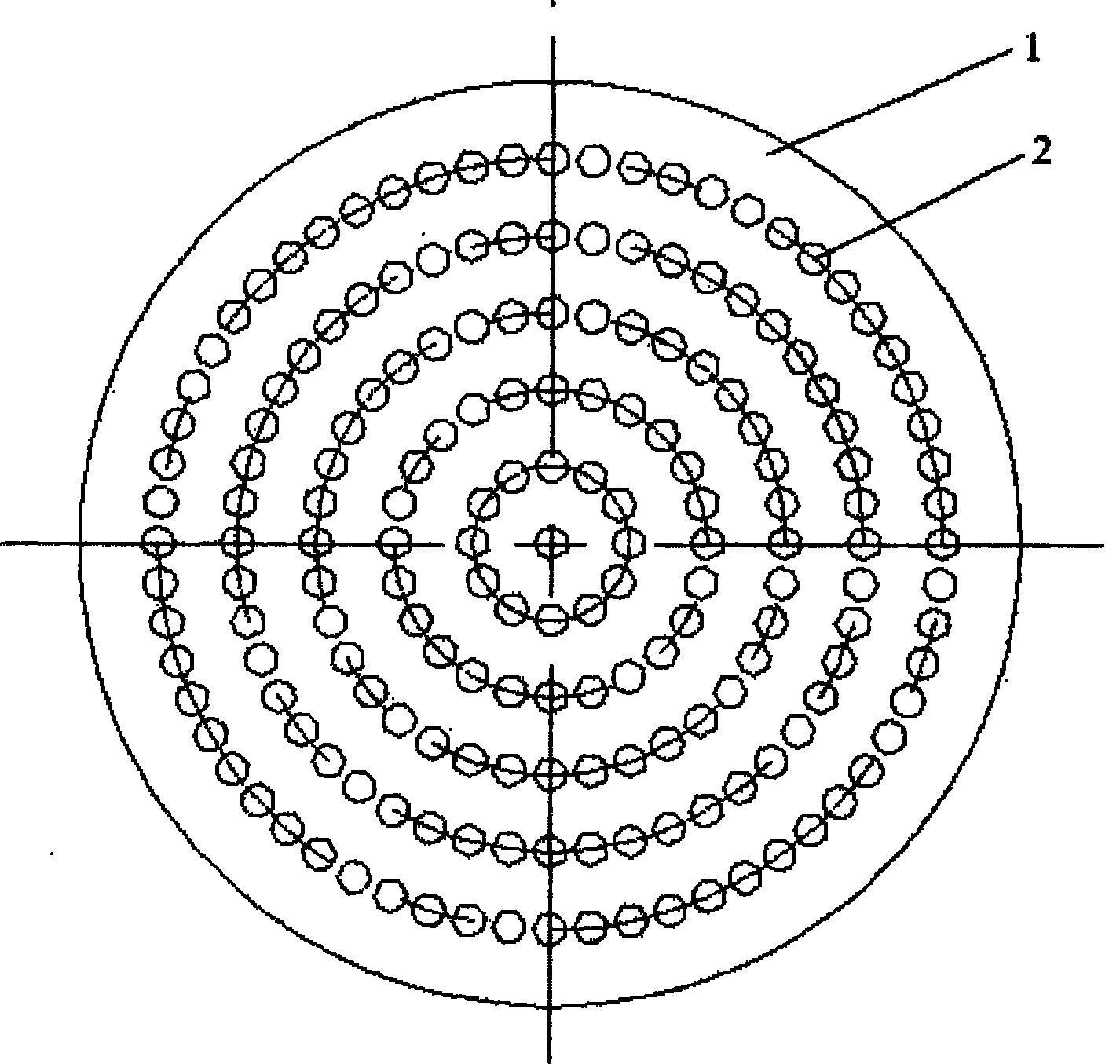

Sieve plate made of graphite

InactiveCN102371247AHigh strengthHigh temperature resistantSievingScreeningGraphiteTemperature resistance

The invention discloses a sieve plate made of graphite. The sieve plate comprises a sieve plate body, the sieve plate body is provided with sieve pores, the sieve pores are circumferentially distributed in the sieve plate body, and the circumferences formed by connecting the sieve pores form concentric circles. The sieve plate made of the graphite has the properties of high strength, temperature resistance, corrosion resistance, accurate fineness, pore blockage resistance and the like; meanwhile, the material adopted in the sieve plate has high abrasion resistance, and the screen is unloaded, so that the sieve plate has long service life, the frequency of changing the sieve surface is reduced, the production cost of an enterprise is reduced, and the production efficiency can be effectively improved.

Owner:NANTONG WULIAN BRAND PLANNING

Large-flux enhanced ultrafiltration membrane and preparation method thereof

ActiveCN110201557AReduce surface tensionImprove hydrophilicityMembranesUltrafiltrationSolventUltrafiltration

The invention relates to a large-flux enhanced ultrafiltration membrane. The large-flux enhanced ultrafiltration membrane is prepared from, by weight, 30-40 parts of dopamine-modified polyvinyl chloride, 10-20 parts of a hydrophilic agent, 40-50 parts of a polar solvent, 10-20 parts of a pore forming agent and 5-10 parts of an auxiliary agent. According to the large-flux enhanced ultrafiltration membrane, by blending and modifying the hydrophilic agent, the auxiliary agent and the dopamine-modified polyvinyl chloride in the polar solvent, the surface tension of the surface of the membrane andthe inner walls of membrane pores is reduced, and the hydrophilicity of the polyvinyl chloride is improved; triethanolamine in the hydrophilic agent has hydrogen-bond interaction with polar bonds in the auxiliary agent and polar bonds in a dopamine composite layer to attract each other, the hydrophilicity can be maintained for a long time accordingly, the antifouling property of the ultrafiltration membrane is improved, and the high operating flux is kept for a long time; the small-molecule pore forming agent does not easily block the pores, the membrane forming performance is good, the pure water flux is good, the degree of entanglement with a main material is low, and the pore forming agent is easily detached from the surface of the membrane; the auxiliary agent effectively improves themelt processability, and the mechanical properties are greatly improved.

Owner:泉州碧蓝膜科技有限责任公司

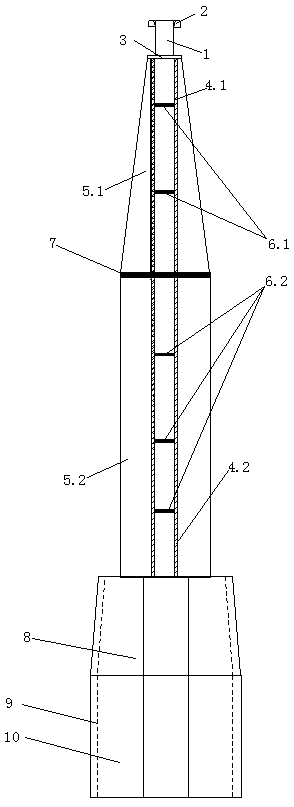

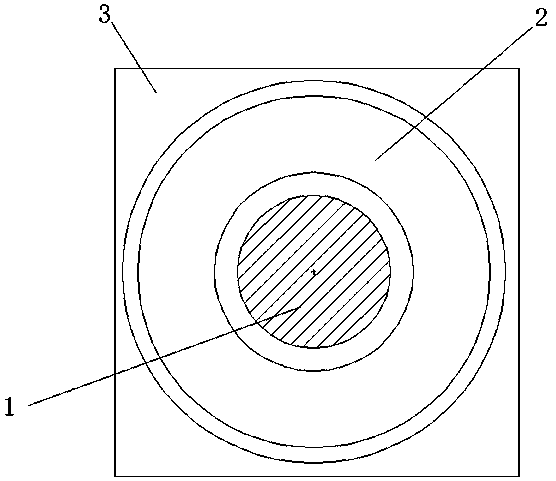

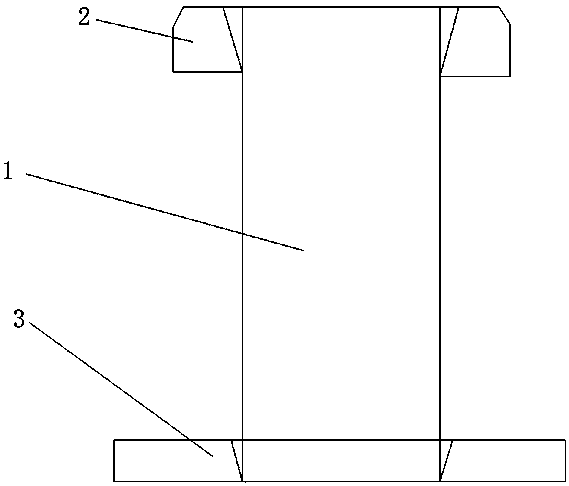

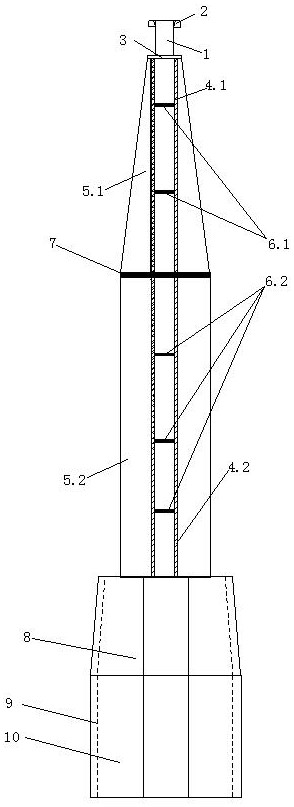

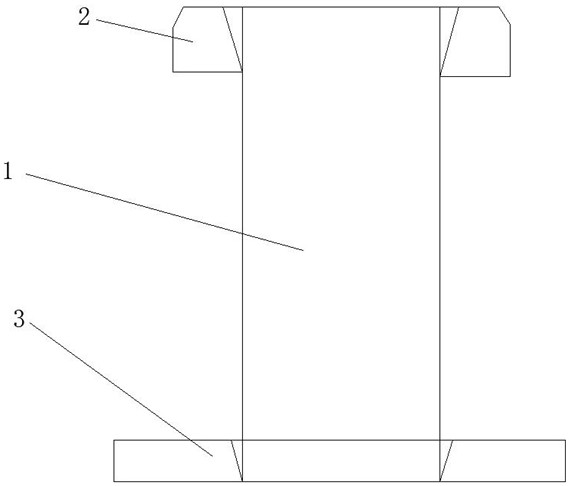

Special rammer for dynamic compaction replacement treatment of flow plastic-soft plastic clay

ActiveCN110904945AReduce lateral frictionReduce lossesSoil preservationDynamic compactionStructural engineering

The invention belongs to the technical field of rammers for foundation treatment in constructional engineering, and particularly relates to a special rammer for dynamic compaction replacement treatment of flow plastic-soft plastic clay. The special rammer comprises a hook device part, an anti-burying hammer lengthening body part and a rammer body part, wherein the height of the anti-burying hammerlengthening body part is 2.8 m or above; the rammer body part comprises an upper trapezoidal circular truncated cone structure and a lower cylindrical structure; and a plurality of semicircular ventholes are uniformly distributed in the outer wall of the rammer body part. According to the special rammer, the problem of hammer burying in the dynamic compaction replacement of the flow plastic-softplastic clay foundation is solved, the rammer can be used for solving the problem that dynamic compaction deep replacement cannot be carried out due to hammer burying in the dynamic compaction replacement treatment of the flow plastic-soft plastic clay, the application range of the dynamic compaction which is an environment-friendly and low-cost treatment technology can be further expanded, and the application market and the development prospect are wide.

Owner:山西机械化建设集团有限公司

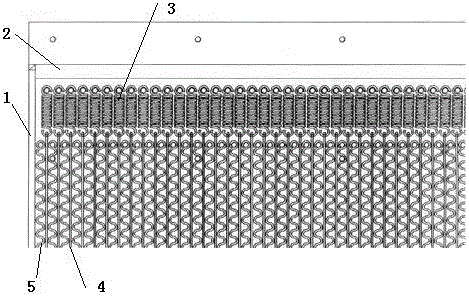

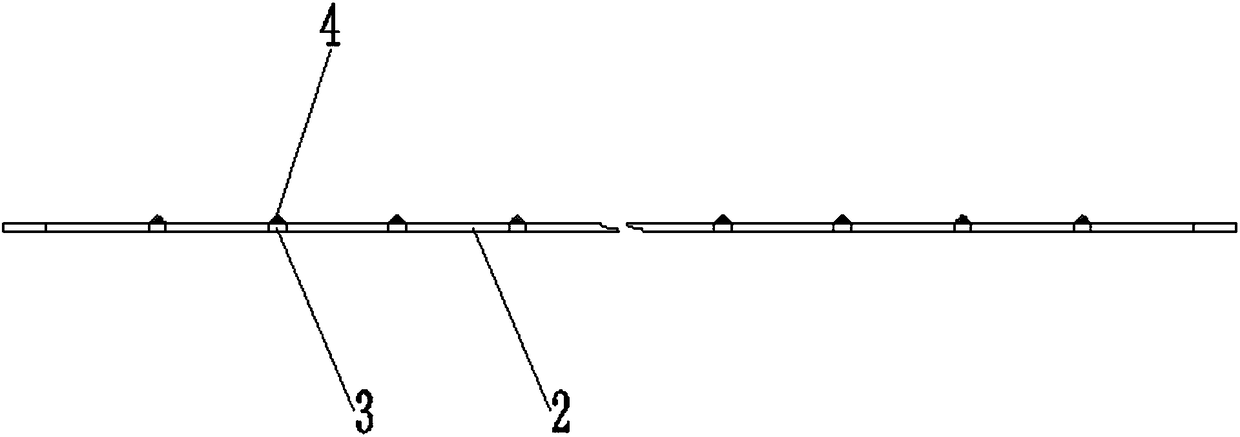

Self-cleaning sieve plate

InactiveCN106076822AImprove screening effectReasonable structureSievingScreeningFixed framePulp and paper industry

The invention relates to a self-cleaning sieve plate. The self-cleaning sieve plate adopts the technical scheme that the self-cleaning sieve plate comprises a sieve plate body, wherein fixed frames are arranged on both sides of the sieve plate body, linear sieve bars and wavy sieve bars are arranged on the sieve plate body in a staggered mode, tension springs are respectively connected to both ends of the linear sieve bars, and the tension springs are fixedly connected with the fixed frames. The self-cleaning sieve plate has the advantages of reasonable structure, difficulty in hole blockage and good sieving stability, and the sieving effect of sieving wet and sticky materials can be effectively increased.

Owner:HENAN WINNER VIBRATING EQUIP

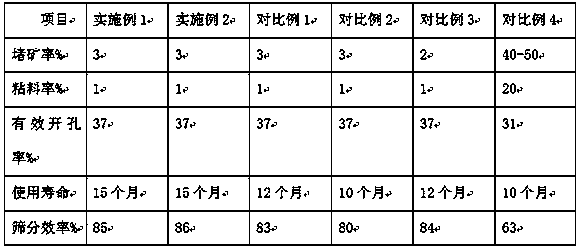

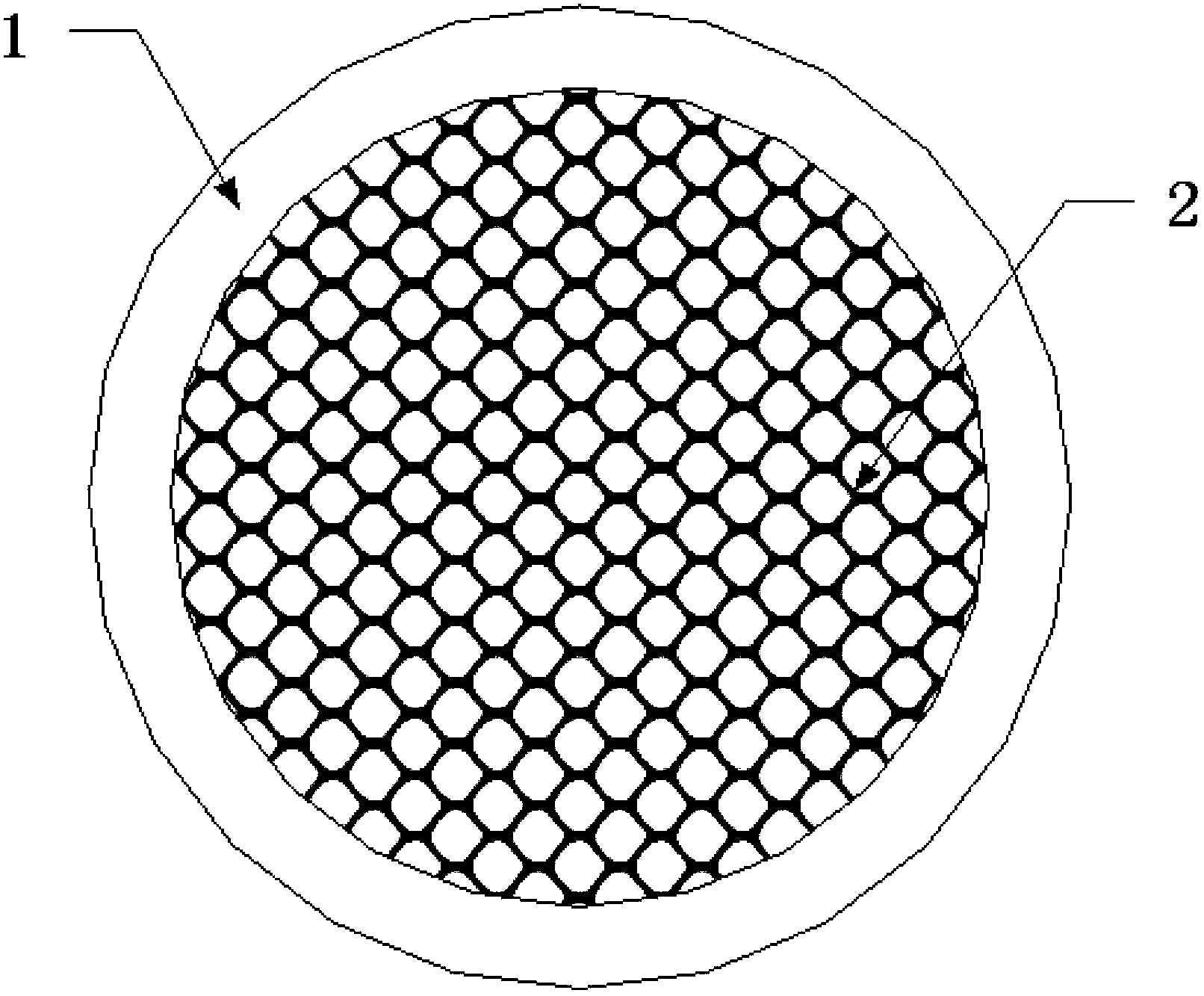

Polyurethane sieve mesh with advantages of noise reducing, high-temperature resistance and corrosion resistance

PendingCN109294211AImprove thermal performanceImproves electrical properties but improves arc resistance of plasticsMechanical propertyChemistry

The invention discloses a polyurethane sieve mesh with advantages of noise reducing, high-temperature resistance and corrosion resistance, wherein the polyurethane sieve mesh comprises thermoplastic polyurethane, a vinyl ester resin, melamine, carboxyl-terminated liquid nitrile butadiene rubber, chlorinated polyethylene, a titanate coupling agent, and a filler. According to the present invention,through the material blending modification, the sieve mesh has advantages of excellent mechanical property, high tensile strength, excellent tear resistance, good elasticity, good resilience, good uniformity and good stability, can maintain the stable performance after multiple use, cannot be clogged, further has advantages of good heat resistance, corrosion resistance, excellent aging resistance,good bearing capacity, good corrosion resistance, good impact resistance, good shock absorption performance, wear resistance and aging resistance, and can be used in ore screening, chemical industryfiltration, and other application fields.

Owner:含山县领创新材料科技有限公司

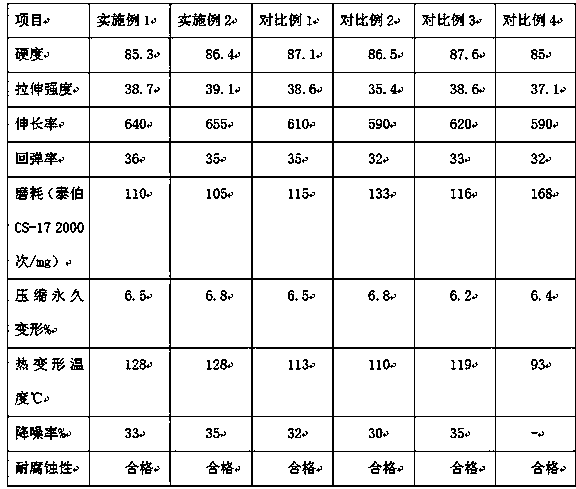

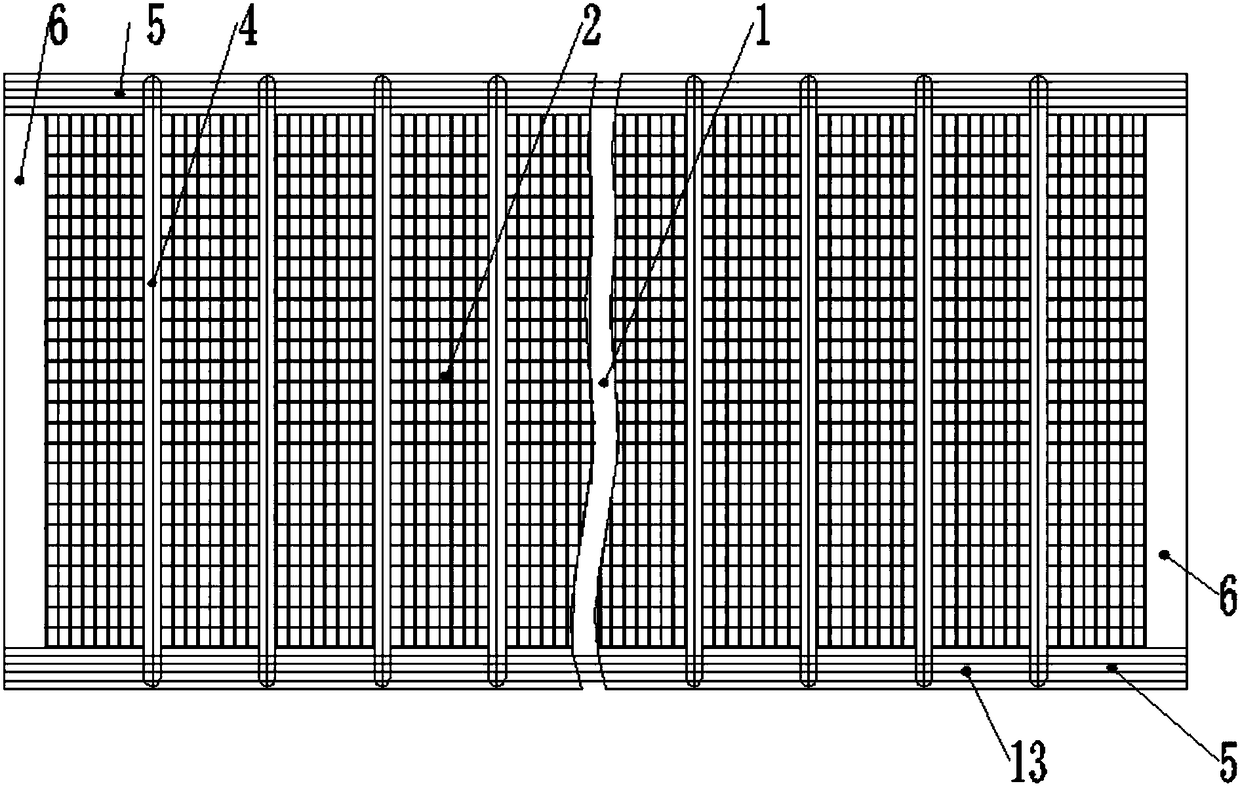

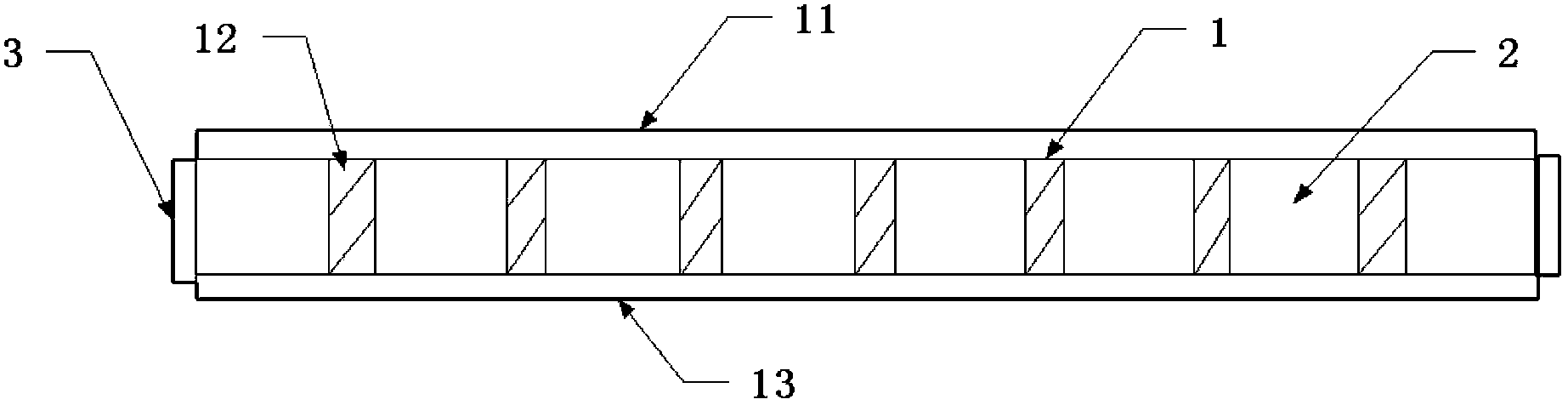

Anti-blocking corrugated plate for screening wet coal slime

The invention discloses an anti-blocking corrugated plate for screening wet coal slime. The anti-blocking corrugated plate for screening the wet coal slime is reasonable in structure and good in use effect. According to the technical scheme, the anti-blocking corrugated plate for screening the wet coal slime comprises a screen plate body. An outer screen plate body frame is a polyurethane covered edge. Transverse screen bars on the screen plate body are corrugated screen bars and linear screen bars. The two types of screen bars are arranged at intervals to form screen holes. The protruding directions of the adjacent corrugations on the same corrugated screen bar are opposite. The anti-blocking corrugated plate for screening the wet coal slime is reasonable in structure, good in use effect and high in hole forming rate; the holes are not likely to be blocked; the service life is long; and the use cost is reduced for an enterprise.

Owner:HENAN WINNER VIBRATING EQUIP

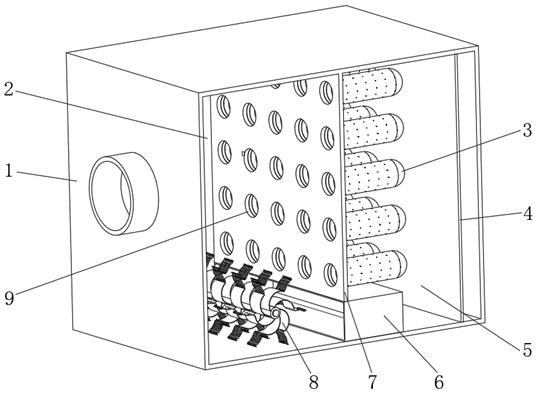

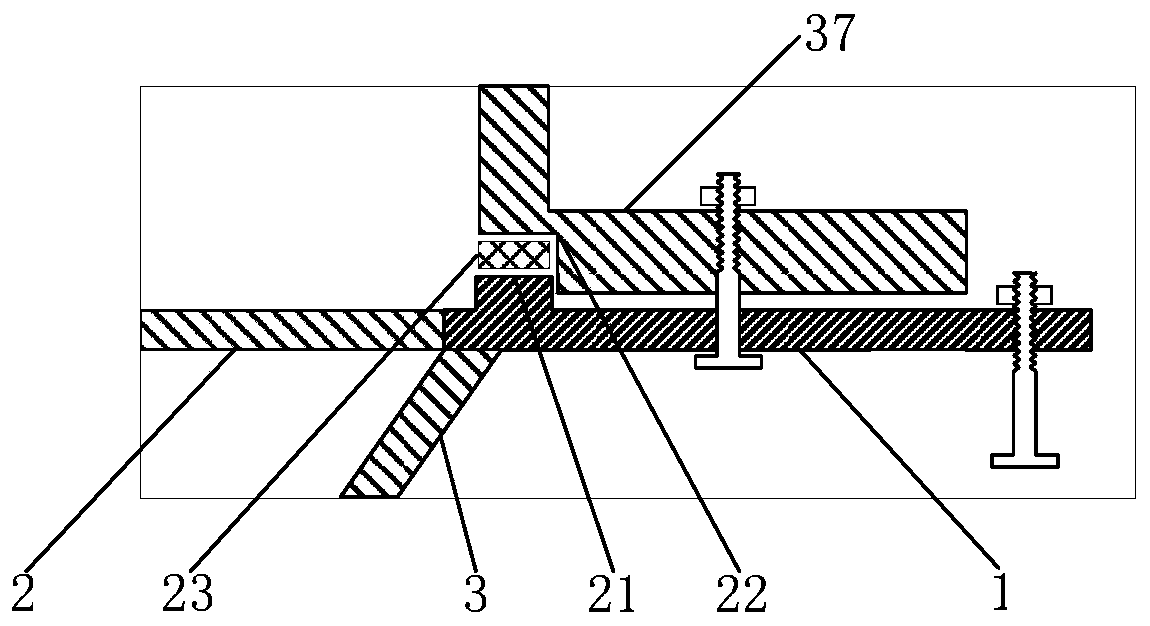

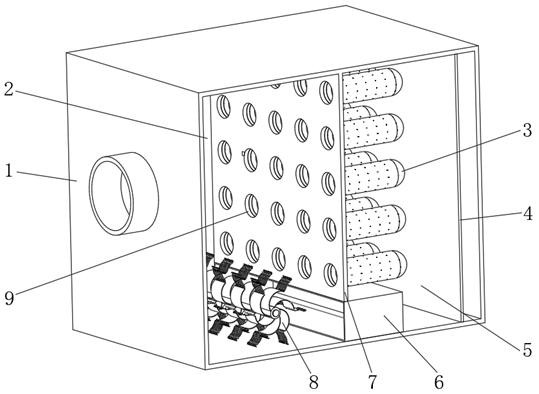

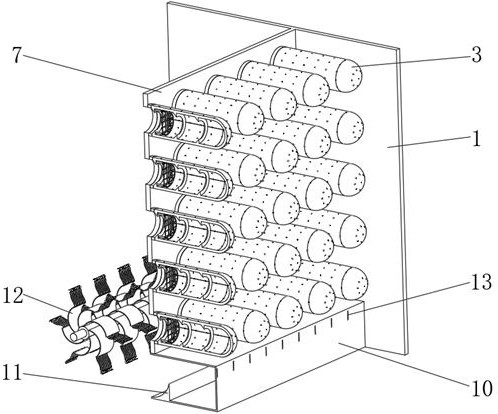

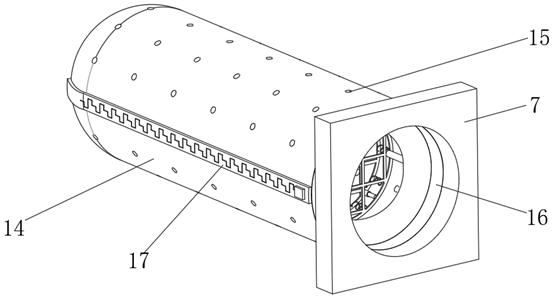

Drainage treatment method and drainage treatment device

ActiveCN112142228BNot easy to plug holesEasy to collectTreatment involving filtrationMultistage water/sewage treatmentStructural engineeringControl theory

The invention discloses a drainage treatment method and a drainage treatment device, which relate to the technical field of drainage treatment; in order to improve the treatment efficiency and effect; The interior is provided with a first cavity and a second cavity, the same filter plate is set between the first cavity and the second cavity, a filter mechanism is provided on the outer wall of one side of the filter plate, and the outer wall of one side of the filter plate is provided with a A through hole adapted to the filter mechanism; the method includes the following steps: installing the input end of the main body on the output end of the water supply device, and connecting the output end of the main body to the drain. The present invention can collect impurities well by setting filter plate, filter sleeve and other structures, and clean them conveniently through the zipper. In addition, the filter holes are evenly opened on the outer wall of the filter sleeve, and cooperate with the pocket structure of the filter sleeve to make the filter The sleeve is not easy to block the hole before the inner space is collected.

Owner:四川发展环境科学技术研究院有限公司

A special rammer for dynamic compaction replacement treatment of fluid-plastic to soft-plastic clay

ActiveCN110904945BReduce lateral frictionReduce lossesSoil preservationDynamic compactionStructural engineering

The invention belongs to the technical field of a rammer for foundation treatment in construction engineering, and specifically relates to a special rammer for dynamic compaction replacement treatment of flow-plastic to soft-plastic clay, including a hook part, an anti-buried hammer extension part and a rammer For the hammer body, the height of the anti-buried hammer extension is more than 2.8 meters. The rammer body includes an upper trapezoidal circular table structure and a lower cylindrical structure. The outer wall of the rammer body is evenly distributed with a number of semicircular ventilation holes. The present invention solves the problem of "buried hammer" in the dynamic compaction replacement of flow-plastic to soft-plastic clay foundations. For the problem that it is impossible to carry out dynamic compaction depth replacement due to hammering, dynamic compaction, an environmentally friendly and low-cost treatment technology, can further expand the scope of application, and has a broad application market and good development prospects.

Owner:山西机械化建设集团有限公司

A kind of thermoplastic polyurethane fine slit screen and its forming method

ActiveCN106216239BFaster molding timeShorten molding timeSievingScreeningPorosityThermoplastic polyurethane

Owner:北京斯克瑞科技有限公司

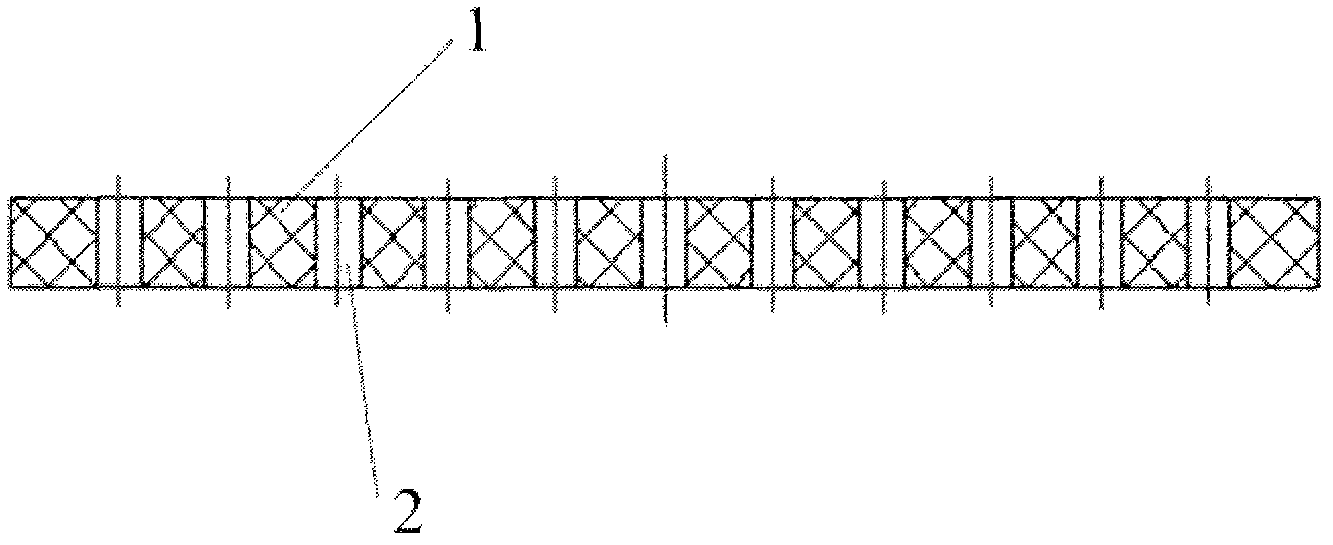

Graphite filter plate

InactiveCN103623990AReduce manufacturing costAccurate finenessSievingScreeningBiochemical engineeringGraphite

The invention provides a graphite filter plate. The graphite filter plate comprises a filter plate body and filtering holes which are evenly arrayed in the filter plate body. The filter plate body comprises an upper layer filter cloth, a middle layer graphite filter plate and a lower layer filter cloth. The upper layer filter cloth and the lower layer filter cloth are fixed on the middle layer graphite filter plate through a fixing ring which is arranged around the middle layer graphite filter plate. The graphite filter plate has the advantages of being high-temperature resistant, corrosion resistant, accurate in fineness, not prone to blocking the holes, capable of avoiding loading of a filter screen, simple in structure, long in service life, and capable of lowering the production cost of enterprises and effectively improving the production efficiency.

Owner:TIANJIN GERUICHAO CARBON PROD

A kind of large-flux enhanced ultrafiltration membrane and preparation method thereof

ActiveCN110201557BReduce surface tensionHigh electronegativityMembranesUltrafiltrationPolymer scienceUltrafiltration

The invention relates to a high-flux reinforced ultrafiltration membrane, which is composed of the following components in parts by weight: 30-40 parts of dopamine-modified polyvinyl chloride; 10-20 parts of a hydrophilic agent; and 40-50 parts of a polar solvent ; 10-20 parts of porogen; 5-15 parts of auxiliary agent. The present invention adopts hydrophilic agent, auxiliary agent and dopamine-modified polyvinyl chloride to be blended and modified in polar solvent, so as to reduce the surface tension of the membrane surface and the inner wall of the membrane hole, and improve the hydrophilicity of polyvinyl chloride. The polar bonds in the triethanolamine and the auxiliary and the polar bonds in the dopamine composite layer produce hydrogen bonds and attract each other, so that the hydrophilicity can be maintained for a long time, the anti-fouling property of the ultrafiltration membrane can be improved, and the UF membrane can be maintained for a long time. High operating flux; in addition, the small molecule porogen is not easy to block pores, has good film-forming performance, good pure water flux, low degree of entanglement with the main material, and is easy to detach from the surface of the film; the auxiliary agent can effectively improve the melt processability , the mechanical properties are greatly enhanced.

Owner:泉州碧蓝膜科技有限责任公司

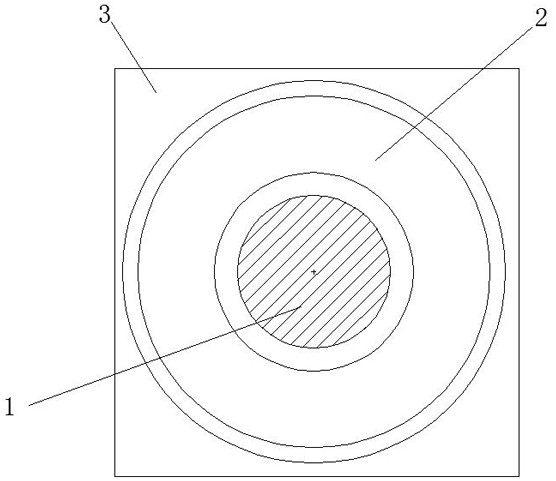

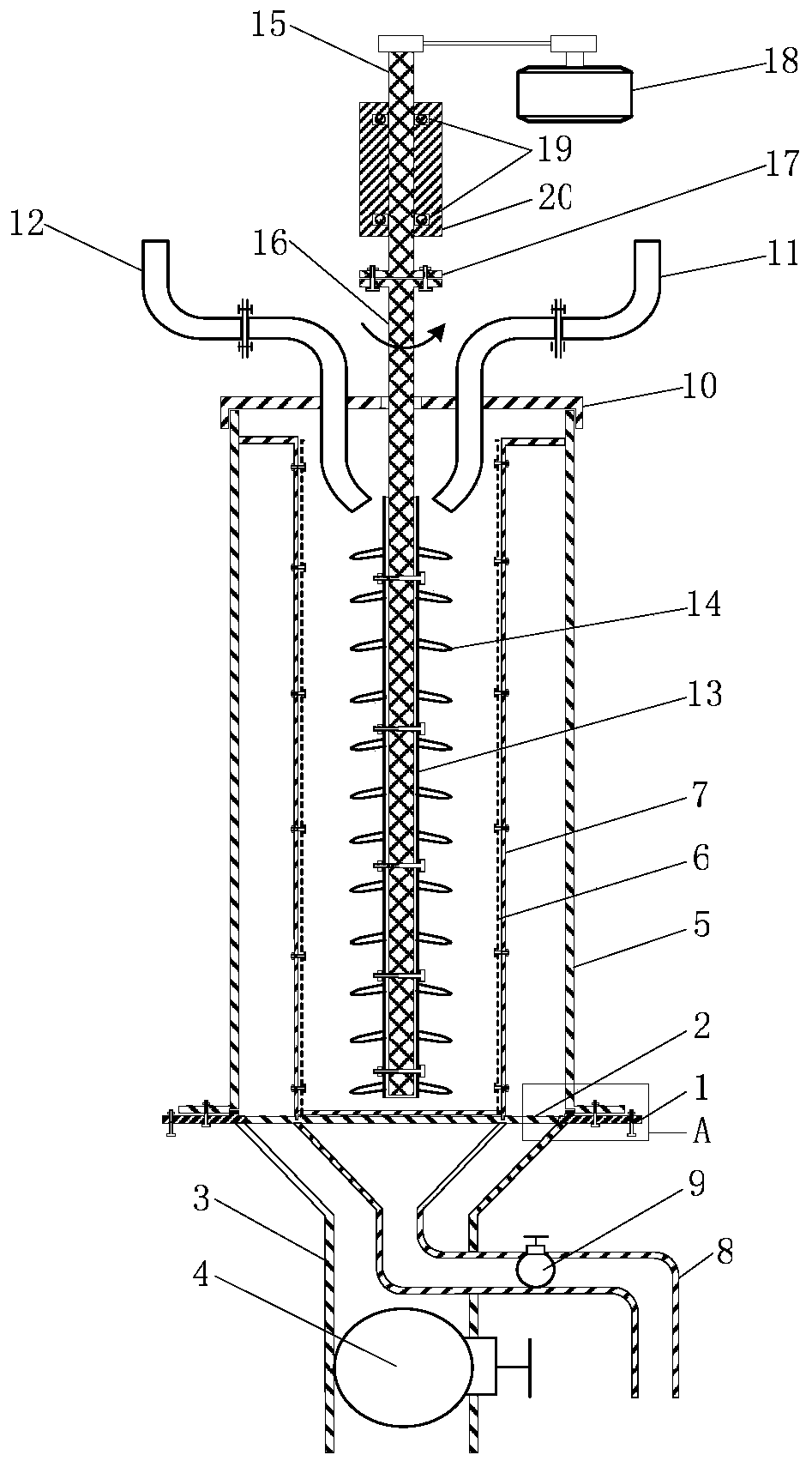

Cyclone Classification Column and Its Method for Classifying Ore Pulp Coarse and Fine Particles

InactiveCN108325763BImprove classification accuracyImprove classification efficiencySingle direction vortexWet separationCoaxial lineEngineering

The invention relates to an eddy flow grading column and method for using an eddy flow grading column in pulp crude / fine grain grading. The eddy flow grading column comprises a frame, a pedestal is fixed at the frame, a horizontal support strip is fixed at the pedestal, a fine grain outlet pipeline is connected below the pedestal, a large valve is arranged at the fine grain outlet pipeline, a tubular cylinder is arranged at the pedestal, a cylindrical screen mesh having a coaxial line is distributed in the tubular cylinder, the cylindrical screen mesh is fixedly at a rack, the bottom of the rack is fixed at the support strip, a coarse grain outlet pipeline is connected below a middle part of the support strip, a small valve is arranged at the coarse grain outlet pipeline, an upper cover isarranged at the top of the tubular cylinder, an ore-feeding pipe and a water inlet pipe are arranged at the upper cover, a through hole is arranged at the center of the upper cover, a rotating shaftis arranged at the coaxial line of the cylindrical screen mesh, a blade spindle sleeve is arranged at the bottom of the rotating shaft, a blade is arranged at the blade spindle sleeve, the rotating shaft is driven by a motor, and the motor is arranged at the frame. The eddy flow grading column has the advantages of good grading precision and high grading efficiency.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

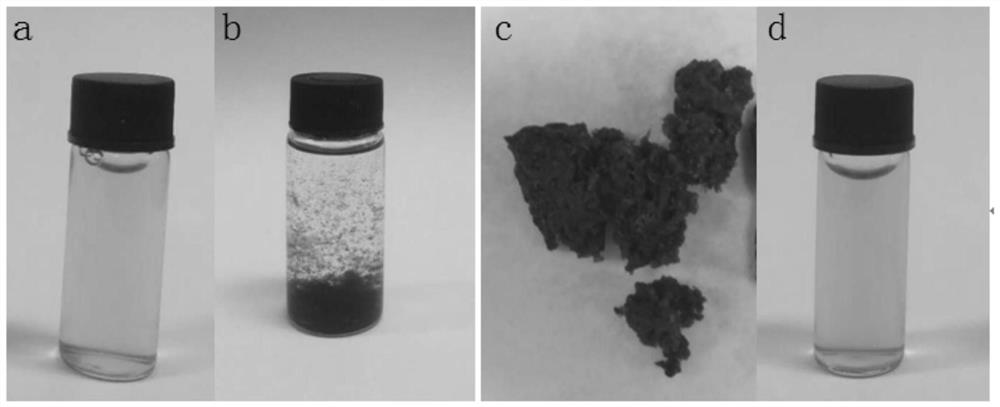

A method and device for concentrating a large graphene oxide solution

The invention discloses a method and a system for concentrating a large graphene oxide solution. The large graphene oxide solution flows through a limited space, and is rapidly sheared in order to coagulate graphene oxide. The coagulated graphene oxide is 60 to 100mg / mL in final concentration after being filtered and collected. The coagulated graphene oxide is unfolded slowly under slow cutting, recovers to a uniform structure, and is dispersed in the solution. The method can be applied to rapid continuous concentration of the graphene oxide solution.

Owner:HANGZHOU GAOXI TECH CO LTD

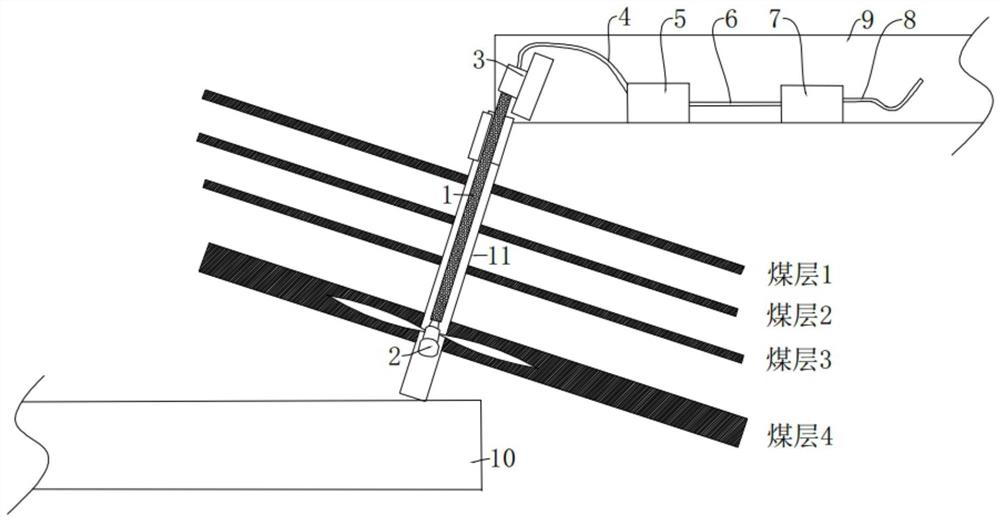

Underground low-permeability short-distance coal seam group hydraulic punching permeability improvement device and application method

PendingCN112228145AImprove breathabilityEasy extractionLiquid/gas jet drillingFluid removalOutfallEngineering

The invention discloses an underground low-permeability short-distance coal seam group hydraulic punching permeability improvement device and an application method thereof. The device comprises a drill rod, a punching drill bit, a directional drilling machine, a first high-pressure rubber hose, a high-pressure water injection pump, a second high-pressure rubber hose, a water tank and a water pipe,wherein the first high-pressure rubber hose and the second high-pressure rubber hose are arranged on a water outlet and a water inlet of the high-pressure water injection pump separately, the water tank is arranged on the second high-pressure rubber hose, the water pipe is arranged on the water tank, the directional drilling machine is arranged on the first high-pressure rubber hose, the drill rod is arranged on the directional drilling machine, the punching drill bit is arranged at the free end of the drill rod, and high-pressure water spraying holes are formed in the punching drill bit. Theinvention relates to the technical field of coal uncovering, in particular to the underground low-permeability short-distance coal seam group hydraulic punching permeability improvement device and the application method thereof. The device and the method have the advantage that the purposes of safely uncovering coal and shortening the coal uncovering construction period are achieved.

Owner:华能云南滇东能源有限责任公司

A large-flux reinforced hollow fiber membrane and its preparation method

ActiveCN110201559BReduce surface tensionOvercoming the problem of decreased hydrophilicityMembranesSemi-permeable membranesHollow fibrePolymer science

The invention relates to a large-flux reinforced hollow fiber membrane, wherein the separation membrane layer is composed of the following components in parts by weight: 22-30 parts of polyvinylidene fluoride, 10-20 parts of hydrophilic agent, 50-50 parts of polar solvent 60 parts, 10-20 parts of porogen, 5-10 parts of auxiliary agent, and the hydrophilic agent contains triethanolamine. The present invention adopts hydrophilic agent, auxiliary agent and polyvinylidene fluoride to blend and modify under polar solvent to reduce the surface tension of the membrane surface and the inner wall of the membrane hole, improve the hydrophilicity of polyvinylidene fluoride, and the hydrophilic agent The triethanolamine can generate hydrogen bonds with the polar bonds in the additives, so that it can maintain the hydrophilicity for a long time, improve the anti-fouling performance of the hollow fiber membrane, and maintain a high operating flux for a long time. The triethanolamine can also be adsorbed on the surface of the hollow fiber material by the hydrogen bond force, thereby enhancing the adhesion strength between the separation membrane layer and the hollow fiber, and adding the hollow fiber as a support can prevent the membrane material from breaking.

Owner:泉州碧蓝膜科技有限责任公司

Drainage treatment method and drainage treatment device

ActiveCN112142228ANot easy to plug holesEasy to collectTreatment involving filtrationMultistage water/sewage treatmentStructural engineeringControl theory

The invention discloses a drainage treatment method and a drainage treatment device, and relates to the technical field of drainage treatment. The processing efficiency and effect are improved. The device comprises a main body; an input end and an output end are arranged on the two sides of the main body respectively; a first cavity and a second cavity are formed in the main body; the same filterplate is arranged between the first cavity and the second cavity; a filter mechanism is arranged on the outer wall of one side of the filter plate; and a through hole matched with the filter mechanismis formed in the outer wall of one side of the filter plate. The method comprises the following steps that the input end of the main body is installed at the output end of the water supply device, and the output end of the main body is connected to a water outlet. By arranging the structures such as the filter plate and the filter sleeve, impurities can be well collected and conveniently cleanedthrough the zipper; and in addition, the filter holes are uniformly formed in the outer wall of the filter sleeve and are matched with the pocket-shaped structure of the filter sleeve, so that the filter sleeve is unlikely to block the holes before the internal space is full.

Owner:四川发展环境科学技术研究院有限公司

White aqueous jet ink

Owner:GUANGDONG JANUS SMART GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com