EGCG preparation method

A technology of extraction solution and extraction tank, which is applied in the field of separation and purification of plant monomers, can solve problems such as insufficient safety and environmental protection, complicated process, etc., and achieve the effects of reduced use and recycling, good membrane stability, and enhanced adsorption and exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] The preparation of embodiment 2 technical grade high-purity EGCG

[0040] (1) Grind the green tea with a pulverizer, weigh 100kg green tea powder, put it into a 1200L extraction tank, add 1000L deionized water, heat up to 90°C, stir at 50r / min, and vacuum extract at 0.12Mpa for 20min.

[0041](2) Take out 250L of the extraction liquid in the extraction tank with a suction filter tube, add 250L of ionized water into the tank and repeat the extraction twice according to step (1).

[0042] (3) Combine the extracts from steps (1) and (2), cool to 50°C, and use Al with a pore size of 0.8 μm 2 o 3 Filtrate with a ceramic membrane filter at 0.15Mpa to obtain filtrate and filter residue, discard the filter residue.

[0043] (4) Take the filtrate of step (3), import it into a vacuum concentrator, concentrate in a vacuum at 40° C. and 0.09 MPa for 90 minutes, and obtain 120 L of concentrated extract; take the extract sample and dry and weigh it, and the calculated extraction ra...

Embodiment 3

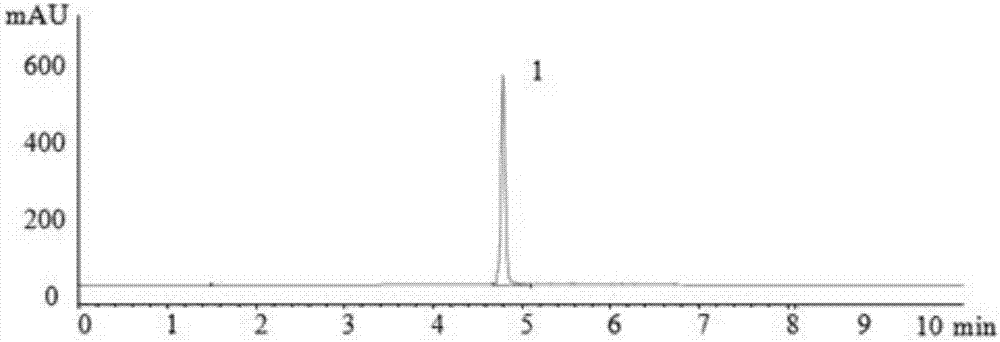

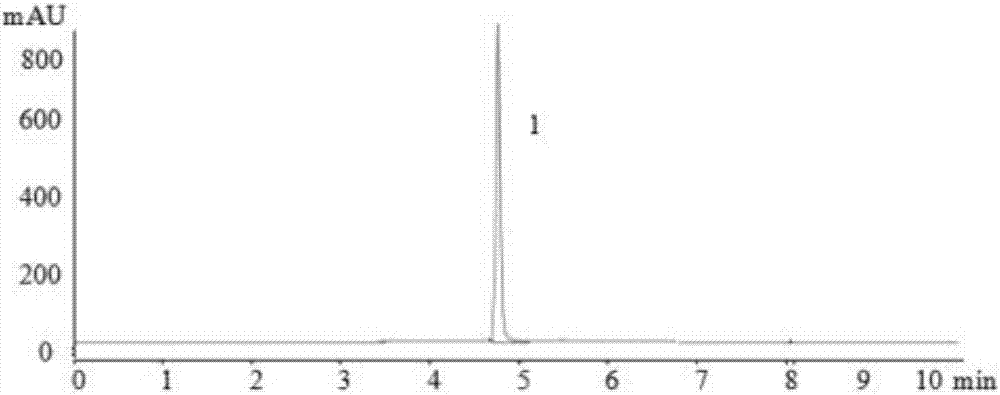

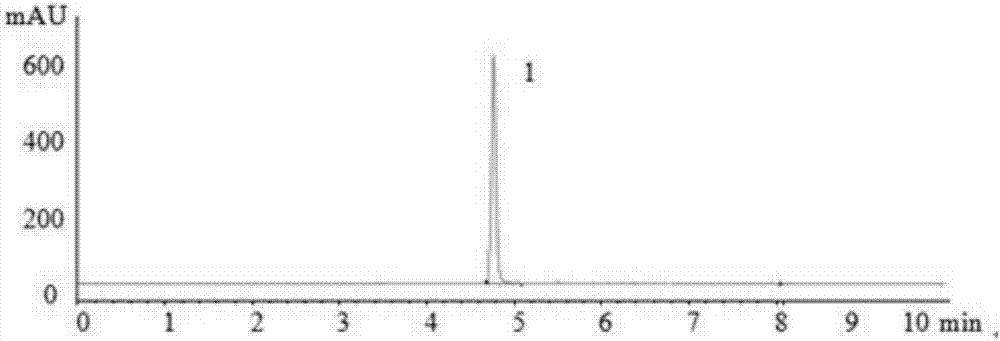

[0048] Embodiment 3 adopts HPLC method to detect EGCG purity

[0049] (1) Detection conditions

[0050] Instrument model: liquid chromatograph Agilent 1260

[0051] Chromatographic column: Agilent Poroshell 120SB-C18 (4.6×100mm, 2.7μm)

[0052] Mobile phase: acetonitrile-0.1% formic acid in water

[0053] Flow rate: 1.0mL / min

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com