Patents

Literature

134results about How to "Reduce the amount of impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

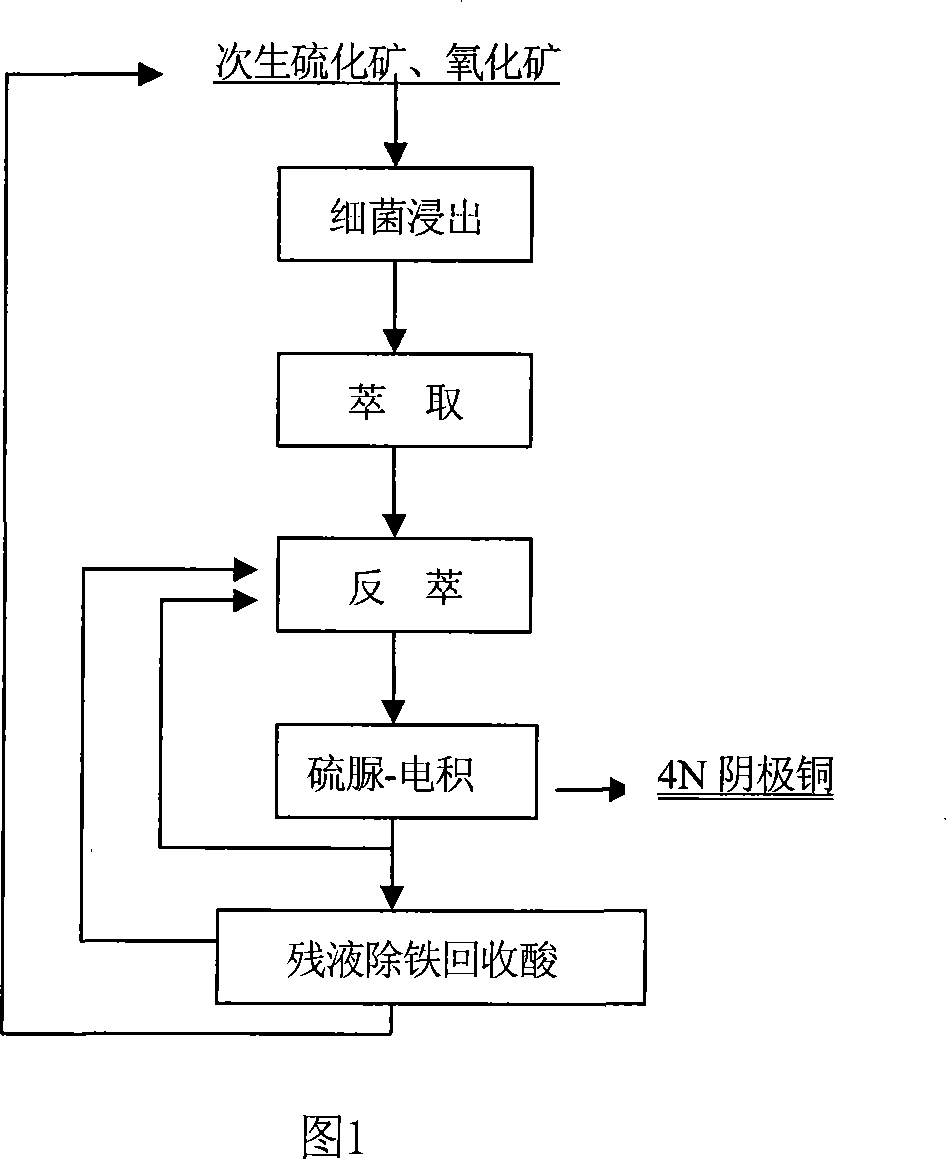

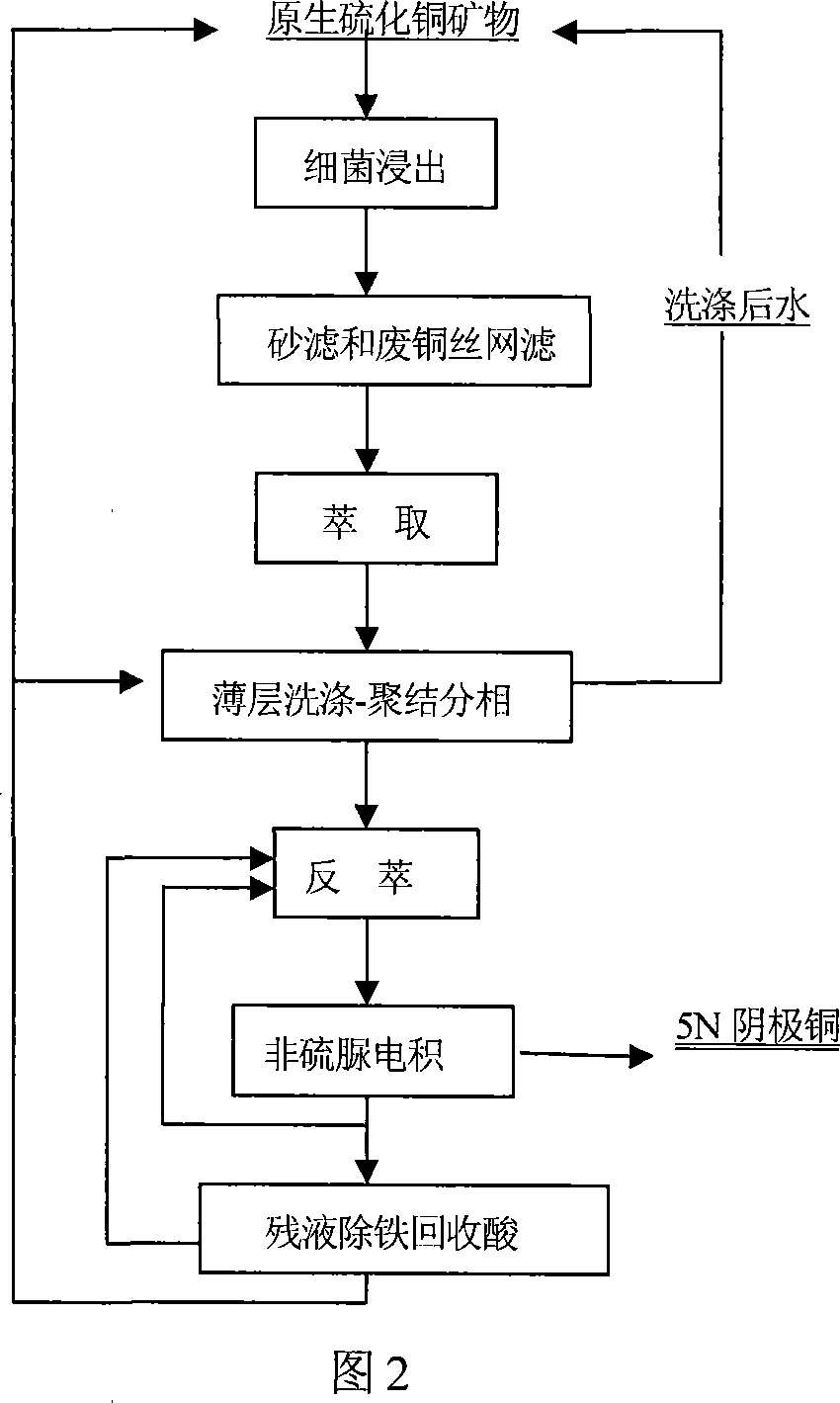

Method of preparing high purity copper by bacteria leaching primary sulfide ore

InactiveCN101033508AEnhanced synergistic leachingIncrease leaching ratePhotography auxillary processesProcess efficiency improvementSulfurThin layer

The invention relates to a method of preparing high pure copper from the leachate of primary sulfide ore bacteria, including: it leaches the primary sulfide ores and its mixture by using the mixture of middle and mesophilic bacterias. It filters and extracts the bacterial leaching solution, and conducts thin-layer wash-condensate, coalescence phase, and back-extraction electrowinning for the organic phase load. The invention uses hybrid strains of bacteria and sub-culture techniques to enhance the synergy of the bacterial leaching role and the minerals leaching rate, uses gelatin and other additives without sulfur element to reduce the sulfur impurities.

Owner:CENT SOUTH UNIV

Inner lining of furnace for treating liquid steel and repairing method

InactiveCN1796331AReduce the amount of impuritiesImprove penetration and erosion resistanceMelt-holding vesselsLiquid steelOxide

This invention involves the inner lining of a molten-steel handling furnace and its maintenance and repair. This invention is aimed to putting forward an inner lining that can satisfy the working conditions of ladle casting materials. In this invention the inner lining of the molten-steel handling furnace is cast from fire-resisting casting materials such as the high-purity corundum-magnesium oxide-spinel system. The raw material system comprises fused spinel, fused magnesite, fused white corundum, fused brown corundum, plate corundum, extra-grade alumina, alumina sponel or a combination of them. The repair of the inner lining comprises the steps of: a. cleaning the damaged inner lining to remove the molten slag layer; b. using a casting material whose purity is the same with that of the previous material to repair the damaged positions, so that the previously designed structure of the inner lining is recovered; c. natural drying of the repaired inner lining for 24-72h; d. baking. The surface activity of the microscale or finer additives can strengthen the agglomeration of the casting materials, thus making the agglomerated inner lining more compact and the repaired layer thinner.

Owner:PUYANG REFRACTORIES GRP CO LTD

Production method of poly ammonium phosphate

A process for preparing ammonium polyphosphate includes such steps as proportionally mixing polyphosphoric acid with the condensating agent chosen from urea, ammonium dicarbonate, melamine, bicynoamine, ammonium sulfate and their mixture, and reacting at 100-500 deg.C under 0.01-0.35 MPa for 5-210 min.

Owner:YUNNAN CHEM RES INST

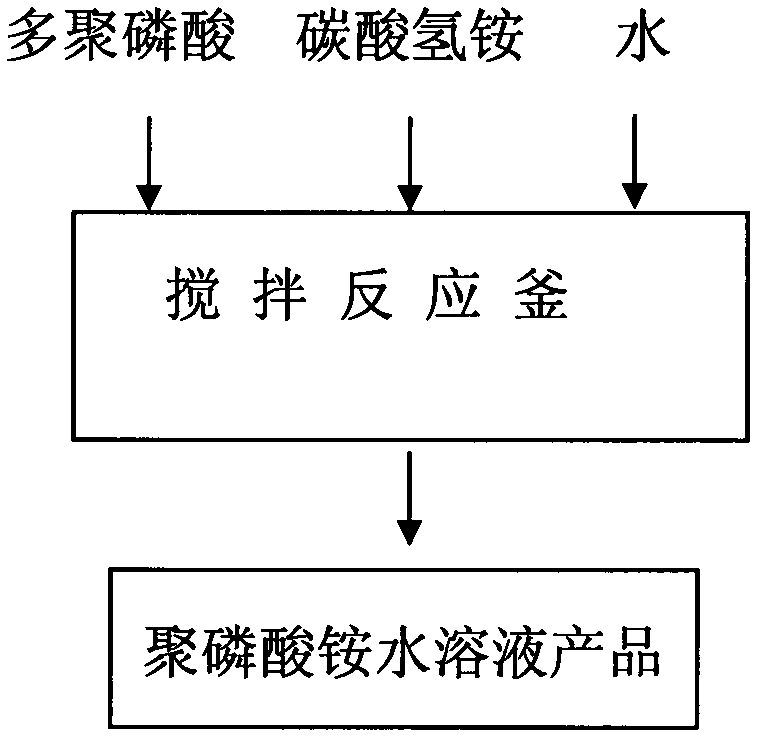

Method for preparing low-polymerization-degree ammonium polyphosphate aqueous solution

ActiveCN103373717AReduce processReduce difficultyPhosphorus compoundsChemical industryEnvironmental resistance

The invention belongs to the technical field of phosphate production in inorganic chemical industry and discloses a novel method for producing a low-polymerization-degree ammonium polyphosphate aqueous solution by using low-temperature methods. Commonly-used ammonium polyphosphate production methods are mainly high-temperature thermal polymerization methods, and methods capable of producing ammonium polyphosphate by using the low-temperature methods do not exist at home and abroad. According to the method, polyphosphoric acid with the concentration of 100% to 120% serves as a main raw material, is adjusted by adding an appropriate amount of water and is mixed with ammonium bicarbonate under a natural, low-temperature and normal-pressure condition, stirring and reacting are carried out, and then, the low-polymerization-degree ammonium polyphosphate aqueous solution with the nitrogen content higher than 11%, the phosphorus pentoxide content higher than 37% and the main content of a dipolymer (ammonium pyrophosphate) is produced in batches, is widely used as a fireproofing flame retardant, a plant nutrient solution (liquid fertilizer) and the like and has high practical values. The method is simple in production operation, high in yield and low in energy consumption, is safe and environmental-friendly and does not need high temperature, the requirements for the performance of equipment and materials are lowered greatly, and the large-scale continuous production is easy to realize.

Owner:BLACK P2 USA INC

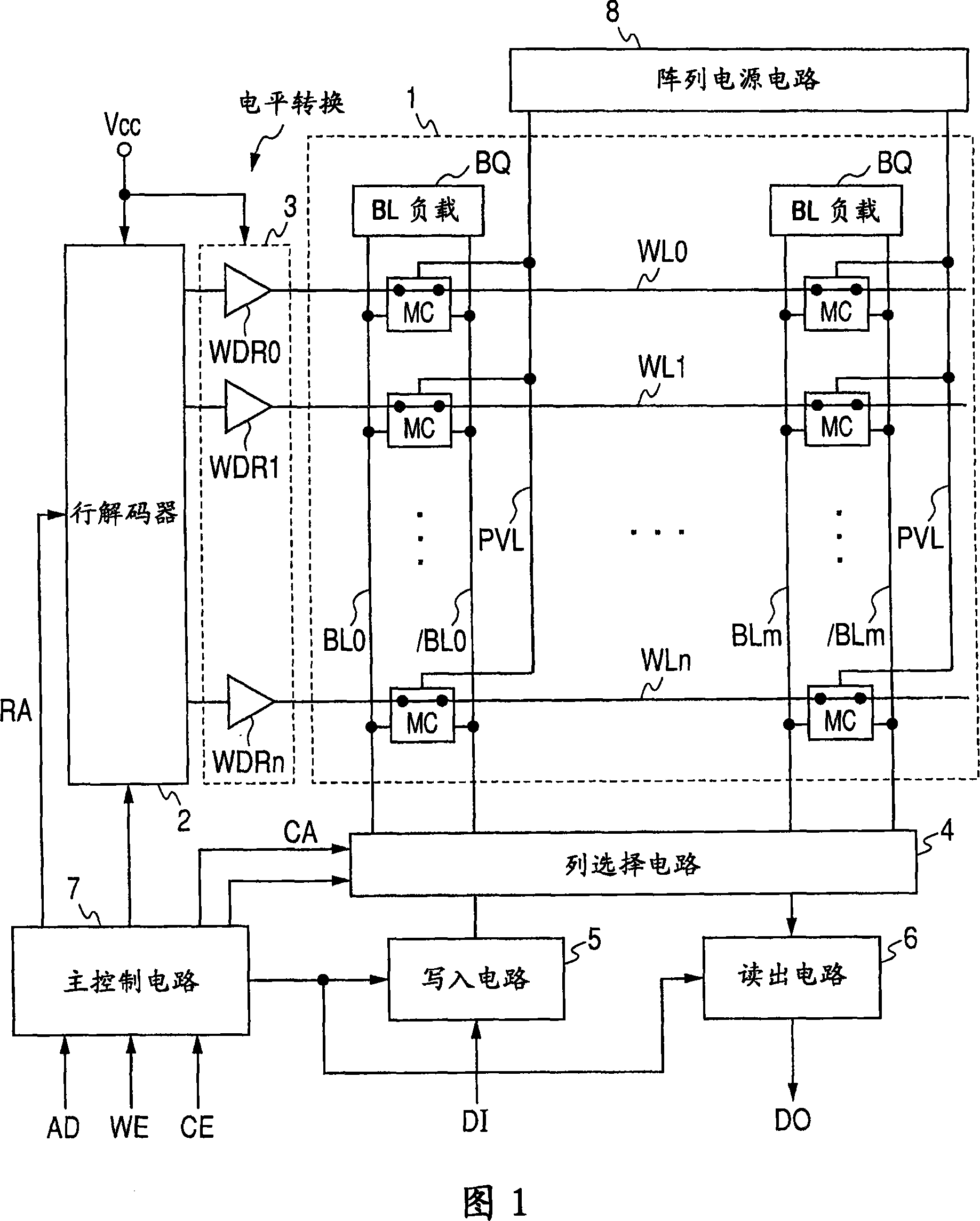

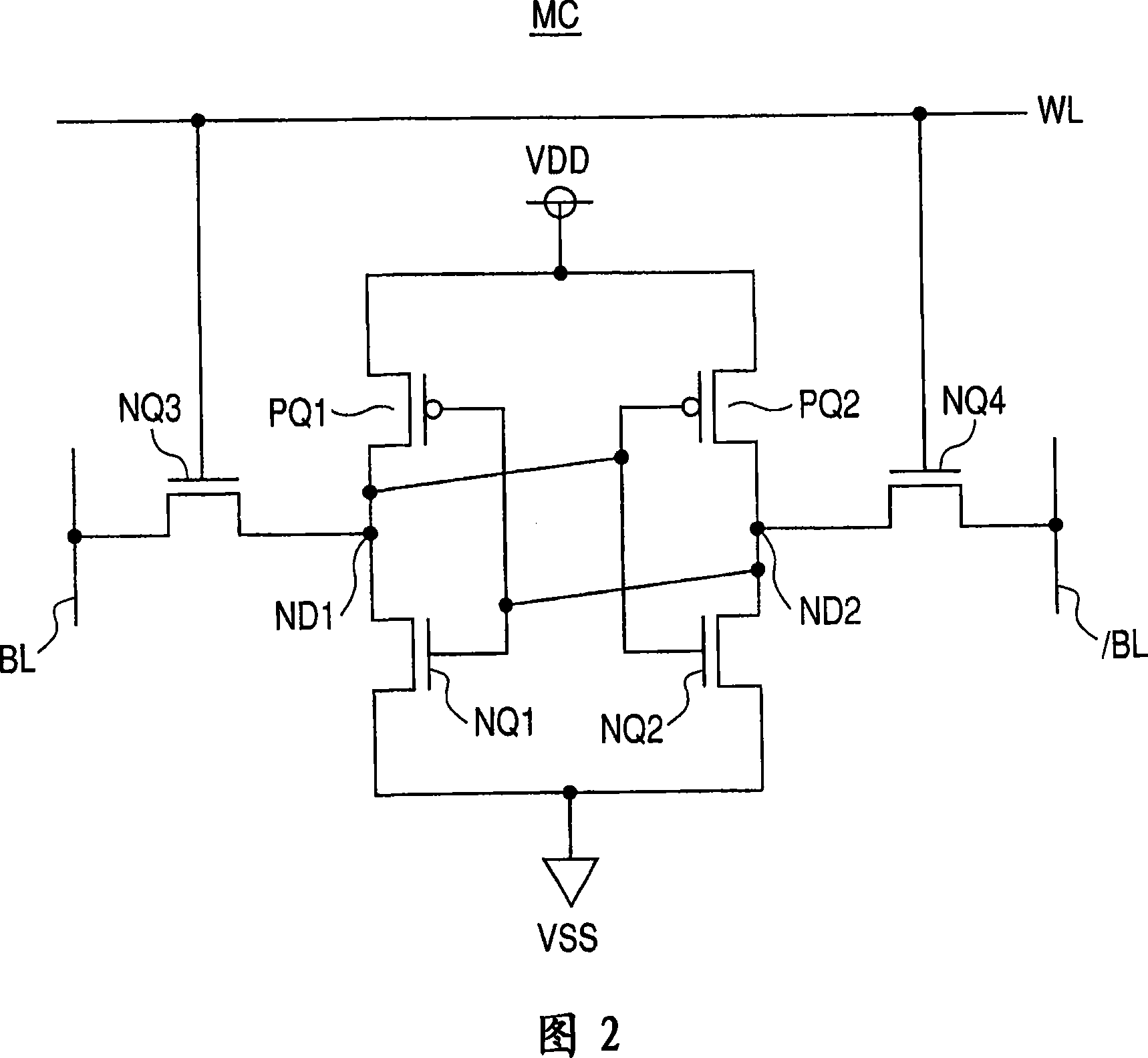

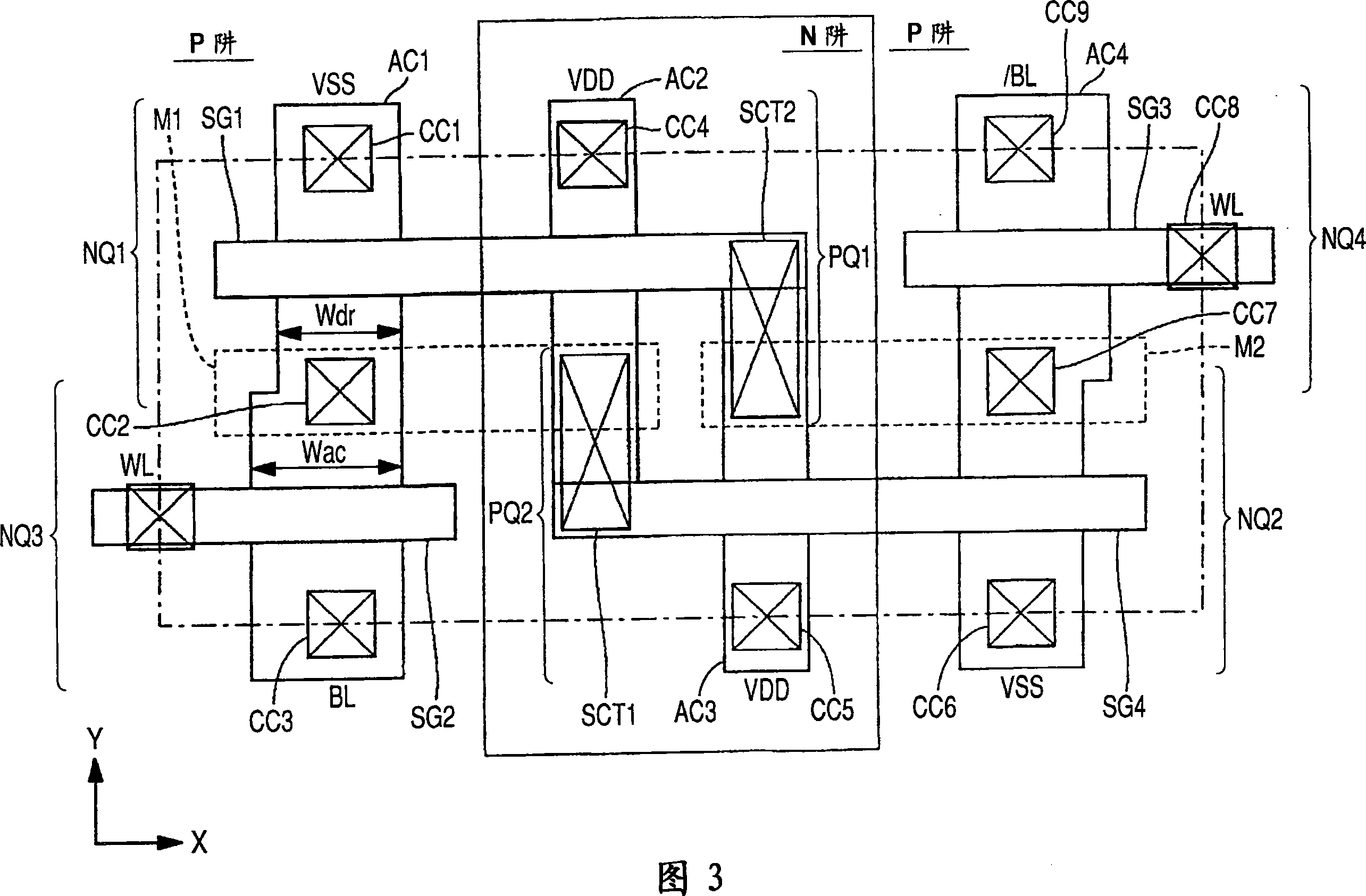

Semiconductor memory device

InactiveCN101127356AIncreased characteristic varianceReduce the amount of impuritiesTransistorSolid-state devicesEngineeringChannel width

The semiconductor memory device which can suppress that the characteristics variation of a transistor increases in connection with microfabrication is offered. In the memory cell of the present invention, channel width of an access transistor is made larger than the channel width of a driver transistor about the relation of the channel width of an access transistor and a driver transistor. That is, since the access transistor can make channel area increase from the driver transistor designed with the minimum designed size, it becomes possible to suppress the increase in the characteristics variation of an access transistor.

Owner:RENESAS TECH CORP

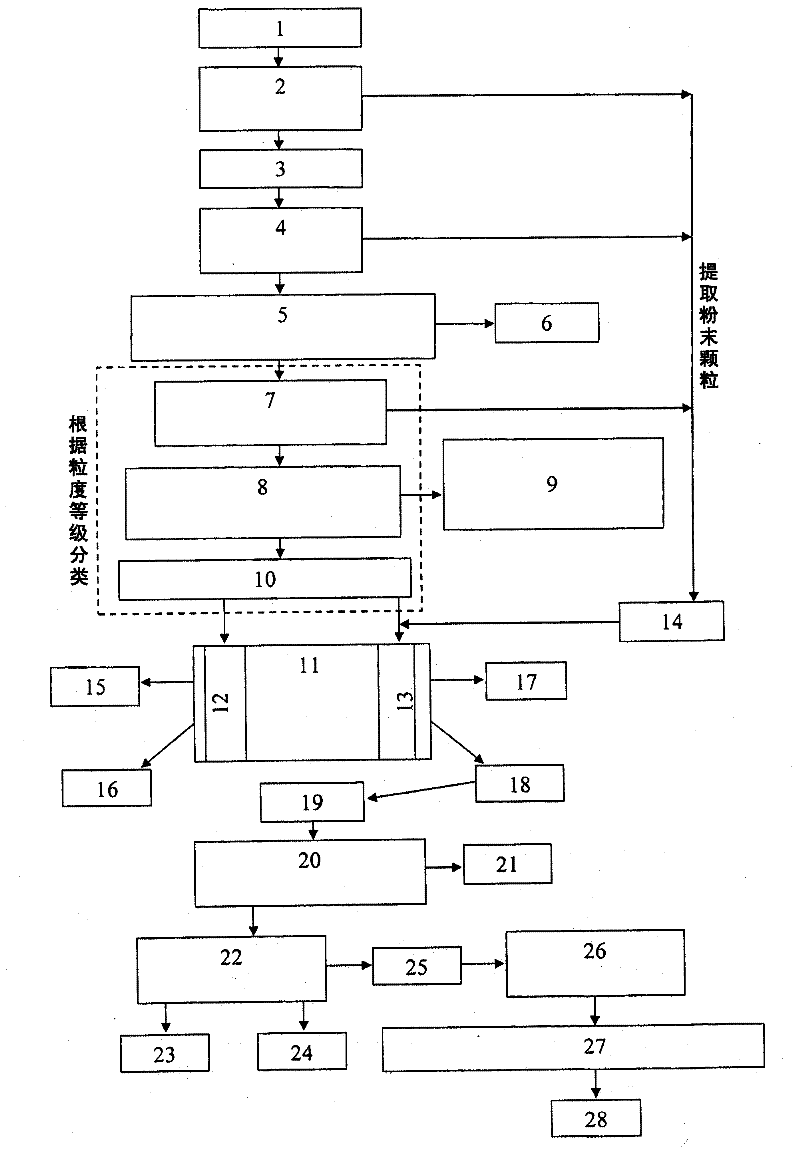

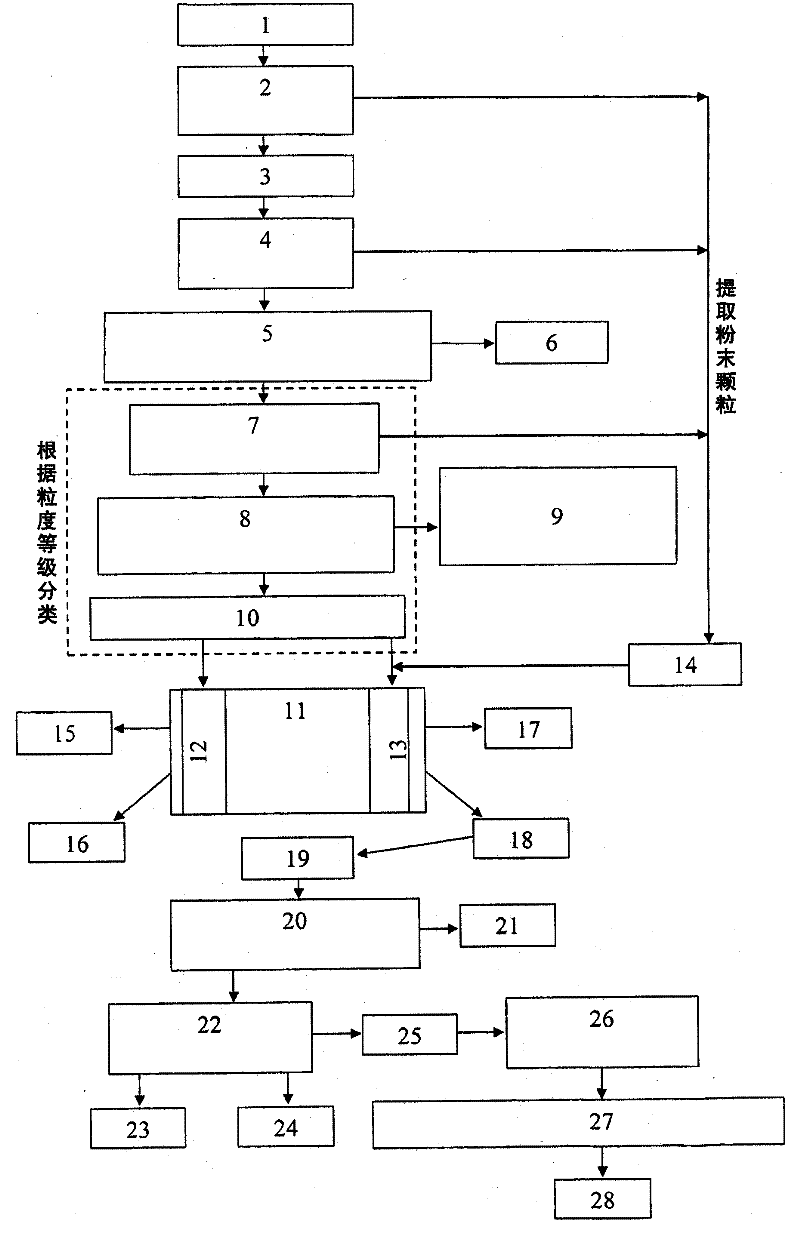

Method for the dry beneficiation of wollastonite ores

InactiveCN102239014AReduce wasteReduce lossesGas current separationMagnetic separationElectrostatic separationPrill

The invention relates to the beneficiation of mineral deposits and can be used for beneficiating wollastonite ores. The method for the dry beneficiation of a wollastonite ore involves the primary and secondary crushing of the ore, the material drying between said crushing stages, the X-ray fluorescent separation of the crushed material after the secondary crushing stage, the classification of the material according to grain-size categories immediately after the X-ray fluorescent separation by sequentially carrying out impact grinding, magnetic separation on a belt conveyor, and air sizing. Then, the method involves the magnetic separation on a roll-type separator for removing impurities from the different size wollastonite concentrate and the extraction of material flour particles at the primary and secondary crushing stages and during the impact grinding of the ore. All the extracted flour particles are delivered to one of the rolls of the roll-type separator, the wollastonite concentrate of one or more grain-sizes is dried and, then, the dried concentrate is exposed to electrostatic separation for removing impurities therefrom. Subsequently, the air sizing of the product received after electrostatic separation is carried out in order to divide said product into fractions having different grain-size. One or more product fractions are additionally crushed and electrostatic charge is removed. The proposed invention makes it possible to improve the product quality and to reduce wollastonite waste.

Owner:阿莱克希・亚利桑德罗维奇・诺萨切夫

Method for producing ammonium polyphosphate by using stepwise reaction and polymerization

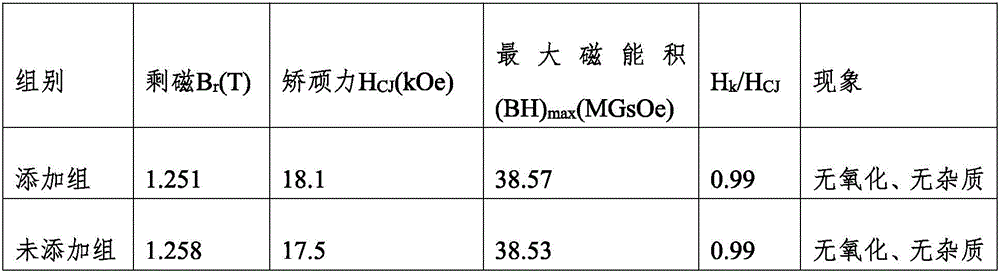

The invention discloses a method for producing ammonium polyphosphate by using a stepwise reaction and polymerization, relates to a method for producing ammonium polyphosphateproducts with different polymerization degrees in the same set of device, in particular to a production method of ammonium polyphosphate with high purity, high polymerization degree and the average polymerization degree larger than 1000. The method comprises the following steps in sequence: a. adding a polycondensation agent into polyphosphoric acid as a raw material in the weight ratio of 1:1 and mixing evenly; b. adding the material obtained by the step a into a continuous synthetic reactor for reacting; and c. further polymerizing products obtained in the step b for 30-300 minutes at the pressure of 0.00MPa-0.6MPa and the temperature of 120DEG C-500DEG C to obtain the high-purity ammonium polyphosphate products with the polymerization degree of 10-1,800. The invention has the advantages of convenient production and control, high yield, low energy consumption and benefit for large-scale continuous industrial production.

Owner:YUNNAN CHEM RES INST

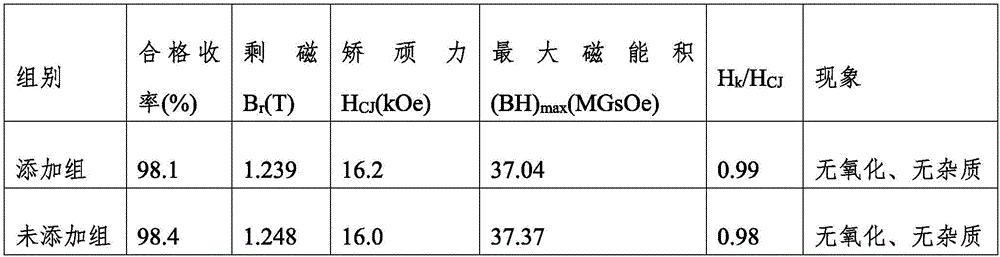

Ultrafine NdFeB powder recovery method

ActiveCN105921736AReduce cost inputSave human effortTransportation and packagingMetal-working apparatusRecovery methodAlloy

The invention belongs to the technical field of comprehensive utilization of waste resources, and particularly relates to an ultrafine NdFeB powder recovery method. The method comprises the following steps: conducting anti-oxidation protection on the ultrafine NdFeB powder, and then transferring the ultrafine NdFeB powder subjected to the anti-oxidation protection to a high-temperature-resistant sintering box; carrying out stage-type heating sintering treatment to achieve 1000-1100 DEG C, and carrying out heat preservation for 1-2 h; and carrying out vacuum self-cooling to achieve material temperature of 880-920 DEG C, and then carrying out inflation air-cooling to reduce the material temperature to 50 DEG C or below, thereby obtaining an ultrafine NdFeB powder alloy. The method provided by the invention is low in cost, simple in technological process, easy to operate and high in recovery rate; microelements are effectively utilized and the resource waste problem is effectively solved; and the ultrafine NdFeB powder alloy recovered according to the method is low in impurity level and reasonable in composition.

Owner:CHINALCO JINYUAN RARE EARTH

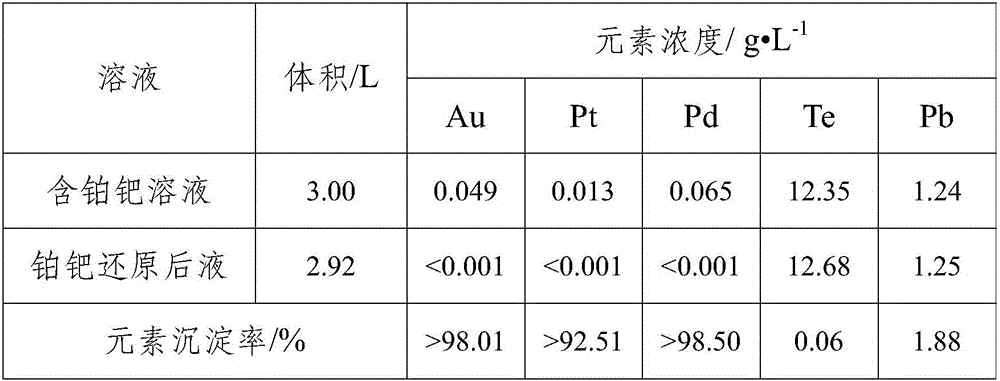

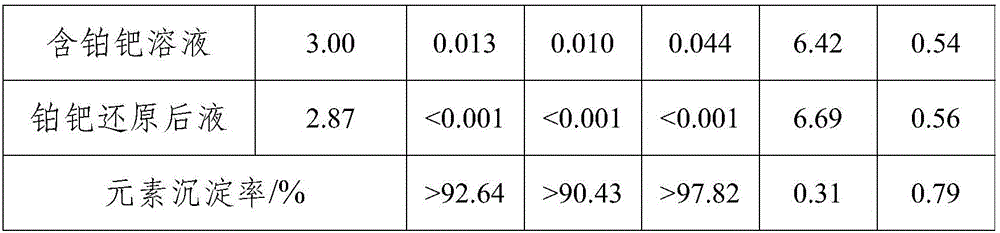

Method for gathering platinum and palladium in solution

The invention provides a method for gathering platinum and palladium in a solution, and relates to separation and recycling of rare and precious metals in wet metallurgy. The method comprises the following steps of taking a solution containing platinum and palladium as a stock solution; carrying out selective reduction by controlling electric potential; and converting the platinum and the palladium in the solution into simple substances and precipitating to obtain concentrate which is rich in platinum and palladium. The method is characterized in that a substance which does not contain heavy metal elements is used as a reducing agent, electric potential of reaction liquid is controlled, the platinum and the palladium in the solution are selectively reduced and precipitated to be below 1 mg / L, and therefore, the platinum and palladium gathering effect is achieved. Compared with a traditional reactive metal substitution method, the method is low in cost and easy to operate, and has good adaptability on stock solutions with different components, and the obtained concentrate containing the platinum and the palladium has little slag, and is high in platinum and palladium gathering degree.

Owner:JIANGXI COPPER CORP

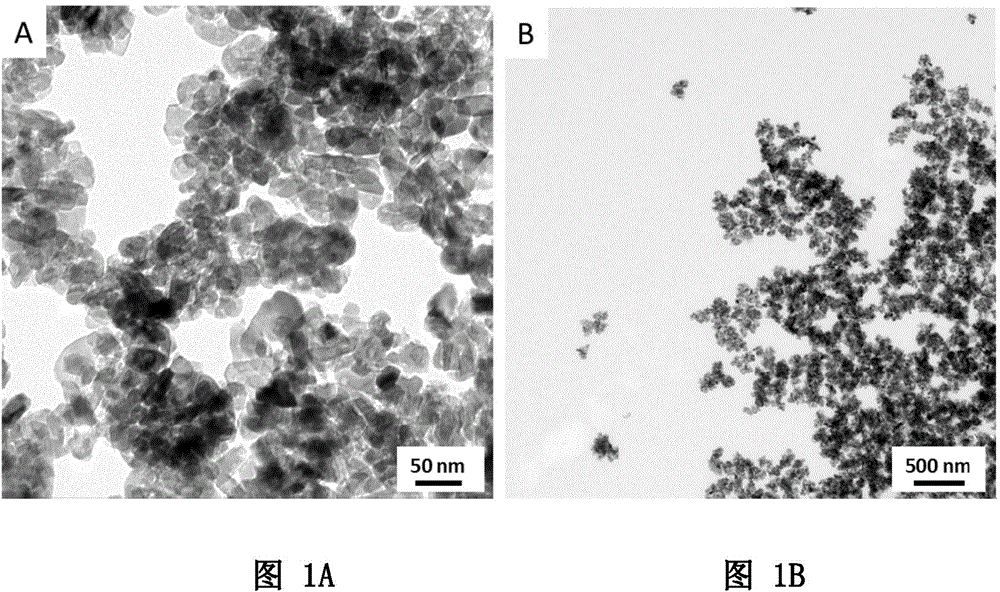

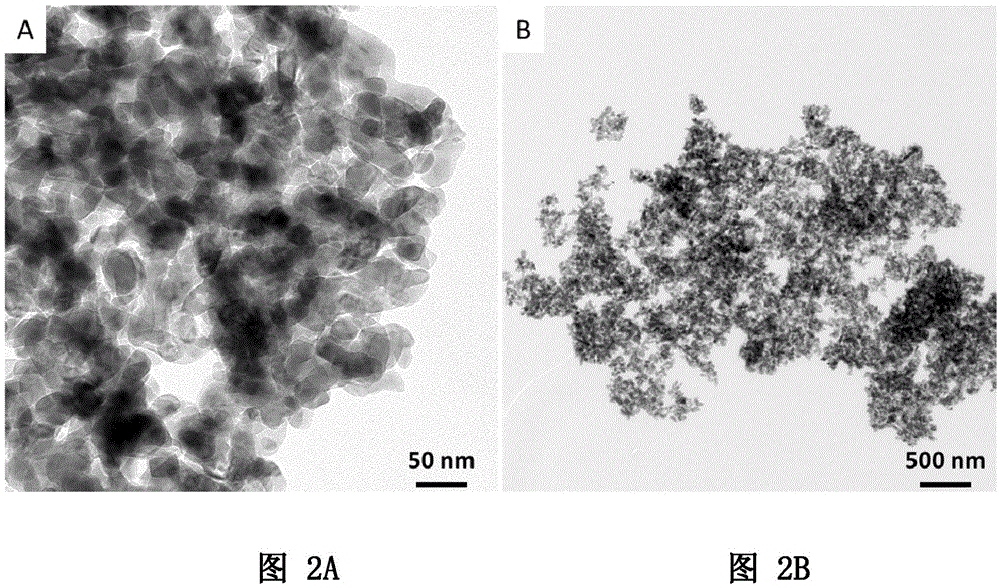

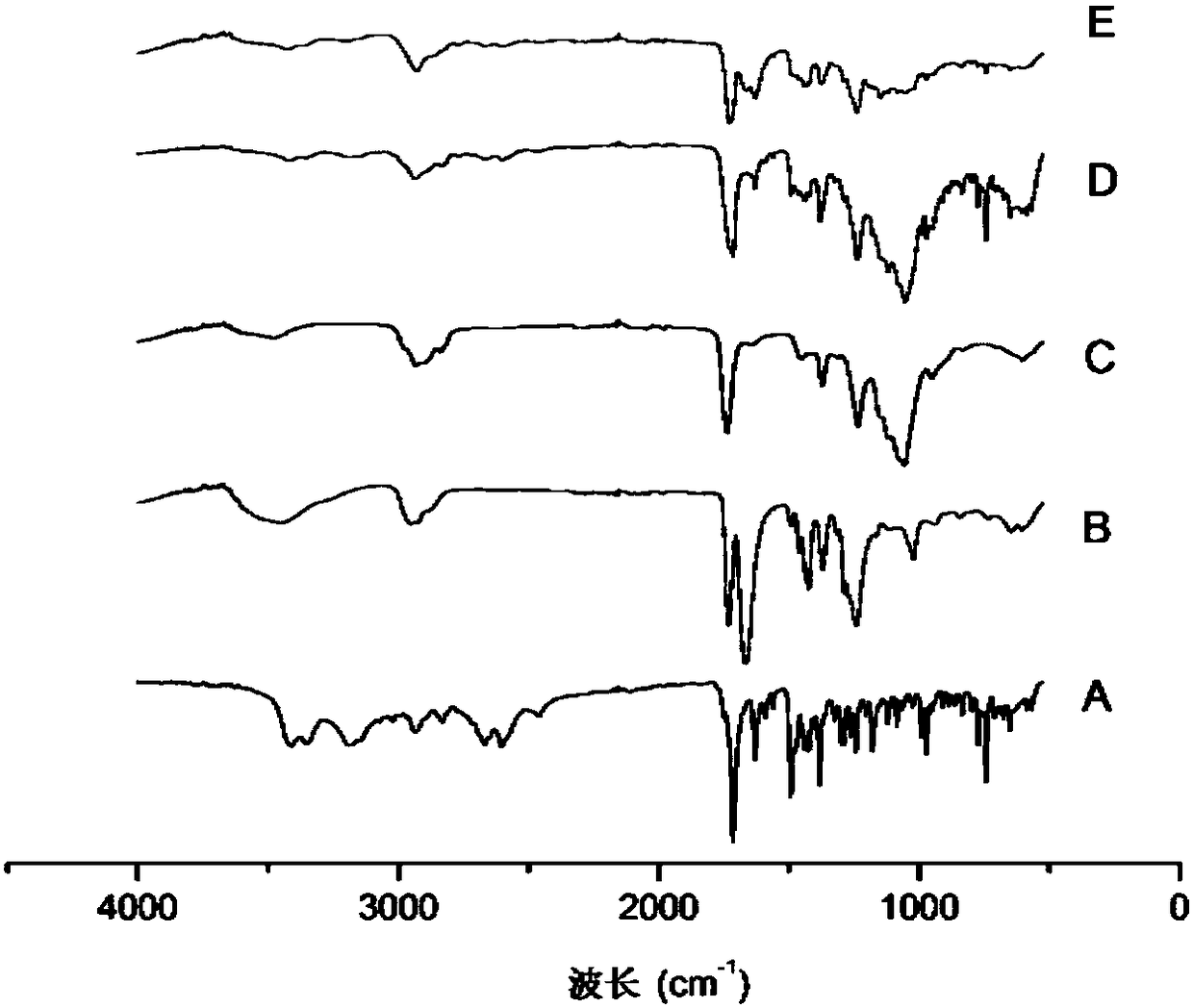

A preparing method of rutile vanadium dioxide nanometer particles and the particles

InactiveCN105753050AInnovativeLow priceMaterial nanotechnologyVanadium oxidesVanadium CompoundsVanadium dioxide

A preparing method of rutile vanadium dioxide nanometer particles is disclosed. The method includes 1) preheating purified water or deionized water until the water is boiling, adding a vanadium compound, stirring to obtain a vanadium compound suspension A, cooling to room temperature, adding ammonia water, sealing a container, and stirring for 0.5-3 h until a transparent solution B is prepared, 2) adding a hydrazine compound into the transparent solution B, stirring to obtain black suspension C, transferring the suspension C to a hydrothermal reactor, heating and reacting to obtain a black brown suspension D, 3) transferring the black brown suspension D into a transparent container, adding ethanol, allowing the mixture to stand so that the mixture is layered naturally after the solution is stationary, removing the supernatant liquid, adding ethanol again, stirring, allowing the mixture to stand, naturally layering, and removing the supernatant liquid again to obtain wet powder E, and 4) drying and oxidizing the wet powder E in a drying oven, firing in an atmosphere furnace containing a protective atmosphere, and treating to obtain the rutile vanadium dioxide nanometer particles. Raw materials of the method are cheap. The method greatly reduces emission of 'three wastes' or secondary environment pollution.

Owner:刘闽苏

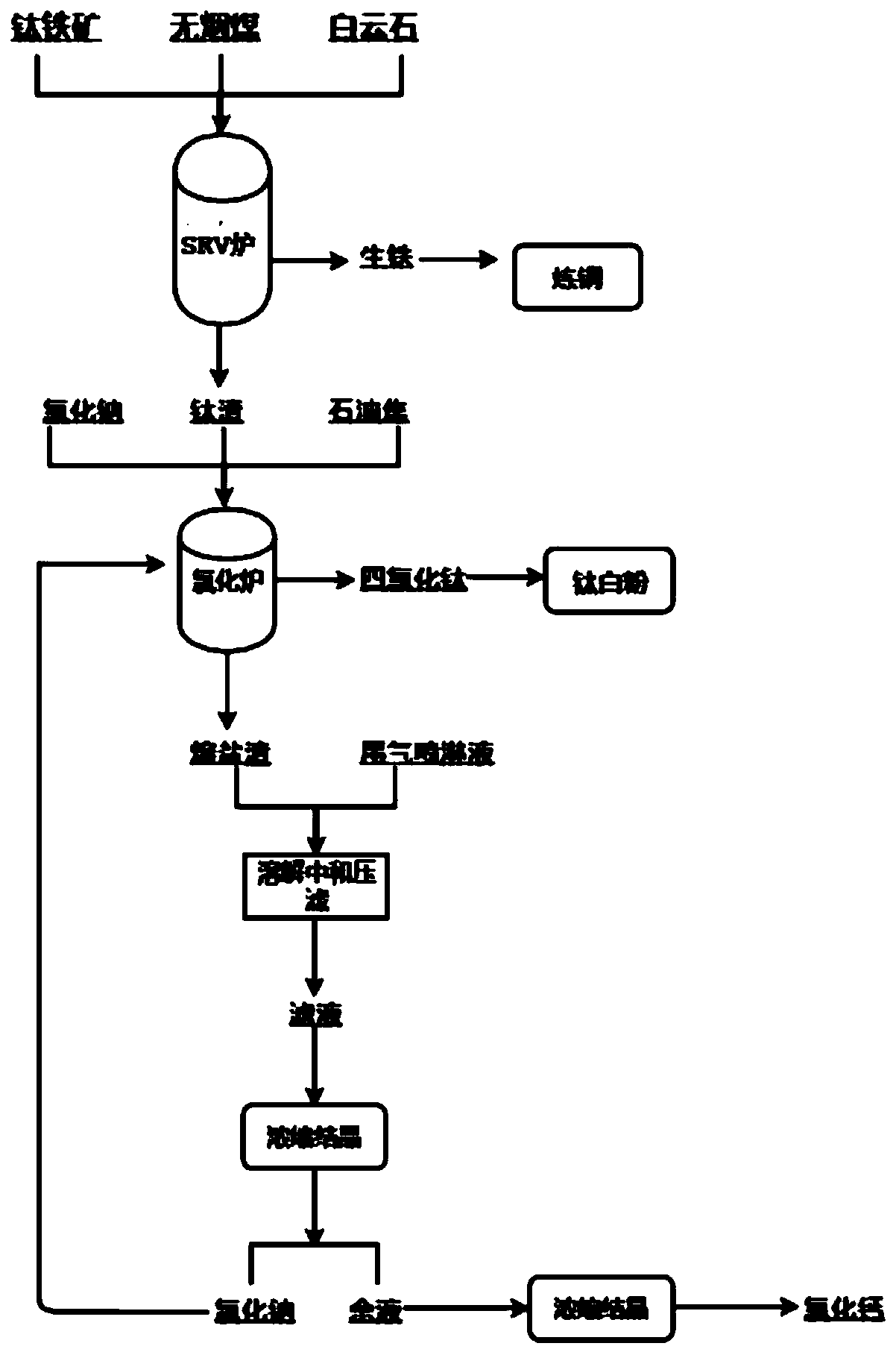

Method for producing titanium slag and titanium white chloride by using Panzhihua ilmenite

InactiveCN110606506AWide applicabilityReduce accumulationCalcium/strontium/barium chloridesTitanium tetrachlorideTitanium tetrachlorideImpurity

The invention discloses a method for producing titanium slag and chlorinated titanium dioxide by using Panzhihua ilmenite, and relates to the field of metallurgy and chemical engineering. The method comprises the following steps: firstly, carrying out reduction smelting on ilmenite by utilizing an HIsmelt smelting reduction technology to obtain titanium slag and pig iron; then feeding the titaniumslag as a raw material into a chlorination furnace, producing titanium dioxide by adopting a molten salt chlorination method; recycling and separating molten salt slag obtained in the production process, and returning the separated sodium chloride into the chlorination furnace. In the titanium slag smelting process, ilmenite powder can be directly utilized, wherein a reducing agent can be commonanthracite with low requirements or contains part of bituminous coal; meanwhile, smelting can be conducted at a low temperature, energy consumption is greatly reduced, and the additional value of by-product pig iron is high; in titanium dioxide chloride production by using the titanium slag, the cyclone dust removal device has a good dust collection effect on flue gas, reduces the impurity contentin crude titanium tetrachloride, effectively utilizes the molten salt slag, reduces the accumulation amount of the molten salt slag, and has good green and environment-friendly significance.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

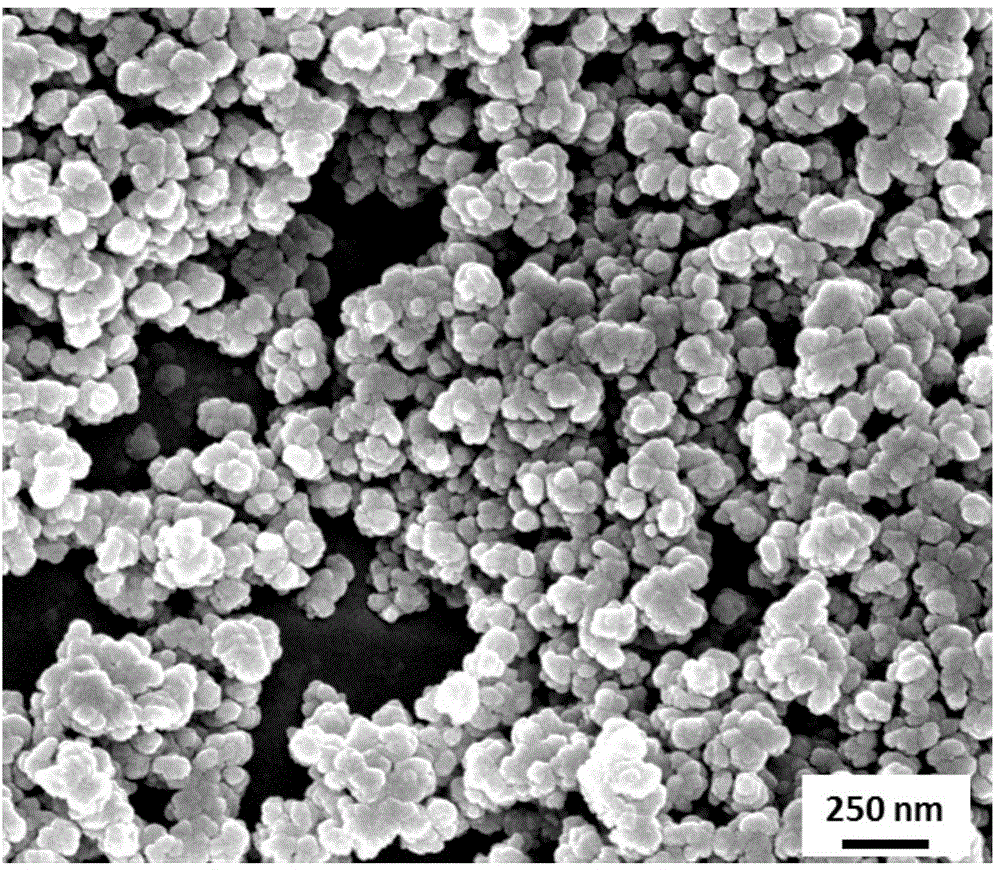

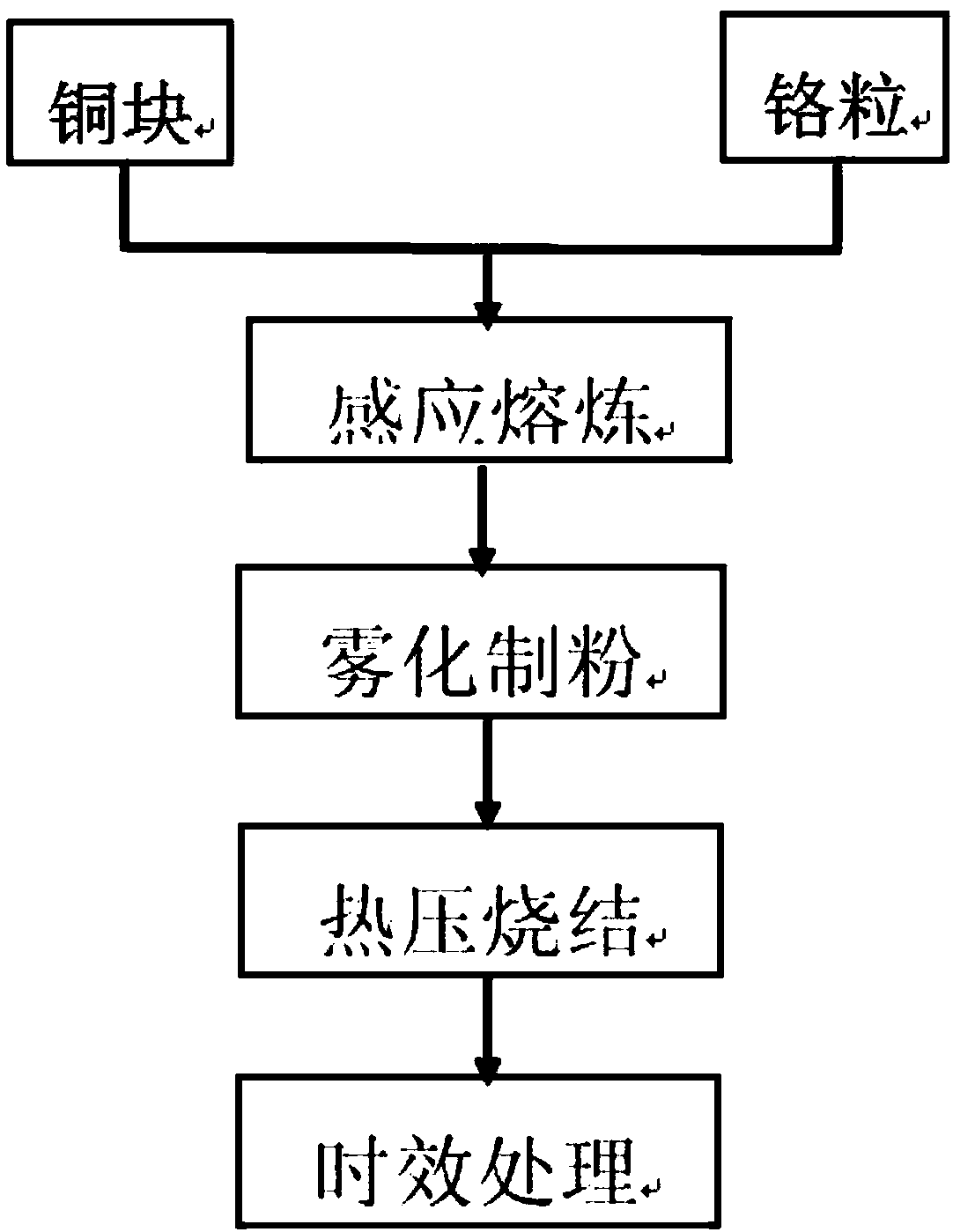

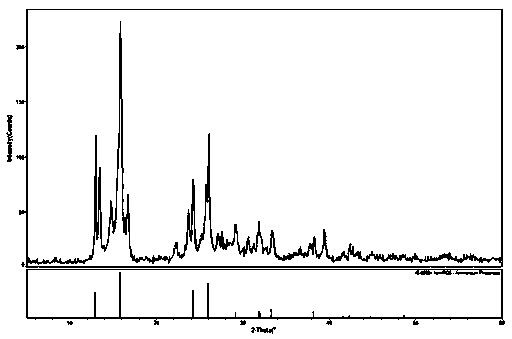

Preparation method of aging-enhanced copper-chromium alloy

InactiveCN107604200AReduce the amount of impuritiesGood alloy composition uniformitySolid solubilityNitrogen gas

The invention discloses a preparation method of an aging-enhanced copper-chromium alloy. The preparation method comprises the following steps that 1, vacuum induction melting is carried out by adopting nitrogen as a protective gas; 2, powder is prepared through atomization by using a ring hole limiting type atomizer; 3, screening is carried out on the atomized alloy powder according to different particle sizes; and 4, hot pressed sintering and aging treatment are carried out in the alloy powder with a certain particle size to obtain the copper-chromium alloy. According to the preparation method of the copper-chromium alloy, the solid solubility of chromium in copper is improved; compared with an alloy prepared through a mechanical ball milling method, the alloy is better in component uniformity; the copper-chromium alloy prepared through gas atomization has fine grain structures and relatively high degree of supersaturation of chromium, and the obtained alloy sample has high conductivity and strength; and phases precipitated from the alloy powder obtained after sintering are small in size and large in number, and the alloy powder can be used for materials of high-energy electric conduction elastic devices and electrical contacts in the aerospace field.

Owner:XIAN UNIV OF TECH

Method for preparing extracts rich in vitexin rhamnoside and vitexin glucoside

InactiveCN102920727AReduce manufacturing costSimple process routeOrganic active ingredientsSugar derivativesIsobutyl alcoholChinese herbs

The invention provides a method for preparing extracts rich in vitexin rhamnoside and vitexin glucoside, and relates to the field of herbal extracting. The method comprises the following steps: a water solution of Chinese hawthorn crude extract is used for being passed through macroporous adsorption resin columns or polyamide columns, and water, solvents, solvents A containing sodium bicarbonate or potassium bicarbonate are used to elute target composition, and eluting liquid is collected. The potential of hydrogen (pH) is adjusted to be between 6 and 7.5, organic solvents are removed, eluting liquid free of the organic solvents is obtained, normal butanol or isobutyl alcohol is used for extracting the target composition, and the solvents are recovered to dry. Or the water solution of the Chinese hawthorn crude extract is used for being passed through the macroporous adsorption resin columns or the polyamide columns, salt is eluted by the water, and then solvents B are used to elute the target composition, the eluting liquid is recovered, and the extracts rich in the vitexin rhamnoside and the vitexin glucoside are obtained after the eluting liquid is dried. According to the method, the vitexin rhamnoside is 30%-55% of the extracts, and the vitexin glucoside is 10%-35% of the extracts.

Owner:苏州衷中医药科技有限公司

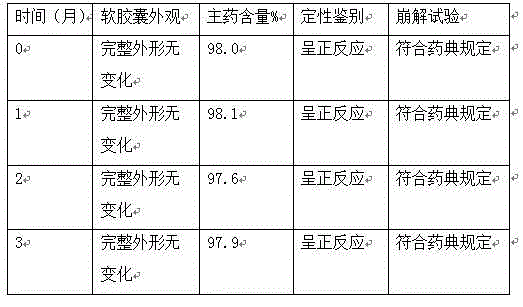

Xanthophyll soft capsule and preparation method thereof

InactiveCN104435355AReduce the amount of impuritiesImprove absorption and utilizationSenses disorderHydroxy compound active ingredientsResearch resultMoisture

The invention discloses a xanthophyll soft capsule. The soft capsule consists of two parts of liquid medicine and a capsule shell. The soft capsule is characterized in that the liquid medicine consists of 5-30mg of xanthophyll, 10-40mg of Chinese wolfberry extracts, 1-10mg of vitamin E and 100-400mg of linseed oil, wherein the liquid medicine of each soft capsule contains 5-40mg of xanthophyll and Chinese wolfberry extracts in parts by weight. According to the invention, high-purity xanthophyll crystal powder is used as a raw material to be made into the soft capsule, the absorption is better, the action is more prominent, and the effect is more significant. Research results show that whether the soft capsule is placed at a room temperature or the soft capsule is in a high-temperature high-moisture accelerated test, the phenomena that the outer shells of the capsule are deformed and cracked and contents overflow are avoided; besides, effective components are all stable when the soft capsule is in a disintegration test, qualitative identification and content measurement, which indicates that the stability of the xanthophyll composite soft capsule preparation disclosed by the invention is good.

Owner:福建省科奥生物技术研发中心有限公司

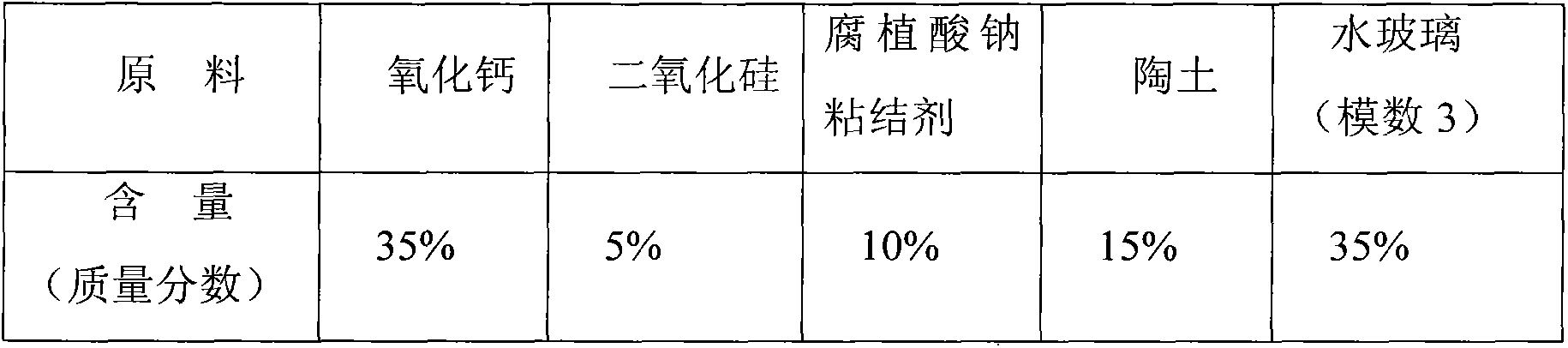

Iron ore cooled agglomerated pellet binder

The invention relates to the field of metallurgy and particularly relates to an iron ore cooled agglomerated pellet binder comprising calcium oxide, silicon dioxide, pottery clay and water glass. The binder disclosed by the invention is economic and practical and has high commercial values; and the binder is applied to the field of metallurgy and has the benefits that raw materials are saved and enterprise benefit is increased.

Owner:承德石油高等专科学校

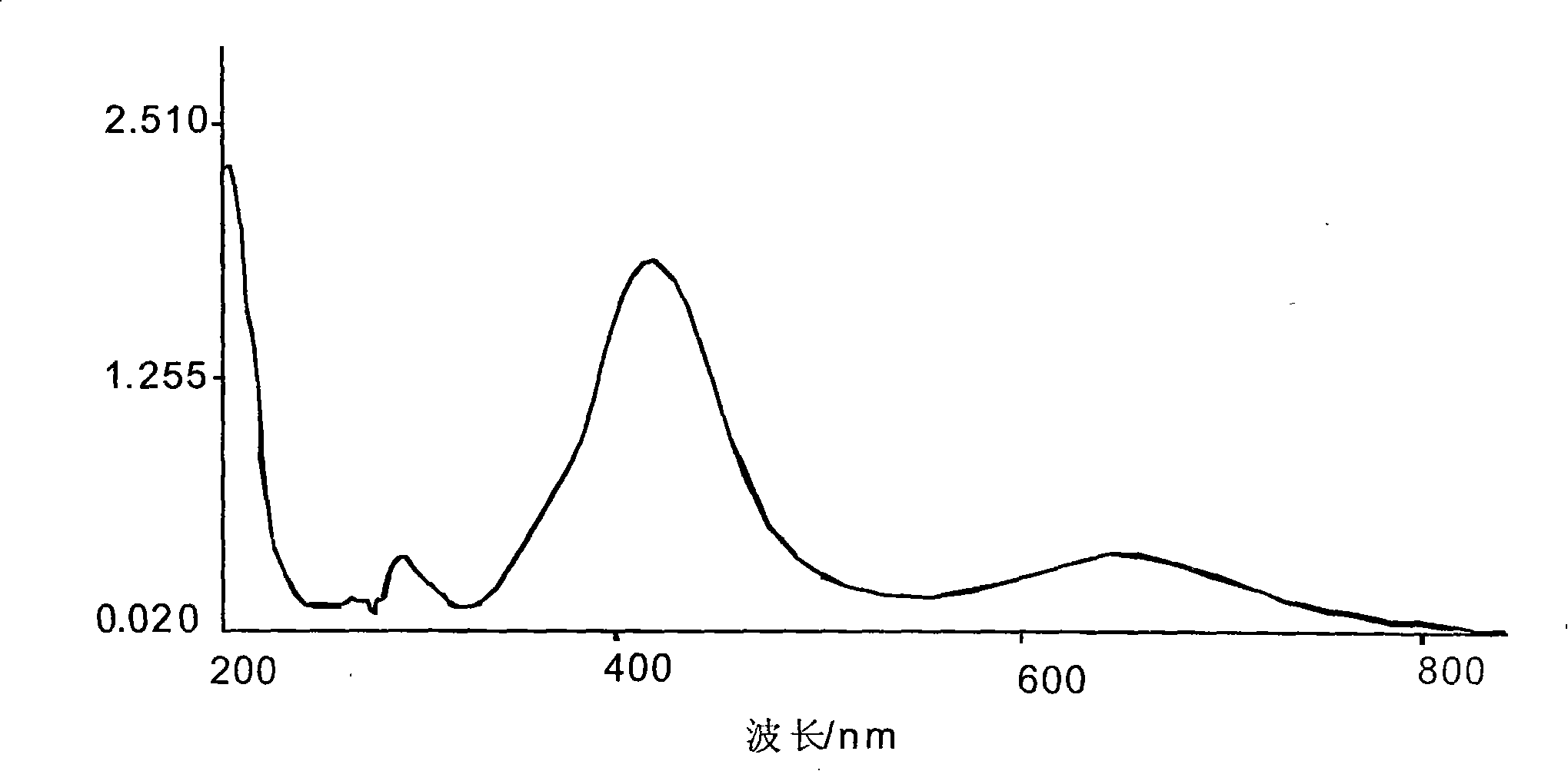

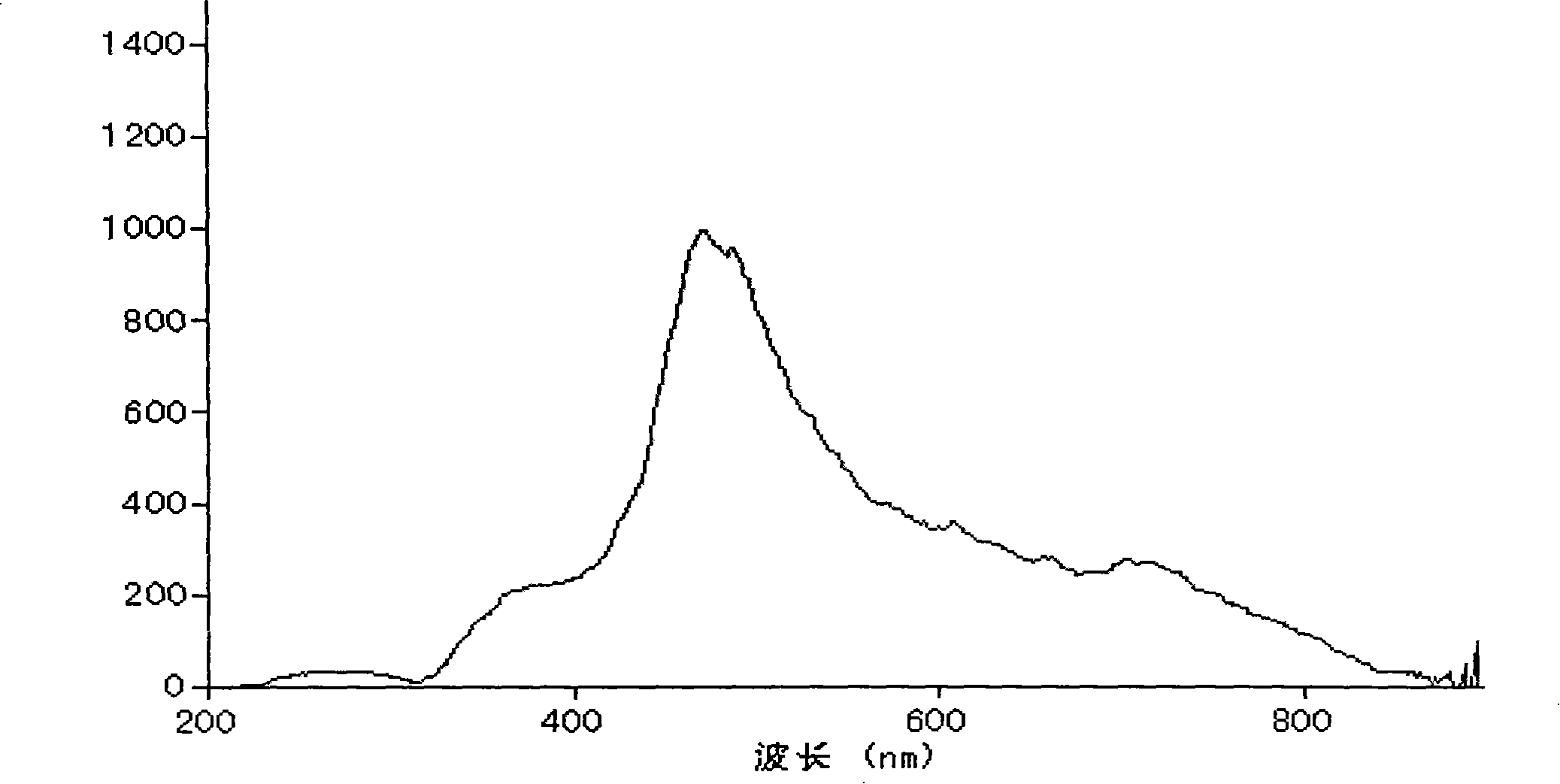

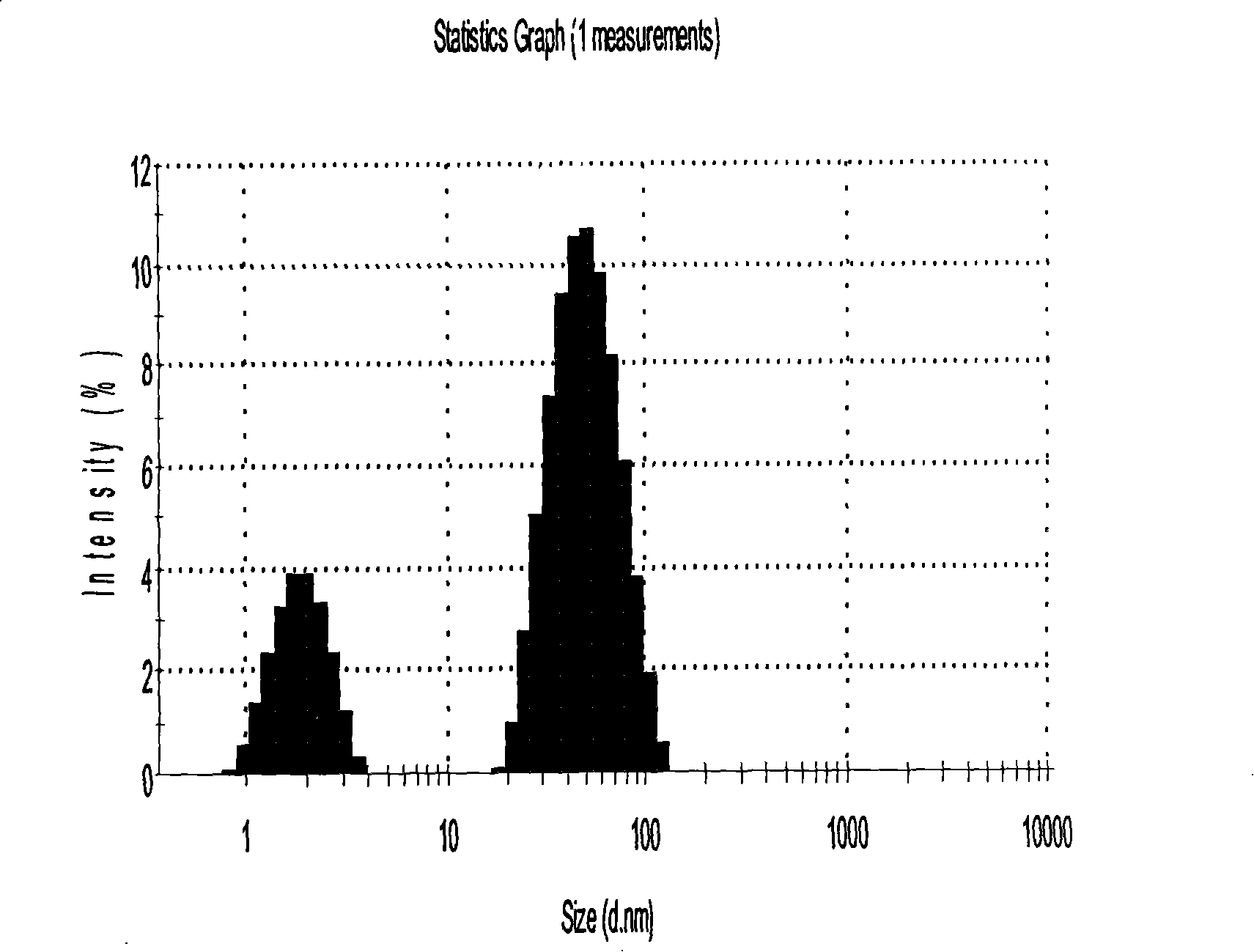

Method for simply and rapidly producing green silver nano-particle

The invention discloses a process for rapidly and conveniently preparing green silver nanometer particles, which is characterized in that the process comprises mixing AgNO3 solution, sodium citrate solution and little water under normal temperature, dropping ascorbic acid solution under a condition of magnetic stirring, and enabling to produce the green silver nanometer particles. The invention has the advantages that the process for preparation is simple, raw materials are easy to be obtained, single green silver nanometer particle can be prepared with good stability and dispersing property.

Owner:GUANGXI NORMAL UNIV

Single-Crystalline Aluminum Nitride Substrate and a Manufacturing Method Thereof

ActiveUS20140346638A1Reduce the amount of impuritiesGood light transmissionPolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalLength wave

The present invention relates to a single-crystalline aluminum nitride wherein a carbon concentration is 1×1014 atoms / cm3 or more and less than 3×1017 atoms / cm3, a chlorine concentration is 1×1014 to 1×1017 atoms / cm3, and an absorption coefficient at 265 nm wavelength is 40 cm−1 or less.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH +1

Method and device for purifying bromine-extracting waste liquid

PendingCN108529788AReduce turbidityDo not change the effective compositionWater treatment parameter controlSludge treatmentLiquid wasteSaline water

The invention discloses a method and a device for purifying bromine-extracting waste liquid. Waste salt sludge generated in the process of refining saline through a chemical process is selected and used for adjusting pH value of the bromine-extracting waste liquid, and turbidity of the bromine-extracting waste liquid is lowered through secondary coagulation process and air flotation process; the method and the device can be used for purifying high-acidity high-salinity bromine-extracting waste liquid, acid corrosiveness of the waste liquid is lowered remarkably, up-to-standard emission is realized, and no acidic pollution is caused to surrounding environment; various suspended matters can be removed effectively, the bromine-extracting waste liquid after being purified is quite clear, the turbidity is lowered remarkably, and 90% of ingredients like silicon and iron in the bromine-extracting waste liquid can be removed without changing original active composition in the same; through purifying treatment, quality of the bromine-extracting waste liquid is improved greatly, the method and the device can be directly used for salt drying in the sun, vacuum salt making and other process using saline, are low in purifying cost and simple in raw material obtaining way, realize treatment of waste by waste and have remarkable environment protection benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +2

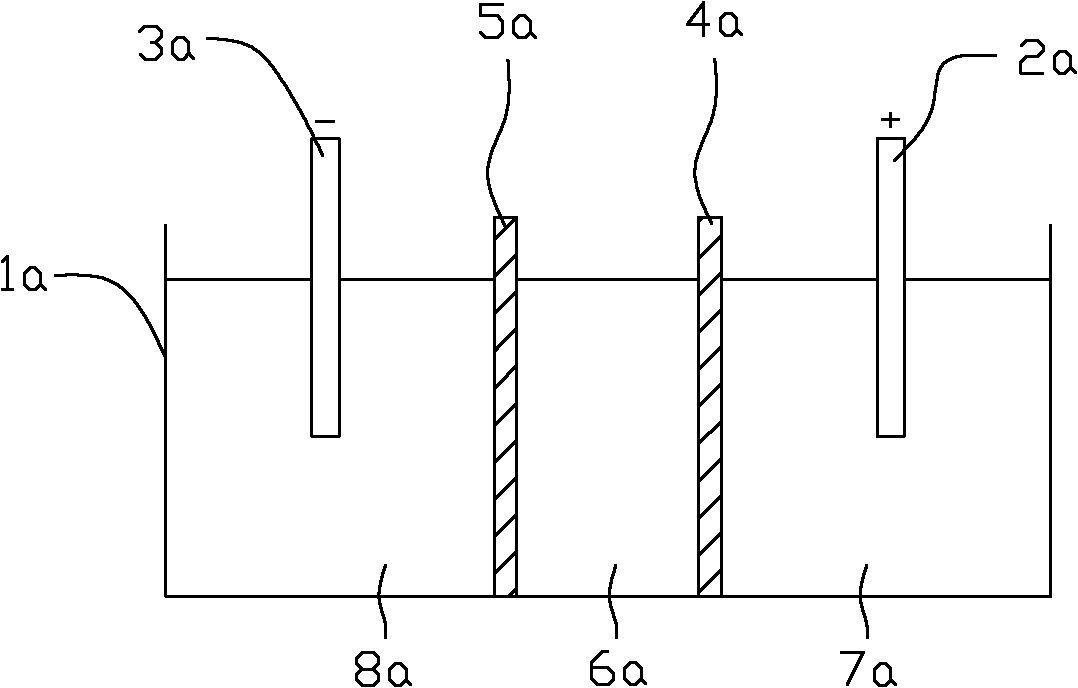

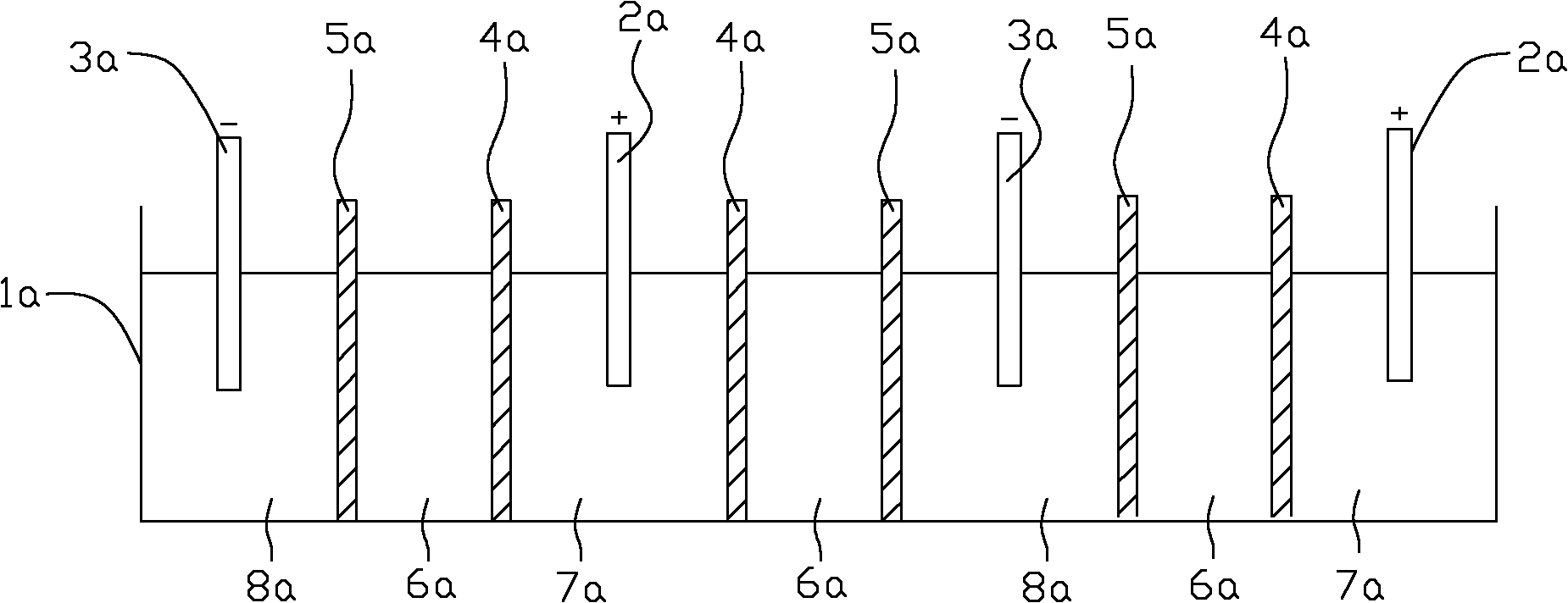

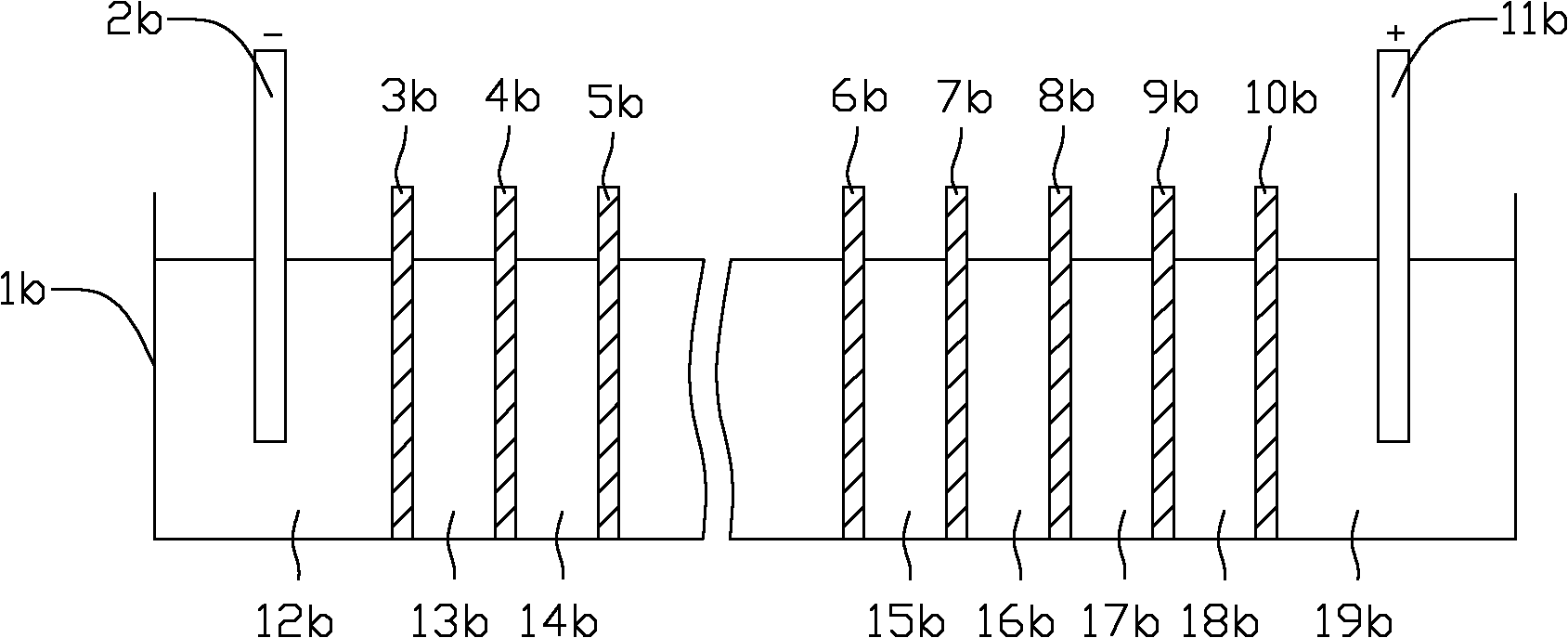

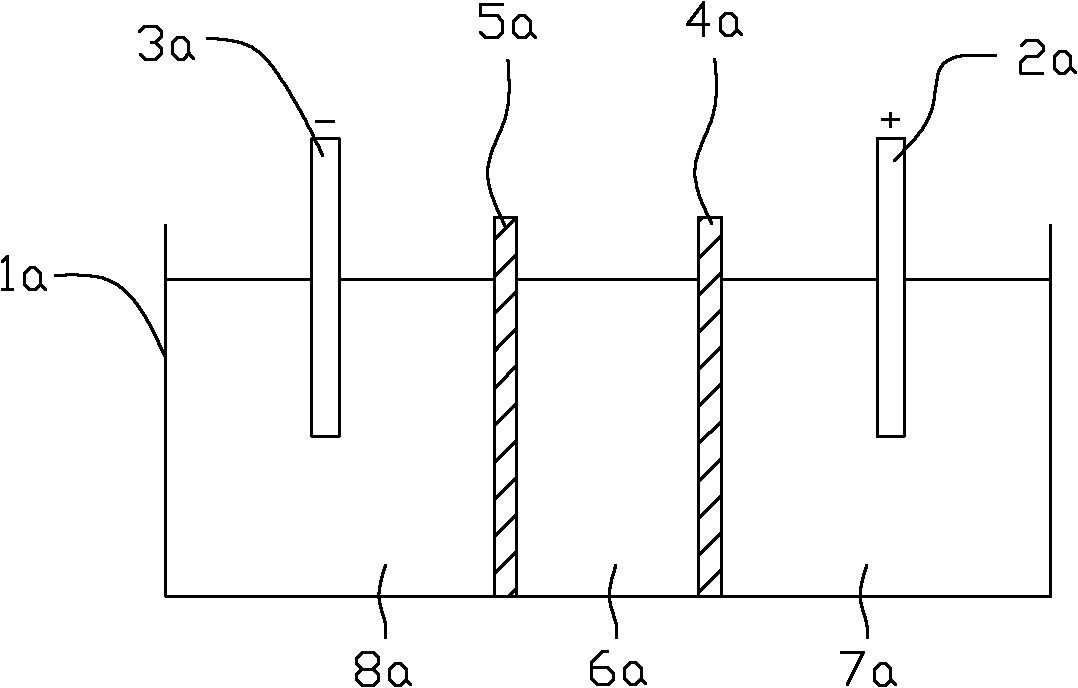

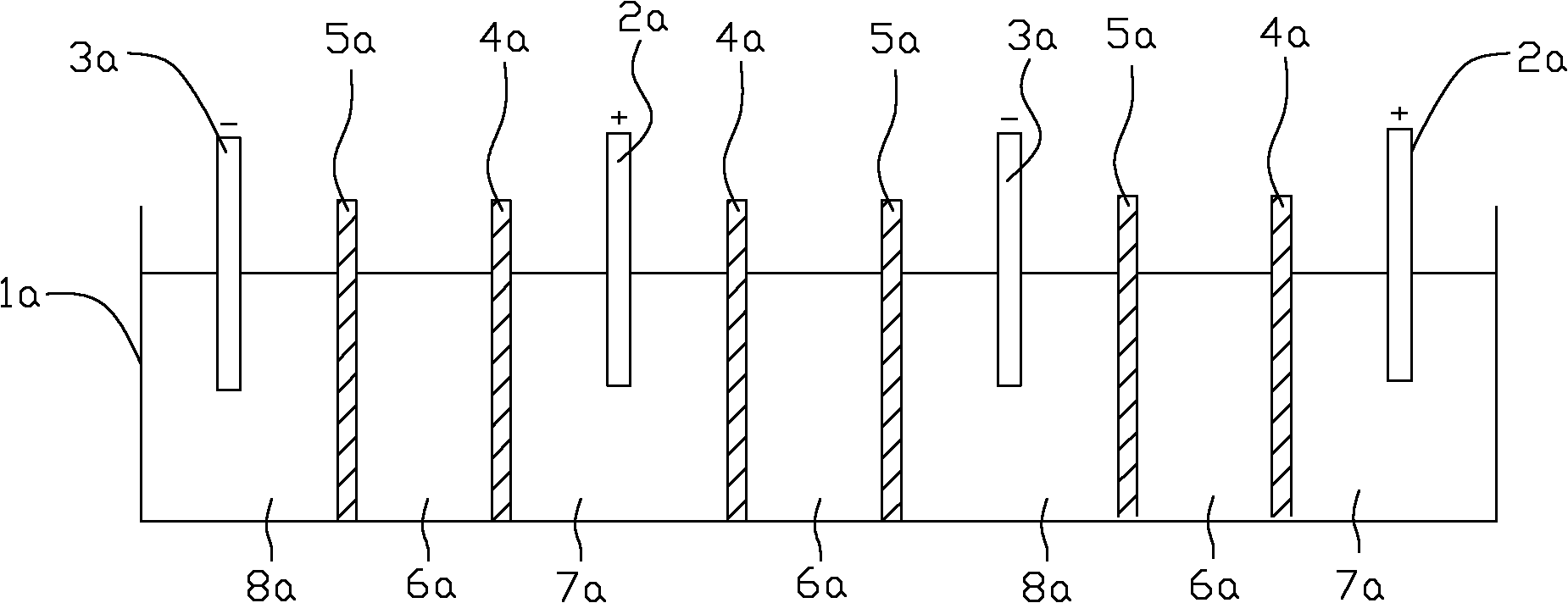

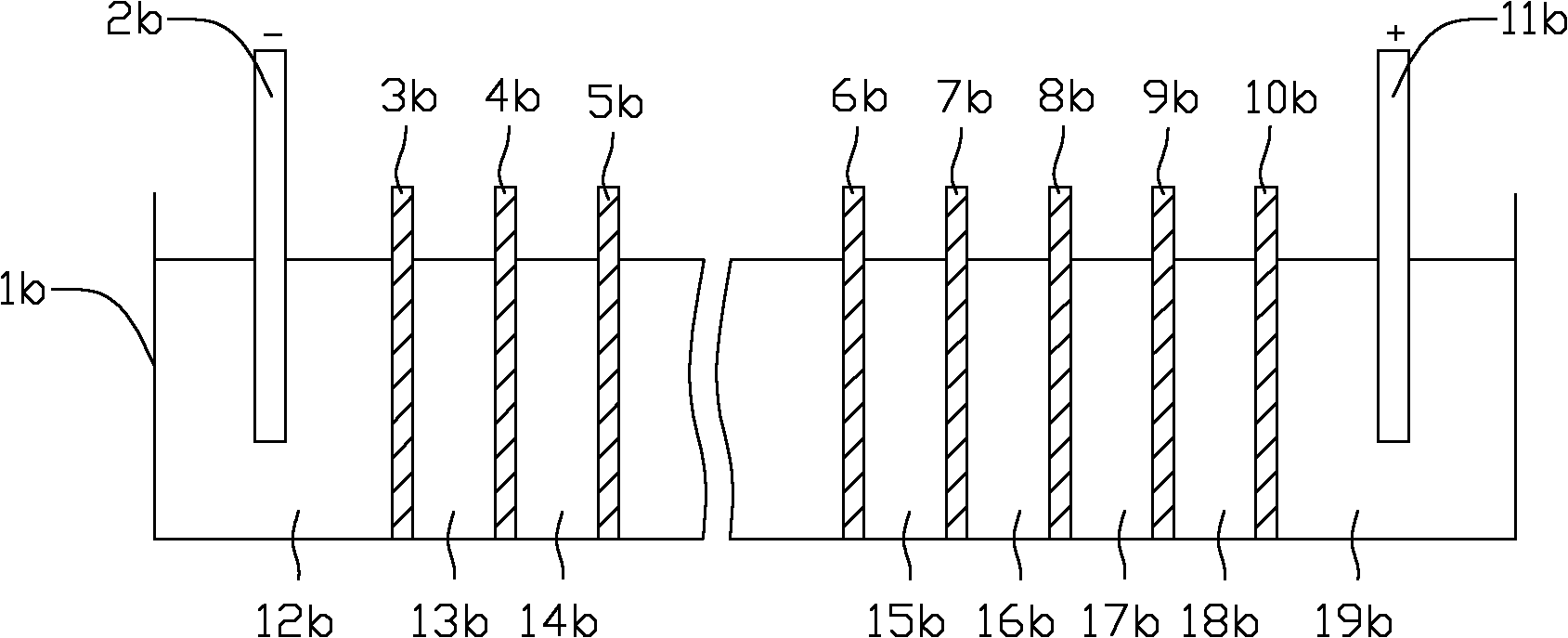

Phosphoric acid purification device

ActiveCN101817513AEasy to separateSimple processPhosphorus compoundsPhosphoric acidIon-exchange membranes

The invention discloses a phosphoric acid purification device utilizing ion exchange membranes for purifying phosphoric acid, which can obtain the high-purity phosphoric acid. The phosphoric acid purification device comprises an electrodialysis device, wherein an anode and a cathode are arranged in the electrodialysis device, a cation exchange membrane and an anion exchange membrane are arranged between the anode and the cathode, an intermediate chamber is formed between the cation exchange membrane and the anion exchange membrane, the cation exchange membrane is near to the cathode, a cathode chamber is formed between the cation exchange membrane and the cathode, the anion exchange membrane is near to the anode, and an anode chamber is formed between the anion exchange membrane and the anode. That is the anode, the anion exchange membrane, the cation exchange membrane and the cathode are sequentially arranged in the electrodialysis device, thereby leading the device to effectively remove the impurities of anions and cations while leading the anions and the cations to pass, further improving the purification effect to the phosphoric acid and being applicable to popularization in the preparation of the food-grade phosphoric acid.

Owner:GUIZHOU CHANHEN CHEM CO LTD

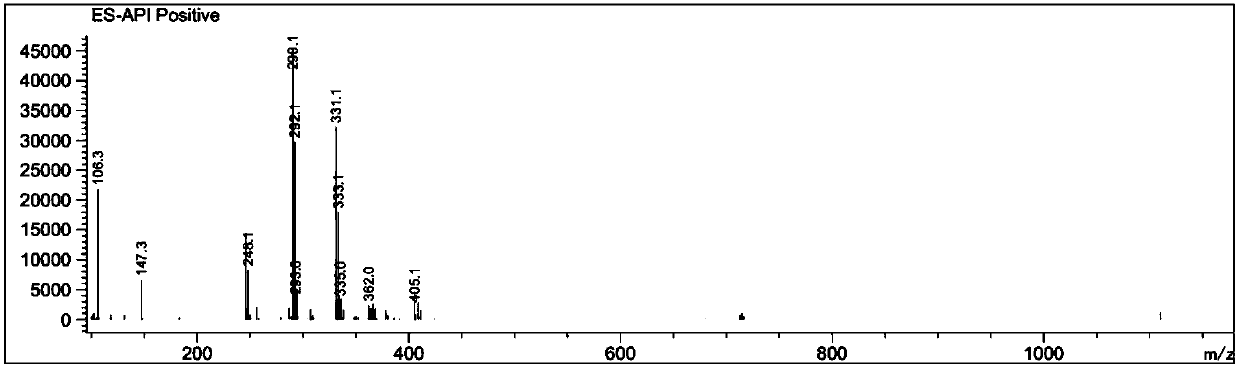

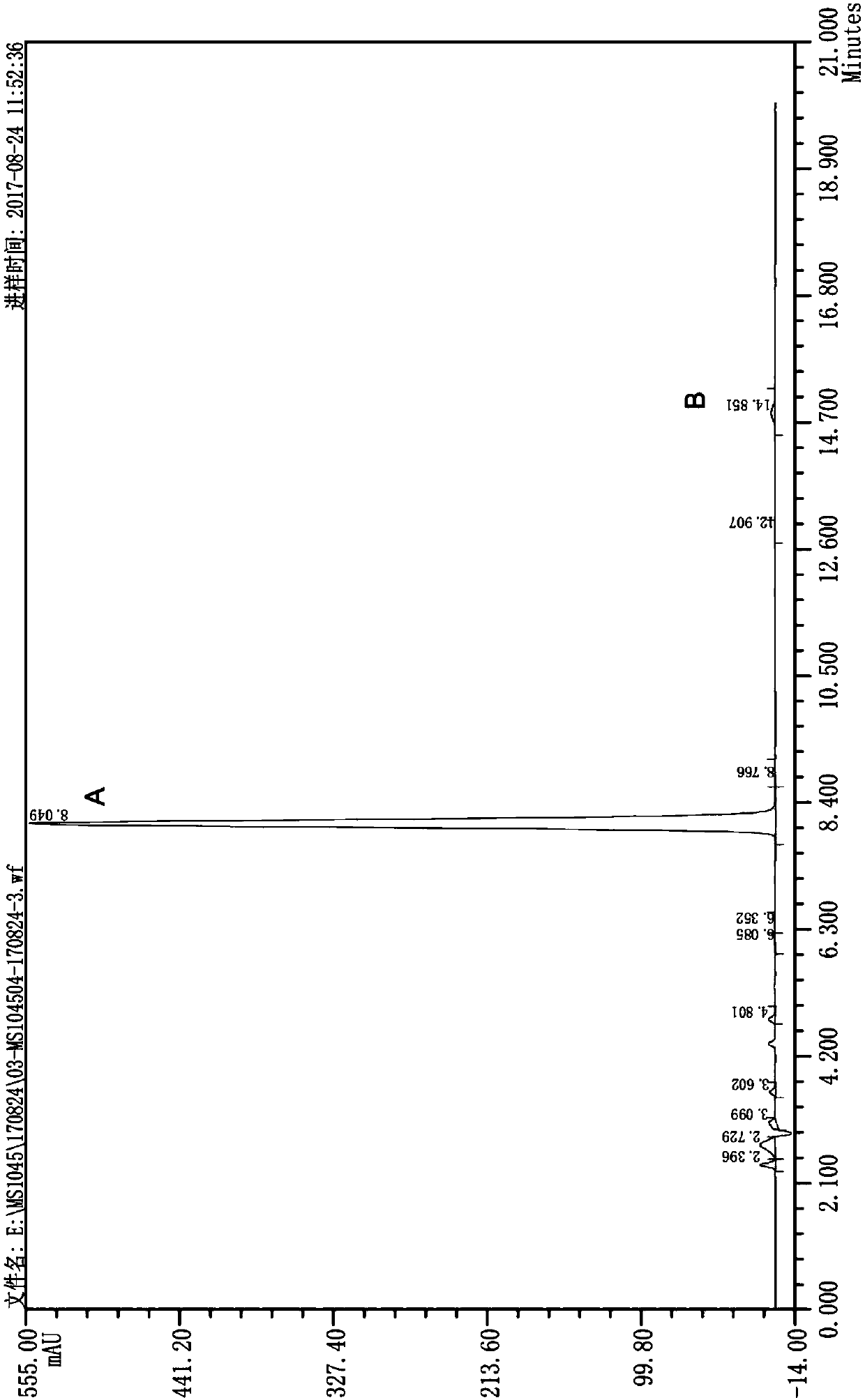

Synthesis method of lifitegrast intermediate

InactiveCN107857728AImprove responseStarting materials are cheap and readily availableOrganic chemistryBenzyl chloroformateSynthesis methods

The invention discloses a preparation method of a lifitegrast intermediate. The preparation method comprises the following steps: (1) taking a compound (1), treating the compound (1) by using tetramethyldiethylamine and n-butyl lithium, adding benzyl chloroformate, reacting at the temperature of 70 DEG C below zero to obtain a compound (2); and (2) taking the compound (2), reacting the compound (2) with a strong alkaline solution, adjusting pH to be 3-4 after the reaction is ended, and extracting to obtain a compound (3). The prepared lifitegrast intermediate is high in process selectivity, high in controllability, high in stability and high in total yield, and is suitable for commercial large-scale production.

Owner:成都惟邦药业有限公司

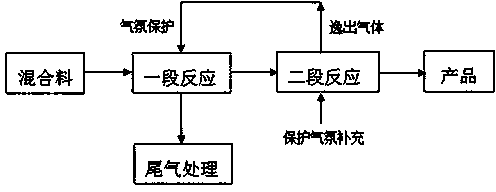

Two-stage type production method of V crystal form type APP (ammonium polyphosphate)

The invention relates to a production method of a chemical product, and discloses a two-stage type production method of V crystal form type APP (ammonium polyphosphate). The production method comprises steps as follows: phosphorus pentoxide is adopted as a raw material, and V crystal form type APP with a stable crystal form is obtained through two stages of reaction; and in the first-stage reaction, phosphorus pentoxide is added to one of urea and tripolycyanamide or a mixture of urea and tripolycyanamide, the raw materials are uniformly mixed, react at the temperature of 160-240 DEG C under the protection of ammonia atmosphere in a polymerization reactor and react and polymerize at the temperature of 240-330 DEG C in a pressure reaction kettle provided with a stirring device so as to obtain the V crystal form type APP product with the stable crystal form. According to the two-stage type technological process, emergent gas in a later reaction process is taken as protection gas of a former reaction system, and the production method has the advantages that the tail gas emission is reduced, the production environment is improved, and the cost is reduced.

Owner:YUNNAN CHEM RES INST

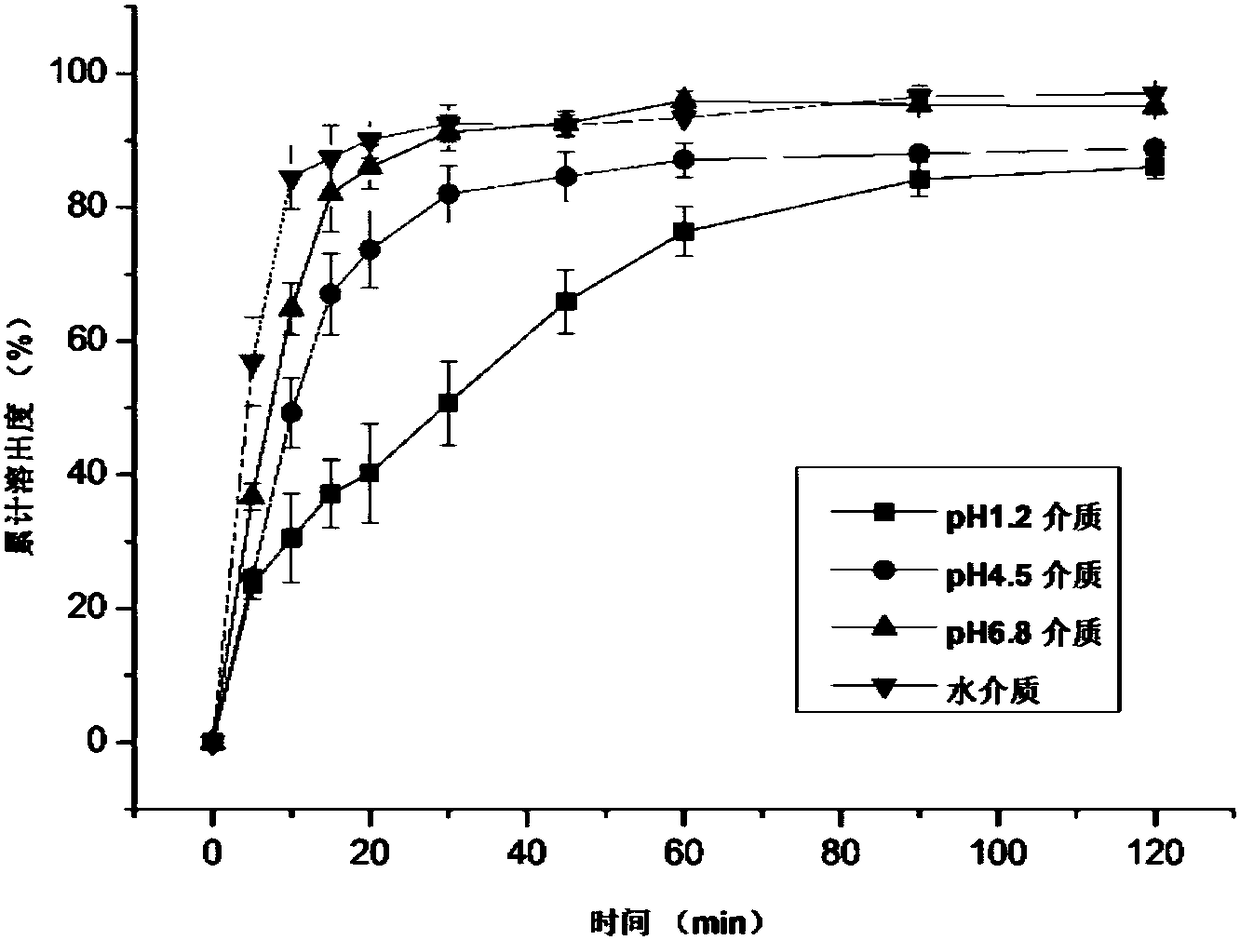

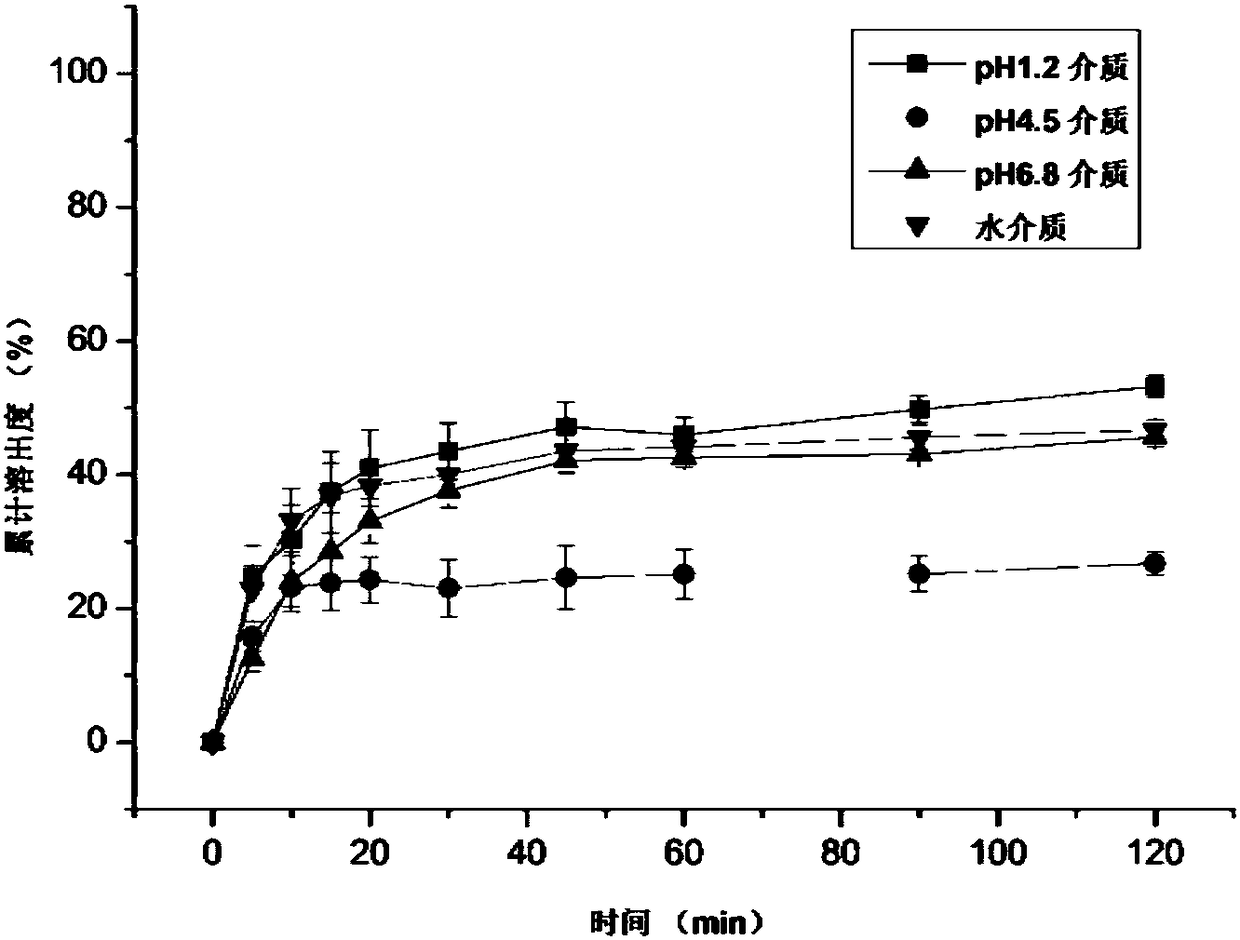

Ziprasidone hydrochloride solid dispersible tablets and hot melt extrusion method thereof

ActiveCN108078934AObvious retentionExtended release timeOrganic active ingredientsNervous disorderTherapeutic effectGlass transition

The invention discloses ziprasidone hydrochloride solid dispersible tablets and a hot melt extrusion method thereof. Based on ziprasidone hydrochloride as a main component, one or two of mixed carriers of copolyvidone S630 or HPMCAS-HF (hydroxypropyl methylcellulose acetate succinate) as a base, a coating material is added, and the glass transition temperature of an extruded mixture can also be reduced; then, a surfactant is added. The ziprasidone hydrochloride solid dispersible tablets are prepared through steps as follows: the raw and auxiliary materials are evenly mixed by a three-dimensional mixing machine, extruded by a hot melt extruder at a high temperature and ground into powder with proper size; the powder is then mixed with a fixed quantity of filler, disintegrant and lubricant sufficiently and uniformly, and direct tableting is preformed, and the ziprasidone hydrochloride solid dispersible tablets are prepared. The prepared ziprasidone hydrochloride solid dispersible tabletshave the advantages that the problem of poor in-vitro dissolution of ziprasidone hydrochloride is solved, bioavailability of ziprasidone hydrochloride under the condition of empty stomach is improved, and the treatment effect of the tablets is improved finally.

Owner:江苏省药物研究所有限公司

Processing technology of leisure beef food with primary taste

The invention relates to the field of food processing, in particular to a processing technology of a leisure beef food with primary taste. The processing technology comprises the steps of selecting materials, dicing, cooking with clean water, dehydration, cutting into slices, subpackaging, sterilization and the like. The invention aims to provide the processing technology of the leisure beef food with primary taste. Under the condition that no artificially synthesized seasoning (essence ) or preservative is added, the leisure beef food which has the primary taste of beef, has a certain shelf life and is safe is produced.

Owner:TONGDAO YOUJIAOTOU FOOD CO LTD

Purification method of phosphoric acid

ActiveCN101817514ABlock throughAvoid pollutionElectrodialysisPhosphorus compoundsChemical industryPurification methods

The invention relates to a purification method of phosphoric acid, which belongs to the technical field of phosphorous chemical industry. The technical problem to be solved by the invention is to improve the purity of the phosphoric acid, effectively remove impurities of anions and cations and obtain high-purity acid for preparing industrial-grade or food-grade phosphoric acid. The technical scheme of the invention is as follows: the purification method of the phosphoric acid adopts the three-chamber electrodialysis method and comprises the following steps: adding phosphoric acid solution to be purified in an anode chamber, adding acid solution in a cathode chamber, and adding ultrapure water or diluted phosphoric acid in an intermediate chamber; and carrying out electrodialysis under the action of a direct current electric field, leading phosphate radicals in the anode chamber to pass through an anion exchange membrane and enter into the intermediate chamber, leading hydrogen ions in the cathode chamber to pass through a cation exchange membrane and enter into the intermediate chamber, and finally obtaining the purified phosphoric acid in the intermediate chamber. The method can separate the phosphoric acid from impurities through the action of the attraction force of the electric field, the concentration difference diffusion and the selective permeability of the anions and the cations and obtain the purified phosphoric acid in the intermediate chamber, the process is simple, and the obtained product has good quality, thereby providing the new process for purifying the phosphoric acid.

Owner:GUIZHOU CHANHEN CHEM CO LTD

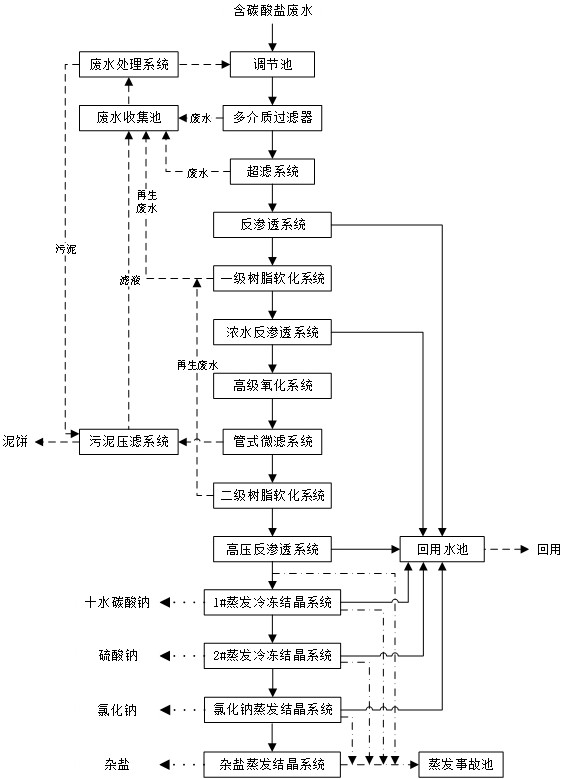

Treatment method of carbonate-containing wastewater

InactiveCN112811701ASolve the impact of scalingSolve the problem of pollutionWater treatment parameter controlScale removal and water softeningSludgeSodium sulfate

The invention discloses a treatment method of carbonate-containing wastewater. The carbonate-containing wastewater passes through a regulating reservoir, a multi-medium filter, an ultrafiltration system, a reverse osmosis system, a primary resin softening system, a concentrated water reverse osmosis system, an advanced oxidation system, a tubular microfiltration system, a secondary resin softening system, a high-pressure reverse osmosis system, a sludge filter pressing system, an evaporation freezing crystallization system, an evaporation crystallization system, a wastewater treatment system, a recycling water tank and the like for process treatment to obtain sodium carbonate decahydrate product salt and by-products sodium sulfate and sodium chloride product salt. The treatment method has the advantages of strong anti-pollution capability, high concentration multiple, high recovery rate, high crystallized salt quality, high automation degree, low investment and low operation cost.

Owner:BEIJING NEWBIOLINK TECH DEV

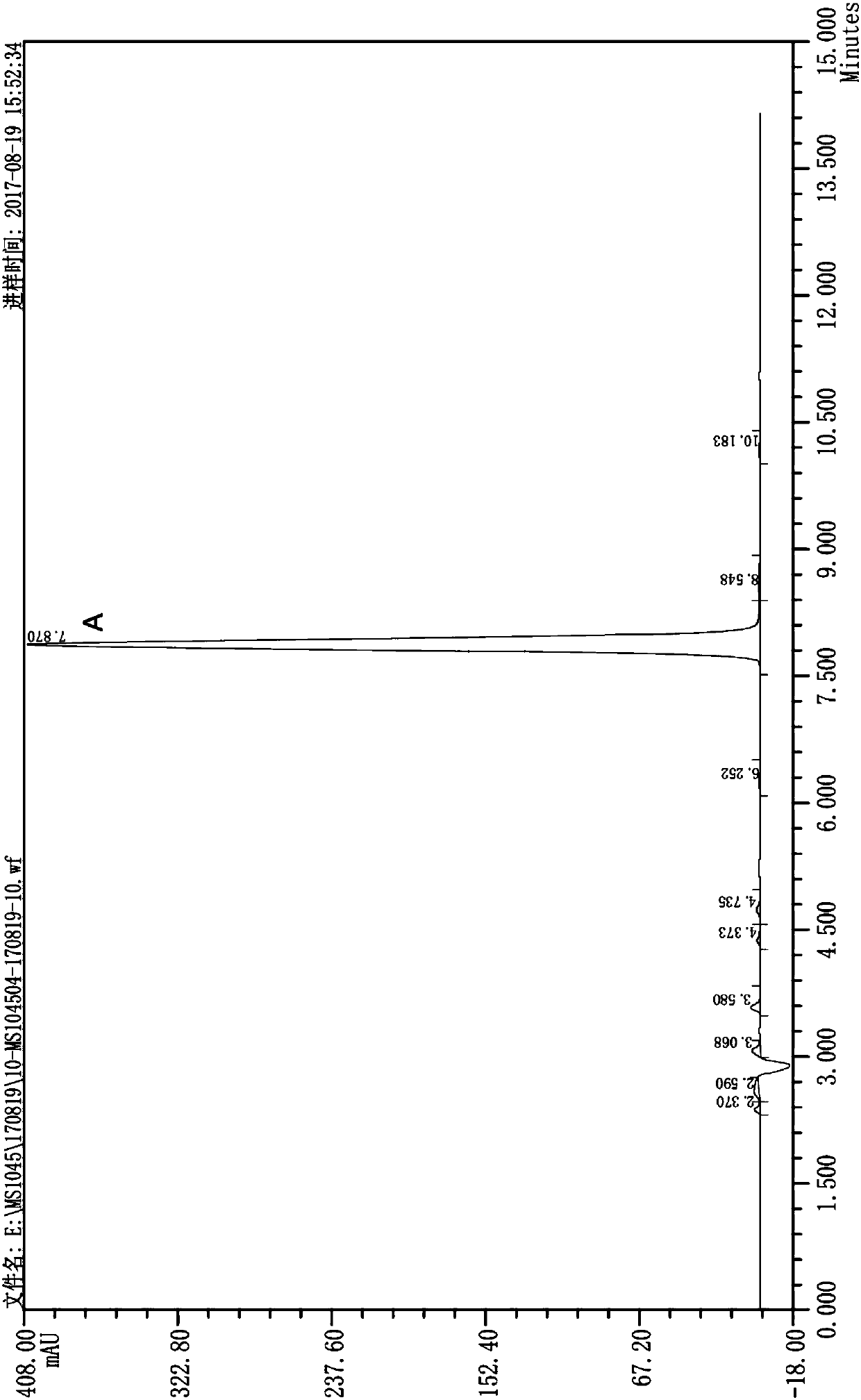

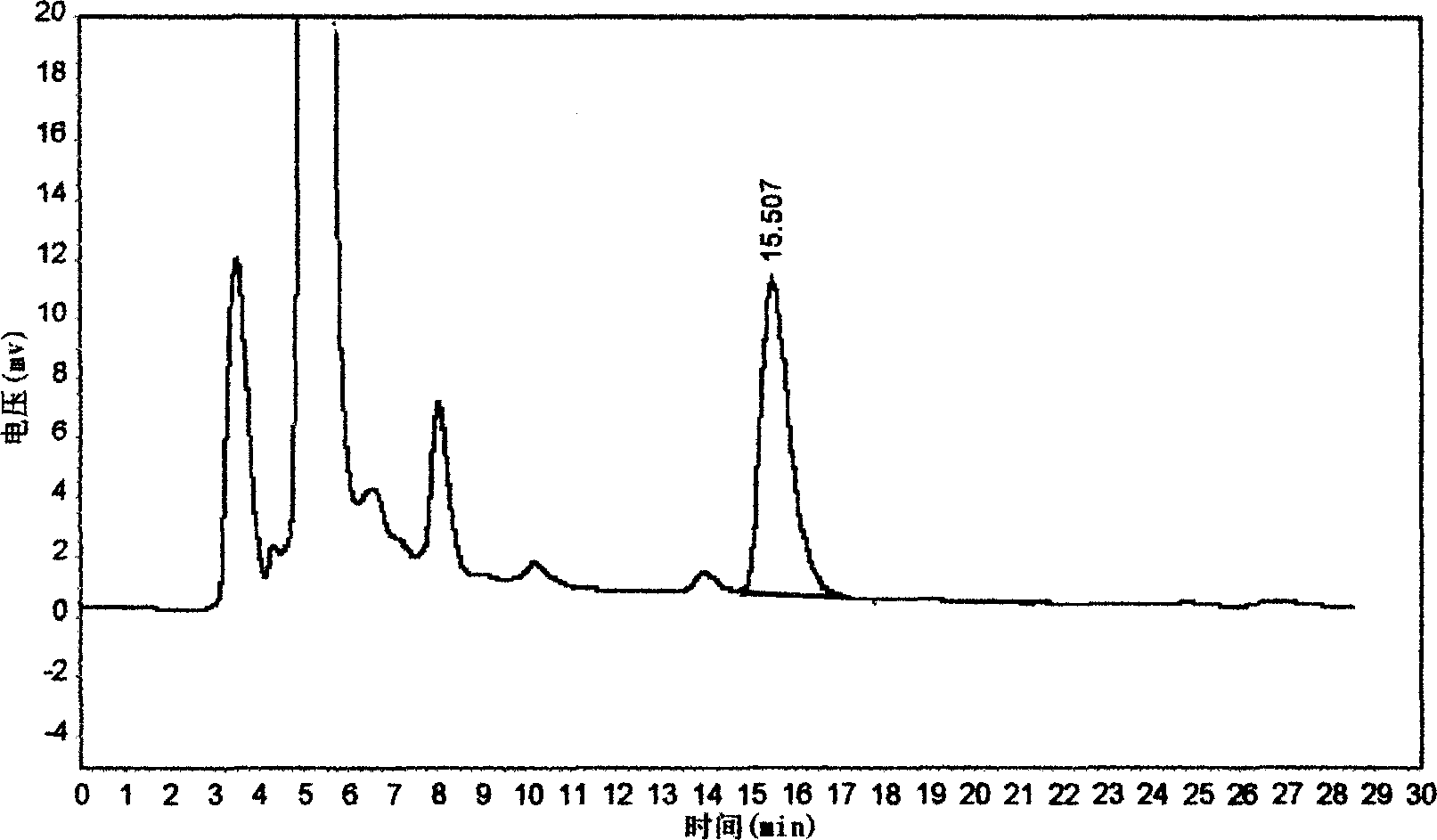

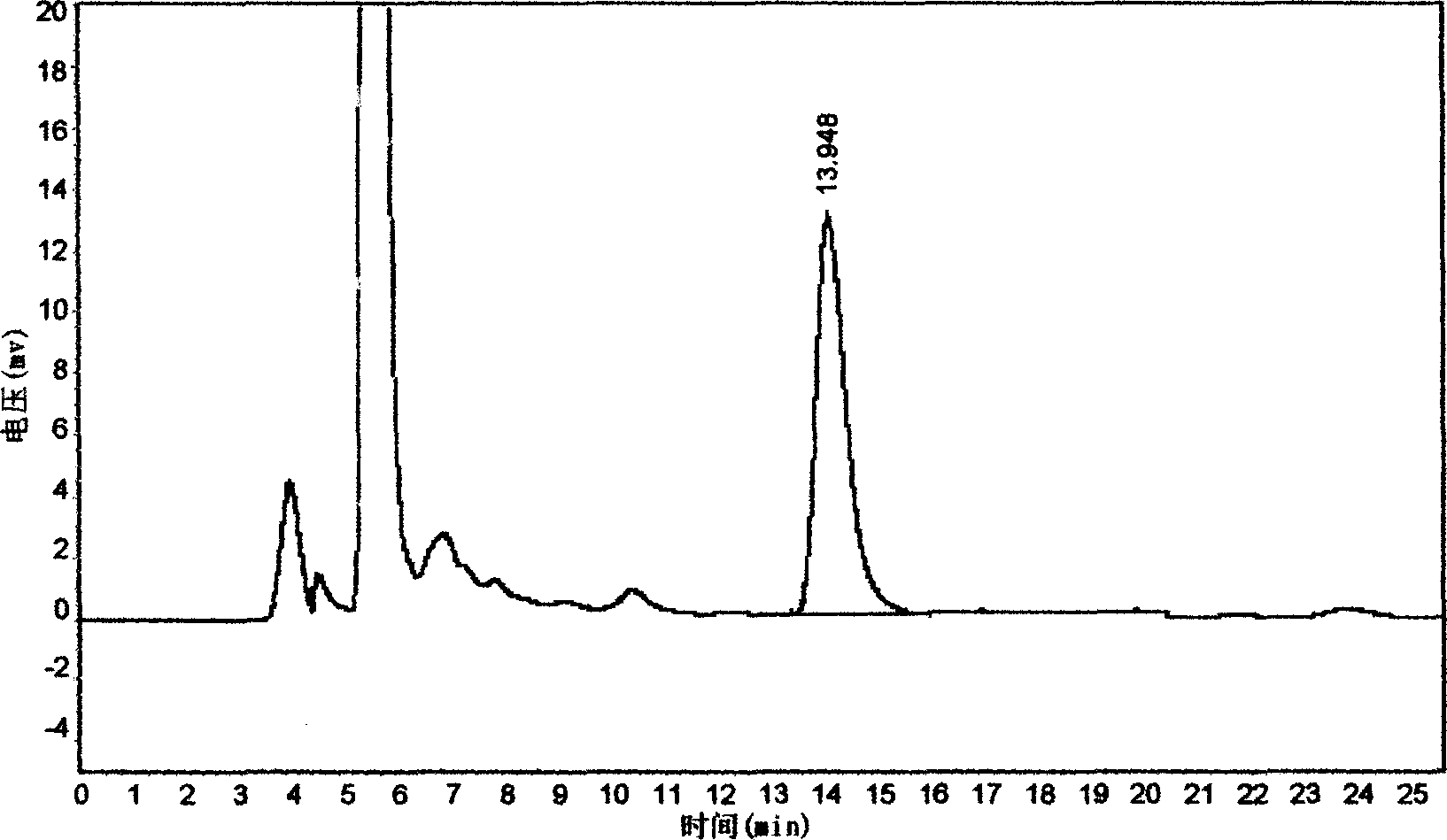

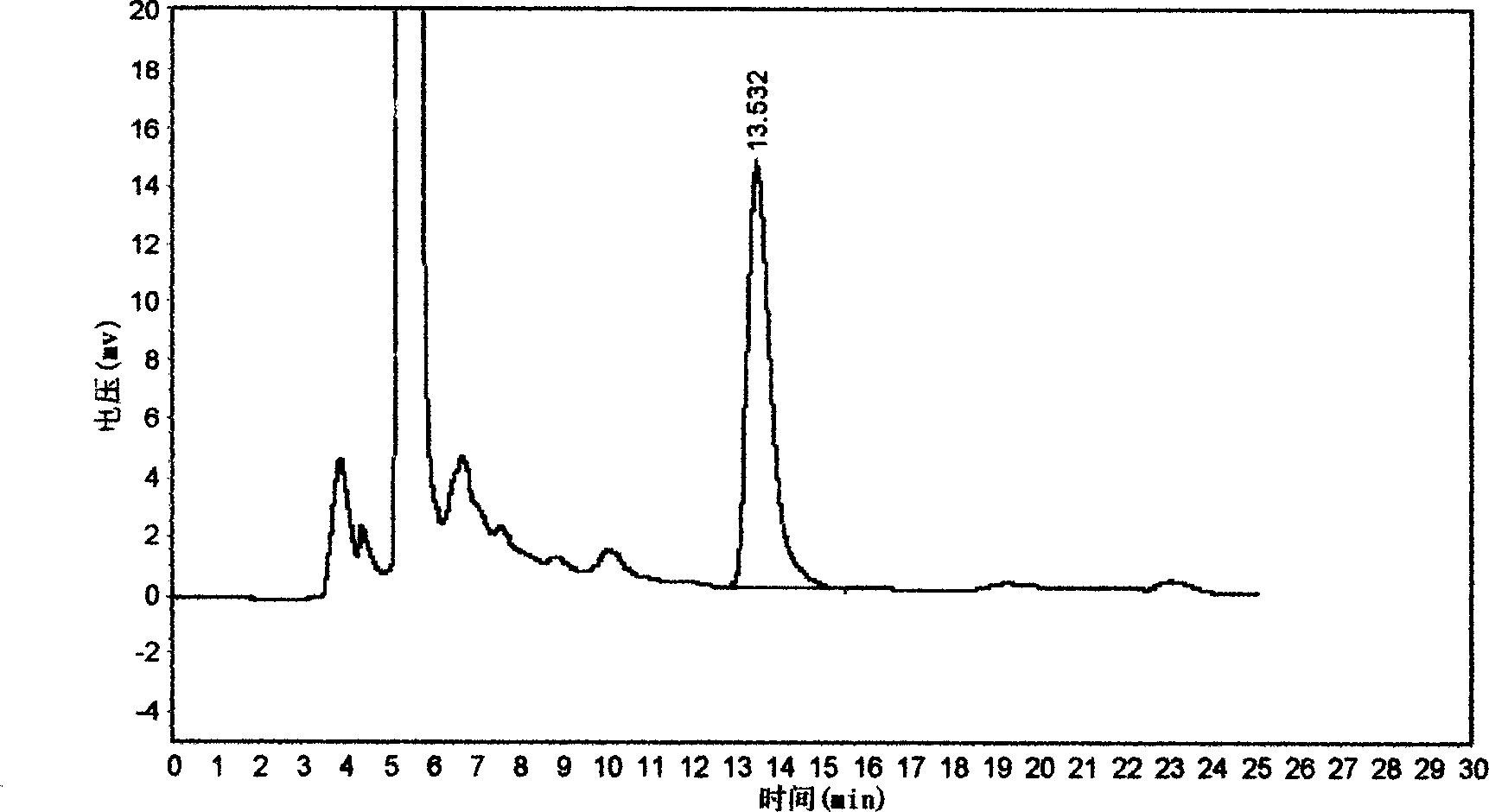

Method for detecting chlorphenamine maleate content in Chinese-western compound preparation

InactiveCN1865985AEliminate the effects ofEliminate distractionsComponent separationSolid solvent extractionChlorphenamine maleateOrganic solvent

The disclosed detection method for Chlorphenamine Maleate content in preparation comprises: with HPLC, using mixed solvent with alcohol and weak-polar organic solution as extraction solution, octadecylsilicane chemically bonded silica as filler, and the mobile phase with brine, aminoethane and acetonitrile. This invention is simple and has well detection effect.

Owner:蔡炜

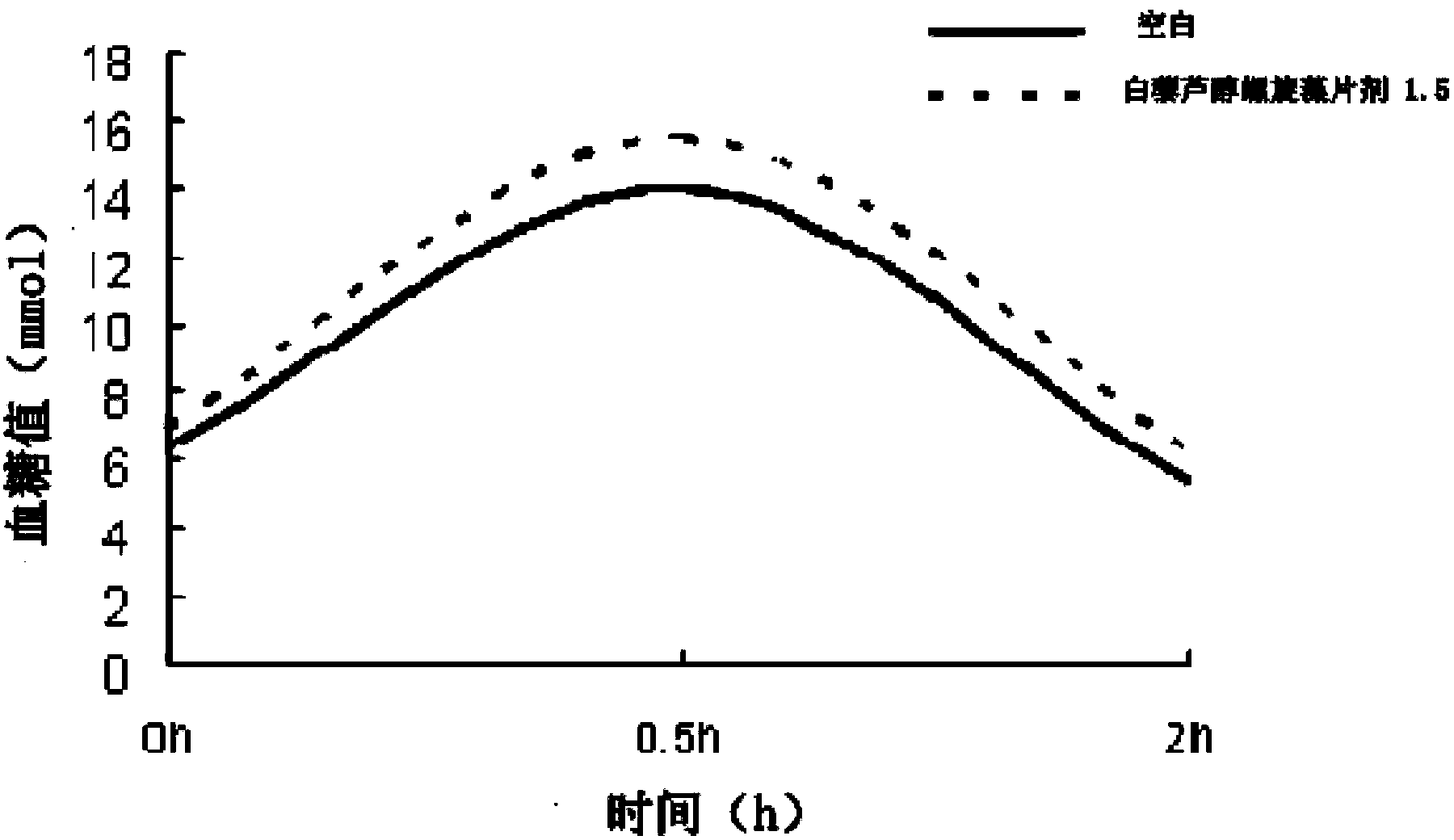

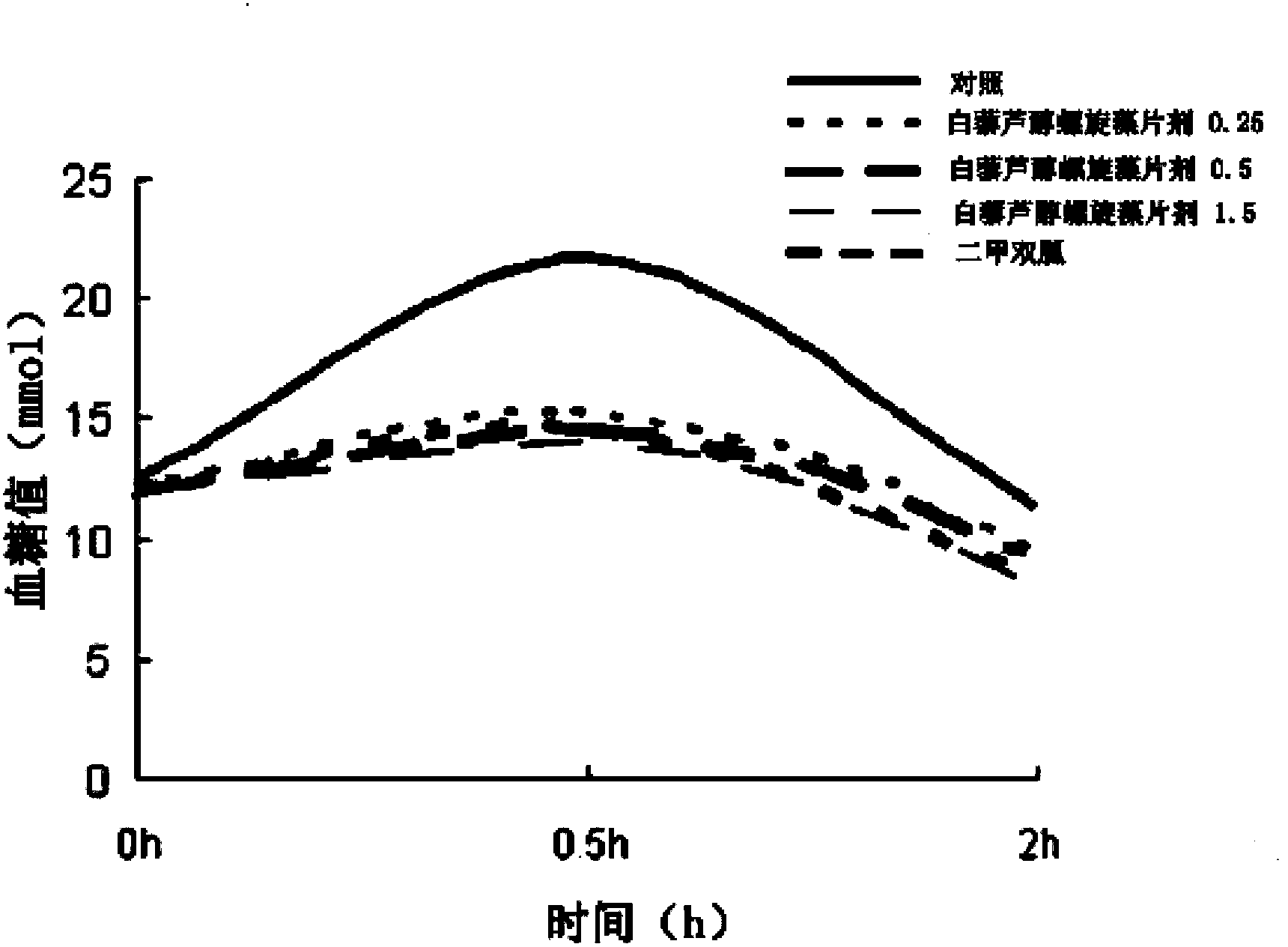

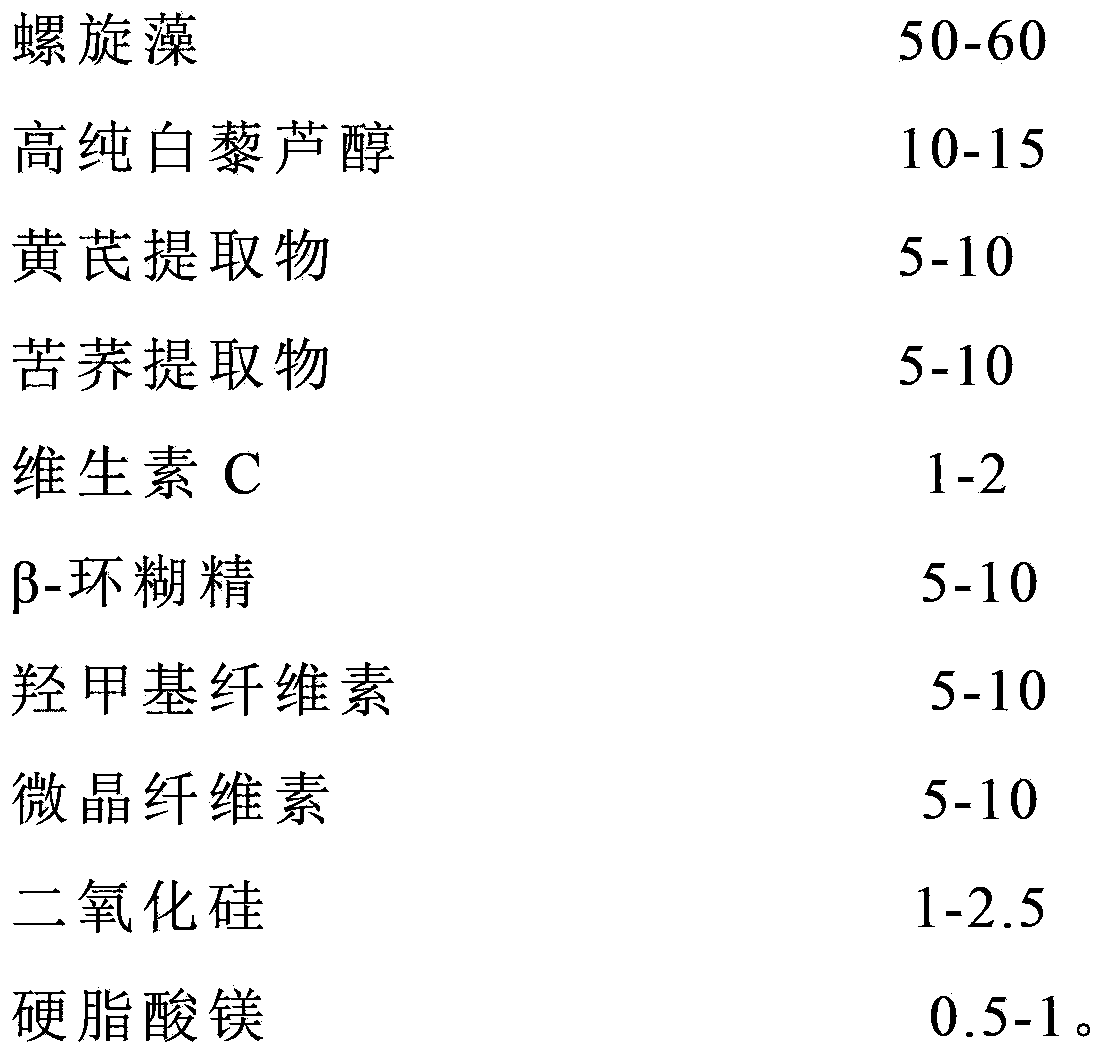

Resveratrol and spirulina composition and preparations and preparation method thereof

ActiveCN103349671AImprove solubilityImprove stabilityHydroxy compound active ingredientsMetabolism disorderSolubilityAdjuvant

The invention relates to a resveratrol and spirulina composition and preparations and a preparation method thereof. The composition comprises spirulina and high-purity resveratrol with the purity higher than 80%; the composition further comprises an astragalus root extract, a tartary buckwheat extract and vitamin C; and a solid preparation is prepared from the composition and adjuvants, wherein the adjuvants comprise hydroxymethyl cellulose, microcrystalline cellulose and beta-cyclodextrin, and the beta-cyclodextrin can be used for improving the solubility and stability of the composition and improving the bioavailability of the solid preparation. The solid preparation disclosed by the invention can be used for promoting the recovery of islet cells, improving glucose tolerance, lowering blood viscosity and the brittleness of capillaries, promoting blood circulation, lowering blood sugar and blood fat and protecting the liver, and has a very good treatment effect on the prevention or treatment of diabetes, complications of diabetes and cardio-cerebral vascular diseases.

Owner:甘肃凯源生物技术开发中心有限责任公司 +4

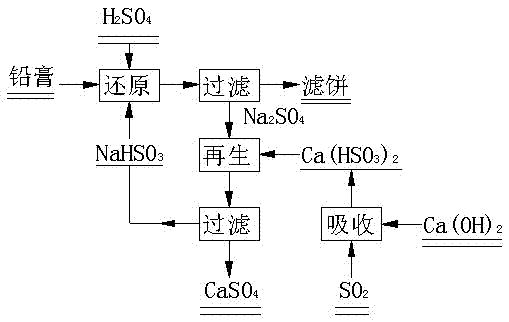

Reducing method for lead dioxide in waste lead plaster

The invention discloses a reducing method for lead dioxide in waste lead plaster, and belongs to the recycling field of the lead dioxide in a waste lead storage battery. The waste lead plaster contains about 30% of PbO2, and during recycling, the PbO2 is required to be converted into bivalent lead (lead oxide or lead sulfate) for being recycled. According to the reducing method, sodium hydrogen sulfite is adopted as a reducing agent for PbO2 in the lead plaster, and sulfuric acid is used as an assistant for converting the PbO2 into lead surface and converting the sodium hydrogen sulfite into sodium sulfate. The sodium sulfate is regenerated into the sodium hydrogen sulfite by use of calcium hydrogen sulfite for being recycled for reducing reaction of PbO2 in the lead plaster, and an obtained byproduct calcium sulfate can be further comprehensively utilized. The calcium hydrogen sulfite for regenerating can be prepared from calcium hydroxide or sulfur dioxide in calcium carbonate absorbing smoke gas. The method has the advantages of being high in lead conversion rate and low in cost.

Owner:XIANGTAN UNIV

Patterned non-woven fabric with concave-convex patterns and preparing method of patterned non-woven fabric

InactiveCN105544090AImprove organizational formEffective treatment effectPattern makingNon-woven fabricsCarbon fibersOptoelectronics

The invention provides a patterned non-woven fabric with concave-convex patterns and a preparing method of the patterned non-woven fabric. The preparing method comprises the following steps that firstly, short fibers of superfine fibers and bamboo carbon fibers are opened and carded to be fully mixed, and then the mixed fibers are laid into a mixed fiber net in a crossed net laying mode; secondly, short fibers of the superfine fibers and bamboo carbon fibers are laid into a superfine fiber net and a bamboo carbon fiber net respectively in the mode of opening, carding and crossed net laying, and then the bamboo carbon fiber net is laid on the surface of the superfine fiber net to form a composite fiber layer; thirdly, the front and back sides of the mixed fiber net prepared in the first step or the front and back sides of the composite fiber layer prepared in the second step are subjected to basic spunlace reinforcing, then the structure and number of spunlace stitches are adjusted, and a fiber net containing initial surface texture is obtained after dehydration and pre-drying; fourthly, the fiber net, containing the initial surface texture, prepared in the third step passes through a concave-convex hot roller with the concave-convex rugged surface, drying and sizing are carried out, and the patterned non-woven fabric with the concave-convex patterns is obtained.

Owner:SUZHOU INSILK CO LTD

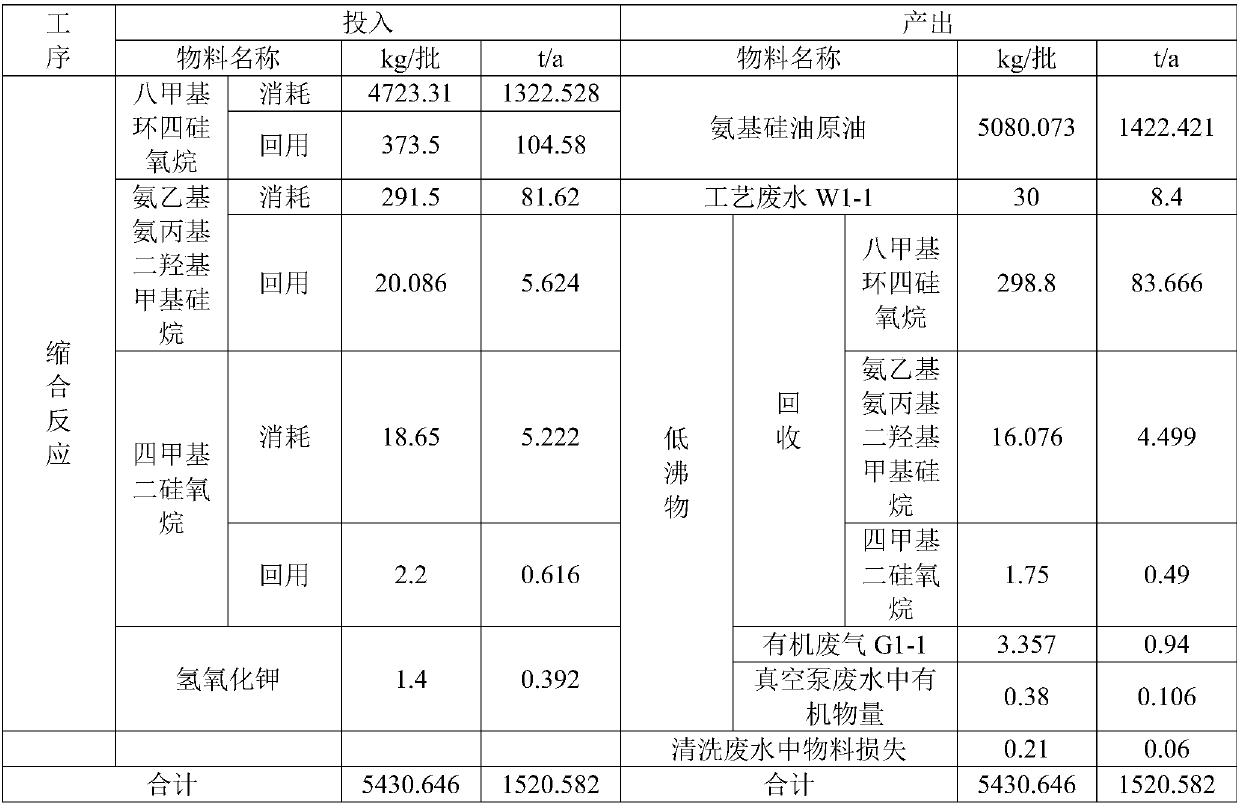

Preparation technology of crude amino silicone oil

InactiveCN108676165AUniform molecular weightHigh molecular weight uniformityDistillationReaction temperature

The invention relates to the field of preparation of silicone oil, in particular to a preparation technology of crude amino silicone oil with relatively high molecular weight uniformity. The preparation technology comprises the following preparation steps: 1), premixing raw materials: premixing mixed dimethylcyclosiloxane and an end-capping agent to obtain a premix I, and premixing a coupling agent and a solid catalyst to obtain a premix II; 2), placing the premix I and the premix II which are obtained in the step 1) in a container, and performing polycondensation to obtain a polycondensationreaction product, wherein during the polycondensation, the reaction temperature is controlled to be 100-200 DEG C; 3), performing reduced pressure distillation on the polycondensation reaction productobtained in the step 2), completing the distillation till the mass tends to be constant, and lowering the temperature to 40 DEG C or below to obtain the crude amino silicone oil.

Owner:ZHEJIANG KEFENG ORGANIC SILICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com