Method for the dry beneficiation of wollastonite ores

A beneficiation method and wollastonite technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as reducing product quality, hindering material particle polarization, reducing separation quality, etc., to achieve quality improvement and loss reduction. , reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] preferred implementation

[0051] The inventive method implements with following method:

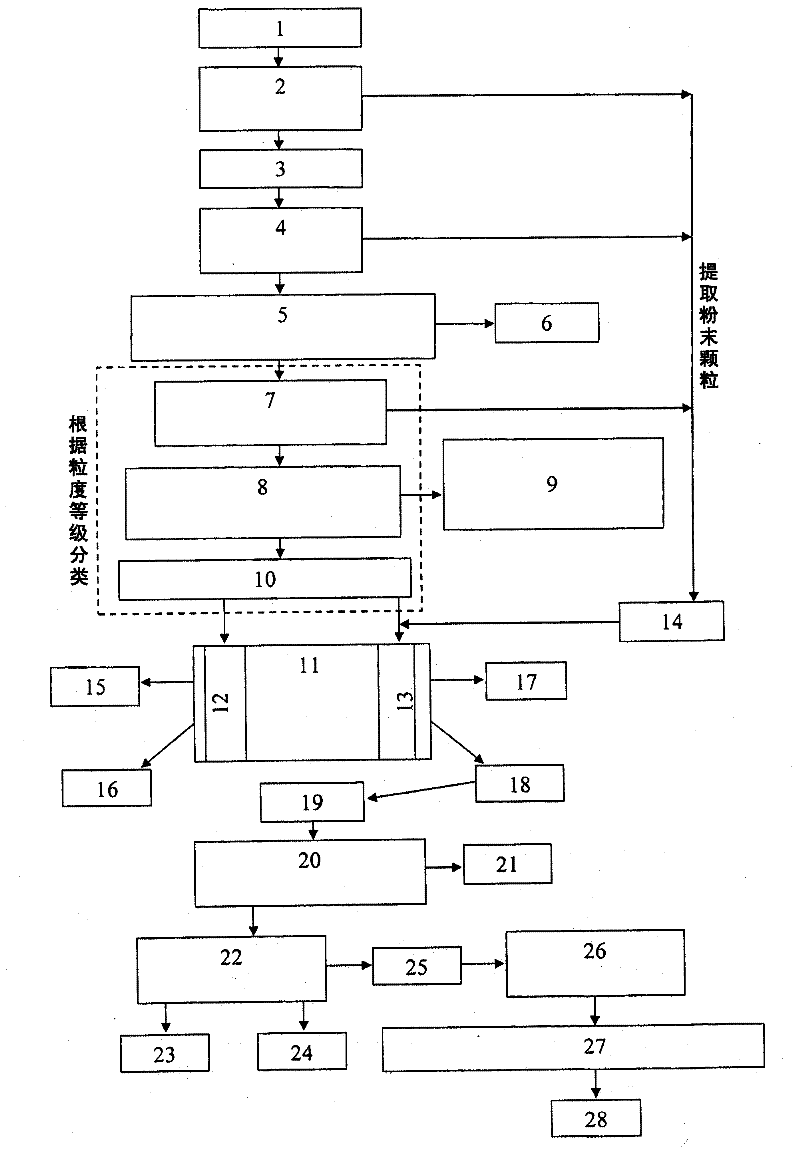

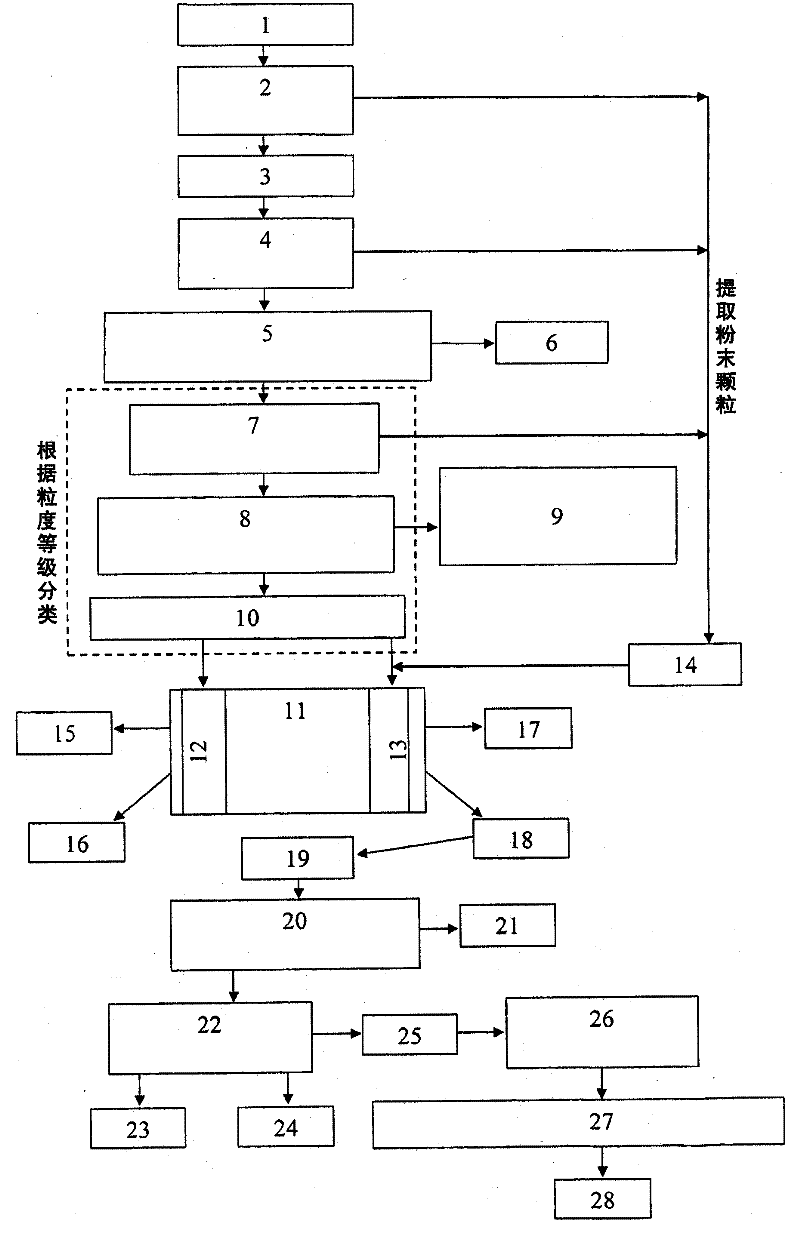

[0052] Wollastonite ore with a wollastonite content of 60-71% purchased from Kain-Suu deposit (Kyrgyz Republic) was used as raw material. The ore is primary (first) crushed to a particle size of 100-120mm in a jaw crusher. The material was then dried with hot air in a container drier. After drying, the material was pulverized a second time in a vibration crusher to a particle size of 30-40 mm. The material is subjected to X-ray fluorescence separation, and the low-content (less than 10%) wollastonite ore flakes are removed to the tailings, and the selected ore is sent to the particle size classification, and first impacted and crushed in the rotating high-speed grinder , followed by magnetic separation on a belt conveyor with magnetic wheels, during which the processed iron and strong magnetic mixture are separated; the remaining material is separated into different particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com