A preparing method of rutile vanadium dioxide nanometer particles and the particles

A vanadium dioxide nanometer and rutile phase technology, applied in vanadium oxide, nanotechnology, nanotechnology and other directions, can solve the problems of restricting the development, promotion and application of glass film for automobiles and residences, low visible light transmittance, and inability to meet demand, etc. Achieve the effect of reducing three waste discharge or secondary environmental pollution, high particle purity and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

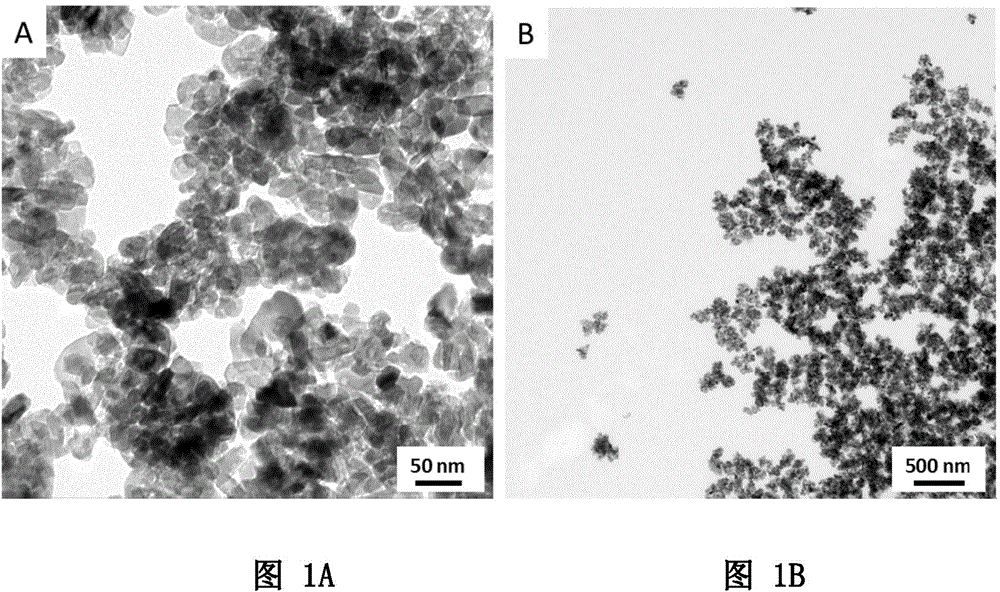

[0034] Preparation of undoped rutile phase nanoparticles

[0035] 1) Precursor preparation:

[0036] Take 2.2g of vanadium pentoxide, put the powder into a 500ml flask, add 230ml of deionized water, preheat to 90°C and keep stirring for 10 minutes, then cool to room temperature. Add 10 ml of 28% ammonia water and stir for 30 minutes, then slowly add 0.6 ml of hydrazine hydrate, and stir for 30 minutes until a black suspension is obtained. The obtained black suspension was transferred to a hydrothermal reactor and kept at 220° C. for 1 day, and the black precursor was obtained after natural cooling.

[0037] 2) Precursor separation and cleaning:

[0038]Transfer the obtained black precursor to a transparent container, add 240ml of absolute alcohol and let it stand for 10 hours until the precursor completely sinks to the bottom, and remove the supernatant. Add 240ml of absolute alcohol to the precursor, stir for 5 minutes and let it stand for 10 hours until the precursor comp...

Embodiment 2

[0048] Preparation of undoped rutile phase nanoparticles

[0049] 1) Precursor preparation:

[0050] Take 2.8g of ammonium metavanadate, put the powder into a 500ml flask, add 230ml of deionized water, preheat to 90°C and keep stirring for 10 minutes, then cool to room temperature. Add 10 ml of 28% ammonia water and stir for 30 minutes, then slowly add 0.6 ml of hydrazine hydrate, and stir for 30 minutes until a black suspension is obtained. The obtained black suspension was transferred to a hydrothermal reactor and kept at 220° C. for 1 day, and the black precursor was obtained after natural cooling.

[0051] 2) Precursor separation and cleaning:

[0052] Transfer the obtained black precursor to a transparent container, add 240ml of absolute alcohol and let it stand for 10 hours until the precursor completely sinks to the bottom, and remove the supernatant. Add 240ml of absolute alcohol to the precursor, stir for 5 minutes and let it stand for 10 hours until the precursor ...

Embodiment 3

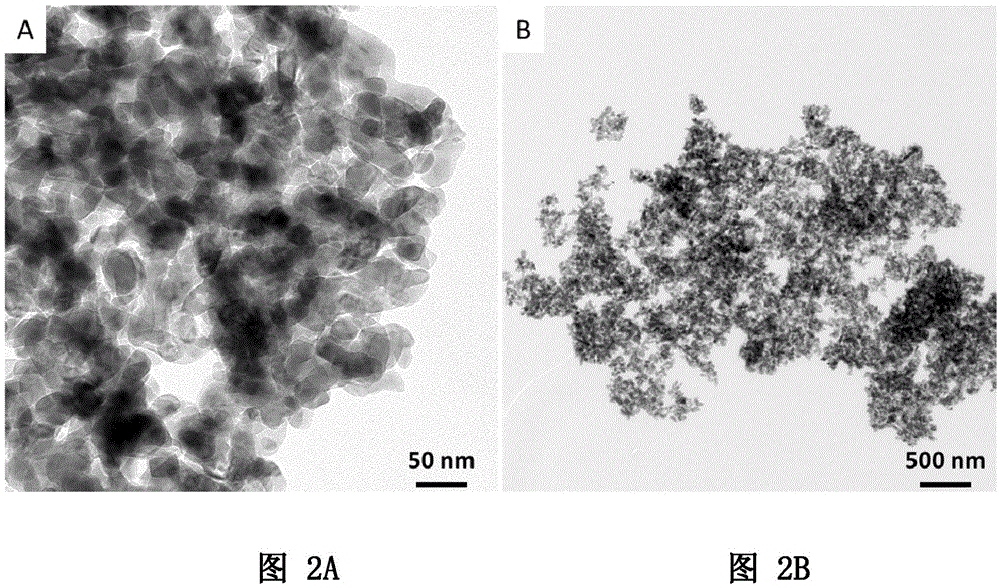

[0058] Preparation of rutile phase nanoparticles doped with tungsten (1%)

[0059] 1) Precursor preparation:

[0060] Take 2.2g of vanadium pentoxide, put the powder into a 500ml flask, add 230ml of deionized water, preheat to 90°C and keep stirring for 10 minutes, then cool to room temperature. Add 10 ml of 28% ammonia water and stir for 30 minutes, then slowly add 0.6 ml of hydrazine hydrate, and stir for 30 minutes until a black suspension is obtained. Add 0.064g of ammonium metatungstate to the black suspension, and stir for 10 minutes, then transfer to a hydrothermal reaction kettle and keep it warm at 220°C for 1 day. After natural cooling, a black precursor is obtained.

[0061] 2) Precursor separation and cleaning:

[0062] Transfer the obtained black precursor to a transparent container, add 240ml of absolute alcohol and let it stand for 10 hours until the precursor completely sinks to the bottom, and remove the supernatant. Add 240ml of absolute alcohol to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com