Method for preparing porous carbon for electrochemical capacitor from egg white used as raw material

A technology of egg white and electrochemistry, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., to achieve the effect of abundant raw materials, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

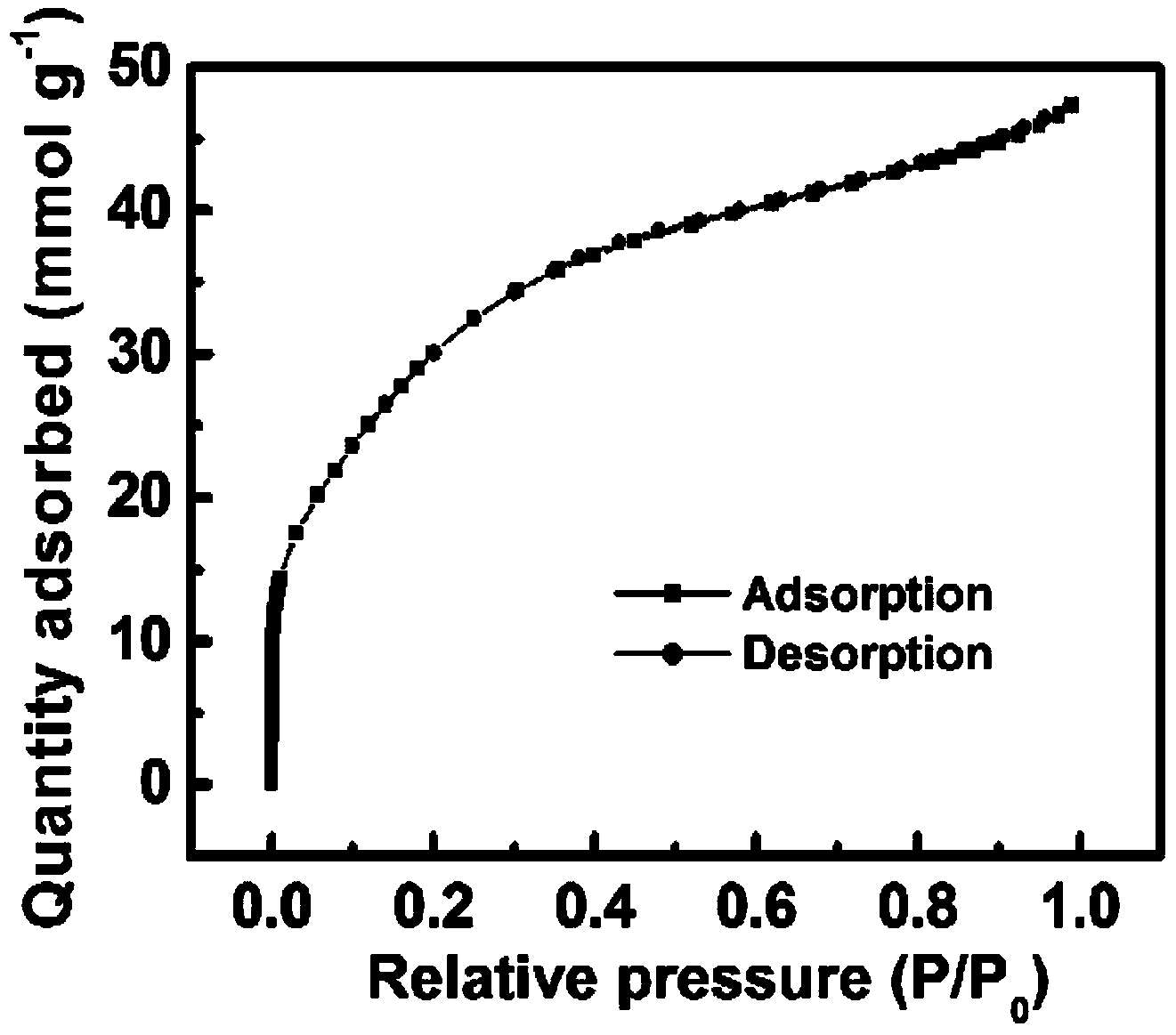

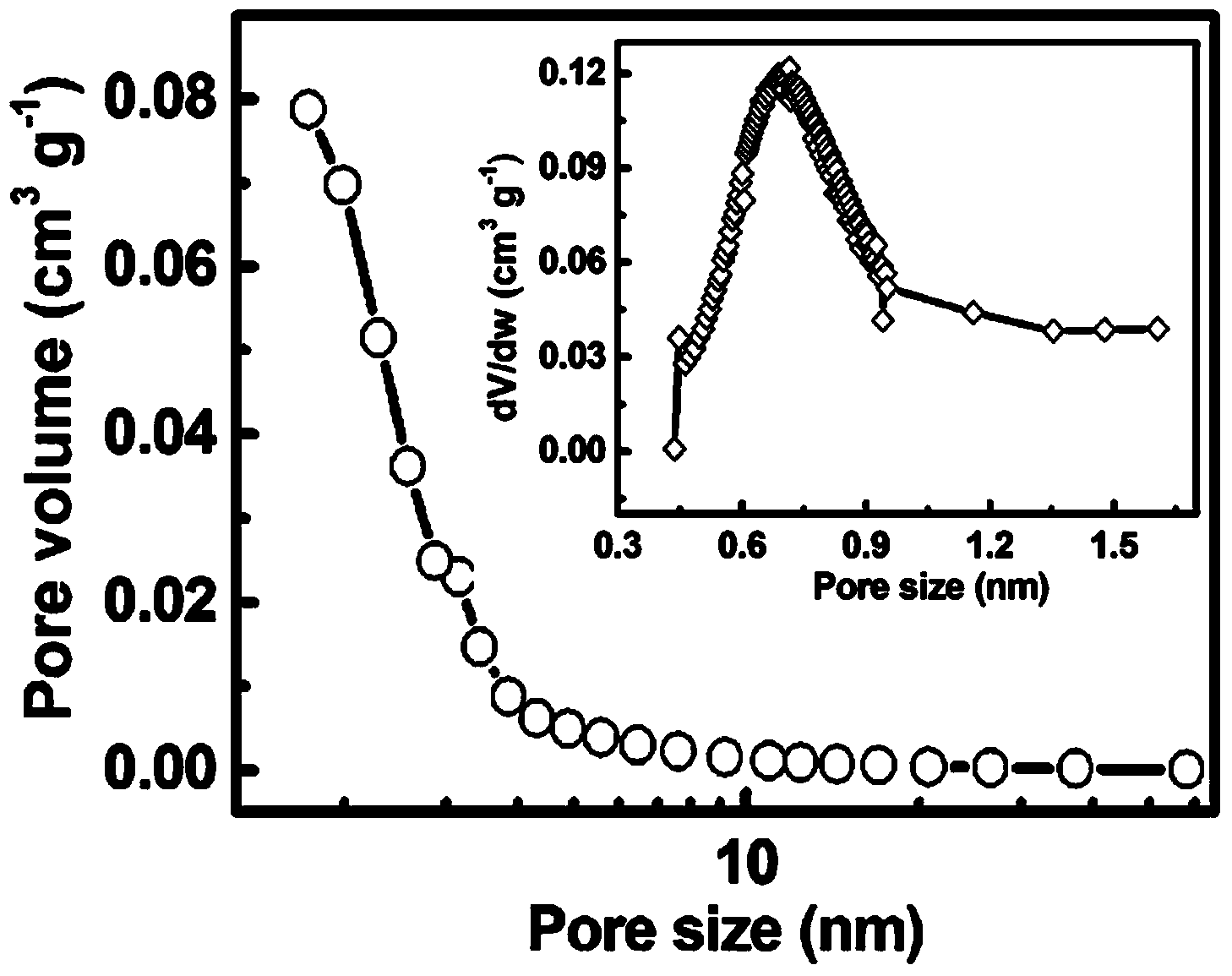

[0031] Buy ordinary eggs at the Ma’anshan Vegetable Market, put the egg whites of two eggs into a beaker, pour 200mL of absolute ethanol into the beaker to precipitate the protein, and dry the precipitated protein in a vacuum drying oven at 60°C, then take 10g and place it in a quartz boat In a tube furnace with nitrogen gas, the temperature was raised to 600°C at a rate of 5°C / min and kept for 2h. Then, the carbon precursor obtained by the above-mentioned pre-carbonization was fully mixed with the activator at a mass ratio of 1:3. The time is 2h. The above-mentioned activated product was washed with 0.1 mol hydrochloric acid, and then washed with deionized water until neutral, and then dried to obtain porous carbon. Such as figure 1 As shown, the specific surface area of the obtained porous carbon is 1450m 2 g -1 .

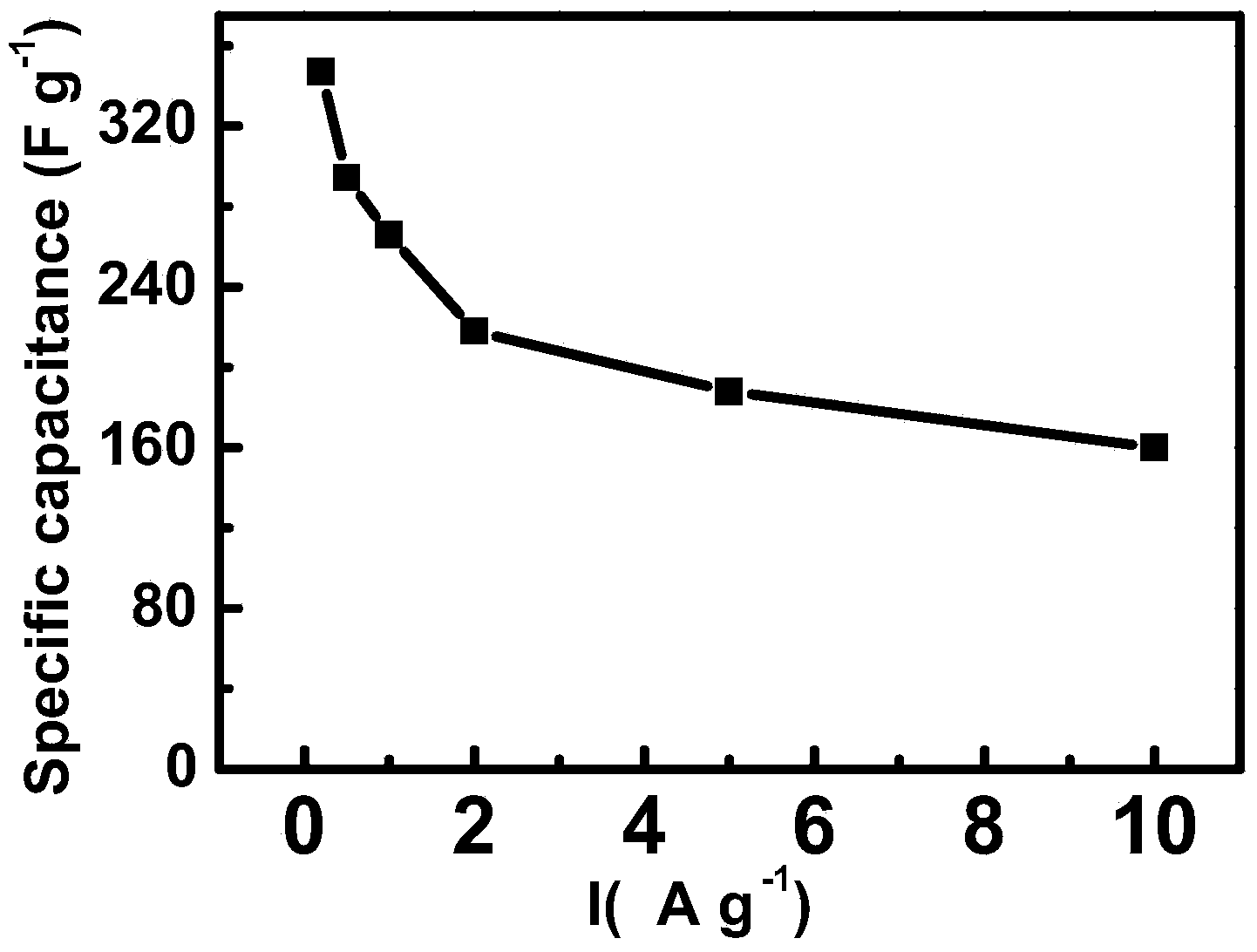

[0032] Take 7mg of the prepared porous carbon, mix evenly according to the ratio of active material: acetylene black: polytetrafluoroethylene = 7:2:1, and...

Embodiment 2

[0035] Buy ordinary eggs at the Ma’anshan Vegetable Market, put the egg whites of two eggs into a beaker, pour 200mL of acetone into the beaker to precipitate the protein, and dry the precipitated protein in a vacuum oven at 60°C, then take 10g and place it in a quartz boat. In a tube furnace with argon gas, the temperature was raised to 450°C at a rate of 3°C / min and kept for 2h. Then, the carbon precursor obtained by the above pre-carbonization was fully mixed with the activator at a mass ratio of 1:2. The activator was potassium hydroxide, and then the temperature was raised to 700°C at a rate of 3°C / min under an argon atmosphere for activation. The activation time is 2h. The above-mentioned activated product was washed with 0.1 mol sulfuric acid, and then washed with deionized water until neutral, and then dried to obtain porous carbon.

[0036] The electrochemical test method of porous carbon is the same as that of Example 1.

Embodiment 3

[0038] Buy ordinary eggs at the Ma’anshan Vegetable Market, take the egg whites of two eggs in a beaker, add sodium chloride solution to the beaker to precipitate the protein, and dry the precipitated protein in a vacuum oven at 60°C, then take 10g and put it in a quartz boat , the temperature was raised to 500°C at a rate of 10°C / min in a tube furnace filled with argon, and kept for 2h. Then, the carbon precursor obtained by the above-mentioned pre-carbonization is fully mixed with the activator at a mass ratio of 1:4. The activator is sodium hydroxide, and then the temperature is raised to 900°C at a rate of 10°C / min under an argon atmosphere for activation. The activation time is 5h. The above-mentioned activated product was washed with 0.1 mol of nitric acid, and then washed with deionized water until neutral, and then dried to obtain porous carbon.

[0039] The electrochemical test method of porous carbon is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com