Method for producing titanium slag and titanium white chloride by using Panzhihua ilmenite

A technology of ilmenite and titanium chloride, which is applied in the direction of titanium tetrachloride, titanium halide, calcium/strontium/barium chloride, etc., to achieve the effect of wide applicability of raw materials, good dust collection effect, and reduced process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

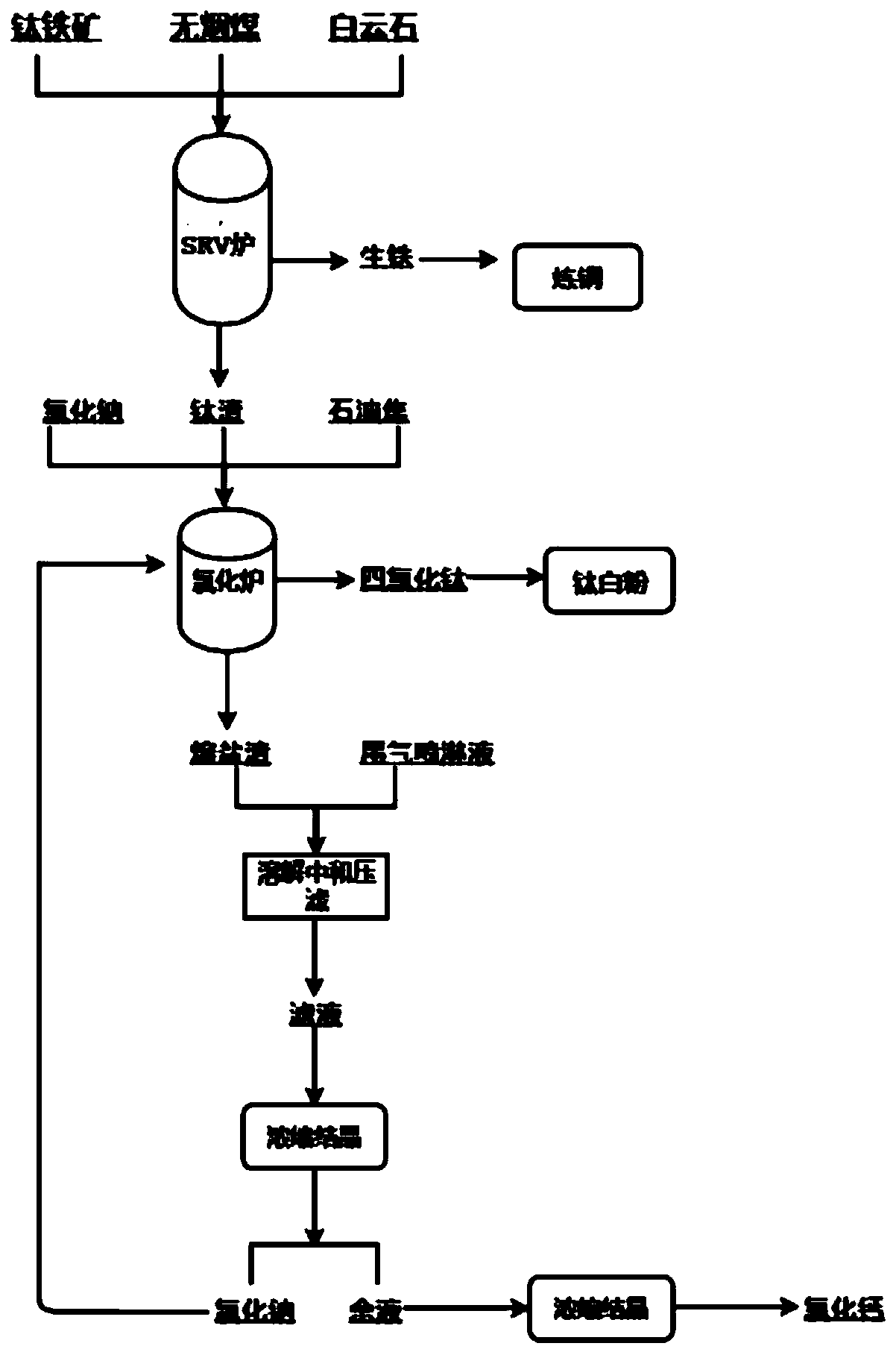

Image

Examples

specific Embodiment 1

[0072] In the SRV furnace, using N 2 The flow of ilmenite powder, coal powder and dolomite is sprayed into the molten pool through the side wall spray gun according to the mass ratio of 1:0.25:0.02, and the furnace top spray gun is blown into 1000 ℃ high-temperature air to control the furnace center temperature to 1600 ℃, and the ilmenite The titanium slag was reacted with coal powder for 4 hours, and the obtained titanium slag was discharged from the slag outlet, and the titanium slag product was obtained after cooling and crushing, and the titanium slag grade was 78%.

[0073] Titanium slag is used as raw material to produce titanium dioxide by molten salt chlorination in the chlorination furnace. During the production process, the dust brought out from the chlorination furnace is collected by a cyclone dust removal device, and coarse TiCl is sprayed at the cyclone dust removal inlet. 4 , Control the outlet temperature of the cyclone dust collector at 147°C.

[0074] The mo...

specific Embodiment 2

[0076] In the SRV furnace, using N 2 The flow of ilmenite, coal powder and auxiliary materials is sprayed into the molten pool through the side wall spray gun according to the mass ratio of 1:0.45:0.1, and the furnace top spray gun is blown into high-temperature air at 1100°C to control the furnace center temperature to 1300°C. The ilmenite powder and The pulverized coal was reacted for 12 hours, and the obtained titanium slag was discharged from the slag discharge port, and the titanium slag product was obtained after cooling and crushing, and the grade of the titanium slag was 72%.

[0077] Titanium slag is used as raw material to produce titanium dioxide by molten salt chlorination in the chlorination furnace. During the production process, the dust brought out from the chlorination furnace is collected by a cyclone dust removal device, and coarse TiCl is sprayed at the cyclone dust removal inlet. 4 , Control the outlet temperature of the cyclone dust collector at 400°C.

[...

specific Embodiment 3

[0080] In the SRV furnace, using N 2 The flow of ilmenite, coal powder and auxiliary materials is sprayed into the molten pool through the side wall spray gun according to the mass ratio of 1:0.3:0.15, and the furnace top spray gun is blown into 1300 ℃ high-temperature air to control the furnace center temperature to 1500 ℃, and the ilmenite powder and The pulverized coal was reacted for 7 hours, and the obtained titanium slag was discharged from the slag discharge port, and the titanium slag product was obtained after cooling and crushing, and the grade of the titanium slag was 74%.

[0081] Titanium slag is used as raw material to produce titanium dioxide by molten salt chlorination in the chlorination furnace. During the production process, the dust brought out from the chlorination furnace is collected by a cyclone dust removal device, and coarse TiCl is sprayed at the cyclone dust removal inlet. 4 , Control the outlet temperature of the cyclone dust collector at 350°C.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com