Two-stage type production method of V crystal form type APP (ammonium polyphosphate)

A technology of ammonium polyphosphate and its production method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as ineffective application in industrial production, and achieve the effects of improving the production environment, increasing efficiency, and stabilizing the crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

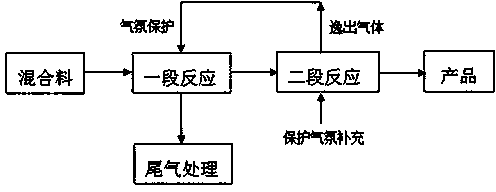

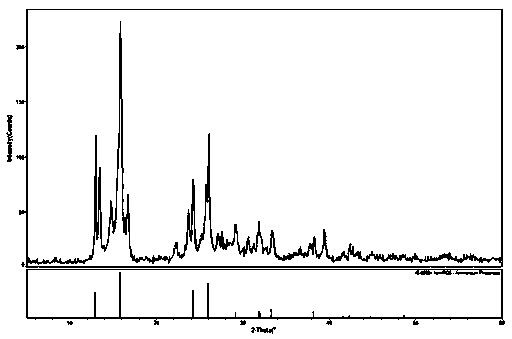

[0024] Use industrial-grade phosphorus pentoxide as raw material, add urea for mixing, the mass ratio of industrial-grade phosphorus pentoxide and urea is 1:0.3, mix the two evenly and put them into the polymerization reactor, at 220℃~240℃ After continuing to react at high temperature for 3 minutes, transfer the material into a pressure reactor with a stirring device, raise the temperature to 240°C, and react for 3 hours to obtain a crystalline V-type ammonium polyphosphate product. The ammonia partial pressure was maintained at 0.05MPa and the flow rate was 0.5L / min throughout the reaction process.

Embodiment 2

[0026] Use industrial-grade phosphorus pentoxide as raw material, add urea for mixing, the mass ratio of industrial-grade phosphorus pentoxide and urea is 1:0.4, mix the two evenly and put them into the polymerization reactor, at 160℃~180℃ After continuing to react at high temperature for 60 minutes, transfer the material into a pressure reactor with a stirring device, raise the temperature to 280°C, and react for 2 hours to obtain a crystalline V-type ammonium polyphosphate product. The ammonia partial pressure was maintained at 0.08MPa and the flow rate was 0.3L / min throughout the reaction process.

Embodiment 3

[0028] Use industrial-grade phosphorus pentoxide as raw material, add urea and melamine for mixing, the mass ratio of industrial-grade phosphorus pentoxide, urea and melamine is 1:0.4:0.05, mix the three evenly and add them to the polymerization reactor, After continuing to react at a temperature of 180°C to 200°C for 30 minutes, transfer the material into a pressure reactor with a stirring device, raise the temperature to 280°C, and react for 2 hours to obtain a crystalline V-type ammonium polyphosphate product. The ammonia partial pressure was maintained at 0.1 MPa and the flow rate was 0.2 L / min throughout the reaction process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com