5'-guanosine-disodium phosphate crystallizing method

A technology of disodium guanosine monophosphate and crystallization, which is applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc. The effect of stable crystal form, promoting crystal transformation and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The crude product of disodium 5'-guanosine monophosphate used in the examples of the present invention is produced by Guangdong Zhaoqing Xinghu Biotechnology Co., Ltd., wherein the content of disodium 5'-guanosine monophosphate is about 70%.

[0036] Weigh 150g of crude 5'-guanosine monophosphate disodium to configure a 15% aqueous solution by weight, add 7.5g of activated carbon and 1.5g of sodium hydrosulfite, react at 45°C for 30 minutes, and filter to obtain 950mL of filtrate.

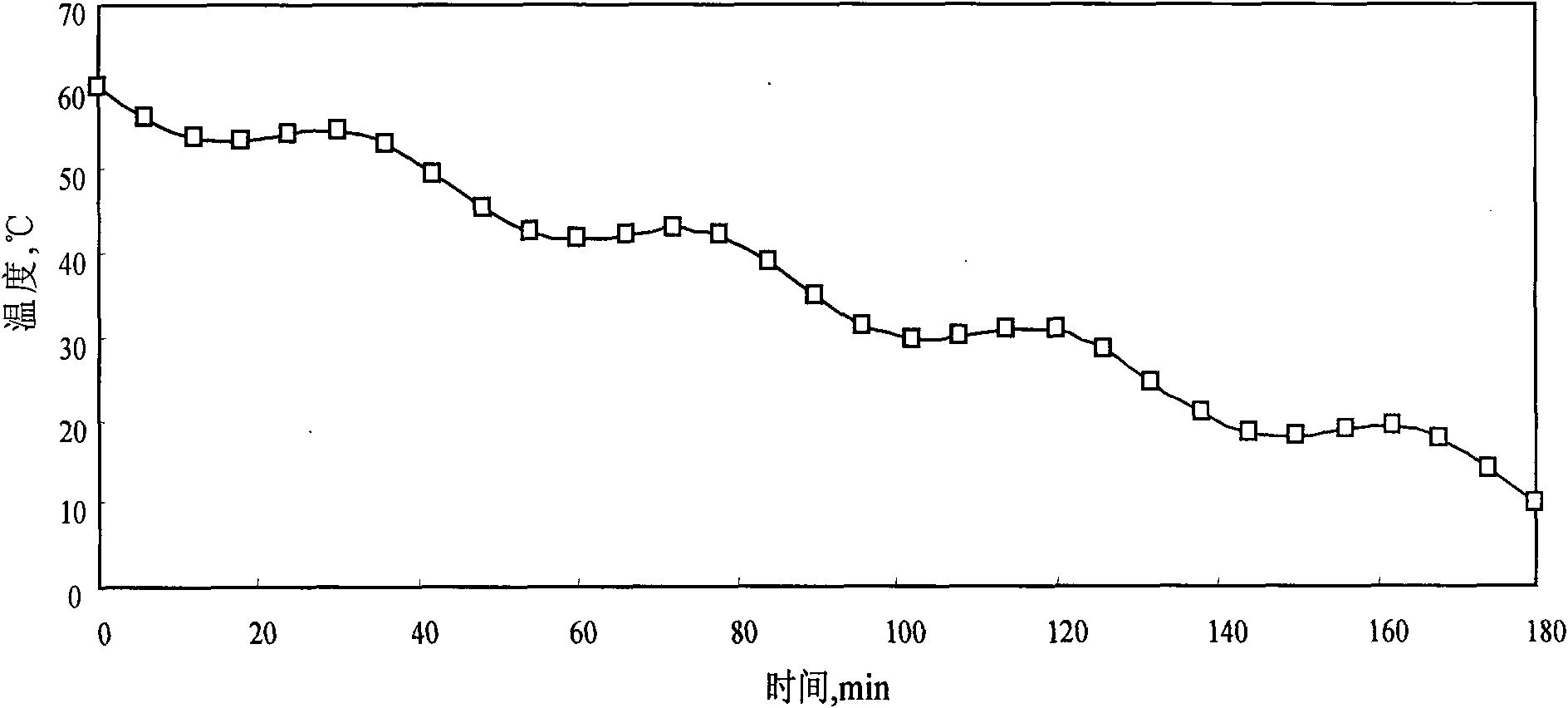

[0037] Add sodium nitrate twice the mass of the crude 5'-guanosine monophosphate disodium, stir and add NaOH to adjust the pH to 10.50; control the stirring speed at 500 rpm, add 1.425L of anti-solvent methanol at one time, and heat to 50°C , and keep warm for 1.0h; adjust the stirring rate to 100 rpm, with the function T = 50 - 3 × sin ( t 7 ) ...

Embodiment 2

[0046] Weigh 50g crude disodium 5'-guanosine monophosphate to prepare a 5wt% aqueous solution, add 2.5g activated carbon and 0.5g sodium hydrosulfite, react at 45°C for 30 minutes, and filter to obtain 981mL filtrate.

[0047] Add sodium formate 0.2 times the mass of the crude product of 5'-guanosine monophosphate disodium, stir and add NaOH to adjust the pH to 9.49; control the stirring speed at 300 rpm, add 2.943 L of anti-solvent methanol at one time, and raise the temperature to 60 ℃, and keep warm for 0.5h; adjust the stirring rate to 300 rpm, with the function T = 60 - 3 × sin ( t 7 ) - 0.27 × t The determined temperature is the cooling temperature, and cooling crystallization is carried out. T is the temperature, and t is the cooling time. The total cooling time is 360 minutes...

Embodiment 3

[0049] Weigh 200g of crude 5'-guanosine monophosphate disodium to prepare a 20wt% aqueous solution, add 10g of activated carbon and 2g of hydrosulfite, react at 45°C for 30 minutes, and filter to obtain 933mL of filtrate.

[0050] Add sodium nitrate 1.0 times the mass of the crude 5'-guanosine monophosphate disodium, stir and add NaOH to adjust the pH to 8.50; control the stirring speed at 800 rpm, add 280 mL of anti-solvent ethanol at one time, and raise the temperature to 55 ℃, the stirring rate was controlled at 150 rpm, and kept warm for 0.6h; the stirring rate was adjusted to 50 rpm, and the function T = 55 - 3 × sin ( t 7 ) - 0.27 × t Carry out cooling crystallization, the cooling time is 120 minutes, and after cooling to about 10°C, the crystal slurry is separated by suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com